Contents

Manufacturing Insight: Pvd Coating Service

Manufacturing Insight: Precision PVD Coating Services for High-Performance CNC Components

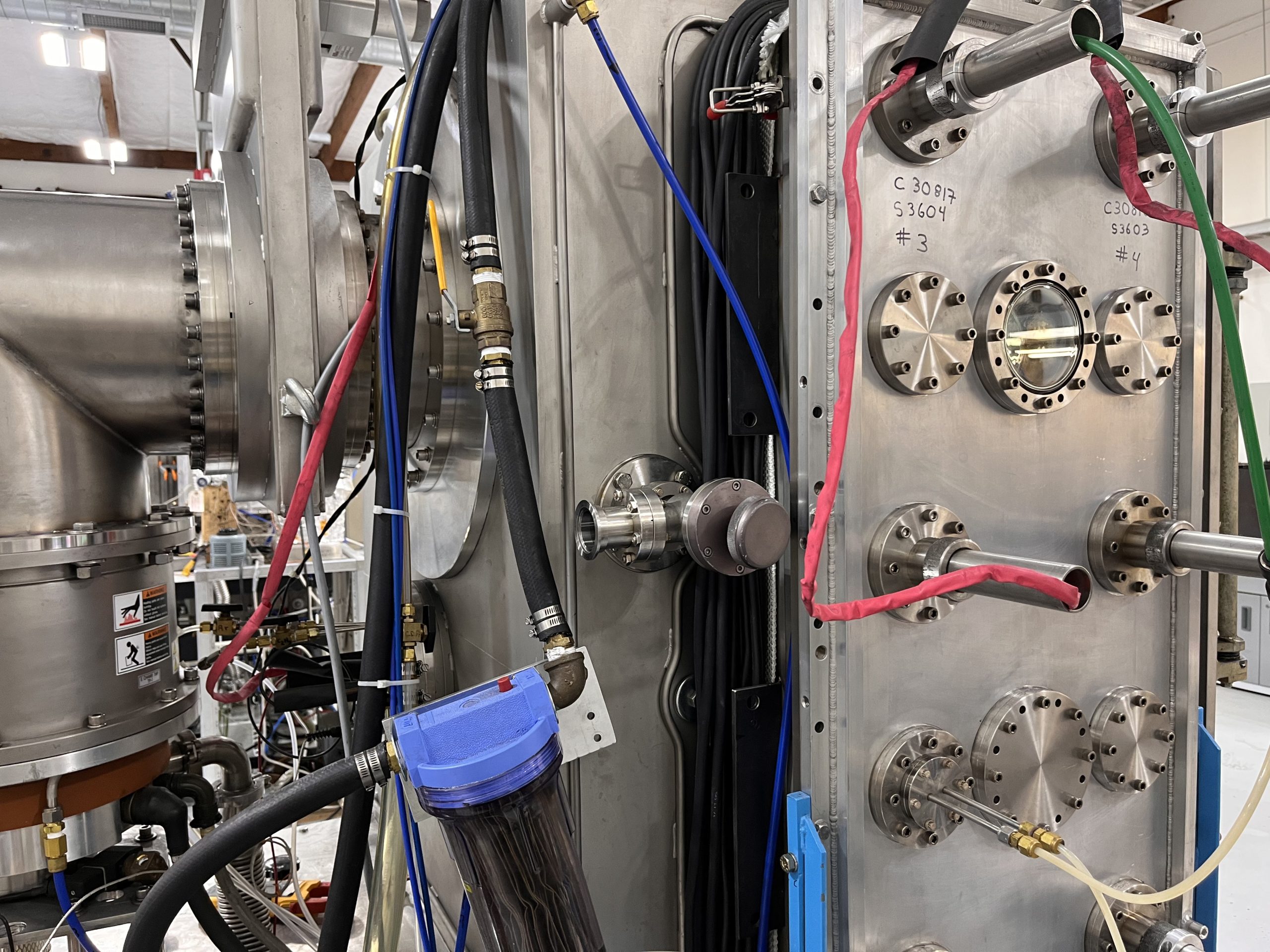

Physical Vapor Deposition (PVD) represents a critical surface engineering technology for enhancing the functional performance and longevity of precision CNC machined components. At Shenzhen Honyo Prototype, we integrate advanced PVD coating capabilities directly within our manufacturing ecosystem, providing clients with a seamless transition from prototype machining to final surface treatment. This vertical integration eliminates secondary vendor dependencies and ensures stringent control over the entire production chain, from initial material selection through to the application of the final functional coating. PVD works by vaporizing a solid target material within a high-vacuum chamber, creating a plasma of ions that subsequently condense onto the substrate, forming an extremely thin, dense, and adherent coating at the atomic level. This process operates at relatively low temperatures (typically 200°C to 500°C), making it uniquely suited for heat-sensitive substrates like hardened tool steels, stainless steels, and certain aluminum alloys commonly used in precision CNC prototypes and low-volume production runs. The resulting coatings offer exceptional hardness, wear resistance, corrosion protection, and reduced friction coefficients, directly addressing demanding requirements in aerospace, medical device, automotive, and industrial tooling applications.

Honyo Prototype leverages state-of-the-art multi-arc and magnetron sputtering PVD systems, enabling the deposition of a versatile range of advanced coating materials tailored to specific application challenges. Our engineering team works collaboratively with clients during the design phase to select the optimal coating type and parameters, ensuring the surface properties align perfectly with functional needs and environmental conditions. Critical to PVD success is meticulous substrate preparation; our integrated CNC machining facility guarantees components arrive at the coating line with the precise surface finish, cleanliness, and dimensional accuracy required for optimal adhesion and coating uniformity. We implement rigorous in-process controls and post-coating validation testing to meet the highest industry standards for quality and repeatability.

The following table outlines key specifications and capabilities of Honyo Prototype’s industrial PVD coating services:

| Parameter | Capability Range | Key Materials Offered | Performance Standard |

| :———————– | :———————————– | :—————————– | :——————————– |

| Coating Thickness | 0.5 µm to 5.0 µm | TiN, TiCN, TiAlN, CrN, DLC | ±0.1 µm control |

| Substrate Hardness (Max) | Up to 65 HRC | | Verified pre-coat |

| Adhesion Strength | Lc > 60 N (Rockwell C) | | ISO 26443 |

| Surface Roughness (Ra) | Maintains substrate finish (≤ 0.1 µm)| | Measured pre/post |

| Corrosion Resistance | > 72 hours neutral salt spray (NSS) | CrN, specialized variants | ASTM B117 |

| Hardness (HV) | 2000 – 4000 HV | TiAlN, CrN, DLC | ISO 14577 |

| Process Temperature | 200°C – 500°C | | Monitored per batch |

| Compliance | RoHS/REACH compliant | | Full material traceability |

Our commitment extends beyond mere coating application. Honyo Prototype provides comprehensive technical support, including failure mode analysis, coating selection guidance based on tribological requirements, and detailed process documentation essential for regulated industries. By embedding PVD expertise within our core CNC machining and rapid prototyping services, we deliver not just a coating, but a fully engineered surface solution that enhances component performance, accelerates time-to-market, and reduces total lifecycle costs for our clients’ most demanding applications. Partner with Honyo to transform your precision metal components with industry-leading PVD technology.

Technical Capabilities

PVD Coating Service – Technical Capabilities

Shenzhen Honyo Prototype integrates Physical Vapor Deposition (PVD) coating services into our comprehensive CNC machining solutions, enhancing the performance and longevity of precision-engineered components. Our in-house PVD coating capability is specifically designed to complement high-accuracy 3, 4, and 5-axis milling and CNC turning operations, ensuring that critical parts used in aerospace, medical, automotive, and industrial applications meet stringent durability and functional requirements.

PVD coating is a vacuum-based surface treatment process that deposits thin, hard, and wear-resistant layers onto metal, alloy, and engineered plastic substrates. At Honyo Prototype, we specialize in applying coatings such as TiN (Titanium Nitride), TiCN (Titanium Carbonitride), CrN (Chromium Nitride), and AlTiN (Aluminum Titanium Nitride), each selected based on the operational demands of the end-use environment. These coatings offer exceptional hardness (ranging from 1,800 HV to over 3,500 HV), low friction coefficients, and resistance to oxidation and corrosion—critical attributes for components subjected to high stress, thermal cycling, or abrasive conditions.

Our PVD process is fully compatible with tight-tolerance machining, supporting dimensional accuracy down to ±0.005 mm. The low-temperature nature of PVD (typically 150°C to 500°C) ensures minimal thermal distortion, preserving the geometric integrity of precision-machined parts. This makes it ideal for post-machining surface enhancement without compromising critical tolerances or surface finishes achieved during 3, 4, and 5-axis CNC operations.

We routinely apply PVD coatings to components machined from a wide range of materials, including tool steels, stainless steels, titanium alloys, and high-strength aluminum alloys. The coating thickness is precisely controlled between 1 µm and 5 µm, allowing for uniform coverage without affecting fit or function in tight assembly interfaces.

Below is a summary of our PVD coating capabilities and compatible materials:

| Coating Type | Hardness (HV) | Thickness Range (µm) | Max Service Temp (°C) | Common Substrate Materials |

|————–|—————|————————|————————|—————————–|

| TiN | 2,200 | 1.0 – 4.0 | 500 | H13, SKD61, 420SS, D2 |

| TiCN | 2,800 | 1.5 – 4.5 | 400 | 17-4PH, 440C, Tool Steels |

| CrN | 1,800 | 1.0 – 5.0 | 700 | 316SS, Titanium Alloys |

| AlTiN | 3,500+ | 2.0 – 5.0 | 800 | Inconel, High-Speed Steels |

All PVD-coated parts undergo rigorous quality inspection, including adhesion testing, thickness measurement via X-ray fluorescence (XRF), and surface roughness verification to ensure compliance with international standards. Our process is optimized to support rapid turnaround times without sacrificing consistency, making it ideal for both prototype development and low-to-medium volume production.

By combining advanced CNC machining with high-performance PVD coating, Shenzhen Honyo Prototype delivers components that meet the dual demands of precision and durability in the most challenging applications.

From CAD to Part: The Process

PVD Coating Service: Production Process Workflow

Shenzhen Honyo Prototype delivers precision PVD coating services integrated within our CNC machining workflow, ensuring optimal adhesion, durability, and aesthetic finish for functional prototypes and low-volume production parts. Our streamlined process from initial design submission to finished coated component prioritizes efficiency and quality control, minimizing time-to-market for your project.

The workflow begins upon CAD file submission via our online portal. Our proprietary AI quoting engine rapidly analyzes the 3D model, automatically identifying critical features impacting PVD application such as complex geometries, tight tolerances, and material suitability. This system generates an accurate, detailed quote within hours, including estimated lead time and specific coating recommendations based on the part’s intended function and substrate material. This initial AI-driven step eliminates manual interpretation delays and provides immediate cost transparency.

Following quote acceptance, the project enters the mandatory Design for Manufacturing (DFM) review phase. Our senior manufacturing engineers conduct a rigorous analysis focused explicitly on PVD process requirements. We scrutinize part geometry for potential coating shadowing, assess surface roughness specifications post-machining to ensure optimal adhesion, verify compatibility between the base material (e.g., aluminum alloys, stainless steel, titanium) and target coating (e.g., TiN, CrN, ZrN), and identify necessary masking areas. Critical dimensional features near tight tolerances are evaluated to confirm they will not be adversely affected by the thin film deposition. This proactive DFM step resolves potential issues before physical production, preventing costly rework and ensuring the final coated part meets all functional and dimensional requirements.

Production commences only after DFM sign-off. Precision-machined substrates undergo stringent pre-treatment: ultrasonic cleaning to remove all contaminants, meticulous masking of non-coated areas using high-temperature tapes or fixtures, and substrate heating within the vacuum chamber. The PVD process itself utilizes magnetron sputtering or cathodic arc evaporation under high vacuum, depositing the chosen metal nitride or carbide layer with atomic-level precision. Strict environmental controls maintain consistent temperature, pressure, and gas flow rates throughout deposition. Post-coating, parts undergo thorough inspection for coating thickness uniformity, adhesion (verified via scratch testing), surface defects, and color consistency against approved standards before final packaging and shipment.

Key PVD process parameters are rigorously controlled to meet project specifications:

| Parameter | Standard Range | Measurement Method | Criticality for Prototypes |

|——————–|———————-|————————–|—————————-|

| Coating Thickness | 0.5 – 5.0 µm | X-ray Fluorescence (XRF) | Ensures wear resistance without altering critical tolerances |

| Adhesion | Lc > 40 N (HRC 60+) | Progressive Load Scratch Test | Prevents delamination under functional stress |

| Surface Roughness (Pre-Coat) | Ra 0.2 – 0.8 µm | Profilometer | Directly impacts final coating smoothness and reflectivity |

| Hardness | 2000 – 3500 HV | Nanoindentation | Validates performance for wear/corrosion resistance claims |

This integrated AI Quote → DFM → Production workflow, combined with Shenzhen Honyo Prototype’s deep expertise in both precision CNC machining and advanced PVD technology, guarantees that your coated prototypes meet the highest standards of quality, functionality, and reliability, accelerating your development cycle with confidence.

Start Your Project

Start Your Project with Precision PVD Coating Services at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, we specialize in delivering high-performance, durable surface finishes through advanced Physical Vapor Deposition (PVD) coating services. As a trusted partner in the CNC machining industry, we understand that component longevity, wear resistance, and aesthetic consistency are critical for your applications. Whether you’re developing precision aerospace components, medical devices, automotive parts, or high-end consumer products, our PVD coating solutions enhance functionality and reliability while maintaining tight dimensional tolerances.

PVD coating is a vacuum-based process that deposits ultra-thin, high-adhesion layers of materials such as titanium nitride (TiN), titanium carbonitride (TiCN), chromium nitride (CrN), and zirconium nitride (ZrN) onto metal, ceramic, or engineered plastic substrates. This results in a surface that resists abrasion, corrosion, and oxidation, all while maintaining the original geometry of your CNC-machined parts. Our state-of-the-art PVD systems are calibrated to ensure uniform coating thickness—typically between 1 to 5 microns—making them ideal for components requiring minimal post-coating processing.

We work closely with engineers and product developers to match coating properties with your performance requirements. Our in-house technical team evaluates substrate material, operating environment, load conditions, and lifecycle expectations to recommend the optimal coating type and process parameters. This collaborative approach ensures that every coated component meets or exceeds functional and regulatory standards.

Our facility in Shenzhen is equipped with ISO-compliant quality control systems, including scanning electron microscopy (SEM), microhardness testing, and adhesion evaluation tools. Every batch undergoes rigorous inspection to verify coating integrity, thickness uniformity, and surface finish quality. We support both low-volume prototyping and high-volume production runs, offering fast turnaround times without compromising precision.

To ensure seamless integration into your development workflow, we accept a wide range of file formats including STEP, IGES, and DXF, and provide expert feedback on part geometry suitability for PVD treatment. Our engineers can advise on fixturing points, masking requirements, and material compatibility to prevent defects and maximize coating performance.

Below is an overview of standard PVD coating specifications we offer:

| Coating Type | Thickness Range (µm) | Hardness (HV) | Primary Benefits | Common Applications |

|————–|————————|—————|——————|———————-|

| TiN | 2–4 | 2,200–2,400 | High wear resistance, golden aesthetic | Cutting tools, molds, fasteners |

| TiCN | 2–5 | 2,800–3,200 | Enhanced toughness, better oxidation resistance | Automotive components, dies |

| CrN | 1–4 | 1,800–2,200 | Excellent corrosion resistance, low friction | Medical devices, food processing |

| ZrN | 2–4 | 1,800–2,000 | Decorative gold alternative, good wear resistance | Consumer electronics, luxury goods |

Starting your project with Honyo Prototype is simple. Reach out to Susan Leo, our dedicated manufacturing coordinator, to discuss your coating needs, request a quote, or submit your design files for evaluation. We are committed to supporting your success with responsive service, technical expertise, and consistent quality.

Contact Susan Leo today at info@hy-proto.com to begin optimizing your CNC-machined components with professional PVD coating services.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.