Contents

Manufacturing Insight: Spot Face In Machining

Manufacturing Insight: Spot Face in Machining

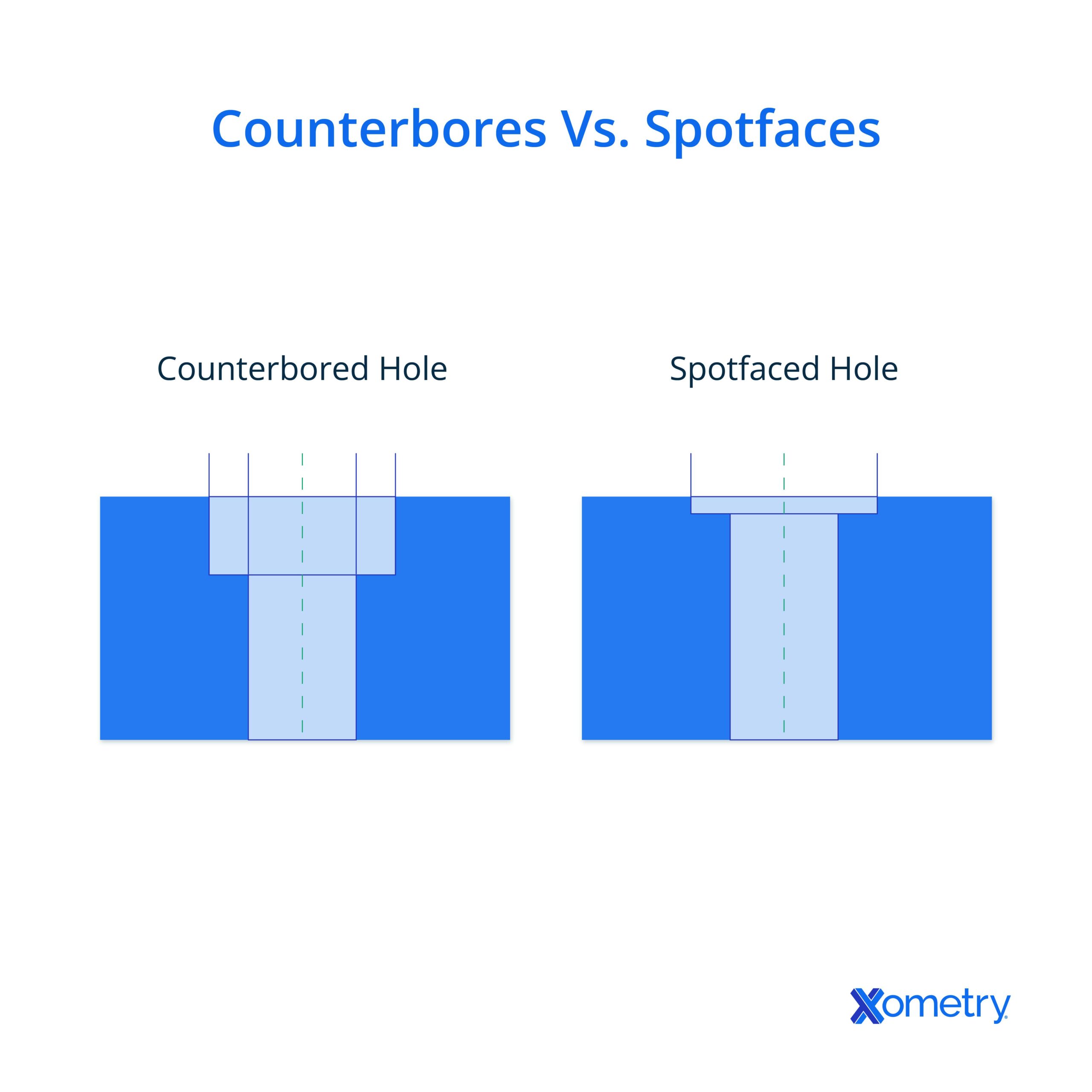

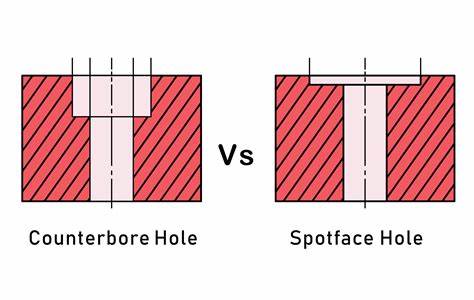

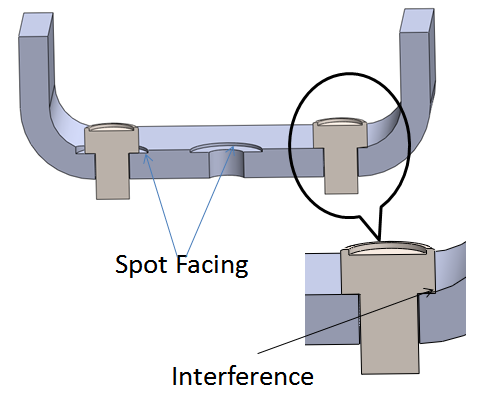

Spot facing is a critical precision machining operation that creates a flat, perpendicular surface around a hole to ensure proper seating for fasteners, washers, or bearings. Unlike counterboring—which enlarges a hole’s diameter—spot facing focuses solely on surface preparation without altering the hole’s core dimensions. This process eliminates irregularities caused by casting, forging, or drilling, guaranteeing uniform load distribution and preventing fastener failure. At Shenzhen Honyo Prototype, we deploy spot facing to resolve real-world assembly challenges in aerospace, automotive, and medical components where tolerance integrity directly impacts safety and performance.

The technical execution demands rigorous control over tool geometry, feed rates, and spindle alignment. Standard spot facing tools include counterbores with pilot guides or specialized fly cutters, but suboptimal parameters often yield surface waviness or concentricity errors. Honyo addresses these pitfalls through our integrated CNC workflow: We begin with 3D simulation to validate tool clearance and avoid chatter, then apply adaptive toolpaths that maintain constant chip load. Our Haas and DMG MORI 5-axis centers utilize rigid tapping cycles with real-time spindle monitoring, ensuring depth accuracy within ±0.02 mm. Crucially, we prioritize material-specific strategies—for aluminum alloys, we use high-speed steel tools with coolant-through delivery to prevent galling, while titanium requires polycrystalline diamond (PCD) cutters at reduced RPMs to manage heat.

Honyo’s competitive edge lies in marrying process science with quality assurance. Every spot face operation undergoes in-process verification via Renishaw probes, measuring flatness deviation before part completion. This eliminates post-machining rework and aligns with ISO 2768-mK geometric standards. Below summarizes our performance benchmarks against industry norms:

| Parameter | Industry Standard | Honyo Precision |

|——————–|——————-|—————–|

| Depth Tolerance | ±0.05 mm | ±0.02 mm |

| Surface Finish (Ra)| 3.2 μm | 1.6 μm |

| Concentricity | 0.1 mm | 0.03 mm |

Beyond specifications, our engineers collaborate early in DFAM (Design for Additive Manufacturing) reviews to identify spot face opportunities in hybrid metal parts. For instance, in a recent drone landing gear assembly, we optimized spot face locations to reduce fastener count by 30% while improving fatigue resistance. All operations are documented per AS9100D traceability protocols, with CMM reports accessible via client dashboards.

Shenzhen Honyo Prototype transforms spot facing from a routine step into a value-driven differentiator. By embedding metrology into the machining sequence and tailoring solutions to material physics, we deliver surfaces that meet Tier-1 automotive and aerospace requirements—on time, every time. Partner with us to convert design intent into flawless assembly readiness.

Technical Capabilities

Spot Face Machining Capability at Shenzhen Honyo Prototype

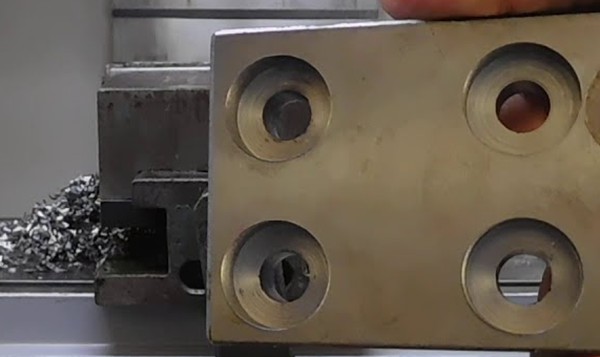

Spot facing is a precision CNC milling operation used to create a flat, smooth surface around a hole to accommodate fastener heads, washers, or sealing components. At Shenzhen Honyo Prototype, spot facing is performed across our advanced 3-axis, 4-axis, and 5-axis milling platforms, enabling precise, repeatable results on complex geometries and tight-tolerance parts. This capability supports industries requiring high-precision assembly, including aerospace, medical devices, and industrial automation.

Our spot face machining process ensures perpendicularity between the spot face surface and the associated hole axis, critical for load distribution and sealing integrity. Using high-rigidity spindles and advanced toolpath strategies, we achieve consistent surface finishes and dimensional accuracy. Spot facing is typically performed after drilling or boring operations, ensuring minimal runout and optimal alignment. Our CNC systems support dynamic tool compensation and in-process probing, allowing us to maintain tolerances down to ±0.005 mm when required.

Spot face diameters are customized based on customer specifications, commonly ranging from 1.5× to 3× the diameter of the associated hole. Standard tooling includes indexed fly cutters and counterbores, with custom tools available for non-standard angles or materials. We support spot facing on a wide range of materials, from aluminum and stainless steel to titanium and engineered plastics, ensuring compatibility with diverse application requirements.

In multi-axis setups, spot facing can be executed on angled or contoured surfaces without re-fixturing, reducing cycle time and improving positional accuracy. This is particularly beneficial for complex parts produced on our 5-axis machining centers, where undercuts and non-orthogonal features are common.

For turning applications, spot facing is integrated into live-tooling operations on our CNC lathes, allowing face flatness on cylindrical components without secondary milling. This hybrid approach enhances efficiency and maintains tight concentricity between turned and milled features.

The following table outlines our standard spot face machining capabilities, including achievable tolerances and compatible materials:

| Parameter | Specification |

|—————————–|————————————————|

| Spot Face Diameter Range | 4 mm – 50 mm (standard), up to 100 mm (custom) |

| Typical Depth | 0.2 mm – 3.0 mm |

| Flatness Tolerance | ±0.01 mm (standard), ±0.005 mm (tight) |

| Surface Finish (Ra) | 1.6 µm – 3.2 µm (standard), 0.8 µm (fine) |

| Positional Tolerance | ±0.02 mm (standard), ±0.01 mm (tight) |

| Angular Accuracy | ±0.1° (relative to hole axis) |

| Compatible Materials | Aluminum (6061, 7075), Stainless Steel (303, 316), Titanium (Gr 2, Gr 5), Brass, PEEK, Delrin, Carbon Steel |

| Primary Equipment | 3-axis, 4-axis, 5-axis CNC Mills, CNC Lathes with Live Tooling |

| Lead Time (Prototype Batch) | 3–7 days (depending on complexity) |

Shenzhen Honyo Prototype combines advanced CNC technology with rigorous quality control to deliver spot face features that meet or exceed industry standards. Our engineering team collaborates with clients during the DFM stage to optimize spot face design, reduce tool wear, and ensure functional performance in final assembly.

From CAD to Part: The Process

Spot Face Machining: From CAD to Finished Part at Honyo Prototype

A spot face is a critical, precisely machined flat surface surrounding a hole, ensuring proper seating for fastener heads, washers, or bearings. At Shenzhen Honyo Prototype, our CNC machining workflow for spot faces integrates advanced digital tools with precision manufacturing, ensuring optimal functionality and assembly integrity. This process begins with your CAD model and progresses seamlessly through quotation, design validation, and production.

The workflow initiates with the AI-Powered Quotation System. Upon receiving your CAD file (STEP, IGES, or native formats), our proprietary AI engine instantly analyzes geometric features, including spot faces. It identifies location, diameter, depth, and specified tolerances relative to the base hole. The system cross-references this data against our extensive material database and machine capabilities, generating an accurate, time-stamped quote within minutes. This initial analysis flags potential complexities, such as spot faces on thin sections, near edges, or requiring non-standard tooling, providing immediate transparency on manufacturability and cost drivers specific to your feature requirements.

Following quotation acceptance, the design enters the mandatory Design for Manufacturability (DFM) Review. Our senior manufacturing engineers conduct a detailed technical assessment focused on spot face feasibility. Key considerations include verifying adequate material stock around the feature to prevent deflection, confirming the spot face diameter provides sufficient clearance for the intended fastener head, and evaluating depth consistency relative to the hole axis. We assess whether standard end mills or specialized tools (e.g., spotface cutters, large-diameter countersinks) are optimal, considering surface finish requirements and proximity to other critical datums. Any conflicts with standard machining practices—such as insufficient clearance for tool access, excessive depth-to-diameter ratios causing chatter, or conflicting geometric dimensioning—are communicated with actionable recommendations to optimize the design for precision and cost-efficiency without compromising function.

Upon DFM approval, the part moves to CNC Production. Programmers generate optimized toolpaths using Mastercam and Siemens NX CAM, prioritizing stability for spot face operations. Standard 2-flute or 4-flute solid carbide end mills are typically selected based on material and finish requirements. The machining sequence ensures the base hole is drilled or reamed first, providing a precise reference. The spot face operation then employs a light finishing pass at controlled spindle speeds and feed rates to achieve the required flatness and surface texture, minimizing burr formation. Critical parameters are strictly monitored:

| Parameter | Typical Value at Honyo | Critical Consideration |

| :—————– | :——————— | :—————————————– |

| Diameter Tolerance | ±0.05 mm | Clearance for fastener head; affects fit |

| Depth Tolerance | ±0.03 mm | Ensures flush seating; prevents tilt |

| Surface Finish (Ra)| 3.2 μm (125 μin) | Minimizes galling; critical for sealing |

| Flatness | 0.02 mm | Directly impacts load distribution |

| Tool Type | Ø6-12mm End Mill | Balance of rigidity and surface quality |

Final quality control employs coordinate measuring machines (CMM) and surface profilometers to verify spot face dimensions, flatness, and finish against the CAD model and client specifications. This rigorous validation ensures the machined spot face reliably supports assembly performance, preventing issues like fastener loosening or uneven load distribution in the end application. Honyo Prototype’s integrated workflow guarantees spot faces are manufactured to exacting standards, directly translating your design intent into a functional, high-precision component.

Start Your Project

Spot Face in Machining: Precision Surface Preparation for Reliable Assemblies

In the world of CNC machining, achieving tight tolerances and consistent surface finishes is critical—especially when it comes to preparing areas for fasteners, seals, or mating components. One essential yet often overlooked machining operation is the spot facing process. At Shenzhen Honyo Prototype, we specialize in high-precision CNC machining services that include spot facing to ensure your components meet exact design specifications and perform reliably in end-use applications.

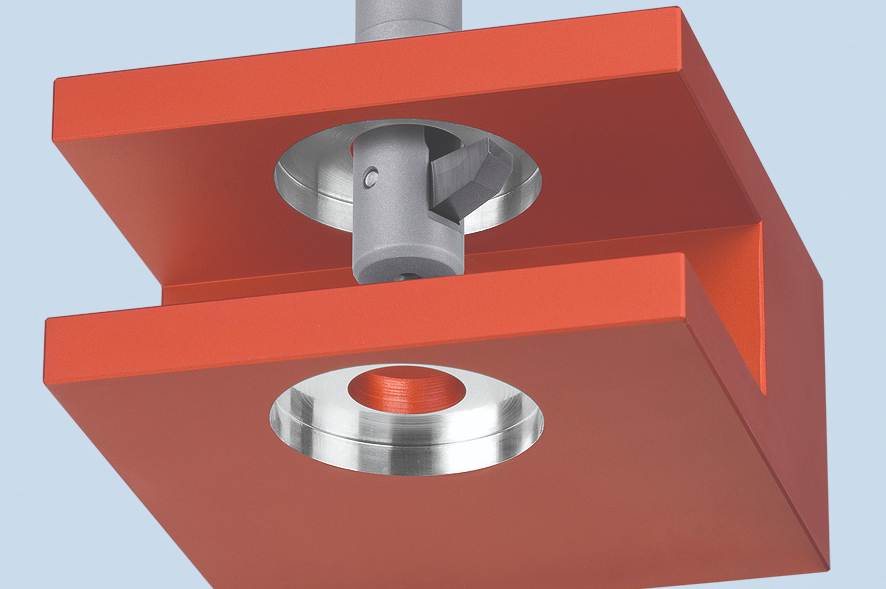

Spot facing involves machining a flat, smooth surface on a workpiece, typically around a hole, to provide a stable seating area for bolts, nuts, washers, or other fastening elements. This operation is crucial when the base material has an uneven or curved surface that could compromise the integrity of the fastened joint. By removing minimal material, spot facing creates a localized flat zone without affecting the surrounding structure—maintaining both strength and functionality.

Our advanced 3-, 4-, and 5-axis CNC milling centers are equipped to perform spot facing with micron-level accuracy. Whether you’re working with aluminum, stainless steel, titanium, or engineering plastics, our machining team applies industry-best practices to deliver consistent results across prototypes and low-volume production runs. We follow your technical drawings and GD&T callouts precisely, ensuring each spot faced surface meets the required flatness, diameter, and depth specifications.

Below are typical spot facing capabilities at Honyo Prototype:

| Parameter | Standard Capability | Precision Option |

|————————-|—————————–|—————————–|

| Spot Face Diameter | 6 mm – 50 mm | Up to 60 mm (custom tools) |

| Depth Tolerance | ±0.1 mm | ±0.05 mm |

| Surface Finish (Ra) | 3.2 µm | 1.6 µm or better |

| Materials | Aluminum, Steel, Stainless, Brass, Plastics | Exotics (Ti, Inconel) |

| Positional Accuracy | ±0.02 mm | ±0.01 mm (with probing) |

| Lead Time (Prototypes) | 3–7 days | Expedited options available |

All operations are supported by in-process inspections and first-article reporting upon request. Our quality management system ensures compliance with ISO 9001 standards, giving you confidence in every machined part.

If your design includes spot faced features—or if you’re unsure whether spot facing is necessary—our engineering team is ready to assist. We offer free design for manufacturability (DFM) reviews to optimize your part geometry, reduce costs, and prevent assembly issues before machining begins.

Start your project with confidence. Contact Susan Leo, Customer Project Manager at Shenzhen Honyo Prototype, to discuss your machining requirements. We’re here to support you from concept to delivery with fast turnaround, technical expertise, and responsive communication.

Email Susan Leo at info@hy-proto.com today to submit your drawings and receive a competitive quote within 4 business hours. Let Honyo Prototype be your trusted partner in precision CNC machining.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.