Contents

Manufacturing Insight: Cnc Screw Machine

Manufacturing Insight: CNC Screw Machine Technology

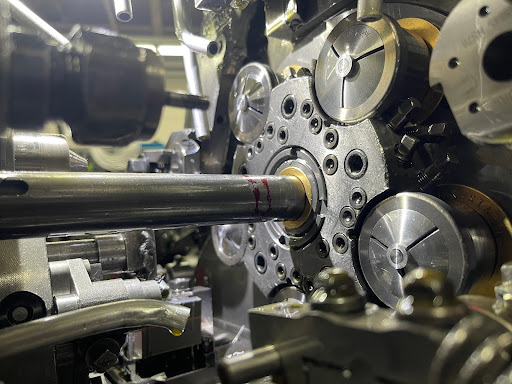

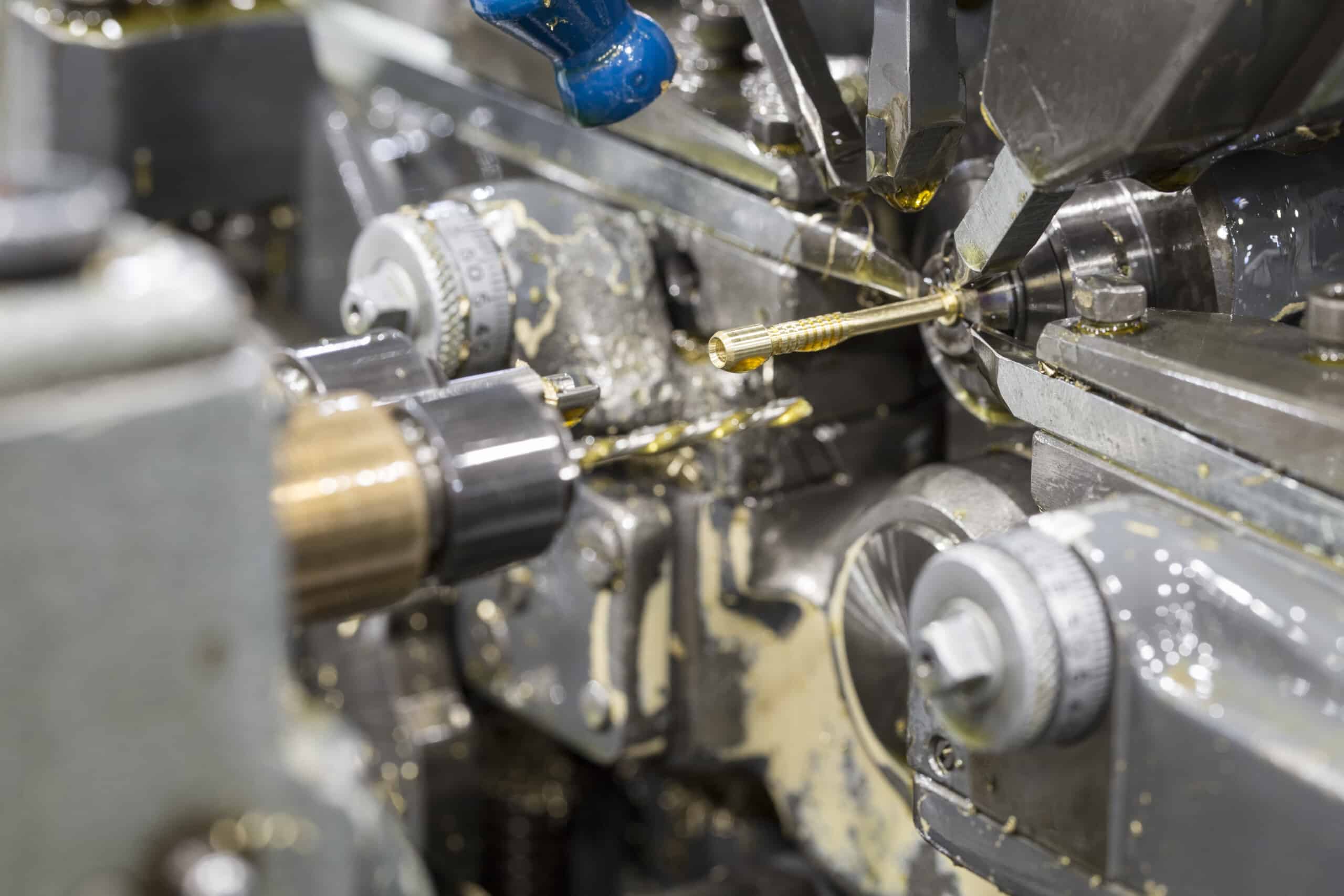

CNC screw machines represent a specialized high-volume production solution within precision machining, distinct from standard CNC lathes or mills. These machines utilize a rotary transfer principle where a single bar stock feedstock is progressively machined through multiple precisely synchronized spindles and tooling stations arranged radially around a central index turret. As the turret rotates, the workpiece transfers sequentially between stations, enabling simultaneous operations like turning, drilling, threading, milling, and cross-hole drilling on a single cycle. This architecture delivers exceptional throughput for complex cylindrical components, significantly reducing cycle times compared to single-spindle machines. Modern CNC screw machines, particularly Type A (Swiss-style) and Type B (multi-spindle) variants controlled by sophisticated CNC systems, have largely superseded older cam-operated models. They offer superior flexibility for rapid changeovers, tighter tolerances, and the ability to handle intricate geometries demanded by industries such as medical device manufacturing (cannulae, bone screws), automotive (fuel injectors, sensor pins), and electronics (connectors, terminals). The core advantage lies in maximizing material utilization and labor efficiency for大批量 production runs, where unit cost reduction is paramount.

Shenzhen Honyo Prototype leverages advanced CNC screw machining capabilities to deliver high-integrity, precision-turned components for demanding applications. Our facility houses state-of-the-art multi-spindle CNC screw machines equipped with live tooling, high-pressure coolant systems, and bar feeders supporting extended unmanned operation. We specialize in producing small to medium diameter parts requiring tight geometric tolerances and exceptional surface finishes, often integrating secondary operations like heat treating, plating, or laser marking within our streamlined workflow. Our engineering team possesses deep expertise in optimizing part programs for the unique kinematics of screw machines, ensuring minimal scrap rates and consistent conformance to stringent specifications. We excel at rapid prototyping for high-volume production validation and seamless transition to full-scale manufacturing, providing clients with a critical path from design intent to certified production parts.

The following table outlines key technical specifications representative of Honyo Prototype’s CNC screw machine capabilities:

| Parameter | Honyo Specification | Typical Industry Standard |

| :———————- | :———————– | :———————— |

| Max Bar Stock Diameter | 32 mm (1.26 in) | 20-38 mm |

| Min Feature Size | 0.3 mm (0.012 in) | 0.5 mm |

| Typical Tolerance | ±0.005 mm (±0.0002 in) | ±0.01 mm |

| Max Part Length | 150 mm (5.9 in) | 100-200 mm |

| Spindle Configurations | 5-6 Spindle CNC Rotary | 4-8 Spindle |

| Secondary Operations | In-house Milling, Threading, Deburring, Metrology | Often Outsourced |

Honyo Prototype provides a critical manufacturing advantage for clients requiring high-volume precision turned components. Our integration of advanced CNC screw machining technology with rigorous quality control systems ensures parts meet the exacting demands of regulated industries while optimizing total production cost. Engineers specifying components for high-volume production should consider CNC screw machining early in the design phase to leverage inherent manufacturability benefits, including reduced lead times and minimized per-unit costs. Partner with Honyo to transform complex cylindrical designs into reliable, high-performance products.

Technical Capabilities

CNC Screw Machine Technical Capabilities at Shenzhen Honyo Prototype

Shenzhen Honyo Prototype leverages advanced CNC screw machine technology to deliver high-precision turned components for industries demanding tight tolerances, complex geometries, and repeatable accuracy. Our multi-axis CNC screw machines support full 3, 4, and 5-axis milling and turning operations, enabling us to produce intricate parts with minimal setup changes and reduced cycle times. These machines are ideal for high-volume production of small to medium-sized components, particularly in aerospace, medical, automotive, and electronics sectors.

Our CNC screw machines are equipped with live tooling, Y-axis capabilities, and sub-spindles, allowing simultaneous milling, drilling, threading, and contouring operations in a single setup. This integrated approach ensures superior part concentricity, reduced handling, and enhanced dimensional consistency. The machines are programmed using industry-leading CAM software, enabling precise toolpath optimization and efficient material removal rates. With automated bar feeding and parts catchers, our systems support unattended operation, improving throughput while maintaining quality.

A key strength of our CNC screw machining service is our ability to hold tight tolerances consistently. We routinely achieve tolerances down to ±0.005 mm (±0.0002″) for critical dimensions, with surface finishes as fine as Ra 0.8 µm (32 µin) achievable through precision tooling and process control. Our quality assurance protocols include in-process inspections using coordinate measuring machines (CMM), optical comparators, and laser micrometers to verify conformance to print specifications.

We support a wide range of engineering-grade materials, including free-machining steels, stainless steels, aluminum alloys, brass, copper, and high-performance plastics such as PEEK and PTFE. Material selection is matched to part function, environmental exposure, and regulatory requirements, ensuring optimal performance in end-use applications.

The following table outlines our standard machining capabilities and achievable tolerances across different material types:

| Parameter | Specification |

|——————————-|—————|

| Machine Types | CNC Swiss-type, CNC Turning Centers, Multi-axis Mill-Turn Centers |

| Axis Configuration | 3, 4, and 5-axis milling and turning |

| Maximum Workpiece Diameter | 38 mm (1.5″) |

| Minimum Feature Size | 0.3 mm (0.012″) |

| Standard Tolerance (milling) | ±0.01 mm (±0.0004″) |

| Tight Tolerance Capability | ±0.005 mm (±0.0002″) |

| Surface Finish (typical) | Ra 1.6–3.2 µm (63–125 µin); down to Ra 0.8 µm (32 µin) with fine finishing |

| Positional Accuracy | ±0.008 mm (±0.0003″) |

| Repeatability | ±0.003 mm (±0.0001″) |

| Material Category | Examples | Machinability Notes |

|——————————-|——————————-|———————-|

| Carbon & Alloy Steels | 12L14, 1215, 4140, 1018 | Excellent for high-strength components; tight tolerance achievable with proper tooling |

| Stainless Steels | 303, 304, 316, 17-4PH | Good corrosion resistance; moderate machinability; cryogenic cooling recommended for fine finishes |

| Aluminum Alloys | 6061, 2024, 7075 | High machinability; excellent for lightweight precision parts |

| Brass & Copper Alloys | C36000 (Free-Cutting Brass), C11000 | Superior surface finish; ideal for electrical and decorative components |

| Engineering Plastics | PEEK, PTFE, Acetal, Nylon | Low thermal conductivity; requires sharp tooling and controlled feed rates |

At Shenzhen Honyo Prototype, our CNC screw machine capabilities are backed by rigorous process validation, real-time monitoring, and a commitment to continuous improvement. We specialize in turning design concepts into high-integrity machined components with exceptional consistency and speed.

From CAD to Part: The Process

CNC Screw Machine Production Workflow: From CAD to Precision Part

At Shenzhen Honyo Prototype, our CNC screw machine production process transforms digital designs into high-precision, high-volume turned components through a rigorously defined workflow. This integrated sequence ensures manufacturability, cost efficiency, and adherence to exacting quality standards from initial inquiry to final shipment. The core phases—AI-Powered Quoting, Engineering-Driven DFM, and Optimized Production—are designed for seamless transition and minimal lead time.

The process initiates with our proprietary AI Quote engine. Upon receiving a client’s 3D CAD model (STEP, IGES, or native formats accepted), the system performs an instant, multi-faceted analysis. It identifies geometric complexity, material requirements, critical tolerances, surface finish specifications, and estimated machine time. Crucially, the AI cross-references this data against our extensive database of historical production runs, material costs, and machine capabilities. This generates a highly accurate preliminary quote within minutes, including realistic lead time projections and potential high-risk features flagged for immediate engineering review. This rapid feedback loop allows clients to make informed design or timeline decisions early.

Following quote acceptance, the project enters the mandatory Design for Manufacturability (DFM) phase, led by our senior manufacturing engineering team. This is not a passive review but an active collaboration. Engineers scrutinize the CAD model specifically for screw machine optimization, focusing on bar stock utilization, tool path efficiency, secondary operation minimization, and feature sequencing. Key considerations include minimizing live-tooling requirements where possible, optimizing parting line placement, ensuring adequate clearance for collet chucks and guide bushings, and validating tolerance stack-ups achievable within the machine’s inherent capabilities. We provide detailed, actionable feedback to the client, suggesting design modifications that significantly reduce cost and cycle time without compromising function—often achieving 15-30% cost savings through strategic DFM insights.

Upon DFM sign-off, the project moves to production. Verified CAD data is directly imported into our CAM systems (Mastercam, ESPRIT) where experienced programmers generate optimized, machine-specific G-code. This code is rigorously simulated offline to prevent collisions and verify toolpaths. Setup technicians then configure the CNC Swiss-type or multi-spindle screw machine, installing precision-ground tooling, collets, and guide bushings. First Article Inspection (FAI) is performed against all critical dimensions using calibrated CMMs, optical comparators, and surface roughness testers. Only after full FAI approval and client sign-off does full production commence. Throughout the run, Statistical Process Control (SPC) monitors key parameters, with automated in-process gauging on critical features ensuring consistent conformance. Final inspection and packaging follow strict protocols before shipment.

This integrated workflow, underpinned by AI efficiency and deep manufacturing expertise, is central to Honyo Prototype’s ability to deliver complex, high-integrity screw machine parts rapidly and reliably. Our focus on proactive DFM and process control minimizes waste and maximizes yield for our clients.

Typical CNC Screw Machine Production Specifications

| Material Category | Common Alloys | Standard Tolerances (mm) | Typical Surface Finish (Ra µm) |

| :—————- | :———— | :———————– | :—————————– |

| Aluminum | 6061, 2011, 7075 | ±0.025 | 0.8 – 1.6 |

| Brass | C36000, C38500 | ±0.012 | 0.4 – 0.8 |

| Stainless Steel | 303, 304, 17-4PH | ±0.010 | 0.2 – 0.8 |

| Carbon Steel | 12L14, 1018 | ±0.025 | 0.8 – 3.2 |

Start Your Project

Start Your CNC Screw Machine Project with Shenzhen Honyo Prototype

When precision, repeatability, and efficiency are critical to your component manufacturing, CNC screw machines deliver unmatched performance for high-volume production of small to medium-sized turned parts. At Shenzhen Honyo Prototype, we specialize in advanced CNC screw machining services tailored to meet the exacting standards of industries such as automotive, medical devices, electronics, and industrial equipment. Our expertise ensures your components are manufactured with micron-level accuracy, consistent quality, and rapid turnaround times.

CNC screw machines—also known as automatic lathes or Swiss-type lathes in certain configurations—are ideal for producing complex cylindrical parts from bar stock with minimal human intervention. These machines excel in volume production, offering tight tolerances, excellent surface finishes, and the ability to perform multiple operations in a single setup, including turning, threading, drilling, grooving, and knurling.

At Honyo Prototype, we operate state-of-the-art CNC screw machines equipped with multi-axis control and bar feed systems, enabling continuous production runs with minimal downtime. Our skilled machinists and engineers work closely with your design team to optimize part geometry, material selection, and machining strategy for manufacturability, cost-efficiency, and performance.

Whether you’re developing a prototype or scaling up to full production, our facility supports a wide range of materials including brass, stainless steel, aluminum, carbon steel, and engineering plastics. We also provide secondary operations such as heat treatment, plating, anodizing, and precision cleaning to deliver fully finished components ready for assembly.

To ensure quality throughout the production cycle, we implement rigorous in-process inspections and final quality checks using precision measurement tools, including CMMs, optical comparators, and surface roughness testers. Our ISO-compliant quality management system guarantees that every part meets your specifications and industry standards.

Below is an overview of our CNC screw machine capabilities:

| Parameter | Specification |

|——————————-|——————————————–|

| Maximum Bar Diameter | 20 mm (0.79 in) |

| Minimum Feature Size | 0.3 mm (0.012 in) |

| Typical Tolerances | ±0.01 mm (±0.0004 in) |

| Standard Surface Finish | Ra 0.8–1.6 μm (32–63 μin) |

| Materials Supported | Brass, Stainless Steel, Aluminum, Steel, Plastics |

| Production Volume Range | Prototypes to 100,000+ units |

| Lead Time (Typical) | 7–15 days (depending on complexity) |

| Secondary Operations | Threading, knurling, drilling, tapping, surface treatments |

Starting your project with Honyo Prototype is simple. We invite you to share your design files (STEP, IGES, DWG, or PDF) and receive a comprehensive manufacturability analysis and competitive quote within 24 hours. Our engineering team is available to provide DFM feedback to optimize cost, lead time, and performance.

Contact Susan Leo today to discuss your CNC screw machine requirements. With her extensive experience in precision manufacturing project management, Susan will guide you through every step—from initial inquiry to final delivery.

Email: info@hy-proto.com

Name: Susan Leo

Company: Shenzhen Honyo Prototype

Service: CNC Machining – Screw Machine Parts

Let us help you turn your design into high-precision reality—efficiently, reliably, and on time.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.