Contents

Manufacturing Insight: Doosan Cnc Machine

Manufacturing Insight: Doosan CNC Machine Technology at Honyo Prototype

Shenzhen Honyo Prototype leverages Doosan CNC machining centers as a cornerstone of our high-precision prototyping and low-volume production capabilities. Renowned globally for robust engineering and exceptional reliability, Doosan machines represent a strategic investment in delivering the dimensional accuracy, surface finish, and process stability demanded by advanced manufacturing sectors, including aerospace, medical devices, and complex consumer electronics. Our selection focuses on Doosan’s vertical and horizontal machining centers, particularly the DL and DM series, engineered from the ground up for demanding applications requiring micron-level tolerances and consistent repeatability. These platforms integrate advanced structural design with sophisticated control systems to minimize vibration and thermal growth, critical factors when machining intricate geometries in challenging materials like titanium alloys, high-performance plastics, and hardened steels.

The core strength of Doosan technology lies in its thermally stable Meehanite cast iron construction and rigid box-in-box architecture, significantly reducing deflection during heavy cuts or fine finishing operations. This inherent stability is complemented by high-torque, direct-drive spindles capable of maintaining precise RPM under load and rapid, accurate axis movements facilitated by high-resolution linear scales and preloaded ball screws. Our machines utilize the Fanuc 31i-B5 control system, offering intuitive programming, powerful simulation tools, and seamless integration with our CAD/CAM suite for efficient workflow from digital model to physical part. Crucially, Doosan’s comprehensive error compensation suite – encompassing multi-axis thermal growth compensation, volumetric accuracy correction, and backlash management – is rigorously validated and maintained within our facility, ensuring the machine’s performance envelope is consistently realized on every component we produce. Below are key specifications representative of the Doosan platforms deployed at Honyo Prototype:

| Parameter | Typical Value (e.g., DL-2000SM) | Significance for Prototyping |

| :—————– | :—————————— | :——————————— |

| Work Envelope (X/Y/Z) | 800 x 500 x 500 mm | Accommodates medium-complexity prototypes |

| Spindle Speed | 12,000 RPM | Enables high-speed machining of aluminum, plastics |

| Rapid Traverse (X/Y/Z) | 48 / 48 / 48 m/min | Minimizes non-cutting time, faster iterations |

| Positioning Accuracy | ±0.003 mm | Essential for tight-tolerance features |

| Repeatability | ±0.002 mm | Guarantees consistency across multiple parts |

At Honyo Prototype, deploying Doosan technology extends beyond machine operation; it encompasses our entire manufacturing philosophy. Our certified engineers and technicians implement stringent process control protocols, including regular laser calibration per ISO 230-2 standards, meticulous tool management with presetter verification, and real-time process monitoring. We leverage the machine’s capabilities for complex 4-axis and 5-axis simultaneous machining, enabling single-setup production of highly intricate prototypes that would otherwise require costly fixtures or secondary operations. This integration of Doosan’s precision engineering with Honyo’s disciplined manufacturing processes and deep application expertise ensures clients receive prototypes that are not only dimensionally accurate but also demonstrative of true production intent, significantly de-risking their product development cycles and accelerating time-to-market. Partnering with Honyo means accessing this proven technology platform optimized for the unique demands of rapid, high-fidelity prototyping.

Technical Capabilities

Doosan CNC Machine Technical Capabilities at Shenzhen Honyo Prototype

Shenzhen Honyo Prototype leverages the precision and reliability of Doosan CNC machines to deliver high-performance machining solutions for prototyping and low-volume production. Our Doosan equipment portfolio includes advanced 3-axis, 4-axis, and 5-axis vertical machining centers, as well as high-precision CNC turning centers. These machines are engineered for superior rigidity, thermal stability, and dynamic accuracy, enabling us to meet the most demanding manufacturing requirements across aerospace, medical, automotive, and industrial sectors.

Our 3-axis CNC milling machines are optimized for high-speed, high-accuracy machining of complex geometries in a single setup. These systems deliver rapid traverse rates of up to 36 m/min and spindle speeds reaching 10,000 rpm, allowing for efficient material removal and fine surface finishes. For components requiring multi-sided access or rotational features, our 4-axis and 5-axis Doosan machining centers provide enhanced flexibility. The 5-axis platforms support simultaneous multi-axis motion with tilt-rotary tables, enabling the production of intricate contours, impellers, molds, and organic forms with minimal manual intervention.

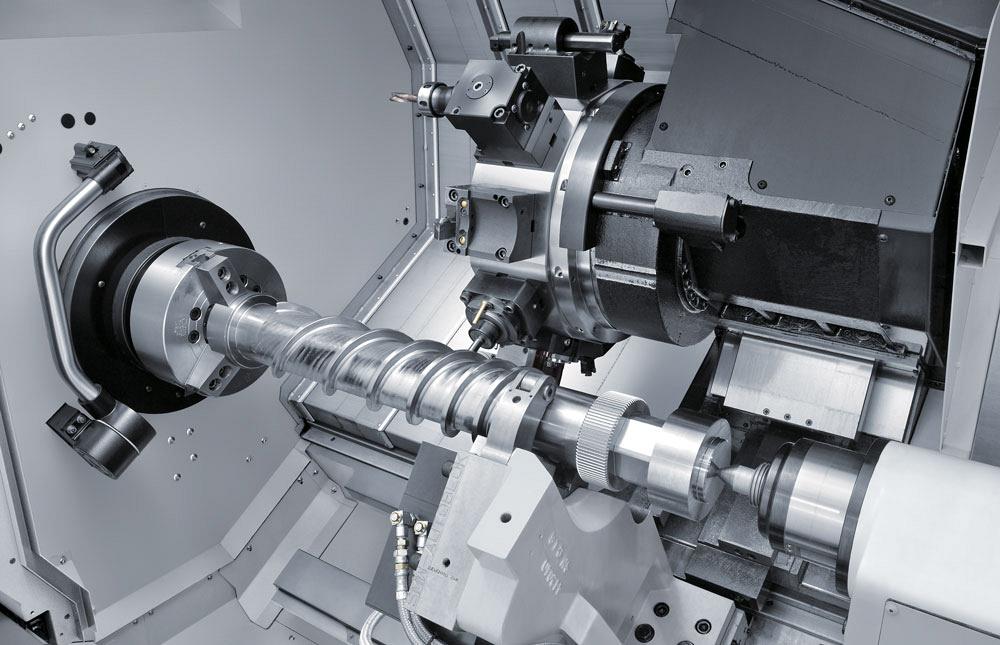

Doosan turning centers at Honyo Prototype are equipped with live tooling and Y-axis capabilities, supporting mill-turn operations for complex turned parts. These machines combine high spindle power with sub-spindle functionality, allowing complete machining of cylindrical components in a single setup. This reduces cycle times and improves part concentricity and dimensional consistency.

A core strength of our Doosan CNC operations is tight-tolerance machining. Our machines are maintained under strict calibration schedules and operate in temperature-controlled environments to minimize thermal drift. With advanced probing systems and in-process measurement, we consistently achieve tolerances down to ±0.005 mm for critical dimensions. Surface finishes as fine as Ra 0.4 µm are routinely attainable, depending on material and geometry.

Below is a summary of achievable tolerances and compatible materials across our Doosan CNC platforms:

| Feature | Typical Tolerance | Notes |

|——–|——————-|——-|

| Linear Dimensions | ±0.01 mm | Standard for 3/4/5-axis milling |

| Critical Dimensions | ±0.005 mm | Achieved with precision tooling and thermal control |

| Hole Diameter | +0.015 / -0 mm | Reamed or precision bored |

| Positional Tolerance | ±0.01 mm | Per GD&T standards |

| Surface Finish (Milled) | Ra 1.6 – 0.4 µm | Depends on tool path and material |

| Surface Finish (Turned) | Ra 1.6 – 0.8 µm | With fine feed rates and sharp inserts |

| Material Category | Examples | Machinability Notes |

|——————|———-|——————–|

| Aluminum Alloys | 6061, 7075, 2024 | Excellent; high-speed machining with long tool life |

| Stainless Steel | 303, 304, 316, 17-4 PH | Moderate; requires rigid setup and controlled feeds |

| Alloy Steels | 4140, P20 | Moderate to difficult; pre-hardened forms require carbide tooling |

| Titanium Alloys | Grade 5 (Ti-6Al-4V) | Challenging; low thermal conductivity requires optimized parameters |

| Plastics | PEEK, Delrin, Acrylic | Low melting point; sharp tools and high-speed cutting essential |

Shenzhen Honyo Prototype’s integration of Doosan CNC technology ensures repeatable, high-accuracy manufacturing for mission-critical components. Our technical expertise, combined with state-of-the-art equipment, allows us to deliver prototypes and production parts that meet stringent engineering and quality standards.

From CAD to Part: The Process

From CAD to Part: Doosan CNC Production Workflow at Honyo Prototype

At Shenzhen Honyo Prototype, our Doosan CNC machining process transforms digital designs into high-precision physical components through a rigorously defined, three-phase workflow. This systematic approach ensures optimal efficiency, quality, and cost-effectiveness for every client project, leveraging the capabilities of our Doosan machine fleet while mitigating common manufacturing risks from inception.

The journey begins with the AI-Powered Quoting Phase. Upon receipt of your CAD model (STEP, IGES, or native formats preferred), our proprietary AI engine performs an instant preliminary analysis. This system evaluates geometric complexity, identifies potential high-risk features requiring manual review, estimates raw material requirements, and calculates baseline machine runtime based on standard cutting parameters. Crucially, it flags early indicators of manufacturability challenges, allowing our engineers to initiate dialogue before formal quoting. This AI step significantly accelerates the initial response time while providing a data-driven foundation for accurate cost estimation, setting realistic expectations for lead time and budget.

This transitions directly into the Critical DFM (Design for Manufacturability) Collaboration. Our Senior Manufacturing Engineers conduct a thorough, manual DFM review, working closely with your design team. We focus on optimizing geometry for Doosan CNC capabilities: verifying feasible tool access, recommending adjustments to internal radii or undercuts, analyzing wall thickness stability, and performing tolerance stack analysis. We assess whether specified surface finishes are achievable within standard cycles or require secondary operations. This phase is iterative; we provide specific, actionable feedback aimed at preserving your core design intent while eliminating costly rework, extended machining times, or scrap potential. Approval of the DFM report is mandatory before proceeding, ensuring alignment and de-risking production.

Precision Production Execution on our Doosan CNC centers represents the culmination of this preparatory work. Programs, rigorously verified via simulation software (Mastercam, Fusion 360), are loaded onto the machine. Raw material is precisely fixtured, and the first article undergoes comprehensive in-process inspection using calibrated CMMs and vision systems against the approved DFM-modified CAD model. Only upon validation of the first article do we proceed to full batch production. Throughout machining, our engineers monitor critical parameters in real-time, leveraging the Doosan machine’s inherent stability and precision. Key performance characteristics of our standard Doosan VMCs utilized in this phase include:

| Parameter | Specification | Significance for Precision |

|——————–|———————|—————————-|

| Spindle Speed | 10,000 RPM | Enables high-speed finishing on complex contours |

| Positioning Accuracy | ±0.003 mm | Ensures tight tolerance compliance across features |

| Repeatability | ±0.002 mm | Guarantees consistency in batch production |

| Table Size (Typical)| 1,000 x 500 mm | Accommodates medium to large prototypes efficiently |

| Control System | Doosan Smart CNC | Provides intuitive operation and robust error compensation |

This integrated workflow—from intelligent AI assessment through collaborative DFM refinement to controlled Doosan machining execution—ensures Shenzhen Honyo Prototype delivers your precision-engineered components on time, within specification, and with minimized cost overhead. The upfront rigor in analysis directly translates to reliability and value in the final part.

Start Your Project

Start Your Next Precision Machining Project with Confidence on Doosan CNC Machines

At Shenzhen Honyo Prototype, we specialize in high-precision CNC machining using state-of-the-art Doosan CNC machines—renowned globally for their rigidity, accuracy, and reliability in demanding production environments. Whether you’re developing functional prototypes, bridge production parts, or full-scale manufacturing runs, our advanced machining capabilities ensure your components meet the strictest tolerances and surface finish requirements.

Our Doosan CNC machining centers, including models from the DNM, DNM High-Speed, and PUMA series, deliver exceptional performance across a wide range of materials such as aluminum, stainless steel, titanium, brass, and engineering plastics. These machines feature high-torque spindles, rapid traverse rates, and robust thermal compensation systems, enabling consistent part quality even during extended production cycles. With 3-axis, 4-axis, and 5-axis machining options, we are equipped to handle complex geometries and tight-tolerance components with ease.

We understand that every project begins with a vision. That’s why our engineering team works closely with clients from the initial design review to final inspection, offering Design for Manufacturability (DFM) feedback to optimize part geometry, reduce lead times, and lower overall production costs. Our quality control processes include CMM inspection, surface roughness testing, and first-article reporting to ensure every component conforms to your specifications.

To get started, simply provide your 3D CAD model (STEP, IGES, or X_T format), material specifications, surface finish requirements, and desired quantities. Our team will respond with a detailed quotation within 12 hours, including lead time estimates, machining strategy, and cost breakdown.

Below is an overview of our primary Doosan CNC machine capabilities:

| Machine Model | Axis Configuration | Table Size (mm) | Spindle Speed (RPM) | Travel (X/Y/Z – mm) | Max Workpiece Size (mm) |

|———————–|———————|——————|———————-|———————-|————————–|

| Doosan DNM 5000 | 3-axis | 800 x 500 | 10,000 | 500 x 400 x 350 | 800 x 500 x 350 |

| Doosan DNM 6700 | 4-axis (indexing) | 1,000 x 600 | 8,000 | 670 x 510 x 460 | 1,000 x 600 x 460 |

| Doosan DNM 5700 MC | 5-axis (continuous)| 800 x 500 | 12,000 | 570 x 510 x 460 | 800 x 500 x 400 |

| Doosan PUMA 3015SY | 2-axis turning | — | 4,500 | — | Ø300 x 650 |

All machines are maintained to OEM standards and operated by certified CNC machinists with over 10 years of industry experience. Our facility in Shenzhen is ISO 9001-certified, ensuring full traceability, process control, and repeatable quality.

Ready to bring your design to life? Contact Susan Leo today at info@hy-proto.com to discuss your project requirements. Include your CAD file and any technical notes, and we’ll provide a comprehensive quote and technical feedback to set your project on the path to success. At Honyo Prototype, precision isn’t just a standard—it’s our commitment.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.