Contents

Manufacturing Insight: Steel 12L14 Properties

Manufacturing Insight: Steel 12L14 Properties for Precision CNC Machining

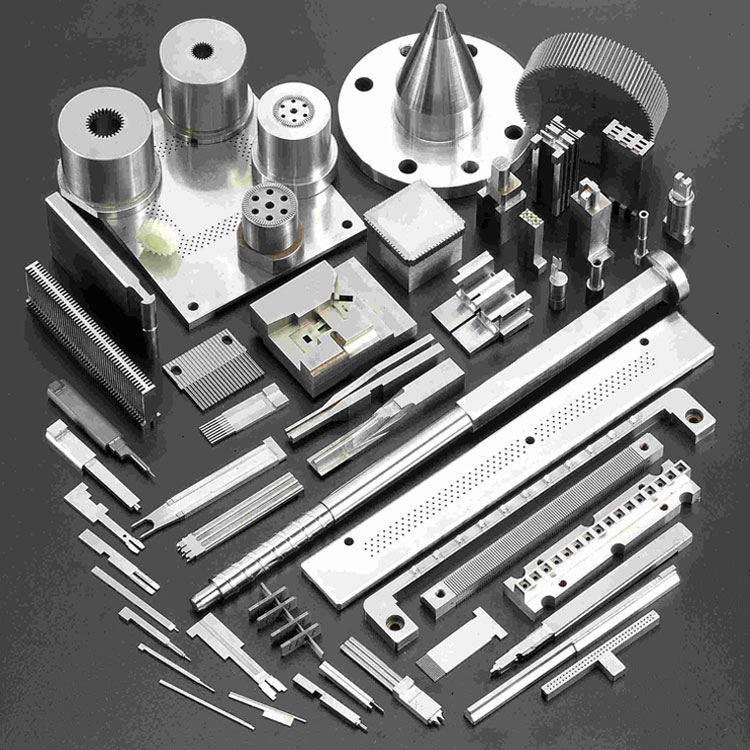

Steel 12L14 is a cornerstone material in high-volume CNC machining due to its exceptional free-machining characteristics, driven by deliberate lead and sulfur additions. At Honyo Prototype, we leverage this alloy’s unique properties to deliver complex, tight-tolerance components with remarkable efficiency and surface finish consistency. Its machinability rating of 180% (relative to AISI 1212) significantly reduces cycle times and tool wear, making it ideal for intricate geometries in automotive, hydraulic, and industrial hardware applications. However, its low weldability and limited fatigue strength necessitate precise process control—a capability embedded in our Shenzhen facility’s operational framework. Understanding 12L14’s behavior ensures optimal part performance and cost-effectiveness for prototyping and low-to-mid volume production.

The following table summarizes critical properties defining 12L14’s performance in CNC environments:

| Property Category | Specification Details |

|————————-|——————————————-|

| Composition (wt%) | C: 0.12–0.17, Mn: 0.85–1.15, Pb: 0.15–0.35, S: 0.26–0.35, P: ≤0.09 |

| Tensile Strength | 540–690 MPa (Ultimate), 415–550 MPa (Yield) |

| Hardness (Brinell) | 140–170 HB |

| Machinability Rating| 180% (AISI 1212 = 100%) |

These properties directly influence CNC strategy. The lead inclusions act as chip breakers, reducing built-up edge and enabling higher feed rates without sacrificing dimensional stability. Simultaneously, sulfur forms manganese sulfides that lubricate the cutting interface, minimizing heat generation. This allows Honyo to maintain tolerances down to ±0.005 mm while extending tool life by 25–40% compared to non-leaded steels. Crucially, the material’s low ductility requires optimized spindle speeds and rigid fixturing to prevent chatter—a challenge addressed through our proprietary machining parameters database, validated across 10,000+ 12L14 production runs.

Honyo Prototype integrates material science with precision manufacturing to overcome 12L14’s limitations. Our ISO 9001-certified processes include real-time coolant monitoring to mitigate lead dust exposure per OSHA guidelines and multi-axis probing for in-process verification of critical features. We prioritize first-article inspection using CMM and optical comparators to validate geometric conformity, especially for threads or undercuts prone to burring. For clients requiring rapid iteration, our digital twin simulation predicts chip flow and thermal deformation, reducing scrap rates by up to 30%. This technical rigor ensures 12L14 components meet functional requirements while accelerating time-to-market.

Leveraging 12L14 effectively demands deep material expertise and adaptive CNC programming—capabilities Honyo Prototype has refined over 15 years of serving global OEMs. We transform its machining advantages into client value through reduced lead times, consistent quality, and engineering collaboration from prototype to production. Partner with us to optimize your 12L14 component designs for manufacturability without compromising performance.

Technical Capabilities

Steel 12L14 Properties and CNC Machining Capabilities at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, we specialize in high-precision CNC machining of free-machining steels, with AISI 12L14 steel being one of the most widely utilized materials for high-volume, tight-tolerance components. Known for its excellent machinability, 12L14 steel is a leaded modification of 12L13, designed to enhance chip breakability and surface finish during high-speed machining operations. This makes it an ideal choice for complex turned and milled parts in industries such as automotive, industrial equipment, and fluid control systems.

12L14 steel is a low-carbon, resulfurized, and leaded carbon steel with a nominal composition of 0.15% carbon, 0.85–1.15% manganese, 0.24–0.33% sulfur, and 0.15–0.35% lead. The addition of sulfur and lead significantly reduces tool wear and improves machining efficiency, especially in automated CNC turning and multi-axis milling environments. However, due to its low weldability and reduced ductility, 12L14 is not recommended for applications requiring post-machining welding or cold forming.

Our 3-, 4-, and 5-axis CNC milling centers are optimized to leverage the free-machining characteristics of 12L14 steel, enabling rapid material removal rates while maintaining exceptional dimensional accuracy and surface integrity. Combined with our CNC turning capabilities, we deliver complex geometries, fine surface finishes, and tight tolerances consistently across both prototyping and low-to-mid volume production runs.

We maintain strict process controls to ensure repeatability and precision, supported by in-house metrology including CMM, optical comparators, and laser micrometers. Our machining parameters for 12L14 are fine-tuned to minimize burring and tool degradation, particularly during deep hole drilling, threading, and slotting operations where chip evacuation is critical.

The following table outlines our standard and precision tolerance capabilities for 12L14 steel across key CNC processes:

| Process | Standard Tolerance (±) | Precision Tolerance (±) | Typical Surface Finish (Ra) | Max Part Size (mm) |

|———————–|————————|————————–|——————————|——————–|

| 3-Axis Milling | 0.05 mm | 0.0125 mm | 1.6–3.2 μm | 600 x 400 x 300 |

| 4-Axis Milling | 0.05 mm | 0.0125 mm | 1.6–3.2 μm | 600 x 400 x 300 |

| 5-Axis Milling | 0.05 mm | 0.01 mm | 0.8–1.6 μm | 500 x 400 x 250 |

| CNC Turning (Swiss) | 0.025 mm | 0.005 mm | 0.8–1.6 μm | Ø38 x 200 |

| CNC Turning (Chucker) | 0.05 mm | 0.01 mm | 1.6–3.2 μm | Ø150 x 500 |

All tolerances are achievable under controlled environmental and inspection conditions. For applications demanding ±0.005 mm or better, we employ process-specific tooling, adaptive machining strategies, and thermal compensation systems. Post-machining deburring and cleaning are standard, with optional passivation or oil-based rust protection available.

Shenzhen Honyo Prototype combines material expertise with advanced CNC technology to deliver robust, repeatable results in 12L14 steel—ensuring your components meet the highest standards in form, fit, and function.

From CAD to Part: The Process

From CAD to Finished Part: Optimized Workflow for 12L14 Steel Machining

At Shenzhen Honyo Prototype, our CNC machining process for 12L14 free-machining steel is engineered for precision, speed, and cost-effectiveness. This leaded steel grade offers exceptional machinability but requires specific handling protocols. Our integrated workflow ensures optimal results from initial inquiry through final inspection, leveraging 12L14’s unique properties while mitigating its limitations for non-structural applications.

The process initiates with our AI-Powered Quoting Engine. Upon receipt of a client’s CAD file, the system performs an immediate material suitability analysis. For 12L14, the AI verifies geometric compatibility with the alloy’s characteristics, flagging potential concerns such as thin walls prone to chatter or features requiring tight tolerances beyond typical free-machining steel capabilities. Simultaneously, it calculates preliminary material yield, machine time estimates based on 12L14’s high-speed machining potential, and lead time projections, providing a rapid, data-driven quote within hours. This initial scan prevents quoting on fundamentally unmanufacturable designs for this specific grade.

Following quote acceptance, the project enters our rigorous Design for Manufacturability (DFM) review. Senior engineers conduct a deep dive into the CAD model, specifically evaluating it against 12L14 steel’s properties. Critical checks include verifying that tolerances align with the ±0.005″ typical capability for this material, assessing surface finish requirements against achievable Ra values, and confirming feature geometries avoid stress concentrations unsuitable for 12L14’s lower strength profile. The DFM report provides actionable feedback to the client, optimizing the design for efficient, high-yield machining while maintaining functional requirements. Understanding the material’s behavior is paramount at this stage.

Key 12L14 Steel Properties Driving Our Process

| Property | Value/Description |

| :——————– | :———————————— |

| Carbon Content | 0.12 – 0.17% |

| Lead (Pb) Content | 0.15 – 0.35% (Machinability enhancer) |

| Tensile Strength | ~540 MPa (78,000 psi) |

| Yield Strength | ~415 MPa (60,000 psi) |

| Typical Machinability | 160% (Relative to 1212 steel = 100%) |

| Common Applications | Precision shafts, pins, fittings, fasteners |

With DFM sign-off, the project moves to CNC production. Our machinists deploy parameters specifically tuned for 12L14. Higher spindle speeds and feed rates are utilized compared to non-leaded steels, capitalizing on the lead inclusions’ chip-breaking and lubricating effects. Coolant selection and application are critical; we use high-quality soluble oils to manage the lead dust generated, ensuring operator safety and environmental compliance per Shenzhen regulations. Tooling strategies prioritize sharp, positive rake geometry cutters to minimize built-up edge. Every stage undergoes in-process inspection, with final parts subjected to stringent CMM verification against the approved drawing, confirming dimensional accuracy and surface integrity specific to 12L14’s machined characteristics. This end-to-end workflow, grounded in deep material knowledge, ensures Honyo delivers 12L14 components with the speed, precision, and reliability our industrial clients demand.

Start Your Project

Optimize Your CNC Machining Projects with Steel 12L14 – Partner with Honyo Prototype

When precision, efficiency, and reliability are critical in CNC machining, steel 12L14 stands out as a top-tier choice for high-volume production and complex components. At Shenzhen Honyo Prototype, we specialize in leveraging the unique properties of 12L14 steel to deliver machined parts that meet exacting industry standards. Whether you’re developing automotive components, hydraulic fittings, or industrial fasteners, understanding the material advantages of 12L14 is the first step toward optimizing your manufacturing outcomes.

Steel 12L14 is a leaded variation of 12L13, engineered specifically to enhance machinability without sacrificing strength or dimensional stability. The addition of lead acts as a built-in lubricant during cutting operations, reducing tool wear and enabling faster machining speeds. This translates into lower production costs, improved surface finishes, and tighter tolerances—key benefits for clients seeking high repeatability and reduced lead times. Its free-machining characteristics make it ideal for automated screw machining, milling, and turning processes, especially in high-speed CNC environments.

Beyond machinability, 12L14 maintains good ductility and cold-forming capabilities, allowing for post-machining operations such as thread rolling or press-fitting. While not recommended for welding or through-hardening due to its low carbon and high sulfur content, 12L14 performs exceptionally well in applications where these processes are not required. The material responds effectively to case hardening, offering improved surface durability while preserving a tough core.

At Honyo Prototype, we combine advanced CNC technology with deep metallurgical expertise to ensure every 12L14 component meets your functional and geometric requirements. Our in-house quality control systems, including CMM inspection and material certification, guarantee consistency across batches. We support prototyping through full-scale production, providing scalable solutions tailored to your project’s lifecycle.

To help you get started, the table below outlines key mechanical and chemical properties of 12L14 steel:

| Property | Value |

|——————————|—————————————-|

| Carbon (C) | 0.13–0.17% |

| Manganese (Mn) | 0.85–1.15% |

| Phosphorus (P) | 0.04–0.09% |

| Sulfur (S) | 0.26–0.35% |

| Lead (Pb) | 0.15–0.35% |

| Tensile Strength (min) | 55,000 psi |

| Yield Strength (min) | 40,000 psi |

| Elongation in 2 inches | 14% (min) |

| Brinell Hardness (HB) | 140–170 |

| Machinability Rating | 170% (relative to 1212 steel) |

With proven expertise in machining free-cutting steels like 12L14, Honyo Prototype is your trusted partner for precision manufacturing in Shenzhen and beyond. We work closely with engineers and product designers to optimize part geometry, material selection, and production methodology from the outset.

Start your next project with confidence. Contact Susan Leo today at info@hy-proto.com to discuss your 12L14 machining needs and receive a fast, detailed quotation.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.