Contents

Manufacturing Insight: Accurate Cnc

Manufacturing Insight Accurate CNC Machining at Shenzhen Honyo Prototype

Precision CNC machining forms the cornerstone of reliable prototyping and low-volume production for demanding engineering applications. At Shenzhen Honyo Prototype, we define accurate CNC as the consistent achievement of tight geometric tolerances, superior surface finishes, and dimensional repeatability within complex part geometries—critical for aerospace, medical, and semiconductor components where failure is not an option. This capability transcends basic machine operation; it requires integrated process control, environmental management, and metrology traceability to international standards. Our facility leverages advanced multi-axis machining centers paired with rigorous in-process verification to transform digital models into physical components meeting ±0.005 mm tolerances, even in challenging materials like Inconel 718 or PEEK.

Honyo Prototype’s accuracy advantage stems from systematic engineering controls across three pillars. First, our machine fleet undergoes continuous thermal compensation and laser calibration cycles, minimizing drift during extended operations. Second, we enforce strict material certification and pre-machining stress-relief protocols to prevent distortion. Third, every critical feature undergoes real-time validation via Renishaw probes and offline CMM verification against GD&T callouts. This eliminates guesswork, ensuring first-article compliance without iterative rework. Unlike standard job shops, we treat tolerance stacks as a holistic system—not isolated dimensions—optimizing toolpaths to maintain parallelism, flatness, and positional accuracy across interconnected features.

Our technical capabilities are quantified in the table below, reflecting baseline performance for production-ready components under controlled shop conditions. Note that achievable tolerances scale with part complexity, material stability, and feature accessibility—factors our engineering team evaluates during DFM analysis.

| Machine Type | Positioning Accuracy | Typical Tolerances | Max Work Envelope | Common Materials Handled |

|——————–|———————-|——————–|——————-|———————————–|

| 5-Axis Milling | ±0.003 mm | ±0.005 mm | 1200 x 800 x 600 mm | Aluminum 7075, Titanium Grade 5, PTFE |

| High-Speed Milling | ±0.002 mm | ±0.003 mm | 600 x 450 x 300 mm | Steel 4140, PEEK, FR4 |

| Precision Turning | ±0.0015 mm | ±0.0025 mm | Ø300 x 500 mm | Brass C360, Stainless 316L, Nylon |

Accuracy without context is meaningless. Honyo Prototype embeds metrology into the manufacturing narrative: we deliver full first-article inspection reports (FAIRs) with 3D deviation maps, not just pass/fail stamps. This transparency allows clients to correlate physical parts with simulation data, accelerating validation cycles. For instance, our recent collaboration on a satellite sensor housing required 12 interdependent datums within 0.01 mm; our process achieved 0.004 mm composite deviation through adaptive fixturing and iterative probe-based error correction.

Ultimately, accurate CNC at Honyo means engineering trust into every spindle rotation. We combine German-engineered machine tools, ISO 17025-accredited measurement systems, and manufacturing engineers with 15+ years of niche application experience. This triad ensures your prototypes perform identically to production intent—no compromises, no surprises. Partner with us to convert precision requirements into physical reality, backed by data you can validate.

Technical Capabilities

Technical Capabilities: Precision CNC Machining at Shenzhen Honyo Prototype

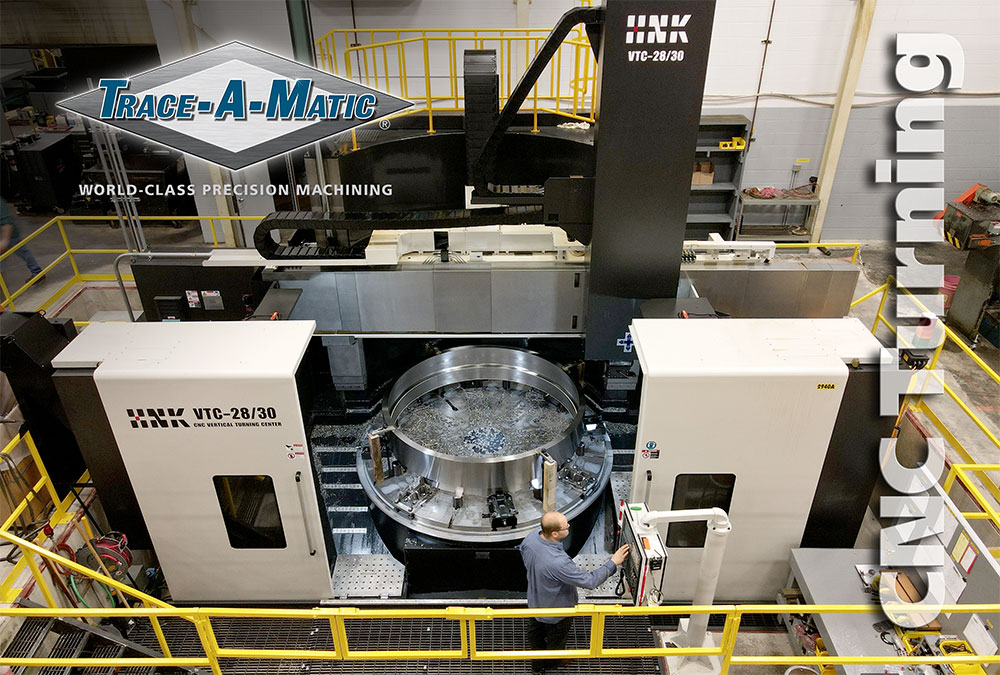

Shenzhen Honyo Prototype delivers high-precision CNC machining services tailored for industries requiring exceptional accuracy, repeatability, and material versatility. Our advanced 3-axis, 4-axis, and 5-axis milling capabilities, combined with precision turning operations, enable us to produce complex geometries with tight tolerances across a wide range of engineering materials. Whether for rapid prototyping, bridge production, or low-volume manufacturing, our machining solutions ensure dimensional consistency and superior surface finishes.

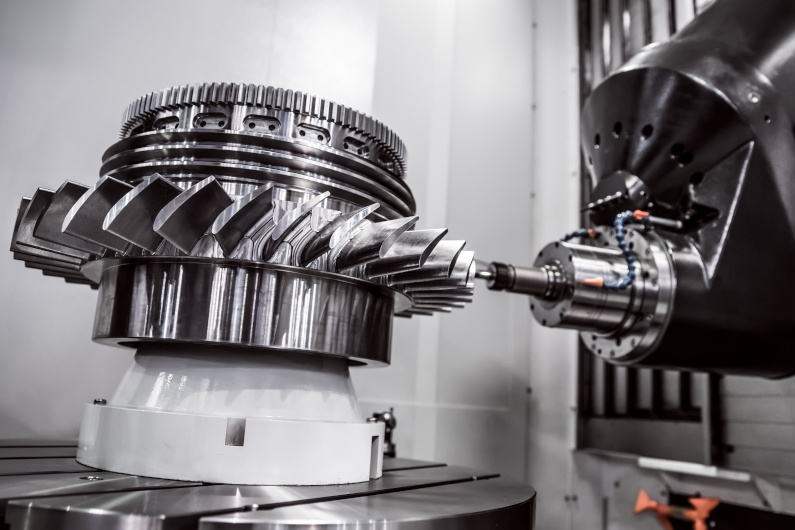

Our 3-axis CNC milling systems are ideal for prismatic parts with straightforward geometries, offering fast cycle times and high accuracy. For components requiring access to multiple sides or intermediate complexity, our 4-axis machines provide rotary indexing for enhanced feature integration. For the most intricate designs—such as aerospace impellers, medical instrumentation, or mold cores—we deploy 5-axis simultaneous machining, which allows toolpath flexibility, reduced setup times, and improved surface precision.

In addition to multi-axis milling, our CNC turning centers support bar-fed and chucking operations for cylindrical and near-net-shaped components. These systems are optimized for high concentricity and fine surface finishes, making them suitable for shafts, fittings, and rotational parts. All machines are maintained to ISO standards and operated by experienced technicians who apply best practices in tool selection, fixturing, and process validation.

A hallmark of our service is our ability to achieve tight tolerances consistently. Standard machining tolerances are held to ±0.05 mm, while precision applications can reach ±0.005 mm depending on part geometry, material, and feature size. Critical dimensions are verified using calibrated CMMs, optical comparators, and surface roughness testers to ensure compliance with engineering requirements.

We support a broad spectrum of metals and engineering plastics, allowing flexibility in material selection based on mechanical, thermal, and environmental demands. Below is a summary of our typical tolerance capabilities and compatible materials.

| Process | Typical Tolerance | Maximum Precision | Common Materials |

|———————-|——————-|——————-|——————|

| 3-Axis Milling | ±0.05 mm | ±0.01 mm | Aluminum 6061, 7075; Steel 1018, 4140; Stainless 303, 316; Brass C360; POM, PC, PEEK |

| 4-Axis Milling | ±0.05 mm | ±0.01 mm | Aluminum 6061, 7075; Stainless 304, 316; Titanium Grade 5; PEEK, Nylon |

| 5-Axis Milling | ±0.05 mm | ±0.005 mm | Aluminum 7075, 2024; Titanium Grade 2, 5; Inconel 718; PEEK, PEI |

| CNC Turning | ±0.05 mm | ±0.01 mm | Aluminum 6061; Stainless 303, 316; Steel 12L14; Brass C360; PTFE, Acetal |

All processes are supported by full documentation, first-article inspection reports (FAIR), and GD&T analysis upon request. At Shenzhen Honyo Prototype, we combine advanced CNC infrastructure with rigorous quality control to deliver components that meet the exacting standards of aerospace, medical, robotics, and high-tech industrial sectors.

From CAD to Part: The Process

From CAD to Part: Honyo Prototype’s Precision CNC Workflow

At Shenzhen Honyo Prototype, our CNC machining process transforms digital designs into high-accuracy physical parts through a rigorously controlled three-stage workflow. This systematic approach minimizes errors, reduces lead times, and ensures first-pass yield for complex prototypes and low-volume production runs. The sequence begins with AI-powered quoting, progresses through collaborative Design for Manufacturability (DFM), and culminates in tightly monitored production.

AI-Powered Quoting System

Upon receiving your CAD file, our proprietary AI engine performs an instant geometric and material feasibility analysis. It cross-references part dimensions, tolerances, and material specifications against machine capabilities, tooling constraints, and historical production data. This initial scan identifies critical red flags—such as undercuts, thin walls below 0.5mm, or non-standard tolerances—before engineering review. The output is a detailed quote with lead time, cost breakdown, and preliminary manufacturability score, enabling rapid project validation. Crucially, this step is not a substitute for human expertise but a filter that accelerates alignment on viable design parameters.

Collaborative DFM Engineering

All projects undergo mandatory DFM analysis by our senior manufacturing engineers. This phase is a dialogue, not a directive: we provide actionable feedback to optimize geometry, material selection, and tolerance stacking while preserving functional intent. Key focus areas include minimizing secondary operations, ensuring proper tool access, and balancing precision with cost efficiency. The table below outlines critical DFM checkpoints:

| DFM Parameter | Honyo Standard Threshold | Common Resolution Path |

|————————|————————–|————————————–|

| Minimum Wall Thickness | ≥ 0.8mm (Aluminum) | Suggest ribbing or geometry revision |

| Hole Depth-to-Diameter | ≤ 10:1 | Propose step drilling or EDM |

| Tolerance (±) | ISO 2768-m | Confirm critical GD&T callouts |

| Surface Finish | Ra 1.6µm (default) | Specify localized polishing zones |

Client approval of the DFM report is required before programming. This collaborative step typically reduces design iterations by 70% and prevents costly mid-production rework.

Precision Production Execution

Approved designs move to our ISO 9001-certified production floor. CNC programs are generated using Mastercam with toolpath simulation validated against the original CAD model. During machining, we enforce real-time process control:

| Verification Stage | Method | Frequency |

|————————|———————————|—————–|

| Setup Calibration | Laser probe + Renishaw tool setter | Per operation |

| In-Process Inspection | CMM spot-checks at 30% completion | Critical features |

| Final Validation | Full CMM report + visual inspection | 100% of parts |

All raw materials are quarantined until certified mill test reports are verified. Parts undergo deburring, cleaning, and non-destructive testing per client specifications. The final output includes a traceability log linking the part to machine parameters, operator ID, and inspection data—ensuring full accountability from CAD file to shipping crate.

This integrated workflow—AI quoting to DFM collaboration to audited production—delivers dimensional accuracy within ±0.005mm while compressing prototyping timelines. By front-loading manufacturability intelligence and embedding quality checks at every phase, Honyo Prototype eliminates guesswork and delivers production-ready parts on the first attempt.

Start Your Project

Start Your Project with Precision CNC Machining at Shenzhen Honyo Prototype

When it comes to high-precision CNC machining, the success of your project begins with the right partner. At Shenzhen Honyo Prototype, we specialize in delivering accurate CNC-machined components tailored to your exact specifications. Whether you’re developing a prototype for validation or scaling into low-volume production, our advanced manufacturing capabilities ensure consistency, speed, and superior quality.

Our CNC machining services integrate state-of-the-art 3-axis, 4-axis, and 5-axis milling, precision turning, and multi-axis Swiss machining to accommodate complex geometries and tight tolerances. With in-house engineering support and rigorous quality control protocols, we produce parts with tolerances as tight as ±0.005 mm, meeting the demands of industries such as aerospace, medical devices, automation, and consumer electronics.

We understand that every project has unique requirements. That’s why we offer a seamless onboarding process designed to accelerate your timeline from concept to physical part. Simply provide your 3D CAD model or technical drawings, and our team will conduct a comprehensive Design for Manufacturability (DFM) analysis to optimize your design for performance, cost-efficiency, and manufacturability—before any material is cut.

Our facility in Shenzhen is equipped with high-speed CNC machines from leading manufacturers, ensuring rapid turnaround without compromising on accuracy. In addition, we support a wide range of materials, including aluminum alloys (6061, 7075), stainless steel (303, 304, 316), titanium, brass, and engineering plastics such as PEEK, Delrin, and nylon. Surface finishing options—including anodizing, bead blasting, powder coating, and passivation—are available to meet both functional and aesthetic requirements.

Below is an overview of our core CNC machining capabilities:

| Feature | Specification |

|——–|—————-|

| Machining Types | 3-axis, 4-axis, 5-axis milling; CNC turning; Swiss machining |

| Maximum Work Envelope | 1200 x 800 x 600 mm (XYZ) |

| Typical Tolerances | ±0.005 mm |

| Materials | Aluminum, stainless steel, titanium, brass, plastics (PEEK, Delrin, etc.) |

| Lead Time | As fast as 3–5 days for prototypes |

| Finishing Options | Anodizing, bead blasting, powder coating, passivation, polishing |

| Quality Standards | ISO 9001:2015 certified, full inspection reports available |

Starting your project with Honyo Prototype is simple and efficient. We prioritize clear communication, technical transparency, and on-time delivery. Our engineering team collaborates closely with clients to resolve design challenges and ensure manufacturability, reducing iterations and minimizing delays.

Ready to bring your design to life? Contact Susan Leo today at info@hy-proto.com to request a quote, submit your CAD files, or discuss your project requirements. With Honyo Prototype, precision isn’t just a promise—it’s built into every part we produce. Let us be your trusted partner in accurate CNC machining.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.