Contents

Manufacturing Insight: Rotational Molding Machines

Manufacturing Insight: Rotational Molding Technology at Honyo Prototype

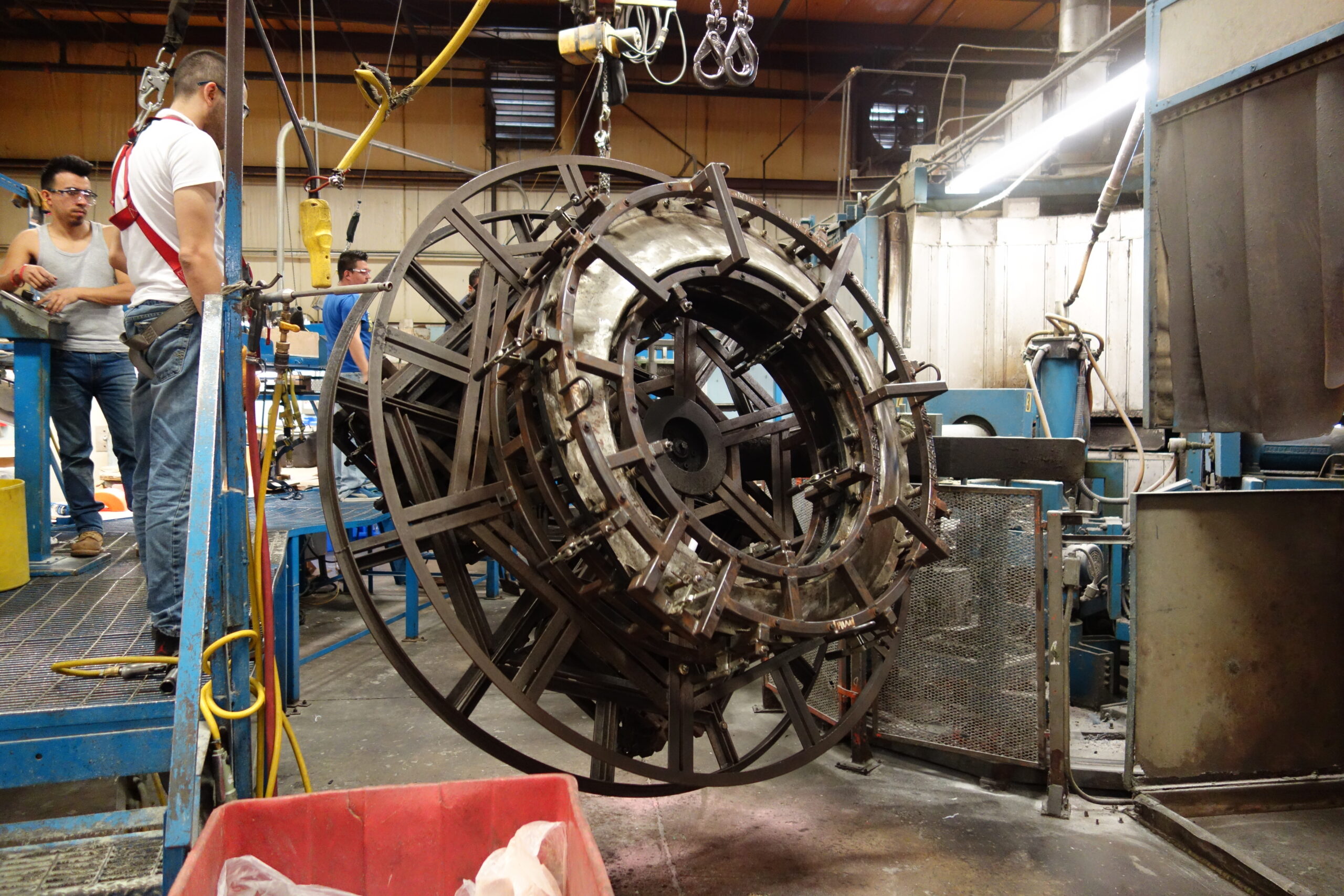

Rotational molding, distinct from injection molding, is a critical low-pressure thermoplastic process ideal for producing seamless, stress-free hollow parts. This method excels where large, complex geometries, consistent wall thickness, and structural integrity are paramount—such as fluid tanks, material handling containers, recreational equipment, and protective housings. Unlike high-pressure injection molding, rotational molding uses gravity-driven biaxial rotation within an oven to evenly distribute powdered polymer against a heated mold cavity. This eliminates weld lines, internal stresses, and the need for expensive high-pressure tooling, making it exceptionally cost-effective for low-to-mid volume production and robust prototype validation of hollow components. The process accommodates a wide range of engineering thermoplastics, including linear low-density polyethylene (LLDPE), polypropylene (PP), and specialty nylons, enabling parts with superior impact resistance and chemical stability.

At Shenzhen Honyo Prototype, we integrate rotational molding within our rapid tooling ecosystem to bridge the gap between concept and production. Our dedicated rotational molding facility features state-of-the-art shuttle and rocker-arm machines designed for precision prototyping and pilot runs. We leverage proprietary mold heating and cooling algorithms to achieve tighter cycle control than standard industry practice, significantly accelerating time-to-part without compromising dimensional accuracy. Our engineering team optimizes powder dispersion, oven dwell times, and cooling phases to ensure uniform wall distribution—critical for validating part performance under real-world stress conditions. This capability is particularly valuable for clients developing outdoor equipment, medical device enclosures, or custom fluid management systems where hollow part integrity is non-negotiable.

Honyo’s rotational molding specifications demonstrate our commitment to high-fidelity prototyping:

| Parameter | Honyo Prototype Capability | Typical Industry Standard |

|——————–|——————————–|——————————–|

| Machine Size Range | Up to 3.0 m³ cavity volume | Often limited to 1.5–2.0 m³ |

| Temperature Control | ±2°C precision | ±5–10°C tolerance |

| Cycle Time Reduction | 15–20% faster vs. baseline | Standard heating/cooling rates |

| Material Support | LLDPE, PP, TPU, filled grades | Primarily basic LLDPE |

| Mold Fabrication | Aluminum or composite rapid tools | Often single-cavity steel |

This technical advantage allows clients to validate designs with production-intent materials and processes before committing to high-volume tooling. Our rotational molding service reduces prototype iteration costs by up to 40% compared to alternative hollow-part methods, while delivering parts that accurately reflect end-use performance characteristics. For engineering teams requiring functional validation of large, complex enclosures or fluid-handling components, Honyo provides the process expertise and agile infrastructure to de-risk development cycles. By mastering both rotational and injection molding under one roof, we offer unparalleled flexibility in selecting the optimal manufacturing pathway—ensuring your design transitions seamlessly from prototype to scalable production.

Technical Capabilities

Technical Capabilities: Rotational Molding at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, our rotational molding capabilities are engineered to deliver high-quality, durable plastic components with exceptional repeatability and design flexibility. Specializing in rapid tooling and injection molding solutions, we leverage advanced rotational molding machines to produce hollow, seamless parts ideal for applications ranging from industrial tanks and automotive components to consumer goods and medical enclosures. Our process integrates precision-engineered steel and aluminum molds, enabling rapid prototyping and low-to-medium volume production with a guaranteed T1 sample delivery within 7 days of tool completion.

Our rotational molding machines operate with a fully programmable heating and cooling cycle, ensuring uniform wall thickness and optimal material distribution. The bi-axial rotation system allows for consistent part geometry, even in complex, asymmetrical designs. We support mold fabrication in both tool steel and aluminum alloys, selected based on production volume, part complexity, and surface finish requirements. Aluminum molds are ideal for rapid prototyping and short-run production due to faster machining and thermal response, while steel molds offer extended durability for higher volume runs and enhanced wear resistance.

Each mold is CNC-machined in-house with tight process control, ensuring dimensional accuracy and surface integrity. Our integrated workflow from CAD-based mold design to molding validation enables rapid iteration and first-article inspection. With a dedicated T1 sample timeline of 7 days, we support accelerated product development cycles without compromising on quality.

Material compatibility spans a broad range of engineering-grade thermoplastics, including linear and cross-linked polyethylene (PE), polypropylene (PP), nylon, and EVA. These materials are selected based on mechanical performance, chemical resistance, UV stability, and regulatory compliance. All materials are pre-processed to precise particle size and flow characteristics to ensure consistent melt behavior during the rotational cycle.

The following table outlines key technical specifications, achievable tolerances, and supported materials for our rotational molding process:

| Parameter | Specification |

|——————————-|——————————————————————————-|

| Machine Size Range | 3.0 m × 2.0 m × 2.0 m (max part envelope) |

| Mold Materials | Aluminum (6061, 7075), Tool Steel (P20, H13) |

| Mold Fabrication Lead Time | 5–7 days (rapid CNC machining and finishing) |

| T1 Sample Delivery | Within 7 days of mold completion |

| Typical Wall Thickness | 3–12 mm (adjustable based on part geometry) |

| Dimensional Tolerance (±) | ±0.5% of nominal dimension (minimum ±0.3 mm) |

| Surface Finish Options | SPI finishes up to A2, textured, grain, or custom matte/glossy |

| Cycle Time Range | 20–60 minutes per cycle (dependent on part size and material) |

| Supported Materials | LDPE, HDPE, LLDPE, XLPE, PP, Nylon 6, EVA |

| Max Heating Temperature | 400°C (controlled convection heating) |

| Cooling Methods | Air and mist cooling for controlled thermal dissipation |

| Part Weight Range | 0.5 kg to 50 kg |

Shenzhen Honyo Prototype’s rotational molding service is designed for engineers and product developers seeking fast, reliable, and scalable solutions for hollow plastic parts. With in-house tooling, strict process control, and a commitment to rapid turnaround, we provide a seamless transition from prototype to production.

From CAD to Part: The Process

Rotational Molding Production Workflow: From CAD to Finished Part

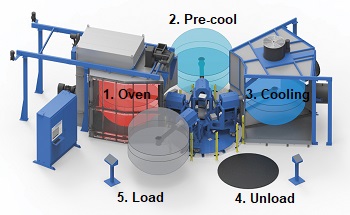

At Shenzhen Honyo Prototype, our rotational molding process delivers high-quality, complex hollow parts efficiently through a tightly integrated workflow. This sequence ensures manufacturability, cost-effectiveness, and adherence to client specifications from initial concept to final component. The core stages—AI Quote, Design for Manufacturability (DFM), and Production—are engineered for rapid tooling success within the rapid prototyping and low-volume production landscape.

AI-Powered Quoting Acceleration

The workflow initiates with the client’s CAD model submission. Our proprietary AI quoting engine rapidly analyzes geometric complexity, material requirements, and dimensional tolerances against our extensive rotational molding database. This system instantly generates a preliminary cost estimate and lead time, significantly reducing traditional quoting delays. The AI cross-references historical cycle data, material usage algorithms, and tooling complexity metrics to provide transparent, data-driven projections. This immediate feedback allows clients to make informed design or budget decisions early, setting a clear foundation for project viability before engineering resources are deeply committed.

Comprehensive Design for Manufacturability (DFM) Review

Following quote acceptance, Honyo’s engineering team conducts a rigorous DFM analysis. This critical phase focuses specifically on rotational molding constraints. We scrutinize wall thickness uniformity to prevent sagging or thin spots during rotation, evaluate draft angles essential for part release from the mold, and assess the feasibility of intricate details or undercuts within the low-pressure process. Potential issues like excessive part weight, stress concentration points, or challenges in achieving specified surface finishes are identified and resolved collaboratively with the client. Our DFM report provides actionable recommendations, such as optimizing rib design for structural integrity without causing sink marks or adjusting radii to ensure consistent material flow during the oven phase. This proactive engineering prevents costly rework and ensures the design is optimized for efficient, high-yield production.

Precision Rotational Molding Production

Approved designs move directly to production using our advanced rotational molding systems. The process begins with pre-measured polymer powder loaded into a precisely machined mold. The mold is securely mounted on an arm within the oven chamber, simultaneously rotating biaxially (typically 4-20 RPM). Critical machine parameters are meticulously controlled throughout the cycle:

| Parameter | Typical Range | Significance |

| :—————– | :———————— | :———————————— |

| Oven Temperature | 250°C – 350°C | Ensures complete powder fusion & gelation |

| Heating Time | 10 – 25 minutes | Material & part size dependent |

| Cooling Method | Air/Water Spray | Controls crystallinity & minimizes warpage |

| Cooling Time | 15 – 30 minutes | Critical for dimensional stability |

| Rotation Speed (X) | 4 – 12 RPM | Influences wall thickness distribution |

| Rotation Speed (Y) | 8 – 20 RPM | Ensures uniform polymer coverage |

After controlled heating and cooling phases, the mold is opened, and the finished part is carefully demolded. Each component undergoes stringent dimensional verification and visual inspection against the original CAD specifications and client requirements before final shipment. This closed-loop workflow, anchored by AI efficiency and deep rotational molding expertise, guarantees Honyo Prototype delivers robust, production-ready parts rapidly and reliably.

Start Your Project

Start Your Project with Honyo Prototype: Expert Rotational Molding Solutions

At Shenzhen Honyo Prototype, we specialize in rapid tooling and injection molding services, with advanced capabilities in rotational molding to support your product development from concept to production. Our state-of-the-art rotational molding machines, combined with precision engineering and rapid turnaround times, make us the ideal partner for low- to mid-volume production runs, complex hollow parts, and durable plastic components across industries such as automotive, medical, consumer goods, and industrial equipment.

Rotational molding—also known as rotomolding—offers unmatched design flexibility, allowing for seamless, stress-free parts with uniform wall thickness and excellent impact resistance. Whether you’re developing large storage tanks, ergonomic enclosures, or lightweight structural components, our team ensures material efficiency, dimensional accuracy, and repeatable quality. We work with a wide range of thermoplastic materials, including polyethylene (HDPE, LDPE, LLDPE), PP, PA, and PVC, tailoring material selection to meet your performance, regulatory, and environmental requirements.

Our rapid tooling approach accelerates your time to market. Using CNC-machined aluminum or cast aluminum molds, we deliver functional prototypes and production tools in as little as 10–15 days, depending on complexity. This agility allows for quick design iterations, reducing development costs and enabling faster validation cycles. Every project is supported by in-house engineering reviews, DFM analysis, and real-time project tracking to ensure alignment with your specifications and timelines.

We understand that starting a new manufacturing project involves critical decisions—from material selection and mold design to production volume and quality control. That’s why our engineering team collaborates closely with clients from the earliest stages, offering technical guidance and process optimization to ensure manufacturability and cost-efficiency.

Below is an overview of our standard rotational molding capabilities:

| Parameter | Specification |

|——————————|———————————————-|

| Machine Types | Shuttle, Swing-Arm, Carousel |

| Maximum Part Size | Up to 3,000 mm x 2,000 mm x 2,000 mm |

| Wall Thickness Range | 2 mm – 25 mm (adjustable per design) |

| Heating Method | Convection or Infrared |

| Typical Cycle Time | 20–60 minutes (depending on part size) |

| Mold Materials | Aluminum (7075, 6061), Cast Aluminum Alloys |

| Lead Time (Tooling) | 10–15 days (prototype), 20–25 days (production) |

| Supported Plastics | HDPE, LDPE, LLDPE, PP, PA, PVC |

| Post-Processing | Trimming, Drilling, Assembly, Surface Finishing |

| Quality Control | In-process inspection, First Article Inspection (FAI), SPC reporting |

Starting your rotational molding project with Honyo Prototype means partnering with a team committed to precision, speed, and transparency. We handle everything from initial design consultation to final part delivery, ensuring a seamless manufacturing experience.

For expert guidance and a personalized quote, contact Susan Leo at info@hy-proto.com. Let us help you turn your concept into a high-performance, production-ready solution—efficiently and reliably.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.