Contents

Manufacturing Insight: Brother Cnc Machine

Manufacturing Insight: Brother CNC Technology at Honyo Prototype

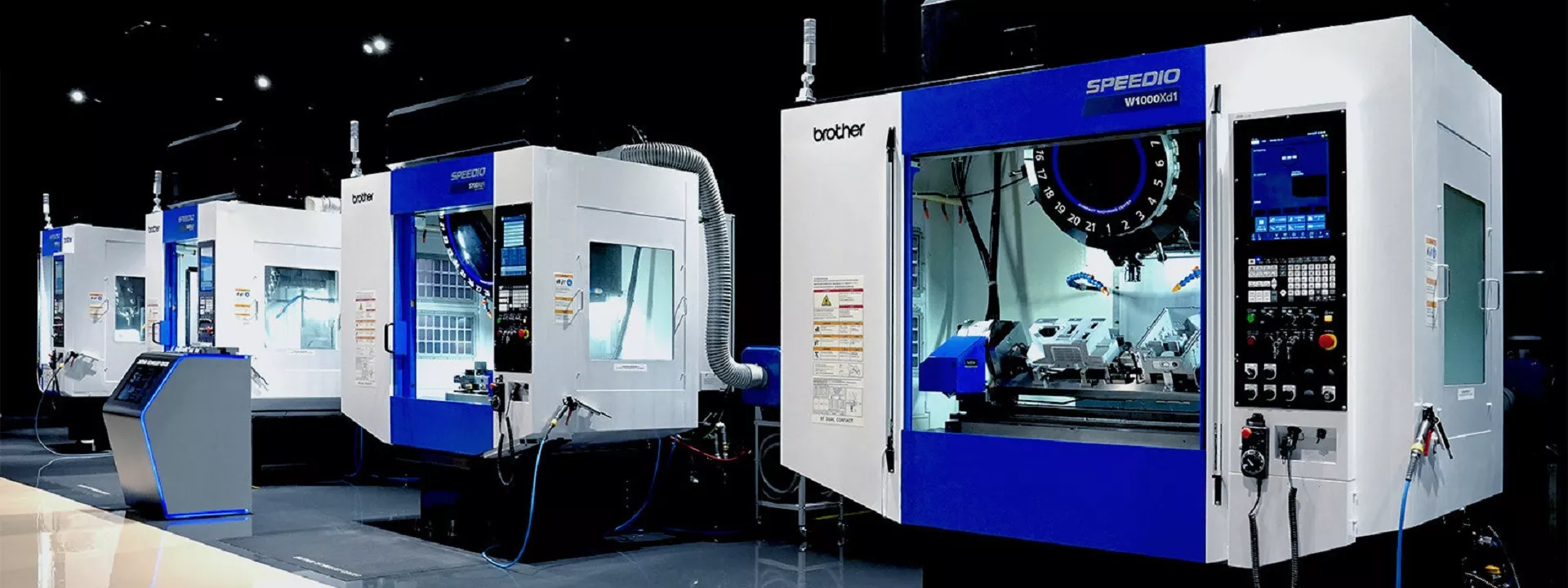

Shenzhen Honyo Prototype leverages Brother CNC machining centers as a cornerstone of our rapid prototyping and low-volume production ecosystem. Renowned for their exceptional speed, rigidity, and thermal stability, Brother’s vertical machining centers (particularly the V-Series) deliver the precision and reliability demanded by today’s complex engineering projects. These machines are engineered to minimize non-cutting time through rapid axis movements (up to 1.0 G acceleration) and swift tool-to-tool changes (as low as 0.9 seconds), directly translating to reduced lead times without compromising accuracy. For clients requiring tight-tolerance components in aerospace, medical, and robotics sectors, this technology ensures first-article success and consistent repeatability, even during extended production runs.

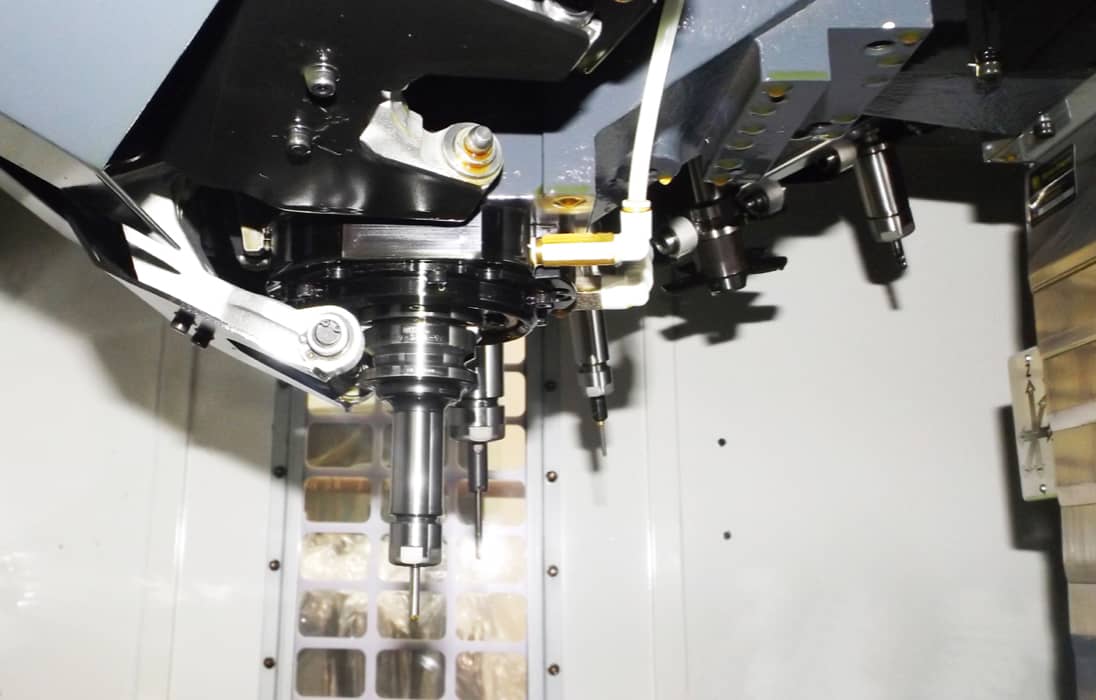

The core advantage lies in Brother’s integrated design philosophy. Unlike conventional CNC platforms, Brother machines utilize a monobloc cast-iron structure with optimized ribbing to dampen vibration, coupled with direct-coupled spindle motors eliminating belt-driven inaccuracies. This results in sub-5-micron positioning repeatability and superior surface finishes critical for functional prototypes. Our facility specifically configures these systems with advanced probing, high-pressure through-spindle coolant, and automated pallet changers to maximize unattended operation. Below are key technical specifications defining our production capability:

| Parameter | Specification | Impact on Prototyping |

|————————-|————————|—————————————-|

| Spindle Speed | 12,000 RPM | Enables high-speed machining of aluminum, plastics, and hardened steels |

| Positioning Accuracy | ±0.003 mm | Ensures dimensional integrity for micro-features and sealing surfaces |

| Rapid Traverse Rate | 60 m/min (X/Y/Z axes) | Reduces cycle times by 25% vs. standard machining centers |

| Tool Capacity | 30-60 tools (ATC) | Supports complex multi-operation parts without manual intervention |

| Control System | FANUC 31i-B5 | Provides intuitive programming and seamless CAD/CAM integration |

At Honyo Prototype, we extend Brother’s inherent capabilities through rigorous process optimization. Our engineering team implements dynamic fixture strategies and custom toolpath validation to exploit the machine’s full 5-axis contouring potential, producing geometries that challenge conventional 3-axis systems. Crucially, we integrate real-time thermal compensation algorithms to counteract ambient fluctuations—ensuring ±0.005 mm tolerances are maintained across 72-hour production cycles. This is non-negotiable for clients validating designs under real-world thermal loads.

Furthermore, our commitment to data-driven manufacturing means every Brother machine feeds operational metrics into our centralized quality management system. Tool wear, vibration analysis, and surface finish data are monitored per ISO 9001 protocols, allowing preemptive adjustments before deviations occur. This proactive approach minimizes scrap rates and guarantees that prototypes mirror final production intent. By combining Brother’s mechanical excellence with Honyo’s process discipline, we deliver parts ready for immediate functional testing or bridge production—accelerating your time-to-market while mitigating engineering risk. Partner with us to transform complex designs into high-fidelity physical assets with unmatched speed and fidelity.

Technical Capabilities

Shenzhen Honyo Prototype leverages advanced CNC technology to deliver high-precision machining solutions for demanding industries such as aerospace, medical, automotive, and industrial equipment. At the core of our production capabilities are our Brother CNC machining centers, renowned for their speed, rigidity, and repeatability. These machines enable us to perform high-efficiency 3-axis, 4-axis, and 5-axis milling operations, as well as precision turning, ensuring complex geometries and tight tolerances are consistently achieved.

The Brother CNC series utilized in our facility includes models from the S-Series and D-Series, equipped with high-speed spindles capable of up to 20,000 RPM. This allows for superior surface finishes and reduced cycle times, particularly when machining intricate contours and thin-wall features. Our 5-axis simultaneous machining capability enables single-setup processing of complex parts, minimizing human error and improving dimensional accuracy. With a compact footprint and high acceleration rates, Brother machines offer exceptional thermal stability and dynamic performance, critical for maintaining precision during extended production runs.

Our machining centers are integrated with Fanuc and Mitsubishi controls, providing robust programming flexibility and real-time monitoring. Automatic tool changers (ATC), tool length measurement systems, and probing capabilities ensure consistent setup validation and process control. For turning operations, we utilize Brother’s hybrid mill-turn centers, combining milling and turning functions in one platform to reduce lead times and improve part concentricity.

Tight tolerance machining is a core strength at Honyo Prototype. We maintain process capabilities to hold ±0.005 mm (±0.0002″) on critical dimensions, with standard tolerances adhering to ISO 2768-mK and customer-specified GD&T requirements. Our quality assurance system includes CMM inspection, optical comparators, and laser measurement tools to verify compliance across all production batches.

The following table outlines the typical tolerances and compatible materials processed on our Brother CNC machines:

| Operation Type | Standard Tolerance | Tight Tolerance Capability | Surface Finish (Ra) | Compatible Materials |

|——————–|——————–|—————————-|———————-|————————|

| 3-Axis Milling | ±0.01 mm | ±0.005 mm | 0.8 – 3.2 µm | Aluminum (6061, 7075), Steel (1018, 4140), Stainless Steel (303, 316), Titanium (Gr2, Gr5), Plastics (PEEK, Delrin, Nylon) |

| 4-Axis Milling | ±0.01 mm | ±0.005 mm | 0.8 – 3.2 µm | Aluminum, Steel, Stainless Steel, Titanium, Plastics |

| 5-Axis Milling | ±0.01 mm | ±0.005 mm | 0.4 – 1.6 µm | Aluminum, Stainless Steel, Titanium, Inconel, Plastics |

| CNC Turning | ±0.01 mm | ±0.005 mm | 0.8 – 3.2 µm | Aluminum, Steel, Stainless Steel, Brass, Plastics |

All materials are sourced to certified standards, and material test reports are available upon request. Our engineering team collaborates closely with clients during the design-for-manufacturability (DFM) phase to optimize part geometry, reduce costs, and ensure full compliance with functional and inspection requirements.

At Shenzhen Honyo Prototype, the integration of Brother CNC technology with rigorous quality systems ensures reliable, repeatable, and high-precision manufacturing for both prototypes and low-to-mid volume production runs.

From CAD to Part: The Process

CAD to Part Workflow: Brother CNC Machining at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, our Brother CNC machining process transforms digital designs into precision components through a rigorously defined workflow. This integrated sequence—AI Quote, DFM, and Production—ensures optimal efficiency, cost control, and part integrity from initial inquiry to final inspection. Our standardized approach minimizes delays while maximizing manufacturability for complex geometries and tight-tolerance requirements.

The workflow begins with AI-Powered Quoting. Upon receiving a CAD model (STEP, IGES, or native formats), our proprietary AI engine instantly analyzes geometric complexity, material requirements, and feature tolerances. This system cross-references historical machining data from our Brother Speedio-series CNC fleet to generate a preliminary quote within minutes. Key parameters assessed include toolpath density, setup frequency, and secondary operation needs. This rapid analysis provides clients with actionable cost and lead time estimates before formal order placement, reducing quotation cycles by up to 70% compared to manual methods.

Following quote acceptance, the Design for Manufacturability (DFM) Review commences. Our senior manufacturing engineers conduct a thorough technical assessment, focusing on optimizing the design for Brother CNC capabilities. We identify potential issues such as non-standard tool access, excessive wall thinness, or tolerance conflicts that could impact cycle time or part yield. Critical DFM adjustments include suggesting radius modifications for internal corners, consolidating features to minimize setups, and validating material suitability against spindle capabilities. Client collaboration is mandatory at this stage; unresolved DFM flags are escalated with specific engineering recommendations to prevent costly rework during production.

The Production Phase leverages Brother CNC machines’ high-speed, high-precision architecture. Approved CAD/CAM files (typically via Mastercam or Fusion 360) are converted into optimized G-code, incorporating machine-specific parameters like thermal displacement compensation and adaptive roughing strategies. All Brother centers undergo pre-machining calibration checks, including laser tool measurement and workpiece probing for datum alignment. Production runs prioritize unattended machining through automated pallet systems, with real-time monitoring of spindle load, vibration, and coolant pressure. Final parts undergo first-article inspection (FAI) per AS9102 standards, followed by batch verification using CMM and optical comparators before shipment.

Brother CNC machines form the backbone of this workflow, delivering the speed and accuracy required for prototyping and low-volume production. Key specifications include:

| Parameter | Specification | Impact on Production |

|——————–|———————————–|———————————–|

| Spindle Speed | 12,000–20,000 RPM | Enables high-MRR machining of aluminum, plastics, and light alloys |

| Positioning Accuracy | ±0.002 mm | Ensures repeatability for tight-tolerance features |

| Thermal Compensation | Real-time sensor network | Maintains dimensional stability during extended runs |

| Tool Magazine Size | 30–60 tools (model-dependent) | Reduces manual tool changes for complex parts |

This end-to-end process—driven by AI insights, engineering rigor, and Brother CNC performance—guarantees that every component meets Honyo Prototype’s standards for quality and on-time delivery. By embedding manufacturability checks early and exploiting machine capabilities fully, we consistently deliver prototypes and production parts with reduced lead times and zero non-conformities.

Start Your Project

Start Your Precision CNC Machining Project with Honyo Prototype

At Shenzhen Honyo Prototype, we specialize in high-accuracy CNC machining services tailored for prototyping and low-volume production. Our advanced manufacturing capabilities, powered by Brother CNC machines, ensure exceptional precision, speed, and consistency across a wide range of engineering-grade materials. Whether you’re developing complex aerospace components, medical devices, or industrial prototypes, our team is equipped to bring your designs to life with tight tolerances and superior surface finishes.

Brother CNC machines are renowned for their high-speed machining, rigid construction, and intelligent control systems. At Honyo Prototype, we leverage these state-of-the-art machines to deliver faster cycle times and improved part accuracy. Our CNC machining center supports 3-axis, 4-axis, and 5-axis milling operations, enabling us to handle intricate geometries and multi-faceted components in a single setup. This reduces lead time and minimizes human error, ensuring your project is completed efficiently and to the highest quality standards.

We work with a wide range of materials including aluminum alloys (6061, 7075), stainless steel (303, 304, 316), brass, copper, titanium, and engineering plastics such as PEEK, ABS, and polycarbonate. Our in-house finishing options include anodizing, powder coating, passivation, polishing, and bead blasting—allowing you to achieve both functional and aesthetic requirements.

Our engineering team performs comprehensive Design for Manufacturability (DFM) analysis on every project to identify potential issues early, optimize toolpaths, and reduce production costs. We also provide real-time project tracking and quality inspection reports, including first-article inspections and CMM reports upon request.

To get started, simply upload your 3D CAD file (STEP, IGES, or X_T format) and receive a detailed quote within 6 business hours. Our expert manufacturing engineers will review your design and recommend the most efficient machining strategy.

Technical Specifications at Honyo Prototype

| Parameter | Capability |

|—————————-|——————————————-|

| Machine Type | Brother CNC Vertical Machining Centers |

| Axis Configuration | 3-axis, 4-axis, 5-axis milling |

| Maximum Work Envelope | 1000 x 600 x 500 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Spindle Speed | Up to 20,000 RPM |

| Materials | Metals, Plastics, Composites |

| Lead Time | As fast as 3 days for simple prototypes |

| Tolerances | Typical: ±0.05 mm, Tight: ±0.01 mm |

| Finishing Options | Anodizing, Plating, Polishing, Painting |

Partner with Honyo Prototype for precision, reliability, and fast turnaround. Let our advanced Brother CNC machining capabilities accelerate your product development cycle.

Contact Susan Leo today at info@hy-proto.com to start your project. Include your CAD file and specific requirements, and our team will provide a detailed quote and production plan tailored to your needs. At Honyo Prototype, we’re committed to turning your ideas into high-performance parts—on time and to specification.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.