Contents

Manufacturing Insight: 4 Axis Machining

Manufacturing Insight: 4 Axis Machining

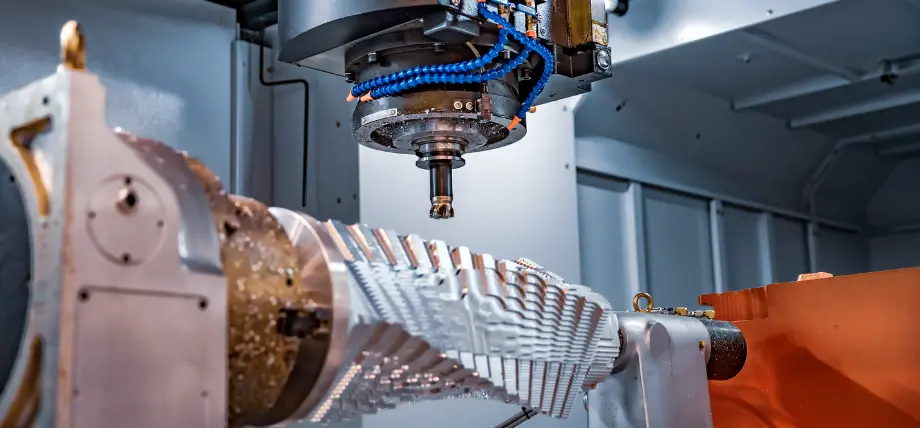

Four-axis CNC machining represents a significant advancement over standard three-axis capabilities, enabling the production of complex geometries with enhanced precision and efficiency. This technology integrates a rotary axis (typically the A-axis, rotating around the X-axis) into the conventional X, Y, and Z linear axes. The addition of this fourth degree of freedom allows the workpiece to be rotated incrementally or continuously during machining. This capability is essential for manufacturing parts requiring features on multiple faces or intricate contours that cannot be achieved in a single setup with three-axis systems. By eliminating the need for manual repositioning, 4-axis machining drastically reduces human error, minimizes cumulative tolerances, and significantly shortens lead times for complex components. It is particularly advantageous for industries demanding high-precision rotational parts, such as aerospace turbine blades, medical instrument housings, and custom automotive fixtures.

The primary operational benefit of 4-axis machining lies in its ability to complete parts requiring multi-sided features within a single machine cycle. This single-setup approach ensures superior dimensional consistency across all machined surfaces, which is critical for assemblies with tight interfacing tolerances. Additionally, the continuous rotary motion facilitates smoother toolpaths for complex organic shapes and helical features, resulting in improved surface finishes and extended tool life compared to segmented 3-axis operations. This process is highly effective for medium-volume production runs of complex prototypes and low-volume end-use parts where the cost of dedicated multi-axis fixtures would be prohibitive.

At Shenzhen Honyo Prototype, we leverage state-of-the-art 4-axis CNC machining centers to deliver exceptional prototype and low-volume production capabilities. Our facility utilizes high-rigidity machines with integrated hydraulic or precision encoder-driven rotary tables, ensuring micron-level repeatability for demanding applications. We specialize in machining a wide range of engineering materials including aluminum alloys, stainless steels, titanium, engineering plastics, and composites. Our process is supported by rigorous in-process inspection protocols using calibrated CMMs and probing systems to maintain strict adherence to geometric dimensioning and tolerancing (GD&T) requirements. The following table outlines our core 4-axis machining specifications:

| Parameter | Capability |

|————————|————————————-|

| Maximum Work Envelope | Ø250mm x 200mm (Diameter x Height) |

| Positioning Accuracy | ±0.005mm |

| Repeatability | ±0.003mm |

| Spindle Speed Range | 8,000 – 24,000 RPM |

| Typical Tolerance | ±0.025mm (standard) |

| Surface Finish (Ra) | 0.8µm – 3.2µm (as machined) |

| Supported File Formats | STEP, IGES, X_T, Parasolid, DWG |

Honyo Prototype excels in transforming complex 3D CAD models into high-integrity functional prototypes and bridge production parts using 4-axis technology. Our engineering team collaborates closely with clients during the Design for Manufacturability (DFM) phase to optimize part geometry for efficient 4-axis machining, reducing costs and accelerating time-to-market. This capability is integral to our value proposition for clients requiring rapid iteration of components with rotational symmetry or multi-faceted features, ensuring technical feasibility without compromising on precision or material integrity. Partner with Honyo to leverage advanced 4-axis machining for your most challenging prototyping and low-volume production needs.

Technical Capabilities

4-Axis CNC Machining Capabilities at Shenzhen Honyo Prototype

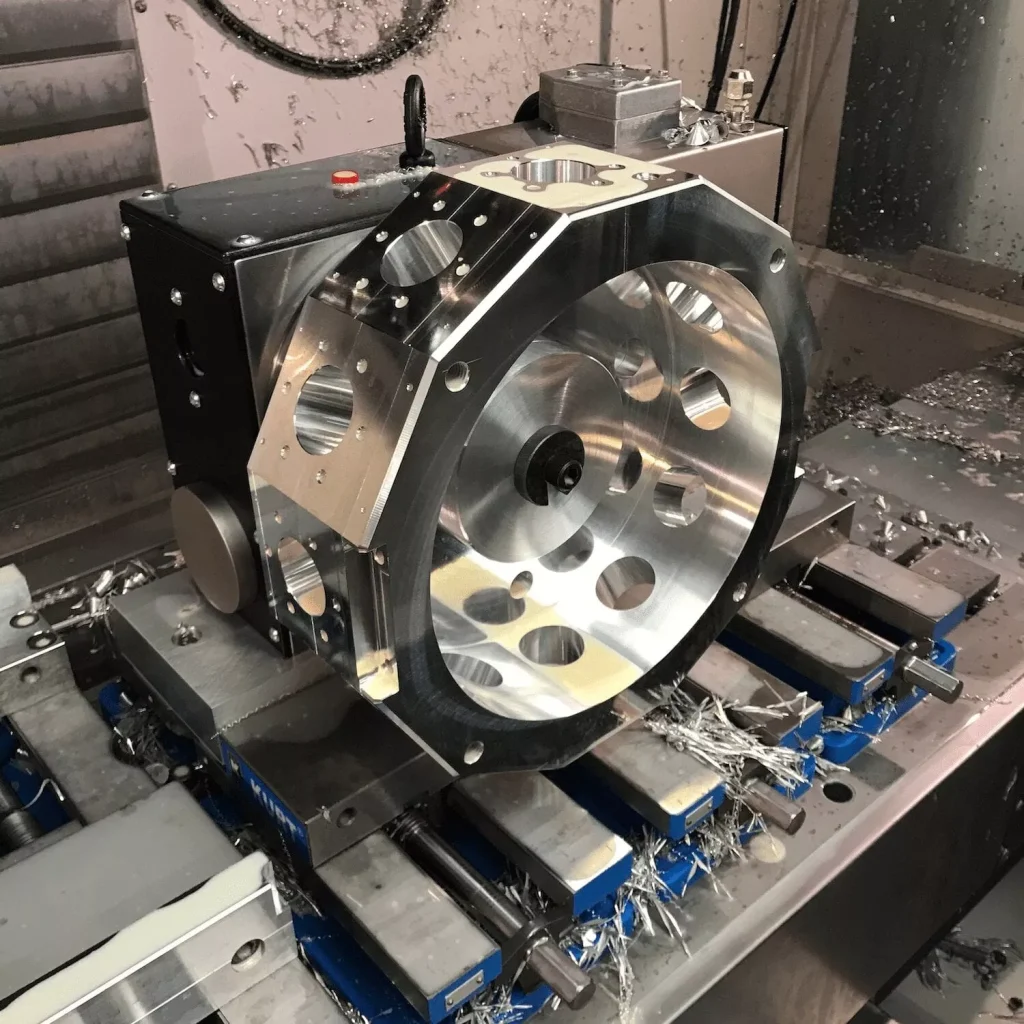

At Shenzhen Honyo Prototype, our 4-axis CNC machining services deliver high-precision components for industries requiring complex geometries and tight tolerances. Leveraging advanced 3-, 4-, and 5-axis milling platforms alongside precision turning capabilities, we support rapid prototyping and low-to-mid volume production with exceptional repeatability and surface finish. Our 4-axis machining centers integrate a rotary fourth axis (A-axis) that enables automatic indexing and continuous contouring, allowing for multi-sided machining without manual repositioning. This significantly improves accuracy, reduces setup time, and enhances feature alignment on complex parts.

Our machining fleet supports a broad range of materials, including aluminum alloys (e.g., 6061, 7075), stainless steels (303, 304, 316), titanium (Grade 5), brass, copper, and engineering plastics such as PEEK, Delrin, and nylon. Each material is processed using optimized toolpaths, cutting parameters, and fixturing strategies to maintain dimensional stability and surface integrity. Our in-house metrology lab, equipped with CMMs, optical comparators, and digital micrometers, ensures every component meets specified tolerances prior to shipment.

We specialize in tight-tolerance machining, routinely holding ±0.005 mm (±0.0002″) on critical dimensions. Our 4-axis systems support simultaneous rotary milling operations, enabling helical interpolation, complex slotting, and undercuts that are unachievable with conventional 3-axis setups. This makes our services ideal for aerospace components, medical devices, automotive actuators, and industrial tooling where angular features and precision alignment are critical.

In addition to milling, our capabilities include precision CNC turning with live tooling, allowing for mill-turn operations that combine rotational and linear cutting in a single setup. This integrated approach minimizes handling errors and accelerates time-to-part for complex cylindrical components with radial or off-axis features.

All programming is performed using industry-leading CAM software (Siemens NX, Mastercam, and Fusion 360), ensuring efficient tool engagement, collision avoidance, and optimal surface finish. Our engineering team conducts a full design for manufacturability (DFM) review on every project to identify opportunities for cost reduction, lead time improvement, and performance optimization.

Below is an overview of our standard machining tolerances and supported materials:

| Feature | Typical Tolerance |

|——–|——————-|

| Linear Dimensions | ±0.005 mm (±0.0002″) |

| Hole Diameter | ±0.01 mm (±0.0004″) |

| Positional Tolerance | ±0.01 mm (±0.0004″) |

| Angular Tolerance | ±0.1° |

| Surface Roughness (Ra) | 0.8 – 3.2 μm (32 – 125 μin) |

| Material Category | Examples |

|——————|———-|

| Aluminum Alloys | 6061, 7075, 2024, 5052 |

| Stainless Steel | 303, 304, 316, 17-4 PH |

| Carbon & Alloy Steel | 1018, 4140, 4340 |

| Titanium | Grade 2, Grade 5 (Ti-6Al-4V) |

| Brass & Copper | C110, C260, C101 |

| Engineering Plastics | PEEK, Delrin, Nylon, PTFE, ABS |

With a focus on precision, speed, and technical expertise, Shenzhen Honyo Prototype provides reliable 4-axis machining solutions for demanding applications across high-tech industries.

From CAD to Part: The Process

4-Axis Machining Production Workflow: From CAD to Precision Part

At Shenzhen Honyo Prototype, our 4-axis CNC machining workflow is engineered for speed and precision in prototype and low-volume production. This integrated process minimizes iterations and ensures manufacturability from the initial design concept through to the finished component. The core sequence leverages automation and expert engineering analysis to deliver complex geometries efficiently.

The workflow commences with the AI-Powered Quoting System. Upon receiving a CAD model (STEP, IGES, or native formats), our proprietary AI engine performs an instant preliminary assessment. It analyzes geometric complexity, identifies potential 4-axis specific features like off-center holes or contoured surfaces requiring rotation, estimates machine time based on toolpaths, and flags obvious manufacturability concerns. This generates a highly accurate initial quote within hours, not days, providing immediate cost and lead time visibility. Crucially, the AI isolates elements demanding deeper human expert review, streamlining the handoff to our engineering team.

This transitions directly into the Critical DFM (Design for Manufacturability) Analysis. Our senior manufacturing engineers conduct a rigorous review, focusing intensely on 4-axis specific challenges. We scrutinize rotational axis requirements: verifying clear rotation paths to avoid collisions, assessing the feasibility of fixturing for secure part holding during indexing or continuous rotation, and evaluating whether complex undercuts truly necessitate 4-axis movement or could be simplified. We provide actionable feedback on optimizing wall thicknesses, radii for tool access, and datum strategies to leverage the rotary axis effectively. This phase ensures the design is not just possible, but optimal for 4-axis production, preventing costly delays later. Client collaboration at this stage is key to refining the design for the fastest, highest-quality outcome.

Production Execution begins only after DFM sign-off. Parts are meticulously fixtured using precision vices or custom soft jaws designed for rotational stability. Our Haas UMC and DMG MORI 4-axis centers execute the verified CNC program. The process leverages the B-axis (rotary table) for either indexed positioning (multiple sides machined in a single setup) or continuous 4-axis contouring for complex organic shapes. In-process inspections using Renishaw probes verify critical dimensions mid-run, while final CMM inspection against the original CAD model guarantees geometric accuracy and surface finish compliance. Strict process control parameters are maintained throughout.

Honyo Prototype’s integrated approach – AI speed in quoting, expert DFM focused on rotational machining realities, and precision-controlled production – ensures your complex 4-axis parts are manufactured right the first time, accelerating your development cycle.

Key 4-Axis Machining Capabilities at Honyo Prototype

| Parameter | Specification Range | Notes |

| :—————– | :———————— | :————————————- |

| Max Work Envelope | Ø 300 mm x 300 mm H | Diameter x Height on rotary table |

| Rotational Accuracy| ± 0.005° | Positional accuracy per index |

| Surface Finish | Ra 0.8 µm – 3.2 µm | Achievable standard range |

| Typical Lead Time | 3-7 Working Days | Post-DFM approval, simple to complex |

| Material Range | Metals, Plastics, Composites | Aluminum, Steel, Titanium, PEEK, etc. |

Start Your Project

Start Your 4-Axis Machining Project with Honyo Prototype

At Shenzhen Honyo Prototype, we specialize in high-precision 4-axis CNC machining for rapid prototyping and low-volume production. Whether you’re developing complex aerospace components, medical devices, or industrial tooling, our advanced 4-axis capabilities deliver superior accuracy, faster turnaround, and cost-effective manufacturing solutions. If you’re ready to bring your design to life with precision engineering and expert support, now is the time to start your project with us.

4-axis machining extends the capabilities of traditional 3-axis systems by incorporating rotational movement around the X-axis (A-axis), allowing parts to be machined from multiple angles without manual repositioning. This capability significantly improves machining efficiency, reduces setup time, and enhances geometric accuracy—especially for parts requiring features on multiple faces or complex contours. At Honyo Prototype, our 4-axis CNC centers are equipped with high-rigidity spindles, advanced tooling systems, and real-time monitoring to ensure consistent quality across all production runs.

We understand that every project has unique requirements. That’s why our engineering team works closely with clients from the initial design phase through final production. We offer design for manufacturability (DFM) analysis, material selection guidance, and process optimization to ensure your part is not only producible but optimized for performance and cost. Our facility supports a wide range of engineering materials, including aluminum alloys, stainless steel, titanium, brass, and high-performance plastics such as PEEK and Delrin.

Our 4-axis machining services are ideal for complex geometries, impellers, housings, fixtures, and multi-faceted prototypes that demand tight tolerances and excellent surface finishes. With in-house CAD/CAM programming and experienced machinists, we maintain full control over the manufacturing process, ensuring repeatability and compliance with ISO 9001 standards.

To help you evaluate the capabilities of our 4-axis machining platform, here are key technical specifications:

| Parameter | Specification |

|———|—————|

| Axis Configuration | X, Y, Z, and A-axis (rotary around X) |

| Maximum Work Envelope | 800 mm × 500 mm × 400 mm |

| Rotary Table Diameter | 200 mm |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Supported Materials | Aluminum, Steel, Stainless Steel, Titanium, Brass, Plastics |

| Typical Tolerances | ±0.01 mm (standard), tighter upon request |

| Surface Finish | As low as Ra 0.8 μm (standard), customizable |

All parts undergo rigorous in-process and final inspection using coordinate measuring machines (CMM) and optical comparators to ensure compliance with your technical drawings and quality expectations.

Starting your 4-axis machining project with Honyo Prototype is simple. Just reach out to our manufacturing team, and we’ll guide you through the quoting and production process. For immediate assistance, contact Susan Leo at info@hy-proto.com. She will provide technical consultation, a detailed project assessment, and a competitive quote tailored to your requirements.

Let Honyo Prototype be your trusted partner in precision 4-axis CNC machining—where engineering excellence meets rapid, reliable production.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.