Contents

Manufacturing Insight: Cnc Laser Pipe Cutting Machine

Manufacturing Insight: CNC Laser Pipe Cutting Technology at Honyo Prototype

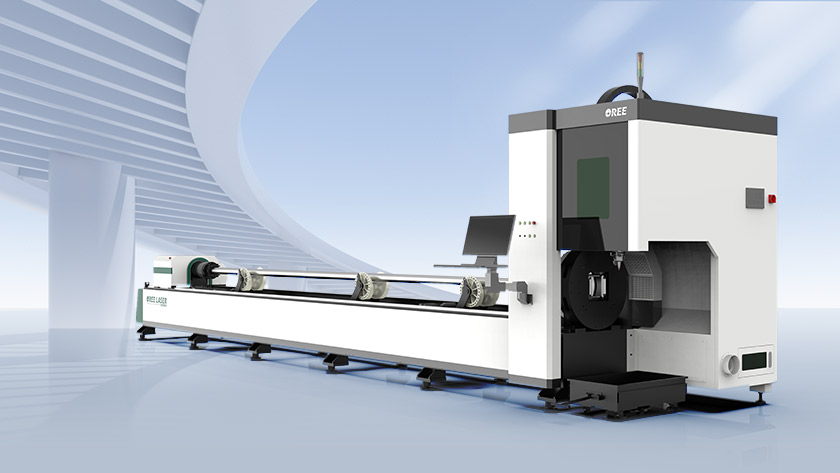

CNC laser pipe cutting represents a transformative capability in modern precision fabrication, enabling the efficient and accurate production of complex tubular components directly from digital models. Unlike traditional sawing, milling, or manual cutting methods, this non-contact process utilizes a high-powered fiber laser beam focused through a precision nozzle to melt, burn, or vaporize material along a programmed path. The integration of multi-axis CNC control with the laser source allows for intricate cuts, bevels, notches, and holes on round, square, rectangular, and custom-profile tubes with exceptional repeatability. This technology is indispensable for industries demanding high-mix, low-to-medium volume parts with stringent geometric tolerances, such as fluid handling systems, structural frameworks, automotive roll cages, and medical device housings, where weld preparation accuracy and minimized secondary operations are critical.

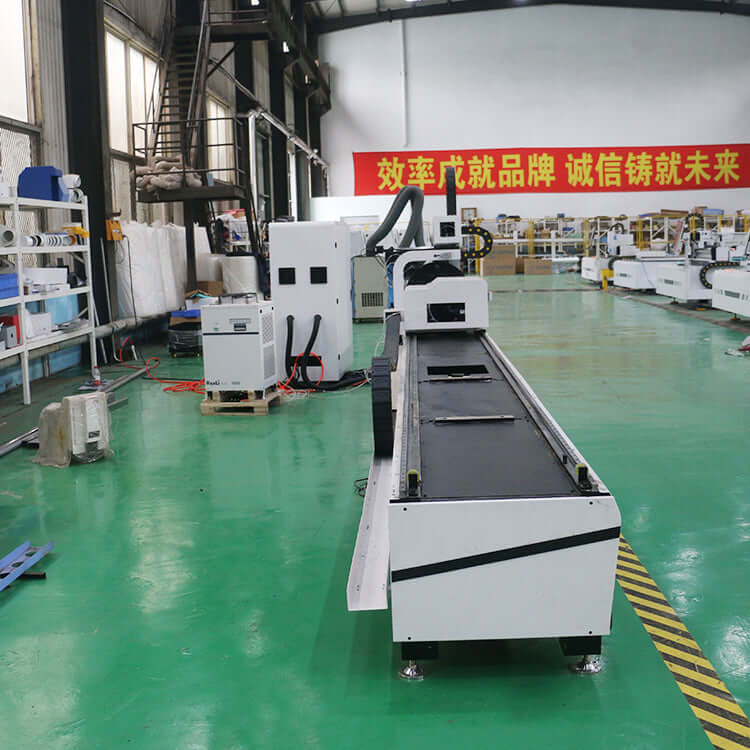

At Shenzhen Honyo Prototype, we leverage state-of-the-art CNC fiber laser pipe cutting systems to deliver rapid prototyping and low-volume production with uncompromising precision. Our machines feature advanced tube handling systems, automatic material loading, and integrated CAD/CAM software that seamlessly translates 3D models into optimized cutting paths. This eliminates manual layout errors and significantly reduces setup times compared to conventional methods. Crucially, our process achieves tight tolerances of ±0.1 mm on cut features and produces clean, dross-free edges that often eliminate the need for post-cut deburring, accelerating time-to-assembly. We specialize in handling a wide range of engineering materials including carbon steel, stainless steel (304, 316), aluminum alloys, and brass tubes, supporting our clients’ transition from initial concept validation through to pilot production runs.

Our core machine specifications ensure robust performance for demanding prototype and production applications:

| Parameter | Specification |

|————————-|—————————-|

| Max Tube Diameter | 150 mm |

| Max Tube Length | 6000 mm |

| Material Thickness Range| 0.5 mm – 8.0 mm |

| Laser Source Power | 1000 W – 3000 W Fiber |

| Positioning Accuracy | ±0.05 mm |

| Typical Cutting Speed | 10 – 60 m/min (varies by material/thickness) |

| Supported File Formats | DXF, DWG, STEP, IGES |

Honyo Prototype’s CNC laser pipe cutting service provides significant value through reduced material waste, elimination of tooling costs for complex geometries, and rapid iteration cycles essential for agile product development. Our Shenzhen-based facility operates under strict ISO 9001 quality management protocols, ensuring consistent part quality and on-time delivery. By integrating this advanced capability within our broader CNC machining and sheet metal fabrication ecosystem, we offer a seamless, one-stop solution for clients requiring fully finished tubular assemblies. This technology is fundamental to our commitment to enabling innovation through precision manufacturing, empowering engineers to realize complex designs with speed and confidence. Partner with Honyo to transform your tubular component concepts into high-precision physical realities.

Technical Capabilities

CNC Laser Pipe Cutting Machine – Technical Capabilities

Shenzhen Honyo Prototype utilizes advanced CNC laser pipe cutting technology to deliver high-precision, complex geometries in tubular and profiled components. Our 3-axis, 4-axis, and 5-axis CNC laser systems are engineered for maximum flexibility, enabling the processing of round, square, rectangular, and custom-shaped tubing with exceptional accuracy and edge quality. These systems integrate seamlessly with our CNC milling and turning capabilities, supporting end-to-end manufacturing of precision components for aerospace, automotive, medical, and industrial applications.

Our CNC laser pipe cutting machines operate with fiber laser sources, delivering peak beam quality and energy efficiency. The equipment supports automatic tube loading and part unloading, allowing for continuous operation and reduced cycle times. With a maximum laser power of up to 3 kW, the system efficiently cuts materials ranging from thin-walled stainless steel to thick carbon steel profiles. The dynamic motion control system ensures high-speed traversal with minimal vibration, maintaining accuracy across long-length tubes up to 6 meters.

The integration of 4-axis and 5-axis cutting heads enables bevel cutting, hole piercing at compound angles, and complex mitering—critical for welded frame assemblies and structural joints. This multi-axis capability eliminates the need for secondary operations in many cases, reducing lead time and improving dimensional consistency. All cutting paths are generated using advanced CAM software that simulates toolpaths and collision detection, ensuring first-time-right production.

Tight tolerance cutting is a core strength of our laser pipe systems. By maintaining stable thermal conditions and using real-time focus control, we achieve consistent cut quality and dimensional repeatability. The following table outlines the achievable tolerances and supported materials:

| Material Type | Thickness Range | Typical Tolerance (± mm) | Max Cutting Length | Surface Finish (Ra) |

|———————|—————–|————————–|——————–|———————|

| Mild Steel | 0.8 – 25 mm | 0.1 | 6000 mm | 6.3 – 12.5 µm |

| Stainless Steel | 0.8 – 20 mm | 0.1 | 6000 mm | 6.3 – 10.0 µm |

| Aluminum Alloys | 1.0 – 15 mm | 0.15 | 6000 mm | 6.3 – 12.5 µm |

| Brass | 1.0 – 12 mm | 0.15 | 6000 mm | 6.3 – 12.5 µm |

| Titanium Alloys | 1.0 – 10 mm | 0.1 | 6000 mm | 6.3 – 10.0 µm |

All parts undergo in-process inspection using precision metrology tools, including CMM and laser scanning, to verify conformance to geometric dimensioning and tolerancing (GD&T) requirements. We maintain ISO 9001-compliant processes to ensure consistency across batch and prototype runs.

With our investment in multi-axis laser technology and process control systems, Shenzhen Honyo Prototype delivers CNC laser pipe cutting solutions that meet the most demanding engineering specifications—combining speed, accuracy, and repeatability for high-integrity component manufacturing.

From CAD to Part: The Process

CNC Laser Pipe Cutting Workflow: From CAD to Finished Part

At Shenzhen Honyo Prototype, our CNC laser pipe cutting process transforms digital designs into precise tubular components through a rigorously defined workflow. This sequence ensures manufacturability, cost efficiency, and dimensional accuracy while minimizing lead times. The core stages are AI-Powered Quoting, Design for Manufacturability (DFM) review, and Production execution.

The process initiates with the AI-Powered Quoting System. Customers submit CAD files in standard vector formats (DXF, DWG, SVG) containing the pipe geometry, cut paths, and end conditions. Honyo’s proprietary AI engine instantly analyzes the file, extracting critical parameters such as total cut length, number of holes, notch complexity, and material type. It cross-references this data against real-time machine capability databases and material cost feeds to generate an accurate, transparent quote within minutes. This eliminates manual estimation delays and provides immediate cost visibility, allowing for rapid project validation. Key inputs like outer diameter, wall thickness, and material grade are validated at this stage to prevent downstream errors.

Following quote acceptance, the design undergoes a mandatory Engineering DFM Review. Our manufacturing engineers conduct a targeted analysis focusing on pipe-specific constraints. Critical checks include verifying minimum wall thickness compatibility with the laser’s power settings, assessing end condition feasibility (e.g., miters, weld prep), optimizing part nesting to maximize material yield on standard pipe stock lengths, and confirming hole sizes and spacing to prevent thermal distortion or part instability during cutting. This phase proactively identifies potential failures, such as unsupported cut sections or features below the machine’s resolution limit, enabling collaborative design adjustments before material is touched. The DFM stage is pivotal in preventing costly rework and ensuring first-pass yield.

| DFM Parameter | Critical Threshold | Impact of Non-Compliance |

|————————|——————–|——————————–|

| Minimum Wall Thickness | ≥ 0.8 mm | Risk of burn-through, deformation |

| Maximum Pipe Diameter | ≤ 300 mm | Machine envelope limitation |

| Minimum Hole Diameter | ≥ Material Thickness | Incomplete cutting, dross |

| Minimum Feature Spacing| ≥ 1.5x Material Thickness | Thermal stress cracking |

Production Execution commences upon DFM sign-off. The validated CAD file is converted into machine-specific G-code, incorporating optimized cutting sequences and laser parameters (power, speed, gas pressure) tailored to the material grade and thickness. Pipes are loaded onto the machine’s precision rotary axis, which stabilizes the workpiece during high-speed cutting. The fiber laser head follows the programmed path, utilizing high-pressure assist gas (N₂ for stainless steel, O₂ for carbon steel) to achieve clean, burr-minimized edges with tight tolerances. In-process monitoring tracks beam focus and pierce quality. Every batch includes rigorous first-article inspection against the original CAD model using calibrated CMMs or optical comparators, verifying critical dimensions and end conditions to Honyo’s standard ±0.1 mm tolerance. Finished parts undergo final deburring and material certification before shipment.

This integrated workflow—AI quoting for speed, DFM for robustness, and precision production with embedded QC—ensures Honyo delivers complex pipe components with exceptional repeatability and minimal time-to-part, directly addressing the demanding requirements of prototyping and low-volume production in aerospace, automotive, and fluid handling industries.

Start Your Project

Start Your Project with Precision CNC Laser Pipe Cutting at Shenzhen Honyo Prototype

When it comes to manufacturing complex metal components, the efficiency and accuracy of CNC laser pipe cutting offer unmatched advantages. At Shenzhen Honyo Prototype, we specialize in high-precision CNC machining services, including advanced laser pipe cutting tailored for industries ranging from automotive and aerospace to construction and industrial equipment. Our state-of-the-art CNC laser pipe cutting machines deliver clean, burr-free cuts on round, square, rectangular, and custom-profiled tubes and pipes—ensuring your components meet exact design specifications.

Whether you’re developing a prototype or preparing for low to mid-volume production, our capabilities support a wide range of materials, including carbon steel, stainless steel, aluminum, and other alloys. With multi-axis cutting heads and automated feeding systems, we achieve intricate cuts, bevels, notches, and joint preparations with tight tolerances down to ±0.1 mm. This level of precision reduces downstream processing, minimizes material waste, and accelerates time-to-market.

Our engineering team collaborates closely with clients from the earliest stages of design to ensure manufacturability, optimize nesting layouts, and select the best material and cutting parameters. We support various file formats including STEP, IGES, DXF, and DWG, enabling seamless integration into your existing workflows. Every project undergoes rigorous quality inspection using coordinate measuring machines (CMM) and optical comparators to ensure dimensional accuracy and consistency.

To help you get started, below are key technical specifications of our CNC laser pipe cutting systems:

| Specification | Details |

|————–|——–|

| Laser Source Power | 1 kW – 3 kW (fiber laser) |

| Maximum Pipe Length | 6,000 mm |

| Round Pipe Diameter Range | Ø10 – Ø300 mm |

| Square/Rectangular Pipe Size | 10×10 mm – 260×260 mm |

| Wall Thickness Range | 0.5 mm – 16 mm (varies by material) |

| Positioning Accuracy | ±0.03 mm/m |

| Cutting Tolerance | ±0.1 mm |

| Supported Materials | Carbon steel, stainless steel, aluminum, alloy steel |

| File Formats Accepted | DXF, DWG, STEP, IGES, X_T |

| Lead Time (Typical) | 3–7 days (prototypes), 7–14 days (production batches) |

Starting your next project with Shenzhen Honyo Prototype is simple. We are committed to providing fast turnaround, competitive pricing, and responsive customer service to support your engineering and production goals. Whether you need a single prototype or a full batch of precision-cut components, our team ensures every part meets the highest standards of quality and performance.

Contact Susan Leo today at info@hy-proto.com to discuss your project requirements. Include your technical drawings, material preferences, and quantity needs, and we’ll provide a detailed quote and production plan within 24 hours. Let us help you transform your designs into reality with advanced CNC laser pipe cutting technology.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.