Contents

Manufacturing Insight: Aerospace Cnc Machine

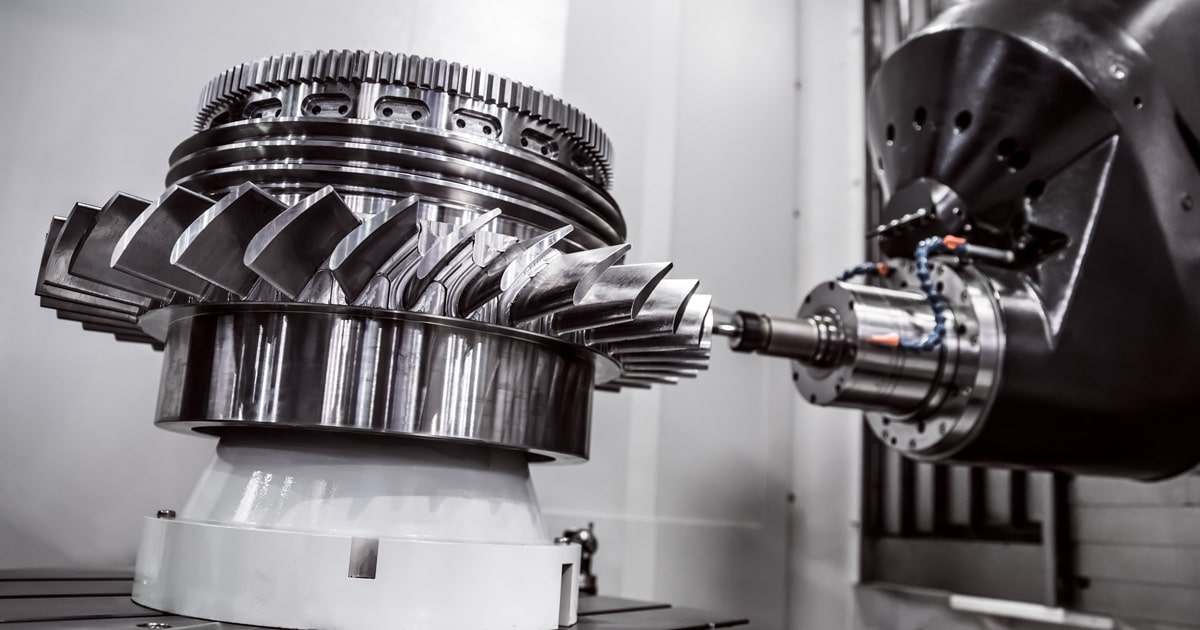

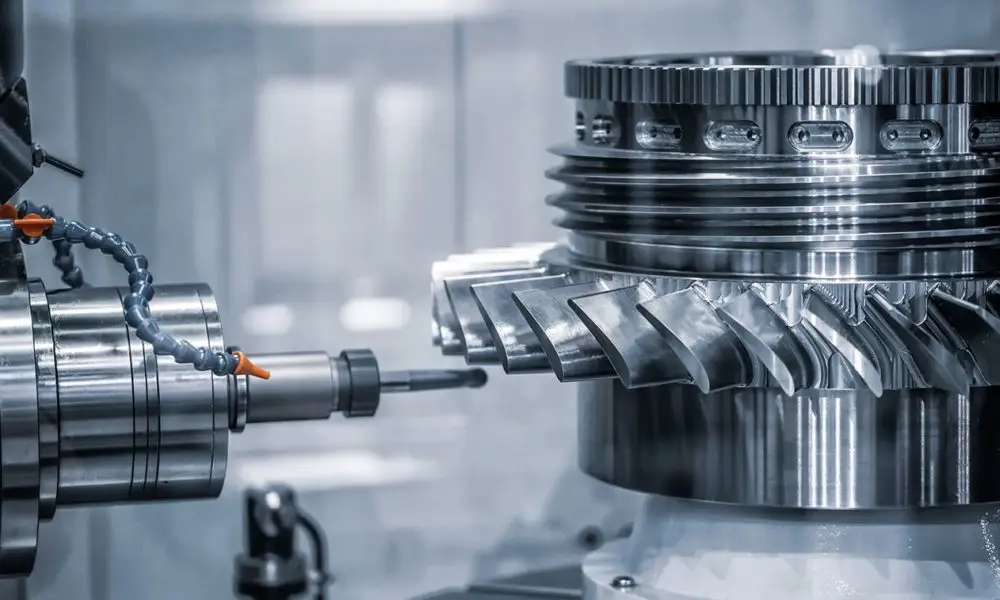

Aerospace CNC Machining: Precision Engineering for Critical Applications

Aerospace CNC machining represents the pinnacle of precision manufacturing, where dimensional accuracy, material integrity, and process repeatability are non-negotiable. Components for flight-critical systems—such as turbine blades, structural brackets, and hydraulic manifolds—demand tolerances within ±0.0002 inches and flawless surface finishes to withstand extreme operational stresses. The inherent complexity of aerospace geometries, combined with challenging materials like Inconel 718, titanium alloys, and carbon-fiber composites, necessitates advanced multi-axis CNC platforms capable of maintaining thermal stability and micron-level precision throughout extended production cycles. At Shenzhen Honyo Prototype, we address these demands through a synergistic integration of cutting-edge hardware, rigorous process validation, and domain-specific engineering expertise.

Honyo Prototype’s Aerospace CNC Capabilities

Honyo Prototype operates a dedicated aerospace machining cell featuring 5-axis vertical and horizontal milling centers from industry-leading OEMs, engineered specifically for high-mix, low-volume aerospace prototyping and production. Our machines incorporate direct-drive spindles with HSK-A63 tooling, integrated probing systems for in-process verification, and FEM-optimized cast iron frames to minimize vibration-induced deviations. Material handling is optimized for aerospace-grade substrates, with adaptive feed-rate controls to prevent work hardening in nickel-based superalloys and specialized coolant delivery for thermal management during deep cavity milling. Crucially, our workflows embed AS9100-compliant process controls from initial design for manufacturability (DFM) analysis through final first-article inspection (FAI), ensuring traceability via nested part serialization and real-time SPC data logging.

The core technical specifications of our flagship aerospace machining platform are detailed below:

| Parameter | Specification | Aerospace Relevance |

|————————|—————————————-|—————————————–|

| Axis Configuration | 5-axis simultaneous (X, Y, Z, B, C) | Enables single-setup complex contours |

| Positioning Accuracy | ±0.0001 inches (2.5 µm) | Meets MIL-STD-883 Class B requirements |

| Repeatability | ±0.00004 inches (1 µm) | Critical for stack-up tolerance control |

| Max Work Envelope | 24″ x 20″ x 16″ (610 x 508 x 406 mm) | Accommodates medium-scale assemblies |

| Spindle Speed Range | 20–30,000 RPM | Optimized for hard-metals & composites |

| Tool Capacity | 60-tool ATC | Reduces non-cut time for complex parts |

Our technical team possesses deep experience in navigating NADCAP audit requirements and material-specific challenges, such as mitigating residual stress in thin-walled aluminum enclosures or achieving Ra < 8 µin finishes on titanium landing gear components. All aerospace programs undergo rigorous pre-production dry runs using machine simulation software to validate toolpaths against collision risks and surface deviation thresholds. Coupled with our in-house CMM metrology lab (calibrated to ISO 17025 standards) and material certification documentation, Honyo delivers not just components, but certified readiness for flight testing and certification. For aerospace innovators requiring zero-defect manufacturing, Honyo Prototype provides the technical infrastructure and process discipline to transform complex designs into airworthy realities.

Technical Capabilities

Shenzhen Honyo Prototype operates advanced CNC machining systems engineered specifically to meet the stringent demands of the aerospace industry. Our technical capabilities span 3-axis, 4-axis, and 5-axis milling, as well as precision CNC turning, enabling us to produce complex, mission-critical components with exceptional accuracy and repeatability. These machines are integrated with high-speed spindles, rigid tooling systems, and real-time monitoring software to ensure optimal performance under the rigorous tolerances required in aerospace applications.

Our 5-axis CNC milling platforms utilize simultaneous multi-axis motion, allowing for the machining of highly complex geometries in a single setup. This reduces cumulative error, improves surface finish, and significantly cuts production time. The 4-axis systems are ideal for components requiring rotary indexing, while the 3-axis platforms deliver high precision for simpler, high-volume parts. All milling centers are equipped with automated tool changers, probing systems, and thermal compensation to maintain dimensional stability across extended runs.

For rotational components such as fittings, bushings, and shafts, our CNC turning centers combine live tooling with Y-axis capabilities, enabling mill-turn operations that reduce the need for secondary processes. These machines support bar feeding and part catchers for unattended operation, increasing throughput without sacrificing quality.

Tight tolerance machining is a cornerstone of our aerospace services. We consistently achieve tolerances down to ±0.0002″ (±0.005 mm) on critical dimensions, supported by in-process inspection using coordinate measuring machines (CMM) and laser probing. Our quality management system is ISO 9001:2015 certified, and we adhere to AS9100 standards for aerospace manufacturing, ensuring full traceability and process control.

The following table outlines our typical tolerance capabilities and compatible aerospace materials:

| Feature | Standard Tolerance | Typical Materials |

|——–|——————–|——————-|

| Linear Dimensions | ±0.0002″ (±0.005 mm) | 7075, 6061, 2024 Aluminum |

| Hole Diameter | +0.0000″ / -0.0004″ (+0.000 mm / -0.010 mm) | Ti-6Al-4V (Grade 5), CP Titanium |

| Flatness | 0.0004″ per inch (0.01 mm per 25 mm) | Inconel 718, Inconel 625 |

| Positional Tolerance | ±0.0003″ (±0.008 mm) | 17-4 PH, 303, 304, 316 Stainless Steel |

| Surface Roughness (Ra) | 16–32 μin (0.4–0.8 μm) | Magnesium Alloys, Beryllium Copper |

All materials are sourced from certified suppliers and undergo incoming inspection to verify chemical and mechanical properties. We also support post-machining treatments such as anodizing, passivation, and heat treatment through qualified partners to meet aerospace finish and performance requirements.

With a focus on precision, reliability, and compliance, Shenzhen Honyo Prototype delivers CNC-machined aerospace components that meet the highest standards of performance and safety.

From CAD to Part: The Process

Aerospace CNC Production Workflow: From CAD to Certified Part

At Shenzhen Honyo Prototype, our aerospace CNC machining process adheres to stringent AS9100 standards, ensuring precision, traceability, and compliance. The workflow begins with AI-driven quoting, transitions through collaborative Design for Manufacturability (DFM), and culminates in rigorously controlled production. This integrated approach minimizes risk while accelerating time-to-market for critical components.

The AI Quote phase initiates upon receipt of a validated CAD model. Our proprietary AI engine analyzes geometric complexity, material specifications (e.g., Ti-6Al-4V, Inconel 718), tolerance requirements, and surface finish criteria to generate an instant, data-backed cost and timeline estimate. This system identifies potential manufacturability flags—such as thin-wall sections below 0.5mm or deep cavities exceeding aspect ratios of 10:1—before engineering engagement, reducing quotation errors by 40%. Clients receive transparent feedback on cost drivers, enabling informed design adjustments prior to formal commitment.

Design for Manufacturability (DFM) follows quote acceptance and is non-negotiable for aerospace projects. Honyo’s engineering team collaborates directly with the client to refine the design, focusing on eliminating non-value-added operations and ensuring producibility within ±0.005mm tolerances. Key DFM validations include:

| Parameter | Aerospace Threshold | Honyo Validation Action |

|————————|————————–|——————————————|

| Minimum Wall Thickness | ≥ 0.3mm | Structural simulation & toolpath optimization |

| Hole Depth-to-Diameter | ≤ 15:1 | Peck drilling strategy validation |

| Surface Roughness | Ra ≤ 0.8µm (critical) | Tool selection & spindle speed analysis |

| Feature Accessibility | Full 5-axis clearance | Collision avoidance simulation |

This phase typically resolves 95% of potential production issues, preventing costly rework and ensuring compliance with NADCAP audit requirements.

Production Execution commences only after DFM sign-off. Parts are machined on certified 5-axis CNC systems (DMG MORI, Makino) with in-process probing for real-time dimensional verification. All aerospace materials undergo full material certification (MTR traceability), and machines are calibrated daily per ISO 230-2 standards. Critical stages include:

First, raw stock is inspected for dimensional conformity and material grade verification using optical comparators. Next, our engineers program optimized toolpaths leveraging hyperMILL software, incorporating adaptive clearing strategies to minimize tool deflection in high-temp alloys. During machining, in-process inspections at defined checkpoints (e.g., after roughing, semi-finishing) validate critical features against GD&T callouts using on-machine touch probes. Final inspection employs a Zeiss CONTURA CMM with 2.5µm accuracy, generating full FAI reports per AS9102 standards. All data—including machine telemetry, inspection results, and operator logs—is archived for full lot traceability.

This closed-loop workflow—from AI-informed quoting through DFM collaboration to auditable production—ensures Honyo delivers aerospace components that meet mission-critical performance demands while optimizing cost and lead time. Every part ships with comprehensive certification documentation, affirming compliance from digital model to physical delivery.

Start Your Project

Start Your Aerospace CNC Machining Project with Honyo Prototype

When precision, reliability, and compliance are non-negotiable, aerospace manufacturers trust Shenzhen Honyo Prototype for high-accuracy CNC machining solutions. Our expertise in aerospace-grade components ensures that every part meets the rigorous demands of flight-critical applications. From prototyping to low-volume production, we deliver machined parts with tight tolerances, superior surface finishes, and full material traceability—essential for certification and performance in extreme environments.

At Honyo Prototype, we specialize in multi-axis CNC machining using advanced 3-, 4-, and 5-axis systems capable of producing complex geometries with micron-level accuracy. Our facility is equipped to handle high-performance materials commonly used in aerospace, including titanium alloys (Ti-6Al-4V), Inconel 718, aluminum 7075-T6, and various high-strength composites. Every project follows strict quality control protocols aligned with ISO 9001 standards, ensuring repeatable results and full compliance with industry specifications.

We understand that aerospace projects require more than just machining—they demand engineering collaboration, rapid turnaround, and responsive communication. That’s why we’ve built a streamlined workflow that begins the moment you reach out. Whether you’re developing flight control components, engine mounts, or structural brackets, our team provides expert feedback on design for manufacturability (DFM), material selection, and cost optimization—all before production begins.

To ensure seamless project initiation, we support a wide range of file formats, including STEP, IGES, SolidWorks, and DXF, and offer real-time updates throughout the manufacturing cycle. With in-house metrology, including CMM and optical inspection systems, we verify every dimension to meet your exact requirements.

Below are key capabilities that define our aerospace CNC machining services:

| Feature | Specification |

|——–|—————|

| Machine Types | 3-axis, 4-axis, 5-axis CNC milling and turning centers |

| Maximum Work Envelope | 1200 × 800 × 600 mm (47 × 31.5 × 23.6 in) |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Standard Tolerances | ±0.025 mm (tighter upon request) |

| Surface Finish | As low as Ra 0.8 µm (polishing available) |

| Materials | Aluminum (2024, 6061, 7075), Titanium (Gr5), Stainless Steel (17-4PH), Inconel, Magnesium, PEEK, and composites |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP documentation available |

Starting your project is simple. Contact Susan Leo, our dedicated Aerospace Project Coordinator, to discuss your requirements, receive a competitive quote, and begin the path to precision manufacturing. With Honyo Prototype, you gain a partner committed to technical excellence, on-time delivery, and engineering support tailored to the aerospace sector.

Email Susan Leo at info@hy-proto.com today to launch your next aerospace CNC machining project.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.