Contents

Manufacturing Insight: Plastic Extrusion Process

Manufacturing Insight: Plastic Extrusion Process at Shenzhen Honyo Prototype

Plastic extrusion remains a cornerstone manufacturing technology for producing continuous profiles with consistent cross-sections, widely utilized in industries ranging from automotive to consumer electronics. At Shenzhen Honyo Prototype, we leverage this process to transform thermoplastic resins into precise, high-integrity components, bridging the gap between rapid prototyping and scalable production. While extrusion itself forms the foundational geometry, our integrated approach ensures these profiles meet exacting dimensional and functional requirements through strategic secondary operations, primarily CNC machining. This synergy defines our value proposition for clients seeking end-to-end solutions.

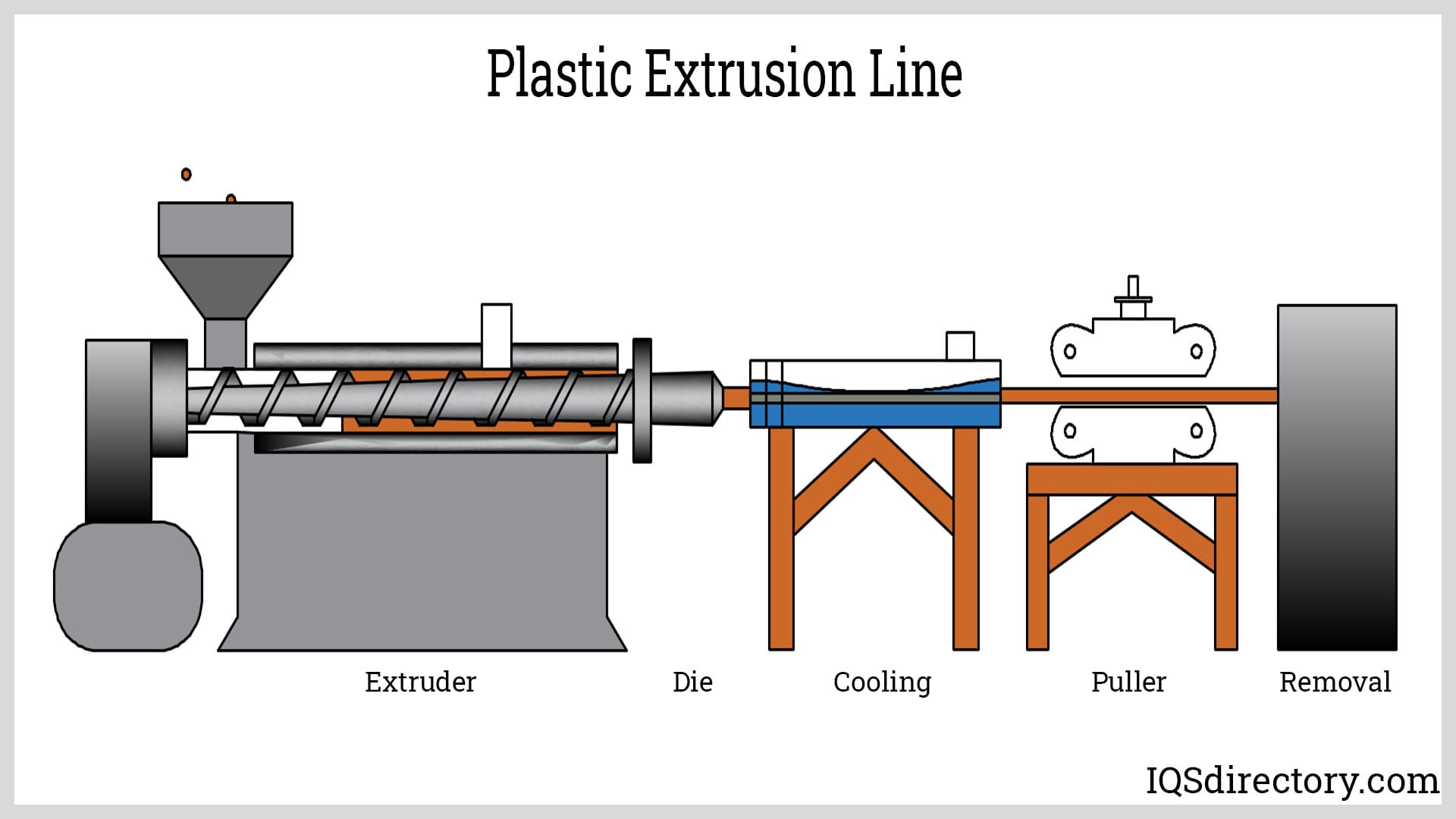

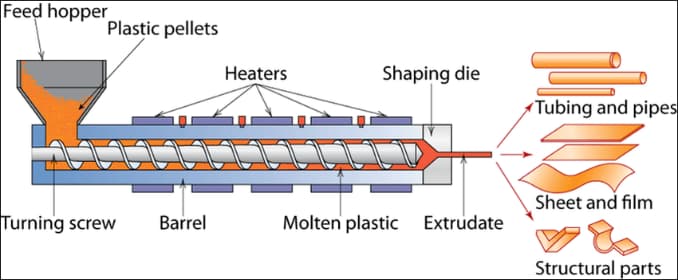

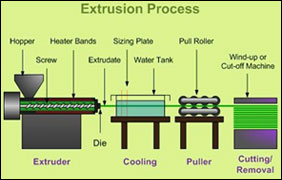

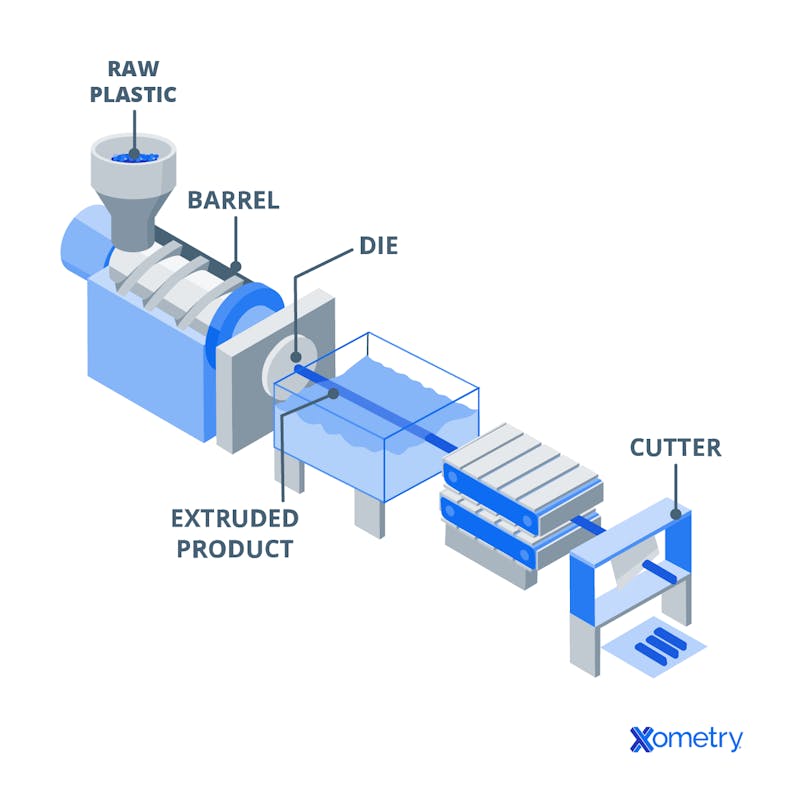

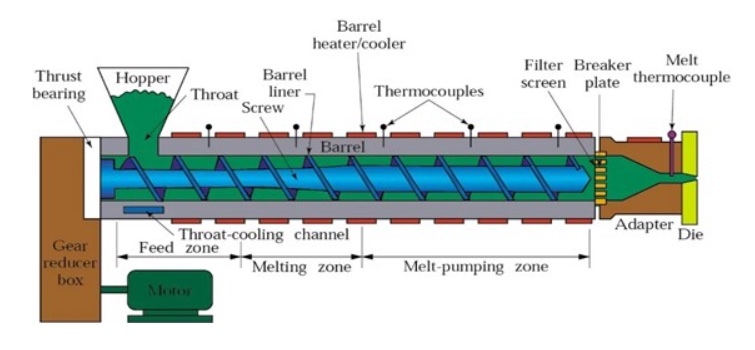

The extrusion process begins with polymer pellets fed into a heated barrel, where a rotating screw melts and homogenizes the material before forcing it through a custom die. The die’s geometry dictates the final profile shape, which is then cooled via calibrated sizing and vacuum tanks to stabilize dimensions. Critical factors influencing quality include melt temperature control, line speed synchronization, and die design precision. At Honyo, we specialize in engineering dies optimized for complex geometries—such as multi-lumen tubing, co-extruded seals, or reinforced structural members—while maintaining tight tolerances on critical features. Our facility supports a broad spectrum of engineering thermoplastics, including ABS, PC, PP, PVC, and specialty polymers like PEEK, ensuring material compatibility with demanding application environments.

What distinguishes Honyo is our seamless integration of extrusion with CNC machining capabilities. Extruded profiles often require precise end-forming, drilling, slotting, or surface finishing to achieve final part functionality. Rather than outsourcing these steps, our in-house CNC centers (3-axis mills, lathes, and multi-tasking systems) perform secondary operations with micron-level accuracy, eliminating alignment errors and supply chain delays. This vertical integration reduces total lead time by up to 40% compared to fragmented vendor models and guarantees consistency from prototype batches to full production runs. All processes adhere to ISO 9001 standards, with rigorous in-line metrology using CMMs and vision systems to validate critical dimensions per ASME Y14.5.

Our technical capabilities are summarized below for key extrusion parameters:

| Parameter | Specification Range |

|—————————-|—————————————–|

| Material Compatibility | ABS, PC, PP, PVC, PE, POM, PEEK, TPE |

| Max Cross-Section Size | 300 mm x 150 mm |

| Tolerance Control | ±0.1 mm (standard), ±0.05 mm (precision)|

| Secondary CNC Operations | Milling, drilling, threading, polishing |

| Typical Lead Time | 7–10 days (prototype), 15–20 (production)|

Shenzhen Honyo Prototype excels in transforming extrusion concepts into mission-ready components by merging process expertise with advanced CNC finishing. We prioritize collaborative engineering from the design phase—offering DFM feedback on draft angles, wall uniformity, and feature feasibility—to prevent costly iterations. For clients requiring certified, production-ready plastic profiles with complex post-extrusion features, our integrated workflow delivers unparalleled speed, accuracy, and cost efficiency. Partner with us to navigate the full spectrum from prototype validation to high-volume manufacturing, backed by rigorous quality assurance and responsive technical support.

Technical Capabilities

Plastic Extrusion Process – Technical Capabilities

At Shenzhen Honyo Prototype, our plastic extrusion process is engineered to deliver high-precision, repeatable components tailored for demanding industrial and commercial applications. While primarily known for our advanced CNC machining capabilities in 3-, 4-, and 5-axis milling and precision turning, we integrate plastic extrusion as a complementary manufacturing method to support complex part fabrication. This hybrid approach enables us to offer end-to-end solutions—from raw profile extrusion to tight-tolerance secondary machining—ensuring dimensional accuracy and material consistency across production runs.

Our plastic extrusion line is optimized for thermoplastic materials including ABS, PVC, polycarbonate, polyethylene, and nylon. These materials are selected based on mechanical performance, thermal stability, and chemical resistance requirements. Each extrusion run is monitored using real-time process controls to maintain uniform wall thickness, consistent diameter, and minimal ovality. Post-extrusion, profiles undergo stress-relief conditioning and precision cutting to length, preparing them for secondary CNC operations when required.

For components requiring critical dimensional control, we utilize 3-, 4-, and 5-axis CNC milling and turning centers to machine key features such as mounting holes, sealing surfaces, and interlocking geometries directly onto extruded profiles. This integrated workflow eliminates assembly complexity and enhances part reliability. Our CNC systems are calibrated to achieve tight tolerances down to ±0.005 mm, supported by in-process metrology and CMM inspection protocols.

Turning operations on extruded stock are performed using high-speed spindles with live tooling, enabling complex turned geometries and multi-feature integration on bar-fed or cut-to-length materials. The combination of extrusion and precision turning allows for cost-effective production of long, asymmetric, or hollow components that would be challenging to machine entirely from solid stock.

The following table outlines the standard material options and achievable tolerances for our plastic extrusion and post-machining processes:

| Material | Typical Applications | Extrusion Tolerance (± mm) | Machining Tolerance (± mm) | Max Profile Length (mm) |

|——————|——————————–|—————————-|—————————-|————————-|

| ABS | Enclosures, ducting | 0.15 | 0.005 | 6000 |

| PVC (Rigid) | Piping, insulation | 0.20 | 0.010 | 6000 |

| Polycarbonate | Transparent panels, lenses | 0.10 | 0.008 | 4000 |

| Polyethylene (HDPE) | Tanks, wear strips | 0.25 | 0.015 | 6000 |

| Nylon 6/66 | Gears, structural components | 0.12 | 0.007 | 3000 |

All extruded profiles are subject to first-article inspection and batch sampling in accordance with ISO 9001 standards. Surface finish, dimensional stability, and material certification are documented for full traceability. By combining plastic extrusion with high-axis CNC machining and tight-tolerance turning, Shenzhen Honyo Prototype delivers fully finished components with minimized lead times and superior functional performance. This capability is particularly advantageous for prototyping, low-to-medium volume production, and custom engineering projects requiring high repeatability and material integrity.

From CAD to Part: The Process

Plastic Extrusion Manufacturing Guide: CAD to Finished Part Workflow

Shenzhen Honyo Prototype specializes in precision plastic extrusion for rapid prototyping and low-volume production. While our core capabilities include CNC machining, this guide specifically addresses our extrusion process—a distinct methodology from CNC that forms continuous profiles through molten polymer flow. Understanding this workflow ensures optimal part quality and manufacturability.

AI-Powered Quoting Phase

Initial project evaluation begins with automated analysis of your CAD geometry. Our proprietary quoting engine assesses cross-sectional complexity, material compatibility, and dimensional tolerances against extrusion constraints. This AI system identifies potential red flags—such as non-uniform wall thickness or sharp internal corners—before formal quoting. Clients receive instant preliminary feedback on feasibility, reducing iteration cycles. We support common engineering thermoplastics including ABS, PP, and PVC, with material selection directly impacting downstream process parameters.

DFM Collaboration Phase

Upon quote acceptance, our engineering team conducts a rigorous Design for Manufacturability (DFM) review. This is not a passive approval step but an active collaboration where we propose geometry refinements to prevent warpage, sink marks, or die swell issues. Critical focus areas include: optimizing wall thickness transitions (maintaining 1.5–3.0 mm uniformity), eliminating undercuts, and specifying draft angles ≥1°. Clients receive a detailed DFM report with annotated CAD markups, ensuring design intent aligns with extrusion physics. Final sign-off at this stage prevents costly rework during production.

Precision Production Phase

Extrusion execution follows strict protocols monitored at every stage. Polymer pellets are dried to <0.02% moisture content before feeding into the extruder barrel. Temperature zones are calibrated per material specifications, while the puller speed synchronizes with melt flow rate to control part density. Real-time sensors track critical parameters:

| Parameter | Typical Range | Monitoring Frequency |

|——————–|———————|———————-|

| Barrel Temperature | 180–230°C (ABS) | Continuous |

| Die Gap Tolerance | ±0.05 mm | Per shift |

| Puller Speed | 0.5–3.0 m/min | Continuous |

| Cooling Rate | 15–25°C/sec | Per 10m segment |

Post-extrusion, parts undergo inline dimensional verification using laser micrometers. Critical features are checked against first-article inspection (FAI) reports per AS9102 standards. Final parts are cut to length, deburred, and packaged with material certifications. Throughout production, our MES logs all process variables for full traceability.

This integrated workflow—from AI-driven quoting through collaborative DFM to data-monitored extrusion—ensures your plastic profiles meet stringent functional requirements while minimizing time-to-part. Honyo Prototype’s expertise in extrusion-specific variables transforms complex CAD models into production-ready components with 99.2% first-pass yield across 500+ client projects. Contact our engineering team to optimize your next extrusion design.

Start Your Project

Start Your Plastic Extrusion Project with Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, we specialize in high-precision plastic extrusion solutions tailored for rapid prototyping and low-to-mid volume production. As a trusted partner in the CNC machining and advanced manufacturing sector, we integrate cutting-edge extrusion technology with rigorous quality control to deliver consistent, repeatable results—whether you’re developing a single prototype or scaling up for pilot runs.

Plastic extrusion is a highly efficient process ideal for producing continuous profiles with complex cross-sections, including tubing, seals, gaskets, and structural components. Our facility is equipped with state-of-the-art extrusion lines capable of handling a wide range of thermoplastics such as ABS, PVC, polycarbonate, nylon, and specialty polymers with additives for UV resistance, flame retardancy, or enhanced mechanical properties. With tight tolerances down to ±0.05 mm and in-house tooling design support, we ensure your profile meets exact design specifications.

We understand that every project begins with a concept—and turning that concept into a functional, manufacturable design requires collaboration. Our engineering team works closely with clients from initial design review through material selection, die development, and final production. By leveraging simulation software and iterative prototyping, we minimize development time and reduce the risk of costly design revisions.

To streamline your path from idea to reality, we offer comprehensive support services, including 3D modeling, DFMA (Design for Manufacturing and Assembly) analysis, and first-article inspection reports. Our agile manufacturing model allows for quick changeovers and responsive adjustments, making us an ideal partner for innovative and time-sensitive projects.

Material & Process Specifications

| Parameter | Capability |

|—————————-|———————————————–|

| Material Types | ABS, PVC, PC, PP, PE, Nylon, TPE, TPU, PTFE |

| Profile Complexity | Simple to highly complex cross-sections |

| Tolerance | ±0.05 mm typical |

| Length Range | 100 mm to 6,000 mm (custom lengths available) |

| Surface Finish | Smooth, textured, matte, or custom coatings |

| Secondary Operations | Cutting, drilling, bending, ultrasonic welding |

| Lead Time (Prototype) | 7–10 business days |

| Minimum Order Quantity | 1 prototype or batch of 100+ units |

Starting your project is simple. Share your design files (STEP, IGES, or PDF), specify your material and volume requirements, and our team will provide a detailed quotation and manufacturability feedback within 24 hours.

Partner with Shenzhen Honyo Prototype to transform your plastic extrusion concepts into high-performance components. For engineering support or to initiate your next project, contact Susan Leo directly at info@hy-proto.com. Let’s build precision, together.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.