Contents

Manufacturing Insight: Difference Between Alloy And Carbon Steel

Understanding Material Selection: Carbon Steel vs. Alloy Steel in Precision CNC Machining

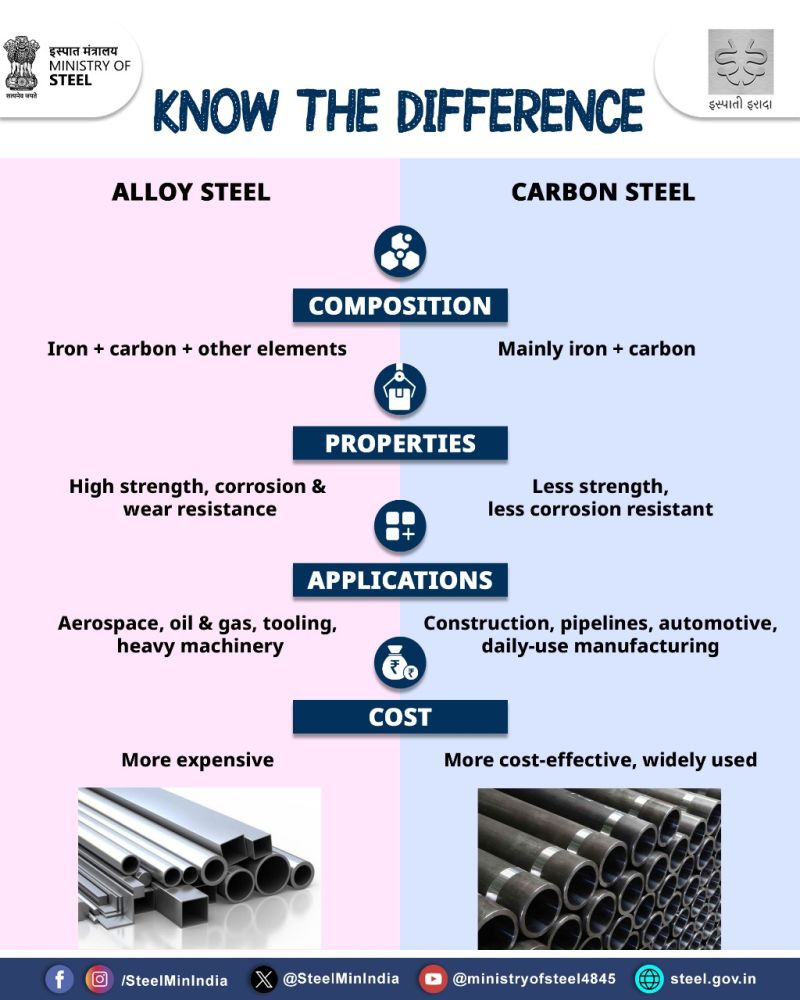

Selecting the appropriate steel grade is a fundamental decision impacting part performance, manufacturability, and cost in CNC machining projects. At Shenzhen Honyo Prototype, our engineering team prioritizes clear material understanding to deliver optimal solutions for clients across aerospace, automotive, and industrial equipment sectors. The distinction between carbon steel and alloy steel lies primarily in their elemental composition and resulting mechanical properties, directly influencing machining strategies and final part characteristics.

Carbon steel, as the name implies, relies predominantly on carbon content (typically ranging from 0.05% to 2.0%) as its chief alloying element to achieve desired strength and hardness. Grades like AISI 1045 offer good machinability, weldability, and relatively low cost, making them suitable for structural components, shafts, and general hardware where extreme strength or environmental resistance isn’t critical. However, their hardenability is limited; achieving significant core strength often requires larger cross-sections or compromises surface hardness. Alloy steels incorporate additional elements such as chromium, nickel, molybdenum, or vanadium, usually in total concentrations exceeding 1.0% but often less than 5.0%. These additions dramatically enhance properties like hardenability, tensile strength, toughness, and wear or corrosion resistance. Common grades like AISI 4140 (chromium-molybdenum) or 8620 (nickel-chromium-molybdenum) are essential for high-stress applications like gears, axles, and tooling where performance demands exceed carbon steel capabilities.

The machining implications of this compositional difference are significant for CNC operations. Alloy steels generally present greater challenges due to their higher strength and work-hardening tendencies, leading to increased tool wear, higher cutting forces, and the need for more rigid setups. Carbon steels typically generate more continuous chips and allow for higher machining speeds under comparable conditions. Material selection must therefore balance the end-use requirements against manufacturability constraints and cost objectives.

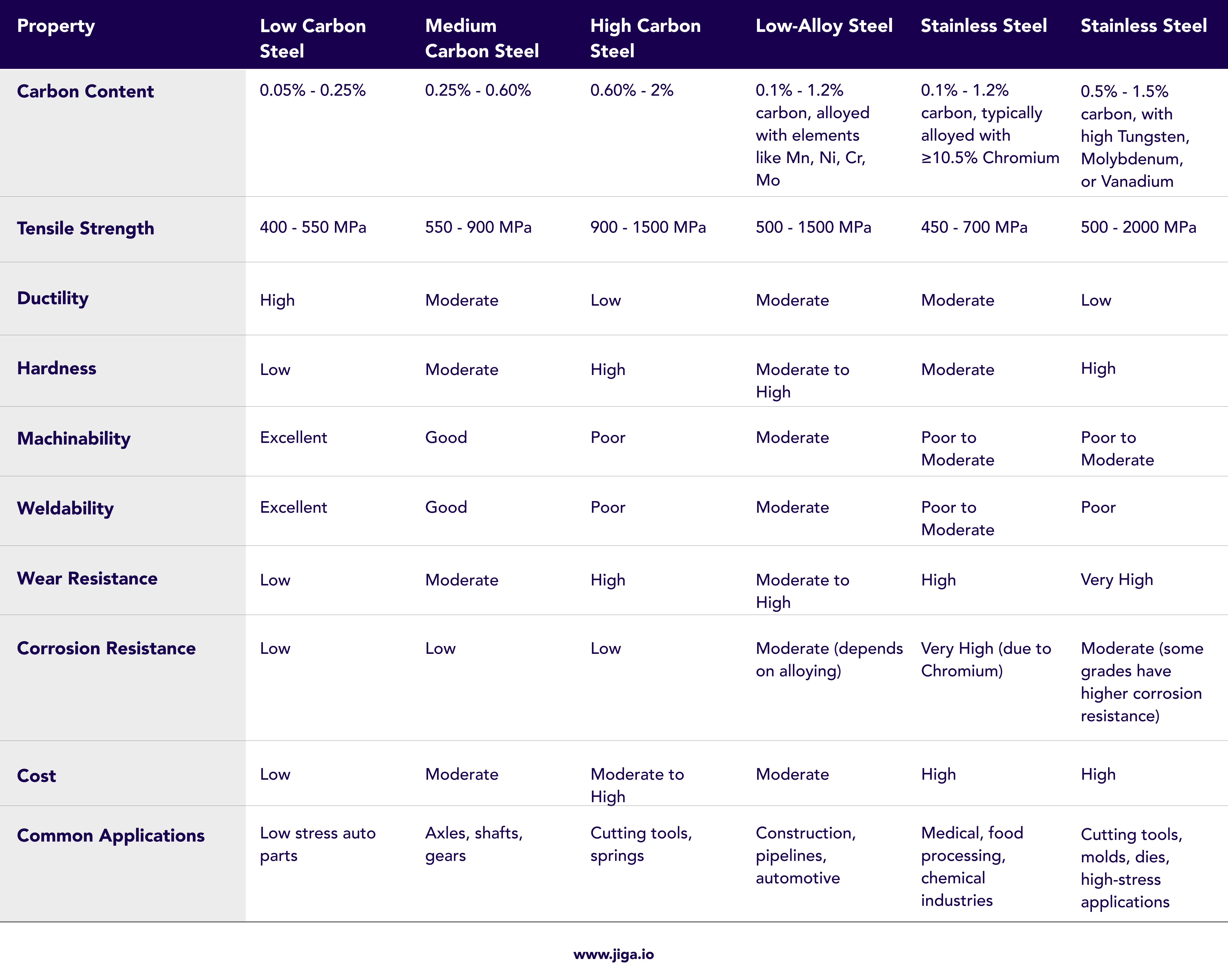

Key properties differentiating common grades are summarized below:

| Property | Carbon Steel (e.g., AISI 1045) | Alloy Steel (e.g., AISI 4140) |

| :——————— | :—————————– | :—————————- |

| Primary Alloying | Carbon (0.43-0.50%) | Cr (0.80-1.10%), Mo (0.15-0.25%) |

| Typical Hardness (HB) | 170-210 (Annealed) | 230-260 (Annealed) |

| Hardenability | Low to Moderate | High |

| Machinability Rating| Good (70-80% of B1112) | Fair (65-70% of B1112) |

| Common Applications| Bolts, Shafts, Frames | Gears, Axles, High-Stress Tooling |

At Honyo Prototype, our CNC machining expertise extends beyond operation to deep materials science understanding. We leverage advanced toolpath strategies, specialized coated carbide tooling libraries, and optimized coolant delivery systems specifically calibrated for the unique demands of both carbon and alloy steels. Our process engineers conduct thorough manufacturability reviews during the quoting phase, advising clients on the most suitable grade based on functional requirements, volume, and cost targets. We recognize that choosing between carbon and alloy steel isn’t merely a technical specification; it’s a strategic decision impacting lead time, tool life, and final part integrity. Partnering with Honyo ensures this critical selection is informed by practical machining experience and a commitment to delivering precision components that meet exacting performance standards. Consult our engineering team early in your design phase to leverage our material and process expertise for optimal outcomes.

Technical Capabilities

Understanding the Difference Between Alloy Steel and Carbon Steel in CNC Machining

In precision CNC machining, material selection plays a critical role in determining the performance, durability, and manufacturability of a component. At Shenzhen Honyo Prototype, we specialize in high-accuracy 3-axis, 4-axis, and 5-axis milling, as well as CNC turning for both alloy steel and carbon steel. Understanding the fundamental differences between these two material families is essential for optimizing design, machining strategy, and end-use functionality.

Carbon steel is primarily composed of iron and carbon, with carbon content typically ranging from 0.05% to 2.0%. It is categorized into low, medium, and high-carbon variants, each offering a balance of strength, ductility, and machinability. Low-carbon steels (e.g., 1018, 1020) are highly formable and weldable, making them suitable for structural parts and prototypes requiring moderate strength. Medium-carbon steels (e.g., 1045) provide improved strength and wear resistance, often used in shafts and gears. High-carbon steels (e.g., 1095) offer high hardness but reduced ductility, requiring careful machining to avoid cracking.

Alloy steel, on the other hand, contains additional alloying elements such as chromium, nickel, molybdenum, or vanadium, which enhance mechanical properties like tensile strength, toughness, and resistance to wear and corrosion. Common examples include 4140 and 4340, which are widely used in aerospace, automotive, and tooling applications. These materials maintain strength at elevated temperatures and are often selected for high-stress environments. However, the increased hardness and work-hardening tendencies of alloy steels can pose challenges in machining, requiring optimized toolpaths, rigid setups, and appropriate tooling.

At Honyo Prototype, our CNC machining centers are equipped to handle both material types with tight tolerance control. Our 3-axis, 4-axis, and 5-axis milling capabilities allow for complex geometries and undercuts, while our CNC turning ensures precise cylindrical features. We maintain tight tolerances down to ±0.005 mm for critical dimensions, surface finishes as fine as Ra 0.8 µm, and strict adherence to GD&T specifications.

Below is a comparison of typical machining tolerances and material properties for common carbon and alloy steels processed in our facility:

| Material | Type | Typical Applications | Machining Tolerance (± mm) | Surface Finish (Ra µm) | Hardness (HRC) | Recommended Process |

|——————|————–|—————————-|—————————-|————————-|—————-|—————————–|

| 1018 | Low-Carbon | Brackets, Shafts | 0.01 | 1.6–3.2 | 12–15 | 3/4-Axis Milling, Turning |

| 1045 | Medium-Carbon| Gears, Axles | 0.008 | 1.6 | 20–25 | 4-Axis Milling, Turning |

| 1095 | High-Carbon | Springs, Cutting Tools | 0.005 | 0.8–1.6 | 35–45 | 3-Axis Milling, Grinding |

| 4140 | Alloy | Tooling, High-Stress Parts | 0.005 | 0.8 | 28–32 | 5-Axis Milling, Turning |

| 4340 | Alloy | Aerospace Components | 0.005 | 0.8 | 30–36 | 5-Axis Milling, Precision Turning |

Our technical team works closely with clients to select the optimal material and machining approach, ensuring dimensional accuracy, repeatability, and performance under operational conditions. Whether prototyping or producing low-volume batches, Honyo Prototype delivers precision-engineered steel components with consistent quality and rapid turnaround.

From CAD to Part: The Process

From CAD to Part: CNC Machining Workflow for Steel Components at Honyo Prototype

Selecting the appropriate steel grade—carbon steel versus alloy steel—is a critical early decision impacting the entire CNC machining workflow at Shenzhen Honyo Prototype. This choice directly influences manufacturability, cost, lead time, and final part performance. Our streamlined process ensures optimal execution from initial inquiry to finished component, specifically tailored to the material’s properties.

The workflow initiates with the AI-Powered Quoting System. Clients submit CAD files (STEP, IGES, or native formats) specifying the required steel grade. Our AI engine instantly analyzes geometric complexity, tolerances, and material selection against historical production data. Crucially, it flags potential mismatches; for instance, suggesting 1045 carbon steel instead of 4140 alloy steel if high strength isn’t essential, recognizing 1045’s superior machinability and lower cost for simpler applications. This initial assessment provides a rapid, data-driven cost and timeline estimate, setting clear expectations.

Material specification then drives the core Design for Manufacturability (DFM) Review. Our senior manufacturing engineers conduct a rigorous analysis, focusing intensely on the implications of the chosen steel. Carbon steels like 1018 or 1045 generally offer excellent machinability with lower cutting forces, allowing for higher feed rates and reduced tool wear. Alloy steels such as 4140 or 4340, while offering superior strength and hardenability, often require slower machining parameters, specialized tooling, and crucially, planned heat treatment sequences after rough machining but before final finishing. The DFM report details specific process adjustments: recommending pre-hardened stock for alloy steels to minimize distortion, adjusting tolerances for post-heat treat growth, or suggesting alternative grades if the design doesn’t fully leverage the alloy’s properties. Material verification documentation is mandated at this stage.

Production Execution leverages the DFM insights for seamless machining. Carbon steel parts typically proceed directly from roughing to finishing operations on multi-axis CNC mills or lathes, maximizing efficiency. For alloy steel components, the process incorporates mandatory intermediate steps: rough machining, stress relief or annealing, final precision machining, and often client-specified heat treatment (quench & temper) followed by potential stress relieving and final surface finishing like grinding. Strict process controls monitor cutting parameters, coolant application, and in-process inspections to manage the higher stresses inherent in machining alloy steels and prevent dimensional instability.

Key material considerations during DFM and production are summarized below:

| Property | Typical Carbon Steel (e.g., 1045) | Typical Alloy Steel (e.g., 4140) | CNC Process Impact |

| :——————– | :——————————– | :——————————- | :—————————————— |

| Machinability Index | 70-80% | 50-65% | Higher feed/speed possible for carbon steel |

| Yield Strength (Annealed) | ~500 MPa | ~600 MPa | Higher cutting forces required for alloy |

| Heat Treatment Requirement | Often not required | Usually required for full spec | Adds steps, potential distortion management |

| Primary Cost Factor | Material cost + machining time | Material cost + HT + extended machining | Alloy parts generally higher cost & lead time |

Honyo Prototype’s integrated workflow—AI quoting, material-centric DFM, and adaptive production—ensures steel components are manufactured efficiently and to specification. By deeply understanding the practical differences between carbon and alloy steels within the CNC process, we minimize iterations, reduce total project cost, and deliver high-integrity prototypes and low-volume production parts precisely when clients need them. Material selection is not just a spec; it’s the foundation of our manufacturing strategy.

Start Your Project

Understanding the Difference Between Alloy and Carbon Steel in CNC Machining

When initiating a CNC machining project, one of the most critical decisions involves material selection. Among the most commonly used materials are alloy steel and carbon steel—two categories often confused due to their similar appearance and mechanical properties. However, understanding their differences is essential for achieving optimal performance, cost-efficiency, and longevity in your final component.

Carbon steel is primarily composed of iron and carbon, with carbon content typically ranging from 0.05% to 2.0%. It is classified into three subcategories: low, medium, and high-carbon steel, each offering a distinct balance of strength, ductility, and machinability. Low-carbon steel is highly formable and weldable, making it suitable for structural components and enclosures. High-carbon variants, while harder and stronger, are more challenging to machine and less ductile.

Alloy steel, on the other hand, contains additional alloying elements such as chromium, nickel, molybdenum, or vanadium. These additives enhance specific properties such as hardness, wear resistance, toughness, and corrosion resistance. For example, chromium improves oxidation resistance, while molybdenum increases strength at elevated temperatures. This makes alloy steel ideal for demanding applications in aerospace, automotive, and heavy machinery sectors where performance under stress is paramount.

One of the key distinctions lies in heat treatment response. Alloy steels generally exhibit superior hardenability compared to carbon steels, allowing for deeper and more uniform heat treatment. This results in components with consistent mechanical properties throughout the cross-section—critical for high-load applications.

From a CNC machining perspective, carbon steels are often easier to machine due to their lower hardness and predictable chip formation. However, alloy steels, while more challenging, offer greater design flexibility when enhanced mechanical properties are required. Tool wear, cutting speeds, and feed rates must be carefully optimized when machining alloy steels to maintain precision and surface finish.

Below is a comparative overview of key properties:

| Property | Carbon Steel (1045) | Alloy Steel (4140) |

|—————————|—————————|—————————-|

| Carbon Content | ~0.45% | ~0.40% |

| Alloying Elements | None significant | Cr, Mo |

| Tensile Strength (MPa) | 570 | 655 |

| Yield Strength (MPa) | 360 | 415 |

| Hardness (HB) | 170 | 200 |

| Machinability Rating | 72% | 65% |

| Common Applications | Shafts, gears, bolts | Axles, spindles, tooling |

Choosing between alloy and carbon steel ultimately depends on your application’s mechanical, environmental, and economic requirements. At Shenzhen Honyo Prototype, we specialize in precision CNC machining and material consultation to ensure your project meets exact performance standards.

Start your project with confidence. Contact Susan Leo at info@hy-proto.com for expert guidance on material selection and manufacturing optimization.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.