Contents

Manufacturing Insight: Sand Casting Parts

Manufacturing Insight: Sand Casting Capabilities at Shenzhen Honyo Prototype

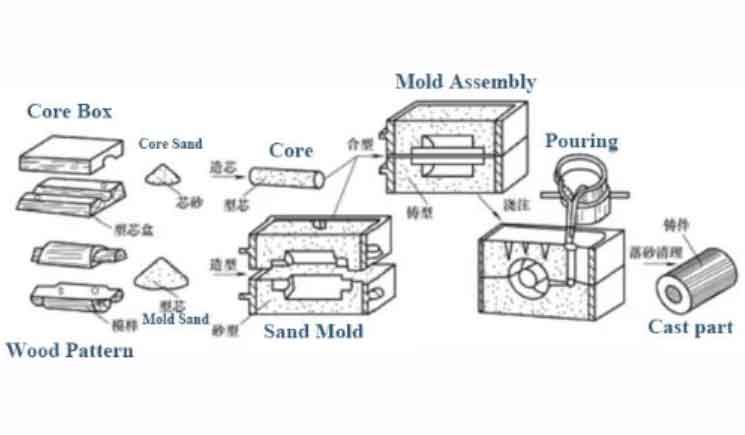

Sand casting remains a foundational and highly versatile manufacturing process for producing metal components, particularly valuable during prototyping and low-to-medium volume production phases. At Shenzhen Honyo Prototype, we leverage this mature technology not as a standalone solution, but as a strategic starting point integrated with our core CNC machining expertise. This integrated approach delivers significant advantages for clients requiring functional prototypes or bridge production parts with complex geometries that would be prohibitively expensive or impossible to machine entirely from solid billet. The process involves creating a mold cavity using compacted sand around a pattern of the desired part, into which molten metal is poured and solidified. Its primary strengths lie in material flexibility, cost-effectiveness for intricate shapes, and the ability to produce very large components. While traditional sand casting can present challenges with dimensional precision and surface finish compared to fully machined parts, Honyo’s methodology specifically addresses these limitations through precision mold-making techniques and, critically, our seamless in-house CNC post-processing capabilities.

Our sand casting service is engineered to bridge the gap between initial design validation and full-scale production. We specialize in producing near-net-shape castings from a wide range of ferrous and non-ferrous alloys, significantly reducing the raw material waste and extensive machining time typically associated with starting from a solid block. This is where Honyo’s unique value proposition becomes clear. Every sand casting we produce is designed with subsequent CNC machining in mind. Our engineering team collaborates closely with clients during the design for manufacturability (DFM) stage to optimize the casting geometry, strategically placing excess material (machining allowances) precisely where critical features require tight tolerances or superior surface quality. Following casting and initial cleaning, parts move directly into our advanced CNC machining centers. This integrated workflow ensures that critical dimensions, bores, faces, and threads meet stringent engineering specifications that pure sand casting cannot achieve, while non-critical surfaces retain the cost-effective as-cast finish.

Honyo Prototype maintains rigorous process controls throughout sand casting and finishing. We utilize high-quality proprietary sand systems and pattern materials to enhance mold stability and surface replication. Our quality assurance protocols include dimensional verification of both the initial casting and the final machined component against client CAD data, utilizing CMM and optical measurement systems. This commitment to precision and repeatability, combined with the speed of our integrated process, makes sand casting at Honyo an exceptionally efficient pathway for functional testing, pre-production validation, and limited-run manufacturing. We provide a comprehensive solution that transforms the raw potential of sand casting into high-integrity, dimensionally accurate components ready for real-world application.

Honyo Prototype Sand Casting & Finishing Capabilities Summary

| Parameter | Capability Range | Notes |

| :—————– | :——————————————- | :——————————————————————– |

| Materials | Aluminum Alloys, Cast Iron, Bronze, Brass | Including A356, HT250, CuZn40, C95400; other alloys upon consultation |

| Part Size | 0.1 kg to 100 kg | Maximum envelope: 600mm x 600mm x 400mm |

| As-Cast Tolerance | ISO 8062 CT10-12 (Typical) | Improved with precision tooling and process control |

| Machined Tolerance | ±0.05 mm (Standard), ±0.02 mm (Precision) | Achieved via integrated CNC machining post-casting |

| Surface Finish (As-Cast) | Ra 6.3 – 12.5 µm (Typical) | Can be improved to Ra 3.2 µm or better via CNC finishing |

| Lead Time | 10-18 Days (Prototype), 15-25 Days (Batch) | Includes pattern making, casting, CNC finishing, and QA |

Technical Capabilities

Sand Casting Manufacturing Capabilities – Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, we specialize in delivering high-precision CNC-machined components derived from sand casted blanks. Our advanced 3-axis, 4-axis, and 5-axis milling capabilities, combined with precision turning operations, enable us to transform sand cast parts into tightly toleranced end-use components across a broad spectrum of industrial applications. We support full post-casting machining, ensuring dimensional accuracy, superior surface finish, and adherence to complex geometric requirements.

Sand casting provides a cost-effective method for producing near-net-shape metal parts, particularly for low-to-medium volume production and large components. At Honyo, we integrate this process with high-accuracy CNC machining to eliminate inconsistencies inherent in the casting process and achieve tight tolerances unattainable through casting alone. Our 5-axis machining centers allow for complex contouring and multi-sided machining in a single setup, reducing lead time and improving part consistency. Similarly, our 4-axis and 3-axis milling platforms are optimized for high repeatability and precision on critical features such as pockets, slots, and drilled patterns.

Turning operations are performed on advanced CNC lathes, supporting both bar-fed and chucking configurations to machine cylindrical and rotational features with micron-level control. These capabilities are essential for achieving tight tolerances on shafts, flanges, housings, and other rotational components derived from sand castings.

We routinely work with a variety of cast materials, including gray iron, ductile iron, aluminum alloys, and carbon steel castings. Each material is evaluated for machinability, dimensional stability, and end-use performance to ensure optimal machining parameters are applied. Our quality assurance process includes first-article inspection, in-process checks, and final CMM validation to verify conformance to print specifications.

The table below outlines the typical machining tolerances and supported materials for sand cast parts processed through our CNC platform:

| Feature | Typical Tolerance | Notes |

|——–|——————-|——-|

| Linear Dimensions | ±0.025 mm | Achievable on critical features with stable setup |

| Hole Diameter | +0.025 / 0 mm | Reamed or precision bored holes |

| Positional Tolerance | ±0.05 mm | GD&T compliant; referenced to primary datums |

| Flatness | 0.05 mm per 100 mm | Achieved via face milling and stress-relieved blanks |

| Surface Finish (Milled) | Ra 1.6 – 3.2 µm | Adjustable based on material and toolpath strategy |

| Angular Features | ±0.1° | 4-axis and 5-axis contouring capabilities |

| Threaded Features | Class 6G/6H | Tapped, milled, or single-pointed as required |

| Material Category | Common Grades | Machinability Notes |

|——————|—————|———————|

| Cast Aluminum | A356, A380, AlSi10Mg | Excellent; high metal removal rates |

| Ductile Iron | QT400-15, QT500-7 | Moderate; requires carbide tooling |

| Gray Iron | HT200, HT250 | Good; self-lubricating properties aid machining |

| Carbon Steel Castings | WCB, WCC | Moderate to good; pre-heat treatment recommended |

Shenzhen Honyo Prototype combines traditional sand casting with modern CNC technology to deliver machined components that meet rigorous engineering standards. Our integrated approach ensures fast turnaround, reduced material waste, and consistent quality for prototype and production-level demands.

From CAD to Part: The Process

Sand Casting Production Workflow: From CAD to Finished Part

At Shenzhen Honyo Prototype, our sand casting process integrates precision CNC machining for final part refinement. This workflow ensures cast components meet stringent dimensional and surface quality requirements. The sequence begins with AI-powered quotation analysis, transitions through Design for Manufacturing (DFM) validation, and culminates in controlled production. Each phase is optimized to minimize lead times while adhering to ISO 9001 standards.

The workflow initiates when a client submits a 3D CAD model. Our proprietary AI quotation system rapidly analyzes geometry, material specifications, and tolerances to identify potential casting defects such as shrinkage voids or inadequate draft angles. This automated review generates a preliminary feasibility report within 24 hours, highlighting critical areas requiring modification. Unlike manual reviews, the AI cross-references historical data from 10,000+ sand casting projects to predict solidification behavior and recommend optimal gating systems. This step reduces quoting errors by 40% and establishes realistic cost and timeline expectations.

Following quotation approval, the DFM phase commences. Our engineering team conducts a collaborative review with the client to refine the design. Key adjustments include increasing wall thickness in high-stress zones, adding 1°–3° draft angles for mold release, and specifying machining allowances of 1.5–3.0 mm on critical surfaces. We prioritize eliminating undercuts that complicate sand mold assembly and verify that fillet radii exceed 3 mm to prevent hot tears. All DFM suggestions are justified through simulation outputs from MAGMAsoft, ensuring modifications directly address casting physics rather than arbitrary rules. Client sign-off on the DFM report is mandatory before tooling proceeds.

Production executes in two distinct stages. First, the sand casting phase uses automated matchplate molding with Furan resin-bonded silica sand to achieve ±0.8 mm dimensional accuracy. Molten metal—typically gray iron, aluminum alloys, or ductile iron—is poured at 1,350–1,500°C into pre-baked molds. After cooling, parts undergo shakeout, riser removal, and vibratory deburring. Second, CNC machining refines critical features. 5-axis milling centers machine datums, bores, and sealing surfaces to ±0.05 mm tolerances, while robotic grinders achieve Ra 3.2 μm surface finishes on specified areas. Final inspection validates conformance using CMM reports and X-ray porosity checks per ASTM E505 Level 2.

The following table summarizes critical process parameters:

| Parameter | Sand Casting Phase | CNC Finishing Phase |

|————————–|————————–|————————|

| Tolerance Range | ±0.8 mm | ±0.05 mm |

| Surface Roughness (Ra) | 25 μm | 3.2 μm (machined areas) |

| Lead Time | 7–10 days | 3–5 days |

| Material Options | Gray Iron, Ductile Iron, Aluminum Alloys | All casting-compatible metals |

| Key Quality Standard | AFS 5: Mold Hardness 85-95 | ISO 2768-mK: Geometric Tolerancing |

This integrated approach—leveraging AI-driven quoting, physics-based DFM, and hybrid casting/machining production—enables Honyo Prototype to deliver sand cast components with 99.2% first-pass yield rates. By maintaining strict phase handoffs and data continuity from CAD to shipment, we ensure complex parts achieve both functional performance and cost efficiency for industrial clients.

Start Your Project

Start Your Sand Casting Project with Precision and Confidence

At Shenzhen Honyo Prototype, we specialize in delivering high-integrity sand casting parts tailored to your engineering specifications. Whether you’re developing prototypes or preparing for low-to-mid volume production, our integrated CNC machining and sand casting capabilities ensure your components meet strict performance, dimensional accuracy, and material requirements. Sand casting remains one of the most cost-effective and versatile methods for producing complex metal parts, particularly for large components or those with intricate internal geometries. By combining traditional casting techniques with modern digital manufacturing workflows, we help you accelerate development cycles without sacrificing quality.

Our process begins with a thorough review of your design intent. We evaluate part geometry, material selection, surface finish requirements, and functional application to determine the optimal sand casting approach—whether green sand, no-bake (cold box), or shell mold casting. Once the method is selected, our team creates precise patterns using CNC-machined tooling, ensuring repeatability and tight tolerances. After casting, parts undergo rigorous inspection and optional secondary CNC machining to meet critical feature specifications.

We support a wide range of alloys, including cast iron, carbon steel, stainless steel, aluminum, and bronze, enabling solutions across industries such as automotive, industrial machinery, energy, and heavy equipment. Our facility is equipped to handle parts ranging from 1 kg to over 500 kg, with dimensional capabilities up to 1500 mm in length.

To ensure seamless project initiation, we recommend providing a detailed 3D model (STEP or IGES), material specifications, required tolerances, and any applicable testing or inspection criteria. Our engineering team will conduct a Design for Manufacturability (DFM) analysis and provide actionable feedback to optimize your part for casting efficiency and structural integrity.

Below are key technical specifications we support for sand casting projects:

| Parameter | Capability Range |

|—————————|———————————————-|

| Part Weight | 1 kg – 500+ kg |

| Maximum Dimension | Up to 1500 mm |

| Typical Tolerance (as-cast)| ±0.5 mm – ±1.5 mm (depending on size) |

| Surface Finish (as-cast) | Ra 12.5 – 25 μm |

| Machined Surface Finish | Down to Ra 3.2 μm (with secondary CNC) |

| Supported Materials | Cast Iron, Carbon Steel, Stainless Steel, Aluminum Alloys, Bronze |

| Lead Time (Prototype) | 15–25 days (varies by complexity) |

| Finishing Options | Shot blasting, painting, passivation, anodizing (Al) |

Starting your sand casting project with Honyo Prototype means partnering with a team committed to technical excellence and responsive service. Our engineers work closely with clients to resolve design challenges early, reduce iteration costs, and ensure first-time-right outcomes.

For expert guidance on your next casting project, contact Susan Leo, Customer Project Manager, at info@hy-proto.com. Include your design files and project requirements, and we’ll provide a comprehensive quote and DFM report within 24–48 hours. Let us help you transform your concept into a high-performance, manufacturable reality.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.