Contents

Manufacturing Insight: Personal Cnc Machine

Manufacturing Insight: Personal CNC Machines and Professional Production Pathways

Personal CNC machines represent an accessible entry point into digital fabrication, primarily serving hobbyists, educators, and micro-workshops. These compact, often desktop-sized systems typically utilize stepper motors, lower-power spindles (500W–1.5kW), and simplified control software. They enable basic milling, routing, and engraving in materials like wood, soft plastics, and occasionally aluminum alloys. While valuable for learning principles of CNC operation and producing simple prototypes or decorative items, inherent limitations exist regarding precision, material versatility, and production scalability. Tolerances often range ±0.1mm, spindle runout can exceed 0.05mm, and work envelopes are constrained, limiting part size and complexity. Surface finish and dimensional consistency on critical features frequently fall short of industrial requirements, especially for functional end-use parts or series production.

Shenzhen Honyo Prototype bridges the gap between initial concept exploration on personal CNC equipment and demanding commercial production. We recognize personal CNCs as a valuable stepping stone but emphasize that transitioning to professional-grade manufacturing requires systems engineered for repeatability, speed, and material integrity. Our industrial CNC machining centers operate with significantly higher specifications, ensuring parts meet stringent engineering standards. This capability is essential for clients moving beyond proof-of-concept models into functional testing, pre-production runs, or low-volume manufacturing where reliability and conformance are non-negotiable.

The following table contrasts typical personal CNC capabilities with Shenzhen Honyo Prototype’s industrial production standards:

| Specification | Typical Personal CNC Machine | Shenzhen Honyo Prototype Standard |

| :——————— | :————————— | :——————————– |

| Spindle Power | 500W – 1.5kW | 7.5kW – 24kW |

| Positioning Accuracy | ±0.1mm | ±0.005mm |

| Repeatability | ±0.05mm | ±0.002mm |

| Max Work Envelope | 300 x 300 x 100 mm | 1000 x 500 x 300 mm (3-axis) |

| Typical Materials | Wood, PLA, HDPE, Soft Al | All Aluminum Alloys, Steels, Titanium, Engineering Plastics, Composites |

| Surface Finish (Ra) | 3.2 – 6.3 µm | 0.8 – 1.6 µm (Machined) |

| Tool Changer | Manual | Automatic (24+ Tool Capacity) |

| Quality Control | Visual/Basic Measurement | CMM, Optical Comparator, SPC Data |

At Honyo, we leverage this industrial capability to transform designs initiated on personal CNC systems into robust, certified components. Our process integrates advanced 5-axis machining, rigorous in-process inspection, and comprehensive post-processing (anodizing, plating, precision grinding) unavailable on desktop platforms. We handle complex geometries, tight-tolerance features (<±0.025mm), and challenging materials like stainless steel or titanium that exceed personal machine capabilities. This ensures dimensional stability, superior surface integrity, and adherence to ISO 9001 quality management protocols.

For engineering teams and innovators leveraging personal CNC technology for initial prototyping, Shenzhen Honyo Prototype provides the essential next step. We offer seamless transition pathways from digital model to certified production part, combining rapid iteration speed with uncompromising quality. Contact our engineering team to discuss how our industrial CNC machining services can elevate your prototype to a production-ready solution, ensuring performance, reliability, and scalability for your market.

Technical Capabilities

Technical Capabilities: Precision CNC Machining for Personal CNC Machines

Shenzhen Honyo Prototype specializes in high-precision CNC machining solutions tailored for personal CNC machine applications. Our advanced 3-axis, 4-axis, and 5-axis milling systems, combined with precision turning capabilities, enable us to deliver complex, high-integrity components with exceptional repeatability and surface finish. These capabilities are ideal for prototyping, low-volume production, and custom engineering projects commonly associated with personal CNC users, including makers, engineers, and R&D teams.

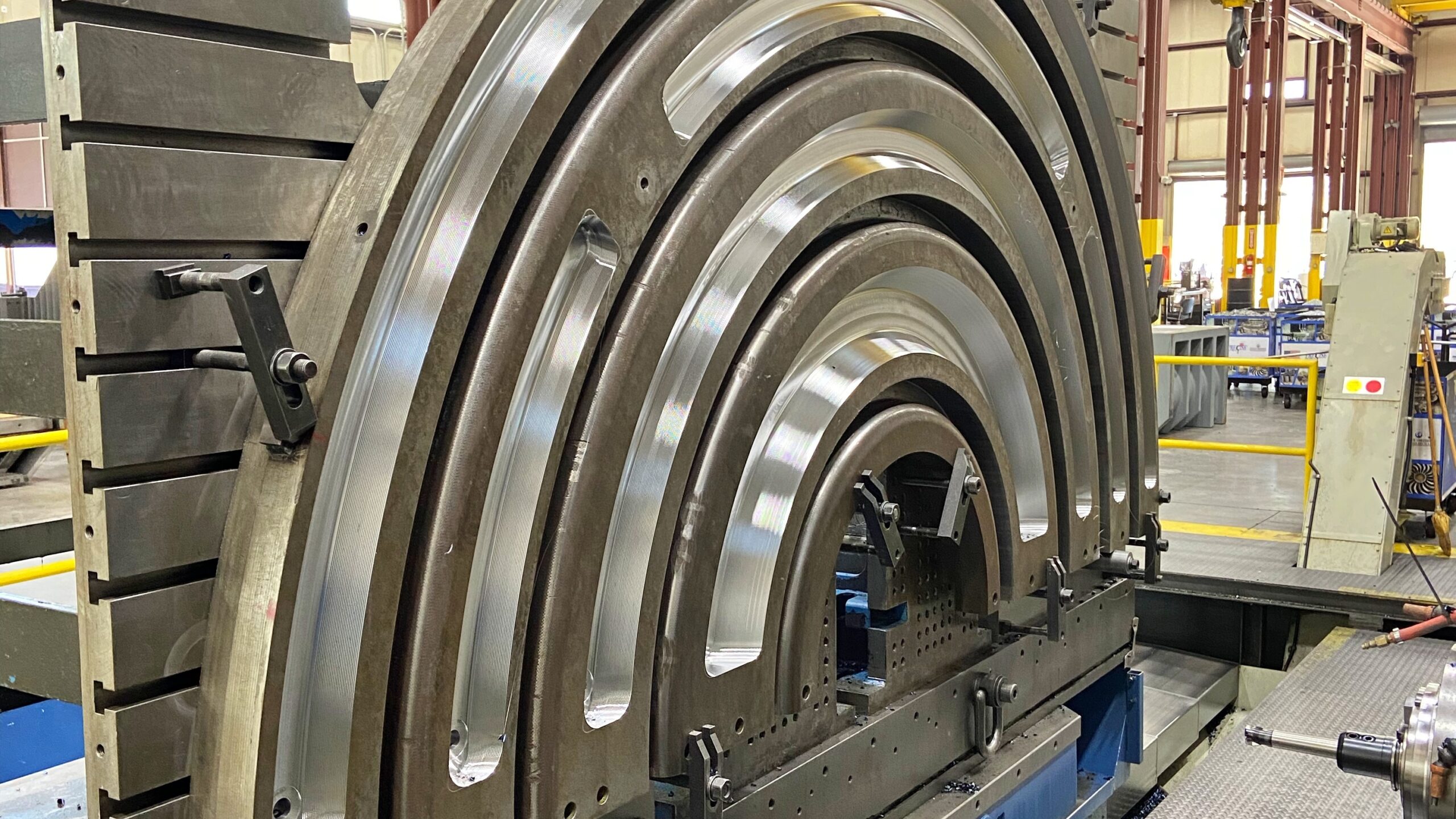

Our 3-axis CNC milling provides robust performance for prismatic parts with straightforward geometries, while 4-axis machining introduces rotary indexing for enhanced feature access and reduced setup cycles. For the most complex organic shapes and multi-faceted components, our 5-axis simultaneous milling ensures unparalleled accuracy and surface continuity, minimizing tool interference and maximizing design freedom. All milling operations are supported by high-resolution tool probing, in-process inspection, and thermal compensation systems to maintain dimensional stability.

In addition to milling, our CNC turning centers support both bar-fed and chucking operations, accommodating a wide range of cylindrical and axially symmetric parts. Tight-tolerance turning is routinely performed with sub-micron tool control, enabling precise diameter control, fine threading, and complex groove geometries. Integration of milling and turning in multi-tasking machines allows for complete machining in a single setup, reducing lead times and improving part concentricity.

Tight tolerances are a cornerstone of our service offering. Standard tolerances are maintained within ±0.05 mm, with precision capabilities down to ±0.005 mm for critical features. Surface finishes as fine as Ra 0.8 μm are achievable through optimized toolpaths and fine finishing tools. These capabilities are consistently maintained across a broad spectrum of engineering materials, from aluminum and stainless steel to engineering plastics and brass.

The following table outlines the typical tolerance and material performance specifications achievable on our personal CNC machine production lines:

| Feature Type | Standard Tolerance | Precision Tolerance | Surface Finish (Typical) | Compatible Materials |

|———————-|——————–|———————-|————————–|——————————————|

| Linear Dimensions | ±0.05 mm | ±0.005 mm | Ra 1.6 – 3.2 μm | Aluminum (6061, 7075), Stainless Steel (303, 316), Brass, Copper |

| Diameter (Turning) | ±0.03 mm | ±0.005 mm | Ra 0.8 – 1.6 μm | Steel (1018, 4140), Titanium, Plastics (POM, PEEK, Nylon) |

| Positional Accuracy | ±0.02 mm | ±0.008 mm | — | All compatible metals and plastics |

| Angular Features | ±0.1° | ±0.05° | Ra 1.6 – 3.2 μm | Aluminum, Brass, Engineering Plastics |

| Threaded Features | Class 6G (Metric) | Class 4G (Metric) | Ra 1.6 μm | Stainless Steel, Brass, Aluminum |

All machining processes are supported by comprehensive quality control, including CMM inspection, optical comparators, and surface roughness testers, ensuring every component meets design intent and functional requirements. At Honyo Prototype, we combine advanced CNC technology with rigorous process control to deliver reliable, high-precision results for personal and professional engineering applications.

From CAD to Part: The Process

Production Process: From CAD to Precision Part

At Shenzhen Honyo Prototype, our CNC machining workflow for personal CNC machine components is engineered for speed, accuracy, and seamless client integration. We eliminate traditional bottlenecks through a rigorously defined three-stage process: AI-Powered Quoting, Collaborative Design for Manufacturability (DFM), and Precision Production. This structured approach ensures optimal outcomes from initial concept to final part delivery, specifically tailored for the demanding requirements of personal CNC applications where precision and material efficiency are paramount.

AI-Powered Quoting initiates the engagement. Clients submit CAD files (STEP, IGES, or native formats) directly to our secure portal. Our proprietary AI engine instantly analyzes geometry, material selection, required tolerances, and surface finish specifications against our extensive manufacturing database and live machine capacity. This cloud-based system generates a technically validated, binding quote within minutes, not days, detailing cost, lead time, and feasibility assessment. Unlike manual quoting, our AI quantifies manufacturability risks upfront, providing immediate transparency on cost drivers and potential constraints. The efficiency gain is significant compared to industry norms.

| Process Stage | Traditional Quoting | Honyo’s AI-Driven Process |

| :—————— | :———————– | :———————— |

| Speed | 24-72+ hours | < 15 minutes |

| Accuracy | Prone to human error | Geometry & database validated |

| Transparency | Limited cost breakdown | Clear drivers & risk flags |

The critical Design for Manufacturability (DFM) Review follows quote acceptance. Our senior manufacturing engineers perform a deep technical analysis, focusing explicitly on personal CNC machine part challenges like thin walls, complex undercuts, or tight positional tolerances. We proactively identify potential issues such as excessive tool deflection, suboptimal material removal rates, or fixture interference. Crucially, this is not a critique but a collaborative optimization phase. We provide specific, actionable recommendations—suggesting minor geometric adjustments, alternative toolpath strategies, or material grade substitutions—to enhance manufacturability without compromising functional intent. Client approval of the DFM report is mandatory before production, ensuring alignment and preventing costly revisions later.

Precision Production Execution leverages Honyo’s Shenzhen facility capabilities. Approved designs move directly to our calibrated CNC machining centers (3-axis, 4-axis, and 5-axis mills, lathes). Programs are rigorously verified using CAM simulation software before any material is cut. During machining, stringent process controls are enforced: in-process inspections with calibrated CMMs or optical comparators at critical stages, documented material traceability, and real-time monitoring of tool wear and machine parameters. For personal CNC components demanding micron-level accuracy, we implement thermal compensation routines and utilize high-precision probing systems. Final inspection against the original CAD model and client specifications is mandatory, with full inspection reports provided. All parts undergo meticulous deburring and cleaning before shipment, ensuring they meet the exacting standards required for reliable integration into personal CNC systems. This integrated workflow guarantees parts are delivered right-first-time, on schedule, and within budget. Submit your CAD files to initiate this proven process.

Start Your Project

Start Your Project with Precision CNC Machining at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, we specialize in delivering high-precision CNC machining services tailored to engineers, designers, and innovators developing personal CNC machines. Whether you’re prototyping a new design or preparing for small-batch production, our advanced manufacturing capabilities ensure your components meet exacting standards for fit, function, and durability. Our team combines state-of-the-art 3-, 4-, and 5-axis CNC machines with rigorous quality control to produce parts from a wide range of engineering-grade metals and plastics.

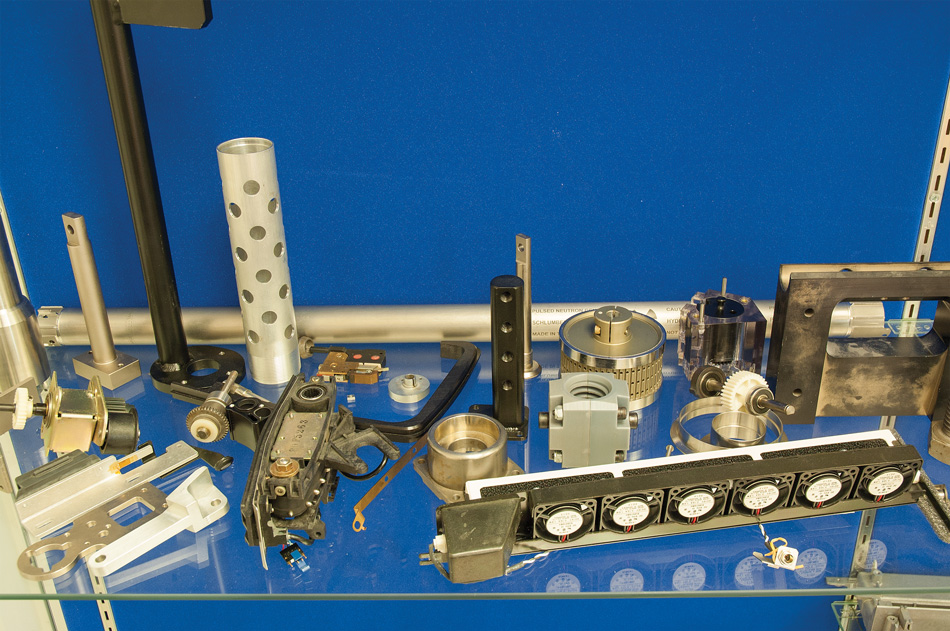

We understand that personal CNC machine projects demand tight tolerances, repeatable accuracy, and materials that can withstand mechanical stress and thermal variation. That’s why we offer custom machining solutions optimized for components such as gantry frames, spindle mounts, linear rail brackets, stepper motor housings, and custom lead screw assemblies. From initial concept to final part delivery, we work closely with you to ensure every detail is manufactured to specification.

Our facility in Shenzhen is equipped with modern CNC centers capable of handling complex geometries and intricate features common in DIY and open-source CNC systems. We support a broad material selection, including aluminum 6061 and 7075, stainless steel 303 and 316, brass, POM (Delrin), polycarbonate, and PEEK, allowing you to match material properties to your machine’s performance requirements. All parts are inspected using precision metrology tools, including CMM and optical comparators, to guarantee compliance with your dimensional and surface finish needs.

To streamline your workflow, we accept a variety of file formats, including STEP, IGES, SolidWorks, and native CAD files. Our engineering team performs a comprehensive Design for Manufacturability (DFM) review on every project to identify potential improvements in tool access, feature optimization, and cost efficiency—helping you avoid delays and reduce overall project risk.

When you partner with Honyo Prototype, you’re not just getting a machining service—you’re gaining a technical collaborator committed to your project’s success. We offer rapid turnaround times, real-time production updates, and full transparency throughout the manufacturing process.

Ready to bring your personal CNC machine design to life? Contact Susan Leo today to discuss your project requirements, request a quote, or schedule a technical consultation. With our expertise and your innovation, we can turn concepts into high-performance reality.

Contact Information

Susan Leo

Senior Manufacturing Engineer

Shenzhen Honyo Prototype

Email: info@hy-proto.com

| Feature | Specification |

|——–|—————|

| CNC Capabilities | 3-axis, 4-axis, 5-axis milling |

| Tolerance | ±0.005 mm (standard), tighter on request |

| Materials | Aluminum, stainless steel, brass, POM, PC, PEEK, and more |

| Max Work Envelope | 1000 × 600 × 500 mm |

| Lead Time | As fast as 3–7 days for prototypes |

| File Formats Accepted | STEP, IGES, STL, SolidWorks, DWG, PDF (with dimensions) |

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.