Contents

Manufacturing Insight: Sheet Metal Fabrication Process

Sheet Metal Fabrication: Precision Engineering for Prototype Excellence

Sheet metal fabrication remains a cornerstone process for producing robust, functional prototypes across aerospace, medical, and industrial electronics sectors. At Shenzhen Honyo Prototype, we leverage advanced digital manufacturing techniques to transform flat metal sheets into complex three-dimensional components with exceptional accuracy and repeatability. Our integrated workflow—encompassing laser cutting, precision bending, and finishing—ensures rapid iteration cycles without compromising on structural integrity or dimensional fidelity. This capability is critical for developing enclosures, brackets, chassis, and structural elements where thermal management, EMI shielding, and mechanical resilience are non-negotiable.

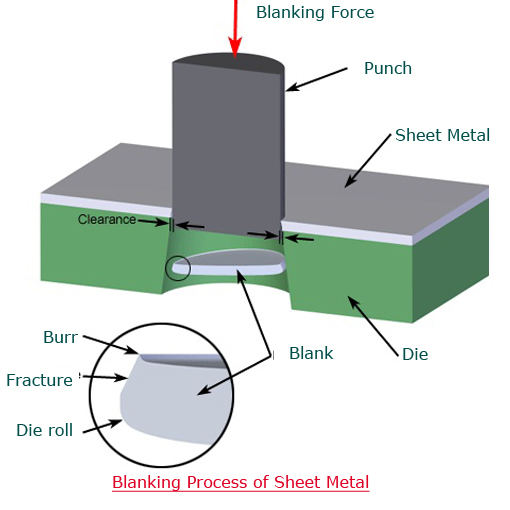

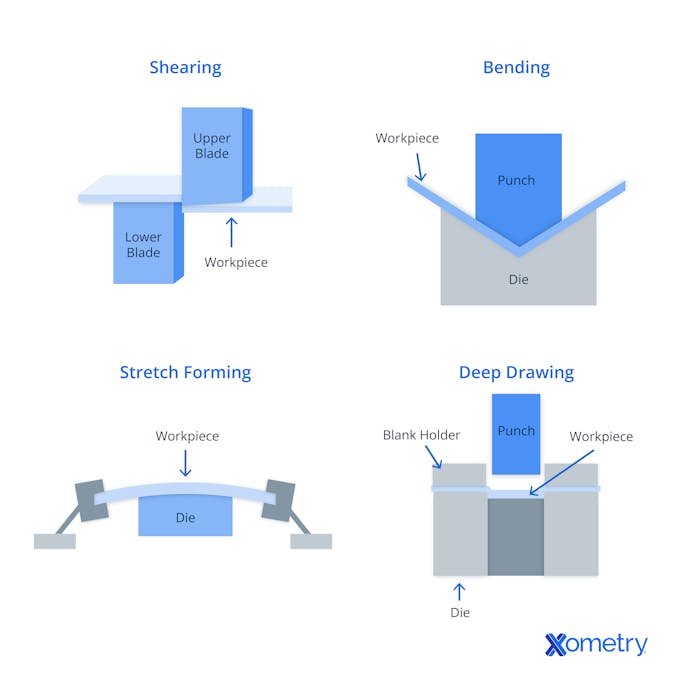

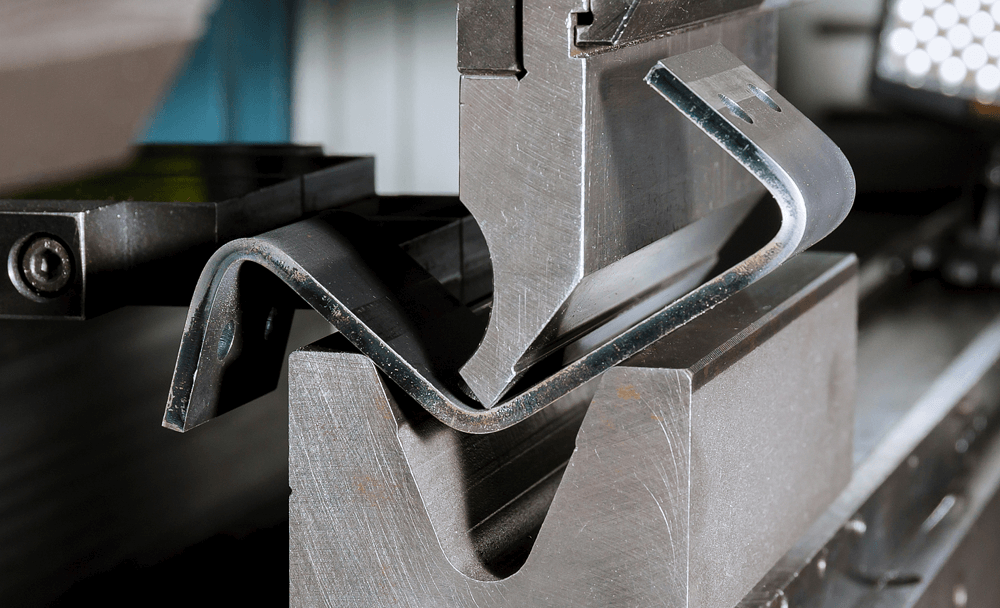

The process begins with high-definition fiber laser cutting, which achieves intricate geometries in materials ranging from 0.5mm to 6.0mm thickness with minimal heat distortion. Subsequent CNC press braking applies exact tonnage and angle control to meet tight angular tolerances, while secondary operations like tapping, welding, and surface finishing (powder coating, anodizing, or plating) are executed in-house to streamline lead times. Crucially, our engineers collaborate early in the design phase to optimize for manufacturability—recommending bend radii, hole placement, and material selection that prevent common pitfalls like stress cracking or tool interference. This proactive DFM (Design for Manufacturability) approach reduces costly revisions and accelerates time-to-test.

Honyo’s Shenzhen facility combines German-engineered machinery with ISO 9001-certified quality protocols to deliver prototypes that mirror end-production quality. We specialize in low-to-medium volume runs where agility and precision outweigh high-volume tooling costs, supporting materials from aluminum alloys and stainless steel to copper and galvanized carbon steel. Below are our core technical capabilities:

| Parameter | Specification Range | Tolerance Standard |

|——————–|—————————————–|————————–|

| Material Thickness | 0.5mm – 6.0mm | ±0.1mm (cutting) |

| Bend Angle | 0° – 180° | ±0.5° |

| Hole Diameter | ≥0.8mm (pierced), ≥1.0mm (punched) | ±0.05mm |

| Surface Finish | As-cut, Deburred, Powder Coated, Anodized | Ra ≤ 1.6μm (machined) |

| Max Part Size | 1500mm x 3000mm (laser bed) | Flatness ≤ 0.1mm/m |

Our competitive edge lies in seamless digital integration—from receiving 3D CAD files (STEP, IGES, DWG) to automated nesting software that minimizes material waste by 15–20%. Every component undergoes in-process CMM validation and first-article inspection, ensuring compliance with ASME Y14.5 geometric dimensioning standards. For clients navigating complex regulatory landscapes, we provide comprehensive documentation packages including material traceability certificates and process validation reports.

In an era where prototype fidelity directly impacts product launch success, Honyo delivers the speed, precision, and engineering partnership required to de-risk development. Partner with us to transform your sheet metal concepts into rigorously validated, production-intent prototypes—engineered for performance, delivered on schedule.

Technical Capabilities

Sheet Metal Fabrication Technical Capabilities

Shenzhen Honyo Prototype offers precision sheet metal fabrication services tailored for rapid prototyping and low-to-mid volume production. Our in-house capabilities encompass laser cutting, CNC bending, and welding, enabling us to deliver high-quality components with tight tolerances and consistent repeatability. We support a wide range of materials and thicknesses, ensuring compatibility with diverse engineering and design requirements across industries such as electronics, industrial equipment, and consumer products.

Our fiber laser cutting systems provide clean, burr-free cuts with minimal heat-affected zones, supporting both intricate geometries and high-speed processing. With a maximum cutting area of 1500 mm × 3000 mm and automated material handling, we ensure efficient throughput without compromising accuracy. CNC press brakes with tooling libraries allow for precise bending operations, supporting complex forming sequences and tight bend radii. All bending programs are verified using offline simulation software to ensure first-time-right results and reduce setup time.

For structural integrity and assembly, we utilize MIG and TIG welding techniques, with certified welders adhering to international quality standards. Post-weld operations such as grinding, deburring, and dimensional inspection ensure a finished product that meets both functional and aesthetic criteria. All fabricated parts undergo first-article inspection and final quality checks using calibrated measurement tools including CMMs and optical comparators.

The following table outlines our standard technical specifications and capabilities for key fabrication processes:

| Process | Material Types | Thickness Range | Tolerance (Typical) | Max Part Size | Notes |

|—————-|———————————-|———————-|—————————-|————————–|—————————————-|

| Laser Cutting | Cold Roll Steel (SPCC), Stainless Steel (SUS304, SUS316), Aluminum (AL5052, AL6061), Galvanized Steel, Copper | 0.5 – 4.0 mm | ±0.1 mm | 1500 × 3000 mm | Nitrogen/Oxygen assist; kerf compensation applied |

| CNC Bending | SPCC, SUS304, AL5052, AL6061 | 0.5 – 3.0 mm | ±0.2° bend angle, ±0.1 mm | 1200 × 1000 mm | Air bending method; tooling optimized per job |

| MIG Welding | Carbon Steel, Stainless Steel, Aluminum | 1.0 – 6.0 mm | ±0.5 mm (dimensional) | 1000 × 800 × 500 mm (assembled) | Argon shielding; spatter control; post-grind optional |

| TIG Welding | Stainless Steel, Aluminum | 0.8 – 4.0 mm | ±0.3 mm (dimensional) | 800 × 600 × 400 mm (assembled) | Precision welds; ideal for thin sheets and visible surfaces |

We maintain ISO 9001-compliant quality management practices throughout our fabrication workflow. Material certifications are available upon request, and we support customer-supplied drawings in STEP, DWG, DXF, and PDF formats. Design for manufacturability (DFM) feedback is provided during quotation to optimize cost, lead time, and performance. With advanced equipment and experienced technicians, Honyo Prototype ensures reliable, high-precision sheet metal solutions from prototype to production.

From CAD to Part: The Process

Sheet Metal Fabrication Production Process: From CAD to Delivered Part

At Shenzhen Honyo Prototype, our sheet metal fabrication workflow is engineered for precision, efficiency, and seamless client collaboration. We transform your digital CAD model into a high-quality physical component through a rigorously defined three-phase sequence: AI-Powered Quoting, Comprehensive Design for Manufacturability (DFM) Analysis, and Streamlined Production Execution. This integrated approach minimizes errors, optimizes cost, and ensures on-time delivery for prototypes and low-to-mid volume production runs.

The process initiates with our proprietary AI Quote system. Upon receiving your 3D CAD file (STEP, IGES, or native formats preferred) and technical requirements, our AI engine rapidly analyzes geometric complexity, material selection, feature density, and surface finish specifications. It cross-references this data against extensive internal databases of machine capabilities, material costs, and historical production metrics. This enables us to generate an exceptionally accurate preliminary quote and estimated lead time within hours, not days, providing immediate project feasibility insight. Crucially, the AI also flags potential high-risk features requiring immediate human review.

Following client approval of the quote, your project enters the mandatory DFM phase. Our senior manufacturing engineers conduct a thorough, collaborative review. We examine bend radii relative to material thickness, hole-to-edge and hole-to-bend spacing, tolerance stack-ups, tooling accessibility, and secondary operation sequencing. This is not a passive checkpoint; we actively engage with your design team to propose actionable optimizations. Solutions may include minor feature relocation, standardizing bend radii, or suggesting alternative fastening methods – all aimed at enhancing manufacturability without compromising functional intent. Formal DFM sign-off from both parties is required before material procurement begins, ensuring alignment and preventing costly revisions later.

With DFM complete, production commences under strict process control. Material is inspected against certified mill test reports. CNC punching or laser cutting forms the flat pattern, leveraging our Amada and Bystronic systems for intricate geometries. Precision press brakes, often utilizing CNC-controlled backgauges and coining techniques, execute bends to tight tolerances. Critical production parameters are meticulously maintained:

| Parameter | Standard Capability | Tight Tolerance Option |

|——————–|———————|————————|

| Material Thickness | 0.5mm – 6.0mm Steel | 0.3mm – 10.0mm (Al/Cu) |

| Cutting Tolerance | ±0.1mm | ±0.05mm |

| Bend Angle | ±1° | ±0.5° |

| Bend Radius | Material x 0.65 | As Specified (Min 0.8t)|

| Hole Position | ±0.1mm | ±0.05mm |

Secondary operations like tapping, welding (MIG/TIG), grinding, and finishing (powder coating, anodizing, plating) follow, each with documented work instructions and in-process inspections. Final dimensional validation against the original CAD model is performed using calibrated CMMs or optical comparators before packaging and shipment. This end-to-end workflow, driven by intelligent automation and deep manufacturing expertise, ensures your sheet metal parts meet exacting quality standards while optimizing time-to-market.

Start Your Project

Start Your Sheet Metal Fabrication Project with Confidence

When it comes to bringing precision sheet metal components from concept to reality, partnering with an experienced manufacturer is essential. At Shenzhen Honyo Prototype, we specialize in high-quality, low-volume and prototype sheet metal fabrication, delivering fast turnaround times without compromising on accuracy or craftsmanship. Whether you’re developing a new product, refining a prototype, or scaling up for pre-production runs, our team is equipped to support your project at every stage.

Our sheet metal fabrication process integrates advanced laser cutting, CNC punching, precision bending, and automated welding technologies, enabling us to produce complex geometries with tight tolerances. We work with a wide range of materials—including stainless steel, aluminum, galvanized steel, and copper—ensuring your parts meet both functional and environmental requirements. From simple enclosures to intricate brackets and chassis, we maintain strict quality control throughout production, adhering to ISO 9001 standards and conducting in-process inspections to guarantee consistency.

One of the key advantages of working with Honyo Prototype is our engineering-first approach. Our team collaborates directly with design and R&D teams to provide Design for Manufacturability (DFM) feedback early in the process. This proactive review helps identify potential issues related to material selection, bend allowances, hole placement, and assembly integration—reducing costly revisions and minimizing lead time.

We understand that speed and responsiveness are critical, especially during the prototyping phase. That’s why we offer rapid quoting, same-week manufacturing, and global shipping to keep your development timeline on track. Our facility in Shenzhen leverages China’s advanced manufacturing ecosystem while maintaining Western-style project management standards, ensuring clear communication and reliable delivery.

To get started, simply share your 2D drawings and 3D models with us. We accept common file formats such as DXF, DWG, STEP, and IGES. Our quoting team will review your design, perform a DFM analysis, and provide a detailed cost breakdown within 24 hours. Once approved, we can typically deliver your first-article parts in as little as 5–7 business days, depending on complexity.

Below is an overview of our standard sheet metal capabilities:

| Parameter | Specification |

|————————-|——————————————–|

| Material Thickness | 0.5 mm – 4.0 mm (up to 6.0 mm on request) |

| Max Blank Size | 1500 mm × 3000 mm |

| Tolerances | ±0.1 mm (bending), ±0.05 mm (cutting) |

| Common Materials | SUS304, SUS316, AL5052, AL6061, SGCC, SPCC |

| Finishing Options | Powder coating, anodizing, plating, passivation, brushing |

| Production Lead Time | 5–10 working days (including assembly) |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP available |

Ready to move forward? Contact Susan Leo today at info@hy-proto.com to submit your design files and receive a no-obligation quote. With technical expertise, responsive service, and a commitment to excellence, Shenzhen Honyo Prototype is your trusted partner for precision sheet metal fabrication.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.