Contents

Manufacturing Insight: Sheet Metal Fabrication Machines

Manufacturing Insight: Sheet Metal Fabrication Machines

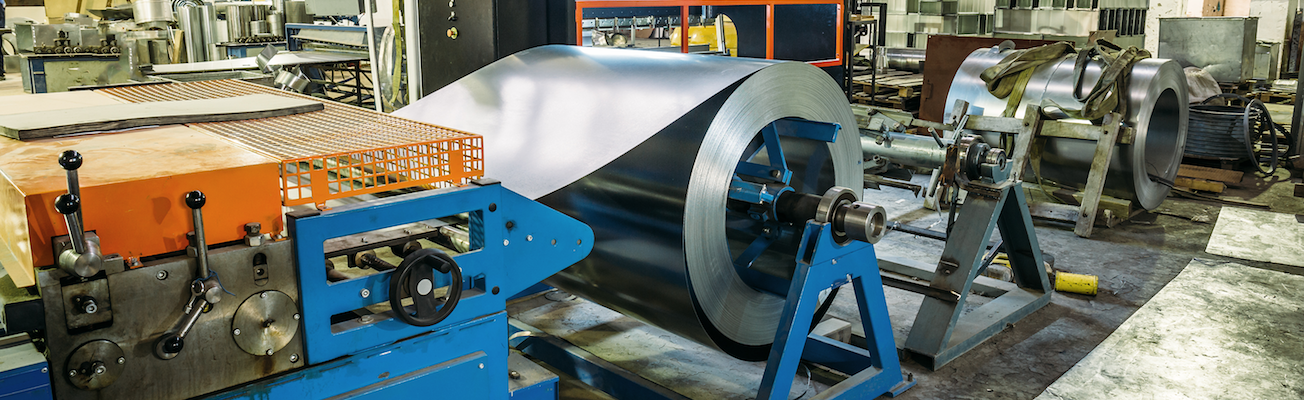

Sheet metal fabrication forms the backbone of precision component production across aerospace, medical, and industrial sectors. At Shenzhen Honyo Prototype, we leverage advanced machinery to transform flat sheet stock into complex, functional parts with exceptional accuracy and repeatability. Understanding the capabilities and limitations of core fabrication equipment is critical for designing manufacturable components and achieving optimal results, especially within the demanding context of rapid prototyping and low-volume production. Our integrated approach ensures designs transition seamlessly from CAD model to physical part, minimizing iterations and accelerating time-to-market.

Honyo Prototype utilizes a strategically selected suite of modern sheet metal machines, each chosen for its precision, speed, and suitability for prototyping workflows. Key capabilities include high-power fiber laser cutting for intricate geometries and clean edges, CNC turret punching for high-speed feature creation, and state-of-the-art CNC press brakes for precise bending operations. Crucially, our equipment features rapid tooling changeovers and seamless CAD/CAM integration, eliminating traditional bottlenecks in prototype fabrication. This allows us to efficiently handle the diverse material types and complex, one-off designs typical of our client base without sacrificing dimensional integrity.

The core machines comprising our sheet metal fabrication capability offer distinct advantages for prototype development:

| Machine Type | Max Sheet Size | Typical Tolerance | Key Materials Handled | Prototype Advantage |

| :——————- | :————- | :—————- | :——————– | :——————————– |

| Fiber Laser Cutter | 1500 x 3000 mm | ±0.1 mm | Steel, SS, Al, Cu | Complex contours, no tooling cost |

| CNC Turret Press | 1250 x 2500 mm | ±0.15 mm | Steel, SS, Al | Fast hole patterns, form features |

| CNC Press Brake | 3000 mm length | ±0.25° / ±0.1 mm | Steel, SS, Al, Brass | Precise bends, quick setup |

| Automatic Turret | 1250 x 2500 mm | ±0.15 mm | Steel, SS, Al | Combined punch/laser efficiency |

This technological foundation directly translates into tangible client benefits. The precision of our fiber lasers ensures clean cuts on thin materials critical for electronics enclosures, while the flexibility of our CNC press brakes accommodates unique bend sequences required for validation prototypes. Rapid digital nesting and job setup minimize material waste and machine downtime, keeping prototype costs predictable and lead times competitive. Furthermore, our engineers provide proactive design-for-manufacturability feedback based on real-time machine capabilities, preventing costly redesigns late in the development cycle.

Shenzhen Honyo Prototype excels at bridging the gap between conceptual design and functional reality. Our investment in versatile, high-precision sheet metal fabrication machinery, combined with deep process expertise, enables us to deliver prototypes that accurately reflect production intent. We understand that a prototype must not only look correct but also function correctly, meeting stringent mechanical and dimensional requirements. Partner with Honyo to leverage manufacturing insights from the earliest design stages, ensuring your sheet metal components are built right the first time, every time.

Technical Capabilities

Shenzhen Honyo Prototype delivers precision sheet metal fabrication services through advanced machinery and stringent process controls. Our technical capabilities in laser cutting, bending, and welding are engineered to support rapid prototyping and low-to-mid volume production with consistent quality and repeatability. Each machine is maintained to OEM specifications and operated by certified technicians to ensure dimensional accuracy and material integrity across diverse metal types and thicknesses.

Our fiber laser cutting systems offer high-speed, high-precision contour cutting for complex geometries. These machines utilize advanced beam delivery and CNC motion control to achieve tight tolerances on both ferrous and non-ferrous materials. With a maximum cutting area of 1500 mm × 3000 mm and power outputs up to 3 kW, we process materials ranging from 0.5 mm to 25 mm in thickness, depending on material type. The non-contact nature of laser cutting minimizes mechanical deformation and supports clean edge quality for downstream finishing or welding operations.

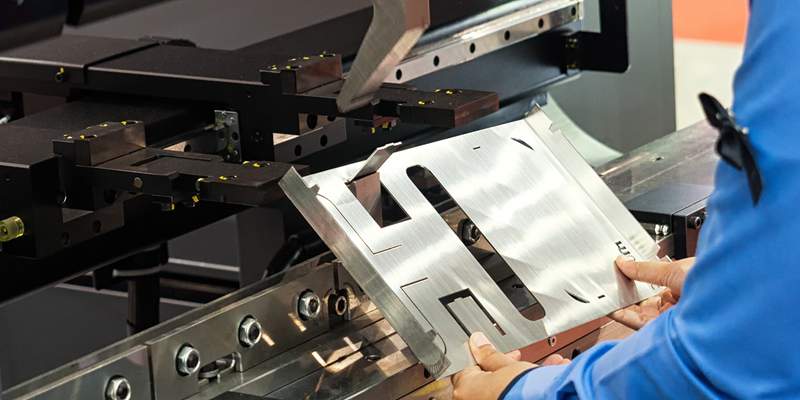

For forming operations, we employ CNC press brakes equipped with automatic tool changers and laser-assisted backgauging systems. These machines enable precise bending of metal sheets with consistent angles and minimal springback. Our bending capacity spans from thin-gauge aluminum to structural steel up to 6 mm in thickness, with a maximum bed length of 2500 mm. Process optimization is supported by offline programming software that simulates bend sequences and detects potential interferences prior to production.

Welding operations are performed using TIG, MIG, and spot welding technologies, selected based on joint design, material compatibility, and finish requirements. Automated welding cells ensure stable arc performance and heat input control, critical for maintaining metallurgical properties and minimizing distortion. All welders are certified to ISO 3834 standards, and critical weldments undergo visual and dimensional inspection, with optional NDT available upon request.

The following table summarizes machine capabilities and achievable tolerances across key processes:

| Process | Material Compatibility | Thickness Range (mm) | Tolerance | Max Workpiece Size (mm) |

|——————|——————————-|———————-|————————|————————–|

| Fiber Laser Cutting | Mild Steel, Stainless Steel, Aluminum, Brass, Copper | 0.5 – 25 | ±0.1 mm | 1500 × 3000 |

| CNC Bending | Mild Steel, Stainless Steel, Aluminum | 0.8 – 6.0 | ±0.2° angular, ±0.2 mm linear | 2500 × 1200 |

| TIG/MIG Welding | Mild Steel, Stainless Steel, Aluminum | 1.0 – 15.0 | ±0.5 mm (joint fit-up) | Custom (fixture-dependent) |

| Spot Welding | Mild Steel, Stainless Steel, Aluminum | 0.5 – 3.0 (per layer) | ±0.3 mm (electrode placement) | 600 × 600 per station |

All fabrication workflows integrate CAD/CAM data directly from customer models, ensuring design fidelity and reducing setup time. Honyo Prototype maintains compliance with ISO 9001:2015 standards across all manufacturing operations, supporting traceability, process validation, and continuous improvement in sheet metal production.

From CAD to Part: The Process

From CAD to Completed Part: Honyo Prototype’s Sheet Metal Fabrication Workflow

At Shenzhen Honyo Prototype, we streamline sheet metal production through a rigorously defined workflow, transforming client CAD data into high-precision parts efficiently. This integrated process minimizes errors, reduces lead times, and ensures manufacturability from the outset. Our methodology centers on three critical, interconnected phases: AI-Powered Quoting, Design for Manufacturability (DFM) Analysis, and Precision Production Execution.

AI-Powered Quoting initiates the process immediately upon receipt of your CAD file. Our proprietary AI engine performs an instant, multi-faceted analysis of the geometry, material specifications, and feature complexity. It evaluates key cost drivers including sheet utilization, required machine hours, secondary operations, and potential geometric challenges. This analysis generates a highly accurate, transparent quote within hours, not days, providing immediate cost visibility and establishing realistic delivery timelines based on actual production parameters, not estimates. The AI system flags potential high-cost features early, enabling proactive discussion before formal order placement.

Following quote acceptance, the Design for Manufacturability (DFM) Analysis phase commences. Our experienced manufacturing engineers conduct a thorough, collaborative review of the CAD model against our specific machine capabilities, material behavior, and process constraints. This is not a passive check but an active partnership. We identify potential issues such as minimum bend radii violations, hole-to-edge proximity problems, excessive tolerances driving cost, or features requiring impractical secondary operations. Crucially, we provide specific, actionable recommendations for design optimization – suggesting minor geometry adjustments that significantly enhance producibility and reduce cost without compromising function. Client feedback on these suggestions is integrated rapidly, typically within 24 hours, ensuring the final design is fully optimized for efficient, high-yield manufacturing on our equipment.

With a DFM-approved design, the project moves to Precision Production Execution. Our integrated digital workflow ensures seamless transfer of validated CAD data directly to the shop floor control systems. Parts are fabricated using state-of-the-art machinery operated by skilled technicians, with real-time process monitoring ensuring adherence to specifications. Key production capabilities are outlined below:

| Machine Type | Key Capabilities | Typical Tolerances |

| :——————– | :—————————————————- | :———————– |

| Fiber Laser Cutters | Up to 25mm mild steel, 15mm stainless, <1mm kerf | ±0.1mm (positioning) |

| CNC Turret Punches | Complex forms, louvers, PEM inserts, up to 6.0mm steel | ±0.15mm (feature loc.) |

| Hydraulic Press Brakes| Up to 200-ton capacity, CNC backgauges, radius forming | ±0.5° (bend angle) |

| Robotic Welders | MIG/TIG, precise seam control, reduced distortion | ±0.5mm (joint fit-up) |

Throughout production, in-process inspections verify critical dimensions after major operations like cutting and bending. Final inspection against the approved drawing, including first-article validation for new parts, guarantees the finished component meets all dimensional, geometric, and surface quality requirements before shipment. This closed-loop workflow – from intelligent quoting through collaborative DFM to digitally controlled production – is the foundation of Honyo Prototype’s commitment to delivering complex sheet metal parts with speed, precision, and exceptional value. We transform your design intent into reality, preventing costly rework and accelerating your time to market.

Start Your Project

Start Your Sheet Metal Fabrication Project with Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, we specialize in delivering precision sheet metal fabrication services tailored to the unique demands of prototyping and low-to-mid volume production. Whether you’re developing a new product, refining a design, or scaling up from prototype to production, our advanced manufacturing capabilities and engineering expertise ensure your project is built to exact specifications—on time and within budget.

Our sheet metal fabrication process leverages state-of-the-art machinery and a rigorous quality control system to produce components with tight tolerances, clean finishes, and consistent repeatability. From laser cutting and CNC punching to precision bending and welding, we handle every stage of production in-house, giving you a single source for end-to-end manufacturing support.

We understand that every project begins with a vision. That’s why our engineering team works closely with clients during the initial design phase to optimize for manufacturability, reduce material waste, and minimize assembly complexity. Our Design for Manufacturability (DFM) feedback is provided early in the process, helping you avoid costly revisions and production delays.

To ensure clarity and accuracy, we support a wide range of file formats, including STEP, IGES, DXF, and DWG. Once your design is finalized, our quoting system delivers fast, transparent pricing with no hidden fees. Lead times are competitive, and we offer expedited services for time-sensitive projects.

Below is an overview of our core sheet metal fabrication capabilities:

| Machine Type | Material Compatibility | Thickness Range | Tolerance | Max Working Area |

|————————|——————————|———————|———————-|————————–|

| Fiber Laser Cutter | Steel, Stainless Steel, Aluminum | 0.5 – 25 mm | ±0.1 mm | 1500 x 3000 mm |

| CNC Turret Punch | Steel, Aluminum, Brass | 0.8 – 6.0 mm | ±0.1 mm | 1270 x 2540 mm |

| CNC Press Brake | Steel, Stainless, Aluminum | 0.5 – 12 mm | ±0.2° bend angle | 3000 mm length |

| Spot & TIG Welding | Carbon Steel, Stainless, Al | 0.8 – 10 mm | Per ISO 15614 | Custom fixturing available |

All fabricated parts are subject to in-process and final inspections using precision measuring tools, including CMMs and laser scanners, ensuring compliance with ISO 9001 standards.

Starting your project is simple. Share your design files and requirements with our team, and we’ll provide a detailed quote, DFM feedback, and timeline within 24 hours. Our goal is to make the transition from concept to physical part as seamless as possible.

For immediate assistance, contact Susan Leo at info@hy-proto.com. With years of experience supporting global clients across industries such as medical, electronics, automation, and consumer goods, Susan will guide you through every step of the process—ensuring your sheet metal components meet the highest standards of quality and performance.

Let Shenzhen Honyo Prototype be your trusted partner in precision manufacturing. Reach out today and turn your design into reality.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.