Contents

Manufacturing Insight: Wire Edm Service

Manufacturing Insight: Wire EDM Service

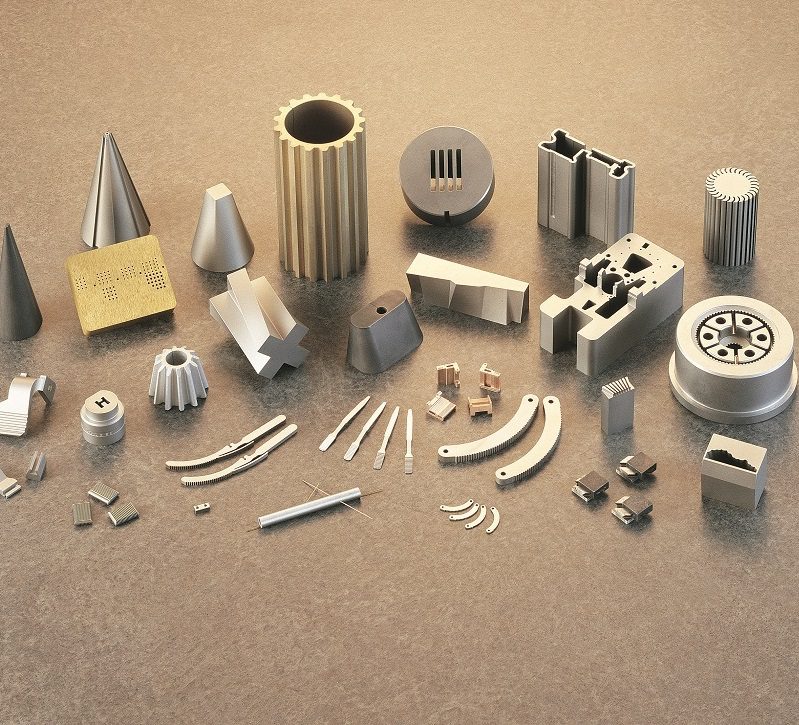

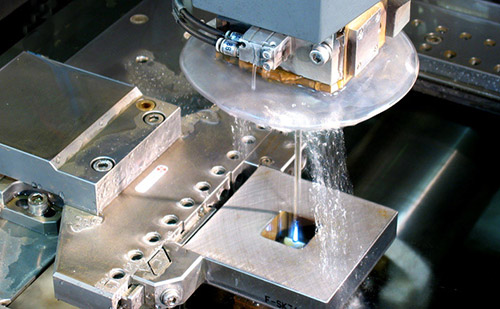

Wire Electrical Discharge Machining (EDM) is a precision subtractive manufacturing process that utilizes controlled thermal erosion to cut conductive materials with exceptional accuracy. Unlike conventional CNC milling, Wire EDM employs a continuously fed brass or zinc-coated wire electrode submerged in dielectric fluid, generating sparks that erode material without direct contact. This non-contact mechanism eliminates mechanical stresses, making it ideal for machining fragile geometries, intricate contours, and hardened alloys up to 65 HRC. At Shenzhen Honyo Prototype, we leverage this technology to solve complex manufacturing challenges where traditional methods fall short—particularly for tight-tolerance components in aerospace, medical, and mold-making applications.

Our Wire EDM service excels in producing parts with micron-level precision and superior surface integrity. The process achieves tolerances down to ±0.002 mm and surface finishes as fine as Ra 0.4 μm, even in difficult-to-machine materials like titanium, Inconel, tool steels, and carbides. Critical capabilities include taper cutting up to ±15°, skiving for high-aspect-ratio features, and multi-axis contouring for 3D geometries. The absence of cutting forces ensures zero distortion on thin-walled sections or delicate components, while the submerged operation minimizes thermal effects and recast layers. This precision is vital for prototyping functional assemblies where fit, sealing, or motion dynamics are non-negotiable.

Honyo Prototype operates state-of-the-art AGIE Charmilles and Sodick wire EDM systems in our Shenzhen facility, each equipped with adaptive control systems for consistent repeatability. Our engineers optimize parameters for speed and surface quality, reducing lead times without compromising accuracy. All processes adhere to ISO 9001 standards, with in-process inspections using CMM and optical comparators to validate critical dimensions. We specialize in rapid prototyping and low-volume production, supporting clients from initial design review through final part validation.

Key technical specifications for our Wire EDM service are summarized below:

| Parameter | Capability Range |

|————————|————————————–|

| Maximum Work Envelope | 400 x 300 x 250 mm (X/Y/Z) |

| Tolerance | ±0.002 mm (standard), ±0.001 mm (opt.) |

| Surface Finish | Ra 0.4 μm to 3.2 μm |

| Taper Angle | ±15° |

| Material Thickness | 1–250 mm |

| Compatible Materials | Steels, Titanium, Inconel, Tungsten Carbide, Copper Alloys |

When your project demands uncompromising precision in hardened or complex geometries, Honyo Prototype delivers engineered solutions with rapid turnaround. Our expertise in Wire EDM transforms design constraints into manufacturing opportunities, ensuring your prototypes perform as intended in real-world applications. Contact our engineering team to discuss how we can elevate your next precision component.

Technical Capabilities

Wire EDM Service – Technical Capabilities

Shenzhen Honyo Prototype delivers precision Wire Electrical Discharge Machining (EDM) services tailored for complex geometries, tight-tolerance components, and high-accuracy requirements across aerospace, medical, automotive, and mold-making industries. Our advanced Wire EDM technology enables the production of intricate parts with exceptional surface finish and dimensional accuracy, particularly in hardened and conductive materials where traditional machining methods fall short.

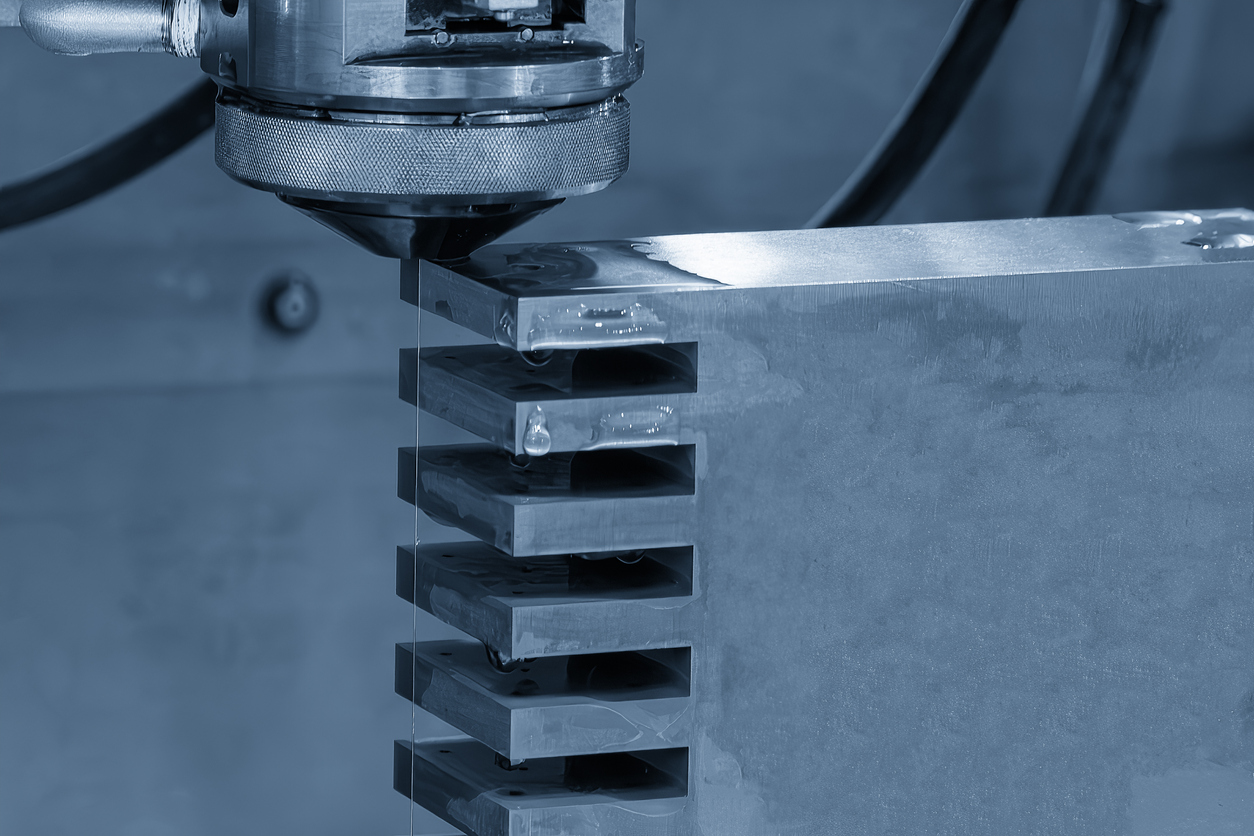

Our Wire EDM process utilizes CNC-controlled brass wire to erode material through a series of rapid electrical discharges, allowing for kerf widths as narrow as 0.18 mm. This non-contact machining method eliminates mechanical stress on the workpiece, making it ideal for delicate or thin-walled components. With full integration into our 3-, 4-, and 5-axis CNC machining ecosystem, Wire EDM at Honyo ensures seamless transition between subtractive and discharge processes, enabling comprehensive manufacturing solutions under one roof.

We specialize in tight-tolerance machining, routinely holding tolerances down to ±0.002 mm (±0.00008″). Our machines are equipped with automatic wire threading, linear motor drives, and closed-loop positioning systems to maintain consistency across long cutting paths and complex contours. Typical applications include precision dies, inserts, gears, nozzles, and prototype components requiring micron-level accuracy.

Material versatility is a cornerstone of our Wire EDM capability. We process a broad range of conductive materials, including hardened tool steels, stainless steels, titanium alloys, tungsten, and exotic alloys. Each job undergoes rigorous in-process inspection using coordinate measuring machines (CMM) and optical comparators to ensure adherence to print specifications.

Our technical team collaborates closely with design and engineering partners to optimize part geometry for manufacturability, minimize lead times, and ensure first-time-right production. With ISO 9001-certified processes and climate-controlled machining environments, Honyo maintains repeatability and quality across both prototypes and low-to-medium volume production runs.

Below is an overview of our standard Wire EDM technical specifications:

| Parameter | Specification |

|—————————-|——————————————–|

| Machine Axes | 4-Axis (U, V, X, Y) with 5-axis联动 support via integrated CNC systems |

| Wire Diameter Range | 0.18 mm – 0.33 mm |

| Maximum Workpiece Size | 400 mm × 300 mm × 200 mm (L × W × H) |

| Maximum Cutting Height | 200 mm |

| Positioning Accuracy | ±0.001 mm |

| Repeatability | ±0.001 mm |

| Surface Finish | Ra 0.4 µm (typical), down to Ra 0.2 µm (fine-cut) |

| Standard Tolerance | ±0.005 mm |

| Tight Tolerance Capability | ±0.002 mm |

| Taper Cutting Angle | Up to ±30° over 100 mm height |

| Material Type | Common Grades Processed |

|—————————-|——————————————–|

| Tool Steels | D2, A2, SKD11, H13, O1 (up to 68 HRC) |

| Stainless Steels | 304, 316, 17-4PH, 440C |

| Titanium Alloys | Ti-6Al-4V, CP Ti |

| Exotic Alloys | Inconel 718, Hastelloy, Monel |

| Tungsten & Molybdenum | Pure Tungsten, TZM |

| Copper Alloys | EDM Copper, Brass |

At Shenzhen Honyo Prototype, Wire EDM is not just a machining step—it’s a precision enabler for innovation. Contact our engineering team to discuss your next high-accuracy project.

From CAD to Part: The Process

Wire EDM Production Workflow: From CAD to Precision Part

At Shenzhen Honyo Prototype, our Wire Electrical Discharge Machining (EDM) service transforms digital designs into high-precision metal components through a rigorously controlled three-phase workflow. This process ensures dimensional accuracy, material integrity, and on-time delivery for complex geometries unattainable via conventional CNC methods.

The workflow initiates with AI-Powered Quoting. Upon receiving a 3D CAD model (STEP, IGES, or native formats), our proprietary AI engine performs instantaneous geometry analysis. It evaluates critical factors including part complexity, required tolerances, material type, and kerf allowances to generate a technically validated cost estimate within minutes. Unlike basic quoting tools, our system flags potential manufacturability risks—such as undersized radii or excessive taper angles—providing actionable feedback before order placement. This phase establishes realistic timelines and cost parameters while confirming technical feasibility.

Subsequently, the Engineering DFM Review phase commences. Our manufacturing engineers conduct a hands-on Design for Manufacturability assessment, focusing exclusively on Wire EDM-specific constraints. We verify electrode path continuity, assess fixture requirements for delicate features, and optimize cutting sequences to minimize thermal distortion. Critical attention is given to internal corner radii (typically ≥0.07mm), taper angle feasibility (up to 30° per side), and material thickness compatibility. Clients receive a detailed DFM report with suggested modifications—such as strategic slot additions for wire threading—ensuring the design aligns with process physics without compromising functional intent. This collaborative step prevents costly iterations and accelerates time-to-part.

Final Production Execution leverages our Makino U3 and AgieCharmilles CUT E series machines under stringent environmental controls. After securing the workpiece in precision-ground fixtures, we execute multi-axis cutting sequences with deionized water dielectric fluid. Process parameters—including pulse duration, servo feed, and wire tension (0.8–1.2 N)—are dynamically adjusted based on real-time spark gap monitoring. All critical dimensions undergo in-process probing per ISO 2768-mK standards, with final inspection via CMM or optical comparators. Parts exceeding 300mm in height undergo segmented machining with micron-level repositioning accuracy.

Key Wire EDM Capabilities at Honyo Prototype

| Parameter | Capability | Notes |

|——————–|—————————–|—————————————-|

| Tolerance | ±0.002 mm | Achievable on hardened tool steels |

| Surface Finish | Ra 0.4 – 1.6 µm | Adjustable via skim cuts |

| Max Work Envelope | 400 x 300 x 300 mm | Taper capability up to 30° |

| Material Thickness | 1 – 300 mm | Optimal for 10–150 mm range |

| Wire Diameter | 0.1 – 0.3 mm | Brass or zinc-coated options |

This integrated workflow—from AI-driven quoting through engineering-led DFM to metrology-verified production—eliminates guesswork and ensures first-article success. By prioritizing technical validation at each stage, Honyo Prototype delivers Wire EDM components that meet aerospace, medical, and mold-making specifications with repeatable precision. Clients receive not just a part, but a documented process audit trail confirming adherence to AS9100 and ISO 9001 standards.

Start Your Project

Start Your Next Precision Project with Honyo’s Wire EDM Service

When it comes to manufacturing high-precision metal components, especially those with intricate geometries and tight tolerances, Wire Electrical Discharge Machining (Wire EDM) stands out as one of the most reliable and accurate processes available. At Shenzhen Honyo Prototype, we specialize in delivering top-tier Wire EDM services tailored to meet the demanding requirements of industries such as aerospace, medical devices, mold & die, and precision instrumentation. Our advanced CNC-controlled Wire EDM machines, combined with decades of engineering expertise, allow us to produce complex parts with exceptional surface finish and micron-level accuracy.

Our Wire EDM process uses a thin, electrically charged brass wire to erode conductive materials with extreme precision. This non-contact method eliminates mechanical stress on the workpiece, making it ideal for delicate or hardened components that cannot be machined using traditional cutting methods. Whether you’re working with tool steel, titanium, inconel, or other difficult-to-machine alloys, our process ensures clean, burr-free cuts with tolerances as tight as ±0.002 mm and surface finishes down to Ra 0.2 µm.

We understand that every project begins with a vision—and turns into reality through collaboration. At Honyo, we work closely with engineers and product developers from the earliest stages to ensure manufacturability, optimize design for performance, and reduce lead times without compromising quality. Our team supports both low-volume prototypes and high-mix production runs, offering fast turnaround times and rigorous quality control throughout.

To help you get started, we’ve outlined our key technical capabilities in the table below:

| Specification | Capability |

|————–|————|

| Maximum Workpiece Size | 400 mm × 300 mm × 250 mm |

| Typical Tolerance | ±0.002 mm |

| Minimum Wire Diameter | 0.1 mm |

| Surface Finish (Standard) | Ra 0.8 – 1.6 µm |

| Surface Finish (Fine Cut) | Ra 0.2 – 0.8 µm |

| Materials Supported | Steel, Stainless Steel, Titanium, Inconel, Tungsten, Brass, Copper, and other conductive metals |

| Lead Time (Prototype) | 3–7 working days |

| Quality Assurance | Full inspection report available (CMM, optical comparator) |

We invite you to send us your 3D CAD models or technical drawings for a fast, no-obligation quote. Our engineering team will review your design, suggest any necessary optimizations, and provide detailed feedback to ensure your part is manufactured to exact specifications.

Ready to move forward? Contact Susan Leo, our dedicated project coordinator, to discuss your Wire EDM requirements. With her support, you’ll have a clear path from concept to completed component—on time and to the highest quality standards.

Email Susan Leo at info@hy-proto.com today and let Honyo Prototype be your trusted partner in precision manufacturing.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.