Contents

Manufacturing Insight: Aluminum Concrete Molds

Manufacturing Insight: Aluminum Concrete Molds for Rapid Construction Solutions

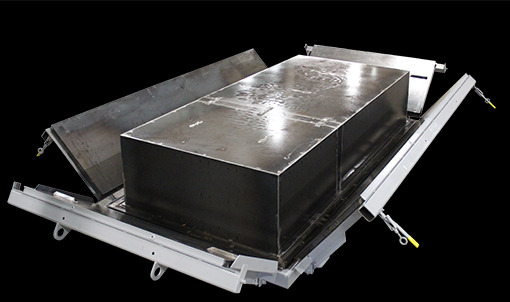

Traditional concrete formwork using wood or steel presents significant challenges in modern construction and precast applications, including lengthy lead times, high material costs, limited reusability, and dimensional instability. Aluminum concrete molds represent a strategic advancement in rapid tooling, specifically engineered to overcome these limitations while accelerating project timelines. At Shenzhen Honyo Prototype, we specialize in the precision manufacturing of high-performance aluminum molds, leveraging our expertise in rapid tooling and injection molding processes adapted for the demanding requirements of concrete casting. These molds are not merely a substitute; they are an engineered system designed for efficiency, precision, and cost-effectiveness in low-to-medium volume production runs common in architectural precast, infrastructure elements, and custom building components.

The inherent properties of aluminum—lightweight yet strong, excellent thermal conductivity, and inherent corrosion resistance—translate directly into tangible project benefits. Aluminum molds significantly reduce handling weight compared to steel, improving jobsite safety and enabling faster setup and stripping cycles. Superior thermal conductivity ensures more uniform concrete curing, minimizing internal stresses and surface defects like honeycombing. Crucially, the dimensional stability of machined aluminum over repeated thermal cycles guarantees consistent part geometry batch after batch, a critical factor for architectural facades or structural elements requiring tight tolerances. This stability, combined with a smooth surface finish achievable through precision machining and optional hardcoat anodizing, directly reduces or eliminates the need for secondary finishing operations on the cast concrete, saving significant labor and time.

Honyo Prototype’s manufacturing process integrates advanced CNC milling and strategic engineering to deliver molds optimized for concrete’s unique properties. We utilize high-grade aluminum alloys processed under stringent quality controls, ensuring molds withstand the abrasion and chemical environment of concrete without premature degradation. Our engineering team collaborates closely with clients during the design phase to optimize mold geometry for demolding, integrate necessary inserts or reinforcement pockets, and specify surface treatments that maximize release and longevity. This proactive approach prevents common field failures and ensures the mold performs reliably from the first pour through hundreds of cycles. Below are key specifications representative of our standard production capability:

| Parameter | Specification | Benefit for Concrete Casting |

| :——————— | :——————————– | :—————————————– |

| Base Material | 6061-T6 Aluminum Alloy | Optimal strength-to-weight ratio, weldability |

| Max Service Temp | 150°C (302°F) | Withstands exothermic heat of curing |

| Typical Tolerance | ±0.1 mm (per 100 mm) | Consistent part geometry, reduced rework |

| Surface Finish (As Machined) | Ra 0.8 – 1.6 µm | Smooth concrete surface, easy release |

| Optional Treatment | Hardcoat Anodizing (50-75 µm) | Enhanced wear/corrosion resistance, 2x+ life |

| Typical Mold Life | 500+ cycles (with maintenance) | Significant cost savings vs. wood/steel |

Engineers gain a critical advantage through reduced lead times; Honyo can typically deliver production-ready aluminum molds in 2-4 weeks from final CAD approval, drastically compressing project schedules compared to traditional steel tooling. This rapid deployment, coupled with the mold’s reusability and precision, delivers a superior return on investment for projects requiring multiple identical units or iterative design validation. Honyo Prototype provides not just a mold, but a validated manufacturing solution ensuring your concrete elements meet exacting specifications, on time and within budget. Partner with us to transform your concrete casting process through advanced aluminum tooling technology.

Technical Capabilities

Technical Capabilities: Aluminum Concrete Molds at Shenzhen Honyo Prototype

Shenzhen Honyo Prototype specializes in rapid tooling solutions for architectural and construction applications, with a core focus on high-precision aluminum concrete molds. Leveraging advanced CNC machining, CAD/CAM integration, and in-house quality control, we deliver durable, dimensionally accurate molds that support both prototyping and low-to-mid volume production runs. Our expertise in aluminum mold manufacturing enables faster lead times, improved thermal conductivity, and cost-effective iterations compared to traditional steel counterparts—making them ideal for precast concrete elements, façade panels, decorative concrete, and custom architectural features.

We offer two primary mold material options—aluminum and steel—tailored to project requirements such as production volume, surface finish, and part complexity. Aluminum molds, typically fabricated from high-grade 6061-T6 or 7075-T6 alloys, are lightweight, corrosion-resistant, and machined to tight tolerances. These molds are best suited for projects requiring rapid turnaround and high detail replication. For high-volume production or applications demanding extreme wear resistance, we provide steel molds using materials such as P20, H13, or 420 stainless steel, which offer extended service life under repetitive casting cycles.

One of our key differentiators is the ability to deliver a fully functional T1 sample within 7 days from design approval. This accelerated timeline is made possible through streamlined workflows, parallel processing, and dedicated project management. Our T1 molds undergo rigorous inspection, including first-article inspection reports (FAIR) and dimensional validation via CMM and coordinate measuring systems, ensuring compliance with client specifications prior to sample release.

All molds are designed with draft angles, venting, and alignment features optimized for concrete demolding and reusability. Surface finishes can be customized—from mirror polish to textured or sandblasted patterns—to achieve the desired aesthetic on the final concrete product. We also integrate lifting points, locating pins, and clamping features as needed for ease of use in the casting environment.

Our technical specifications for mold tolerances and material performance are detailed below:

| Feature | Aluminum Molds (6061-T6 / 7075-T6) | Steel Molds (P20 / H13 / 420 Stainless) |

|——–|————————————-|—————————————-|

| Typical Tolerance | ±0.05 mm | ±0.03 mm |

| Surface Roughness (as-machined) | Ra 0.8 – 3.2 µm | Ra 0.4 – 1.6 µm |

| Hardness | 95–105 HB (6061-T6) | 28–52 HRC (depending on grade) |

| Thermal Conductivity | 167 W/m·K | 25–35 W/m·K |

| Mold Life (cycles) | 500–2,000 | 10,000+ |

| Lead Time (T1 Sample) | 7 days | 10–14 days |

| Best For | Prototypes, low-to-mid volume, complex geometries | High-volume production, heavy-duty use |

At Shenzhen Honyo Prototype, we combine engineering precision with rapid manufacturing agility to deliver aluminum concrete molds that meet the demanding needs of modern construction and architectural design.

From CAD to Part: The Process

Production Process: Aluminum Concrete Mold Workflow

At Shenzhen Honyo Prototype, our rapid tooling process for aluminum concrete molds transforms client CAD data into high-performance production tools with exceptional speed and precision. This streamlined workflow, integrating AI-driven analysis and expert engineering, minimizes lead times while ensuring mold integrity for demanding concrete casting applications. The core sequence progresses from initial quotation through Design for Manufacturability (DFM) validation to final production and delivery.

AI-Driven Quoting & Feasibility Assessment

The process initiates when the client submits a 3D CAD model. Our proprietary AI quoting engine immediately analyzes the geometry, extracting critical parameters such as part volume, complexity, undercuts, and required surface finish. This system cross-references historical production data, material costs (primarily 6061-T6 aluminum), and machine utilization rates to generate a highly accurate cost estimate and preliminary lead time within minutes. Crucially, the AI performs an initial feasibility screen, flagging potential high-risk features like insufficient draft angles or excessively thin walls that could compromise mold life or concrete release. This provides the client with actionable data before formal commitment.

Comprehensive DFM Analysis & Optimization

Following quote acceptance, our engineering team conducts an in-depth DFM review. This stage is paramount for concrete molds, where factors like thermal cycling, abrasive concrete mix, and demolding forces dictate longevity. Engineers scrutinize draft angles (typically 1°-3° minimum), uniform wall thickness to prevent warpage during curing cycles, strategic placement of vents and ejector pins to avoid air traps and surface defects, and robust structural support to withstand concrete pressure. We simulate mold filling and cooling characteristics, optimizing internal water line layouts for efficient thermal management. Client collaboration is encouraged; we provide specific, actionable recommendations to enhance manufacturability and part quality, often preventing costly revisions post-machining. This proactive engineering ensures the mold design aligns perfectly with both concrete casting requirements and rapid aluminum tooling capabilities.

Precision Production & Quality Assurance

Approved designs move directly to production. High-speed CNC machining centers (primarily 3-axis and 5-axis mills) accurately fabricate mold cavities, cores, and inserts from aerospace-grade aluminum billet. Tight tolerances are maintained throughout, leveraging in-process probing for critical dimensions. Post-machining, surfaces undergo controlled finishing; cavity surfaces typically achieve 3.2 μm Ra to balance concrete release and surface texture requirements, while parting lines and shut-offs receive finer polishing. Optional surface treatments like hard anodizing (Type III) are applied to significantly enhance wear resistance against abrasive concrete. Rigorous first-article inspection validates all critical dimensions against the original CAD model using CMM and optical comparators before final assembly, pressure testing, and shipment. This integrated approach guarantees molds deliver consistent, high-quality concrete parts from the first pour.

Key Aluminum Mold Specifications

| Parameter | Standard Value | Notes |

| :—————– | :——————- | :————————————- |

| Base Material | 6061-T6 Aluminum | Aerospace grade, optimal strength/machinability |

| Typical Hardness | 95 HB | After T6 heat treatment |

| Standard Tolerance | ±0.05 mm (±0.002″) | Critical features tighter per request |

| Surface Finish (Cavity) | 3.2 μm Ra (125 μin) | As-machined; polished areas finer |

| Max Mold Size (Typical) | 600 x 600 x 400 mm | Custom larger sizes possible |

This end-to-end workflow, underpinned by AI efficiency and deep manufacturing expertise, provides clients with a strategic advantage: rapid validation, reduced time-to-market for concrete products, and molds engineered for reliable, high-volume production.

Start Your Project

Start Your Project with High-Precision Aluminum Concrete Molds from Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, we specialize in delivering rapid tooling and injection molding solutions tailored for architectural precast, infrastructure development, and custom construction applications. Our advanced manufacturing capabilities enable us to produce high-performance aluminum concrete molds with exceptional accuracy, durability, and turnaround speed. Whether you’re developing prototypes for façade elements, structural components, or decorative concrete products, our engineering team ensures your design transitions seamlessly from concept to production.

Aluminum concrete molds offer a superior alternative to traditional steel or wood tooling, combining lightweight handling with excellent thermal conductivity and corrosion resistance. These properties translate into faster demolding cycles, improved surface finishes, and extended mold life—critical advantages in today’s competitive construction and architectural markets. At Honyo, we utilize CNC-machined 6061-T6 and 7075-T6 aluminum alloys, selected for their dimensional stability and wear resistance under repeated casting conditions.

Our rapid tooling process begins with your 3D CAD model. From there, our engineers conduct a comprehensive design for manufacturing (DFM) review to optimize parting lines, draft angles, venting, and ejector systems. This proactive approach minimizes defects, reduces rework, and accelerates time-to-market. We support both low-volume pilot runs and medium-volume production, making our services ideal for architects, precast manufacturers, and civil engineering firms requiring agile, cost-effective tooling solutions.

We understand that every project has unique dimensional, textural, and performance requirements. That’s why we offer customizable mold configurations, including multi-cavity layouts, integrated alignment pins, and surface treatments such as anodizing or textured finishes to match architectural specifications. Our quality control protocols include first-article inspection reports (FAIR), geometric dimensioning and tolerancing (GD&T) verification, and repeatable metrology using CMM and laser scanning.

Below is an overview of our standard aluminum mold capabilities:

| Specification | Detail |

|————-|——–|

| Material Options | 6061-T6, 7075-T6 Aluminum |

| Tolerance | ±0.05 mm (typical) |

| Surface Finish | As-machined, bead-blasted, anodized, or custom texture |

| Maximum Mold Size | 1200 x 800 x 600 mm |

| Lead Time | 7–15 days (based on complexity) |

| Applications | Precast concrete panels, cladding, columns, stairs, landscaping elements |

| Supported File Formats | STEP, IGES, X_T, SLDPRT, DWG, DXF |

Starting your project with Honyo is simple. Share your design files and technical requirements, and our team will provide a detailed quote, DFM feedback, and production timeline within 24 hours. We support global clients with end-to-end project management, from initial prototyping to final mold delivery with shipping documentation.

For immediate assistance, contact Susan Leo at info@hy-proto.com. Let Shenzhen Honyo Prototype be your trusted partner in turning innovative concrete designs into high-precision, production-ready molds.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.