Contents

Manufacturing Insight: 5 Axis Cnc Machining Center

Manufacturing Insight: 5-Axis CNC Machining Center Capabilities at Shenzhen Honyo Prototype

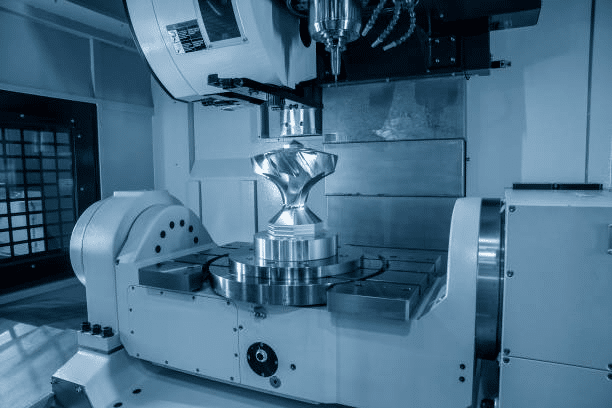

Shenzhen Honyo Prototype leverages advanced 5-axis CNC machining centers to deliver complex, high-precision components with exceptional efficiency. Unlike conventional 3-axis systems constrained to linear X, Y, and Z movements, true 5-axis machining integrates two rotational axes (typically A/B or A/C) enabling the cutting tool to approach the workpiece from virtually any angle in a single setup. This simultaneous multi-axis motion is fundamental to producing intricate geometries—such as organic aerospace contours, medical implant surfaces, and fluid turbine blades—that would otherwise require multiple fixtures, secondary operations, or specialized tooling. The elimination of repositioning not only drastically reduces lead times and cumulative error but also significantly enhances part accuracy and surface finish consistency by maintaining a constant optimal tool-to-part orientation.

At Honyo, our 5-axis machining capability is engineered for demanding prototyping and low-volume production. We utilize state-of-the-art vertical machining centers equipped with high-torque, high-RPM spindles and robust rotary tables designed for rigorous continuous contouring. Our engineering team possesses deep expertise in complex multi-axis programming (using Mastercam and Siemens NX CAM) and meticulous process validation, ensuring optimal toolpaths that maximize material removal rates while preventing collisions and maintaining micron-level tolerances. This proficiency extends across diverse materials, including aerospace-grade aluminum alloys (7075-T6, 2024), titanium (Ti-6Al-4V), stainless steel (17-4PH, 316L), engineered plastics (PEEK, Delrin), and exotic superalloys, where thermal management and tool wear mitigation are critical.

Honyo Prototype’s specific 5-axis machining center specifications ensure superior output for client projects. Key technical parameters are standardized across our primary production units:

| Parameter | Specification |

|————————-|———————————–|

| Travel (X/Y/Z) | 1,000 mm / 600 mm / 500 mm |

| Rotary Axis Range (B) | -110° to +20° |

| Spindle Speed | 24,000 RPM |

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.002 mm |

Rigorous in-process quality control is integral to our 5-axis workflow. We implement real-time probing for workpiece alignment verification and automated tool length/diameter compensation, ensuring dimensional integrity throughout extended machining cycles. Coordinate Measuring Machine (CMM) validation against CAD models is standard for critical features, guaranteeing compliance with stringent GD&T requirements common in automotive, medical, and aerospace sectors. This systematic approach minimizes scrap, accelerates time-to-part validation, and provides clients with reliable, repeatable results even for the most challenging geometries. Partnering with Honyo Prototype for 5-axis machining translates to faster iteration cycles, reduced assembly complexity through consolidated part designs, and access to precision manufacturing that meets the highest global industry standards. Our commitment to technological investment and engineering excellence ensures your complex components are produced with unmatched accuracy and efficiency.

Technical Capabilities

5-Axis CNC Machining Center – Technical Capabilities

Shenzhen Honyo Prototype utilizes advanced 5-axis CNC machining centers to deliver high-precision components for complex geometries across aerospace, medical, automotive, and industrial applications. Our multi-axis machining capability enables simultaneous movement across five axes (X, Y, Z, A, and B), allowing tool access from virtually any direction. This eliminates the need for multiple setups, improves part accuracy, and reduces lead times significantly compared to conventional 3-axis systems.

Our facility supports 3-axis, 4-axis, and full 5-axis simultaneous milling, as well as integrated milling-turning operations for hybrid components. The combination of high-rigidity machine beds, thermal compensation systems, and precision spindles ensures consistent performance under demanding production conditions. Each machine is equipped with automatic tool changers (ATC), high-resolution probing systems, and real-time tool wear monitoring to maintain dimensional integrity throughout production runs.

A critical strength of our 5-axis platform is the ability to achieve tight tolerances down to ±0.005 mm for critical features. This level of precision is maintained through continuous in-process inspection using on-machine touch probes and post-machining verification via coordinate measuring machines (CMM). Complex contours, organic shapes, and deep cavities are machined with superior surface finish and geometric accuracy, making our services ideal for prototyping and low-to-mid volume production.

We support a broad range of engineering materials, from aluminum and titanium alloys to stainless steels, plastics, and exotic superalloys. Material selection is optimized based on functional requirements, environmental exposure, and mechanical performance. All materials are sourced from certified suppliers and undergo incoming inspection to ensure consistency.

The following table outlines the standard technical specifications and achievable tolerances across common material groups:

| Parameter | Specification |

|———|—————|

| Axis Configuration | 3-axis, 4-axis (rotary indexing), 5-axis simultaneous |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Maximum Work Envelope | 1,200 × 800 × 600 mm (X×Y×Z) |

| Tool-to-Part Reach | Full 5-sided machining with tilt/swivel capability |

| Material Category | Typical Materials | Tolerance Range (Standard) | Tolerance Range (Tight) | Surface Finish (Ra) |

|——————|——————-|—————————-|————————–|———————|

| Aluminum Alloys | 6061, 7075, 2024 | ±0.01 mm | ±0.005 mm | 0.8 – 3.2 µm |

| Stainless Steel | 303, 304, 316, 17-4 PH | ±0.01 mm | ±0.008 mm | 1.6 – 3.2 µm |

| Titanium Alloys | Grade 2, Grade 5 (Ti-6Al-4V) | ±0.01 mm | ±0.008 mm | 1.6 – 3.2 µm |

| Engineering Plastics | PEEK, PEI (Ultem), PTFE, Nylon | ±0.02 mm | ±0.01 mm | 1.6 – 6.3 µm |

| Exotic Alloys | Inconel 718, Hastelloy C276 | ±0.015 mm | ±0.01 mm | 1.6 – 3.2 µm |

All machining programs are developed using industry-leading CAM software with simulation and collision detection, ensuring optimal toolpaths and process reliability. At Shenzhen Honyo Prototype, we combine cutting-edge 5-axis technology with rigorous quality control to deliver precision-machined components that meet the most demanding engineering specifications.

From CAD to Part: The Process

From CAD to Precision Part: The 5-Axis CNC Machining Workflow at Honyo Prototype

At Shenzhen Honyo Prototype, our 5-axis CNC machining centers transform complex CAD models into high-integrity prototypes and low-volume production parts through a rigorously defined workflow. This integrated process ensures dimensional accuracy, optimizes manufacturability, and minimizes lead times, delivering exceptional value for demanding B2B applications. The journey begins with seamless digital integration and concludes with certified part delivery.

The workflow initiates with our proprietary AI-powered quoting system. Upon receiving a customer’s 3D CAD file (STEP, IGES, Parasolid), the AI engine performs an instant geometric analysis. It assesses feature complexity, material requirements, fixture needs, and machine time estimation with high precision. This eliminates manual interpretation delays, providing customers with a highly accurate, data-driven quote within hours—not days—enabling faster project kickoff and procurement decisions. Critical parameters driving the quote include part volume, material type, and required surface finishes.

Following quote acceptance, the Design for Manufacturability (DFM) phase is paramount. Our senior manufacturing engineers conduct a comprehensive review, focusing specifically on 5-axis capabilities. We analyze undercuts, deep cavities, thin walls, and complex contours to identify potential machining challenges early. This is not merely a review; it’s a collaborative optimization step. We provide actionable feedback to refine the design for optimal tool access, reduced setup次数, improved surface finish, and enhanced structural integrity during machining. Key DFM considerations include minimizing non-productive toolpath motion, ensuring adequate tool clearance in all orientations, and verifying fixturing stability for the full 5-axis envelope. This proactive step significantly reduces the risk of costly rework or failed first articles.

Production commences only after DFM sign-off and final CAD approval. Our certified machinists import the validated model into Mastercam or Siemens NX, generating sophisticated 5-axis simultaneous or positional toolpaths. Rigorous virtual machine simulation verifies collision avoidance and optimal kinematics before any metal is cut. High-precision Renishaw probes verify workpiece alignment and tool geometry on-machine. Machining leverages the full capabilities of our DMG MORI and Hermle 5-axis centers, enabling single-setup completion of intricate geometries impossible with 3-axis methods. Strict in-process inspection using CMMs and optical comparators ensures adherence to tolerances throughout the run.

The following tables summarize critical machine capabilities and achievable tolerances for standard production:

| Machine Capability | Specification |

|——————————|—————————————|

| Typical Working Envelope | 800 x 600 x 500 mm (X, Y, Z) |

| Rotary Axis Range (B/C) | Continuous 360° (C), ±120° (B) |

| Maximum Spindle Speed | 24,000 RPM |

| Positioning Accuracy (ISO) | ≤ 0.005 mm |

| Repeatability (ISO) | ≤ 0.003 mm |

| Achievable Tolerance | Standard Capability |

|——————————|—————————————|

| Linear Dimensions | ±0.010 mm |

| Angular Features | ±0.05° |

| Profile of Surface | 0.025 mm |

| Surface Roughness (Ra) | 0.8 µm (Typical), down to 0.4 µm |

This structured workflow—from AI-driven quoting through collaborative DFM to precision 5-axis execution—ensures Honyo Prototype consistently delivers complex, high-accuracy parts with exceptional first-pass yield. By integrating advanced technology with deep manufacturing expertise, we transform challenging designs into reality, accelerating your time-to-market while guaranteeing quality.

Start Your Project

Start Your Next Precision Manufacturing Project with Honyo’s 5-Axis CNC Machining Center

At Shenzhen Honyo Prototype, we specialize in high-precision 5-axis CNC machining services designed to meet the most demanding engineering and production requirements. Whether you’re developing complex aerospace components, intricate medical devices, or high-performance automotive parts, our advanced machining capabilities ensure superior accuracy, surface finish, and geometric flexibility. Our state-of-the-art 5-axis CNC machining centers eliminate the need for multiple setups, reduce cycle times, and maintain tight tolerances down to ±0.005 mm, delivering parts faster and with greater consistency.

Our manufacturing process integrates cutting-edge CNC technology with expert engineering oversight. From prototype development to low- to mid-volume production runs, we support a wide range of materials—including aluminum, stainless steel, titanium, brass, and engineering plastics—ensuring your design intent is fully realized in the final product. With full 360° workpiece accessibility and continuous multi-axis motion, our 5-axis systems produce complex contours and undercuts that are unachievable with traditional 3-axis machines.

We understand that every project begins with a vision. That’s why our team works closely with engineers and product designers to review DFM (Design for Manufacturability) early in the development cycle. This collaborative approach minimizes delays, reduces material waste, and optimizes tool paths for cost-efficiency without sacrificing quality.

To ensure transparency and reliability, we maintain strict quality control protocols throughout production. All parts undergo comprehensive inspection using coordinate measuring machines (CMM) and advanced metrology tools to verify dimensional accuracy and compliance with technical specifications.

Below are key specifications of our 5-axis CNC machining capabilities:

| Parameter | Specification |

|——————————-|———————————————-|

| Machine Type | 5-Axis Simultaneous Machining Centers |

| Travel (X/Y/Z) | 1,000 mm × 600 mm × 500 mm (max) |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Supported Materials | Aluminum, Steel, Stainless Steel, Titanium, Brass, Plastics (e.g., PEEK, Delrin) |

| Maximum Workpiece Size | 950 mm × 550 mm × 450 mm |

| Lead Times | As fast as 5–7 days for prototypes |

| Finishing Options | As-machined, Bead Blast, Anodizing, Powder Coat, Passivation |

Starting your project with Honyo Prototype is simple. Share your CAD files, technical drawings, or 3D models with our engineering team for a fast and detailed quotation. We support STEP, IGES, STL, and DWG formats and provide DFM feedback within 12 hours of submission.

For immediate assistance, contact Susan Leo, our dedicated Project Coordinator, who will guide you through every step of the manufacturing process. With years of experience in precision CNC services, Susan ensures your project is handled with technical excellence and responsive communication.

Contact Susan Leo today at info@hy-proto.com to discuss your 5-axis machining needs. Let Honyo Prototype turn your designs into high-precision reality.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.