Contents

Manufacturing Insight: Laser Metal Cutting Service

Manufacturing Insight: Precision Laser Metal Cutting at Honyo Prototype

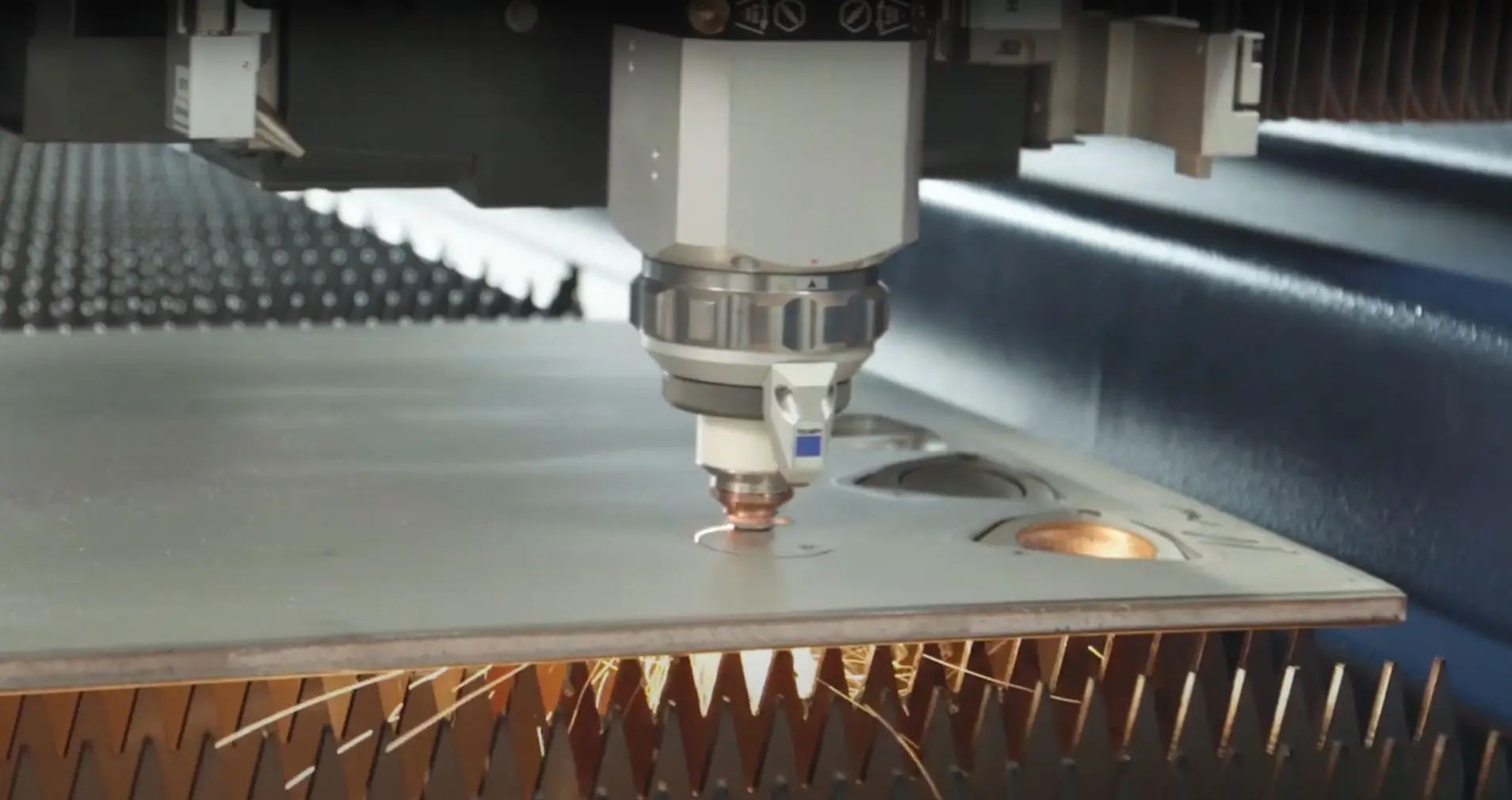

Laser metal cutting represents a cornerstone technology in modern sheet metal fabrication, particularly for rapid prototyping and low-to-medium volume production. This non-contact thermal process utilizes a highly focused, high-power laser beam to melt, burn, or vaporize material along a programmed path, delivering exceptional accuracy, clean edges, and design flexibility unattainable with traditional mechanical methods. The core principle involves directing coherent light energy, typically from a fiber or CO₂ laser source, through precision optics onto the workpiece surface. Assist gases, such as nitrogen for oxidation-free cuts on stainless steel and aluminum or oxygen for enhanced cutting speed on mild steel, are critical for ejecting molten material and influencing edge quality. This process excels at producing complex geometries, intricate contours, and tight internal features with minimal heat-affected zones, making it indispensable for demanding prototype development where form, fit, and function must be validated quickly and accurately.

Honyo Prototype leverages state-of-the-art fiber laser cutting systems to deliver superior results for our B2B manufacturing partners. Fiber lasers offer significant advantages for prototyping applications, including higher electrical efficiency, lower maintenance requirements, and superior beam quality for cutting thin to medium thickness materials compared to older CO₂ technology. Our commitment to precision engineering ensures consistent part quality across diverse project requirements. We maintain stringent process controls for dimensional accuracy and edge finish, directly impacting downstream operations like bending, welding, and assembly during the prototype validation phase. Understanding material behavior under the laser beam and optimizing parameters like power, speed, and gas pressure are essential for achieving the required edge characteristics – whether a smooth, burr-free finish for visible components or a clean cut optimized for subsequent finishing processes.

The following table outlines Honyo Prototype’s core laser cutting capabilities for common sheet metal prototyping materials:

| Material Type | Typical Thickness Range | Standard Tolerance (±) | Key Application Notes |

| :—————— | :———————- | :——————— | :—————————————- |

| Mild Steel (SPCC) | 0.5 mm – 12 mm | 0.05 mm | Optimal with oxygen assist for speed |

| Stainless Steel (SUS304) | 0.5 mm – 8 mm | 0.05 mm | Nitrogen assist for clean, oxide-free cut |

| Aluminum (AL5052) | 0.5 mm – 6 mm | 0.08 mm | Requires specific parameters for reflectivity |

| Brass & Copper | 0.5 mm – 3 mm | 0.10 mm | Challenging due to high thermal conductivity |

Our integrated manufacturing environment allows seamless transition from laser cutting to secondary operations like CNC bending, welding, and finishing, all under one roof. This vertical integration is crucial for prototype development, minimizing lead times, reducing handling errors, and ensuring design intent is maintained throughout the build. Honyo Prototype’s engineering team works collaboratively with clients during the design for manufacturability (DFM) stage, providing expert feedback on optimizing part geometry for laser cutting efficiency, minimizing waste, and ensuring the final prototype meets functional specifications. By combining advanced laser technology with deep process expertise and a focus on prototype-specific challenges, Honyo delivers the precision, speed, and reliability necessary to accelerate your product development cycles and bring innovative metal components to market faster.

Technical Capabilities

Shenzhen Honyo Prototype delivers high-precision laser metal cutting services as part of our comprehensive sheet metal fabrication capabilities. Our state-of-the-art fiber laser cutting systems enable clean, accurate, and efficient processing of a wide range of conductive and non-conductive metals. With integrated automation and advanced CNC controls, we support both low-volume prototyping and high-volume production runs, ensuring consistent quality and fast turnaround times.

Our laser cutting process utilizes high-intensity beams to melt, burn, or vaporize materials along programmed paths, producing intricate geometries with minimal heat distortion. This non-contact method ensures excellent edge quality, tight dimensional accuracy, and the ability to cut complex contours, slots, and holes that are difficult or impractical with traditional mechanical methods. Typical applications include chassis components, brackets, enclosures, heat sinks, and custom structural parts across industries such as industrial equipment, telecommunications, automotive, and consumer electronics.

Complementing our cutting capabilities, we offer precision bending using CNC press brakes equipped with a range of dies and tooling. This allows us to achieve accurate bend angles, consistent part flatness, and tight bend radii, even on complex multi-bend components. Our skilled technicians apply bend allowance compensation and perform in-process inspections to maintain geometric integrity throughout forming operations.

For assemblies requiring permanent joints, we provide TIG and MIG welding services on stainless steel, aluminum, and carbon steel. Our certified welders follow strict procedures to ensure strong, clean welds with minimal spatter and distortion. Post-weld treatments such as grinding, polishing, and deburring are available to meet cosmetic and functional requirements.

The following table outlines the key technical specifications, material compatibility, and achievable tolerances for our laser cutting, bending, and welding services:

| Process | Material Types | Thickness Range | Tolerance (Typical) | Max Work Envelope |

|——————-|————————————|———————|—————————-|—————————|

| Laser Cutting | Stainless Steel, Carbon Steel, Aluminum, Brass, Copper | 0.5 – 25 mm | ±0.1 mm (up to 3 mm), ±0.2 mm (3–6 mm), ±0.3 mm (>6 mm) | 1500 x 3000 mm |

| CNC Bending | Stainless Steel, Carbon Steel, Aluminum | 0.8 – 12 mm | ±0.2° angular, ±0.1 mm linear | 2000 mm (max bend length) |

| MIG/TIG Welding | Stainless Steel, Carbon Steel, Aluminum | 1.0 – 20 mm | ±0.5 mm (joint alignment) | 2500 x 1200 x 800 mm (assembled) |

All processes are supported by in-house engineering review, DFM analysis, and first-article inspection reports upon request. We maintain ISO 9001-compliant quality systems and utilize coordinate measuring machines (CMM) and laser scanners for dimensional verification. Whether you require simple flat blanks or fully fabricated welded assemblies, Shenzhen Honyo Prototype provides end-to-end manufacturing support with technical precision and responsive service.

From CAD to Part: The Process

Honyo Prototype Laser Metal Cutting: From CAD to Finished Part

Our laser metal cutting service delivers precision sheet metal components through a rigorously defined workflow, ensuring efficiency, quality, and rapid turnaround from initial inquiry to shipped part. This process eliminates ambiguity and leverages automation where beneficial while maintaining critical engineering oversight. The journey begins when a customer uploads their CAD file to our online platform. Our proprietary AI-powered quoting engine instantly analyzes the geometry, material specifications, quantity, and complexity. It calculates precise machine time, material utilization, and secondary operation requirements, generating a detailed, transparent quote within minutes. This immediate feedback allows for rapid project initiation and informed decision-making, significantly reducing the traditional sales cycle lag inherent in manual quoting processes.

Following quote acceptance and order confirmation, the CAD file enters the essential Design for Manufacturability (DFM) review phase. This is not an automated step; it is conducted by our experienced Senior Manufacturing Engineers. They meticulously examine the design for potential issues impacting cost, quality, or lead time. Key considerations include minimum feature sizes relative to material thickness, optimal part orientation for cutting efficiency, nesting density to maximize sheet utilization, potential heat distortion risks, and the feasibility of required tolerances. Crucially, our engineers proactively identify opportunities for design refinement. We provide specific, actionable feedback and suggestions to the customer, such as adjusting hole sizes, modifying edge clearances, or optimizing bend sequences, aimed at enhancing manufacturability without compromising function, often leading to significant cost and time savings.

Once DFM is approved, the validated CAD data drives the production phase. Our state-of-the-art fiber laser cutting systems, renowned for speed and precision on reflective and non-reflective metals, are programmed directly from the engineered files. Advanced nesting software maximizes material yield, minimizing waste. The cutting process parameters – laser power, assist gas type and pressure, cutting speed, and focal point position – are precisely selected based on the specific material grade, thickness, and desired edge quality. Strict in-process quality checks monitor critical dimensions, edge squareness, and surface finish against the original specifications throughout the run.

Key Laser Cutting Capabilities

| Parameter | Specification Range |

| :—————– | :—————————— |

| Material Thickness | Mild Steel: 0.5mm – 25mm |

| | Stainless Steel: 0.5mm – 20mm |

| | Aluminum: 0.5mm – 15mm |

| Positional Accuracy| ±0.1 mm |

| Edge Squareness | < 0.1 mm per 10mm thickness |

| Surface Roughness | Ra 3.2 µm (typical) |

| Kerf Width | 0.10mm – 0.25mm (material dep.) |

After cutting, parts undergo final inspection per agreed quality standards, including verification of critical features using CMM or optical comparators where specified. Deburring is performed as required by the application, and parts are carefully packaged for shipment. This integrated workflow – AI-driven quoting, expert DFM collaboration, and precision laser production – ensures Honyo Prototype consistently delivers high-quality, cost-effective sheet metal components with exceptional speed for prototyping and low-to-mid volume production.

Start Your Project

Start Your Next Precision Metal Project with Confidence

At Shenzhen Honyo Prototype, we specialize in delivering high-precision laser metal cutting services tailored to the exacting demands of modern sheet metal fabrication. Whether you’re developing a prototype, scaling up for low-volume production, or managing full-scale manufacturing runs, our advanced laser cutting capabilities ensure accuracy, repeatability, and fast turnaround times. Our state-of-the-art fiber and CO₂ laser systems support a broad range of metals, thicknesses, and geometries, allowing us to meet the diverse needs of industries including electronics, automotive, medical devices, and industrial equipment.

We understand that starting a new project involves more than just cutting metal—it requires collaboration, technical insight, and responsive support from a manufacturing partner you can trust. From the moment you submit your design, our engineering team reviews your files for manufacturability, material compatibility, and cost optimization. We provide expert feedback to help refine your design, reduce waste, and improve assembly efficiency—ensuring your parts are not only cut to precision but also ready for the next phase of production.

Our laser cutting process achieves tight tolerances down to ±0.1 mm, with clean edges that minimize secondary finishing. With automated material handling and nesting software, we maximize material utilization and reduce lead times, giving you faster time-to-market and lower per-part costs. Whether you’re working with stainless steel, aluminum, carbon steel, or specialty alloys, we maintain strict quality control throughout the process, backed by ISO 9001:2015 certification.

To help you plan your project effectively, here are our standard laser cutting capabilities:

| Material Type | Maximum Thickness | Typical Tolerance | Minimum Hole Diameter | Edge Quality Finish |

|———————|——————-|——————-|————————|———————-|

| Stainless Steel | 25 mm | ±0.1 mm | 0.8 × material thickness | Burr-free, clean cut |

| Aluminum | 20 mm | ±0.1 mm | 1.0 × material thickness | Smooth, oxide-free |

| Carbon Steel | 30 mm | ±0.15 mm | 0.9 × material thickness | Minimal dross |

| Galvanized Steel | 20 mm | ±0.15 mm | 1.0 × material thickness | Clean, consistent |

All projects begin with a detailed review of your 2D or 3D CAD files in DXF, DWG, or STEP format. We support batch processing and provide real-time updates throughout production. Our team is committed to transparency, technical excellence, and on-time delivery—every time.

Ready to bring your design to life? Contact Susan Leo, Customer Project Manager at Shenzhen Honyo Prototype, to discuss your laser cutting requirements. We offer free quotations, technical consultations, and rapid prototyping support to help you move quickly from concept to physical part.

Email Susan Leo at info@hy-proto.com today to start your project with a manufacturing partner built for precision, speed, and reliability.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.