Contents

Manufacturing Insight: Steel Machinery

Steel Machinery Manufacturing: Precision Engineering for Demanding Applications

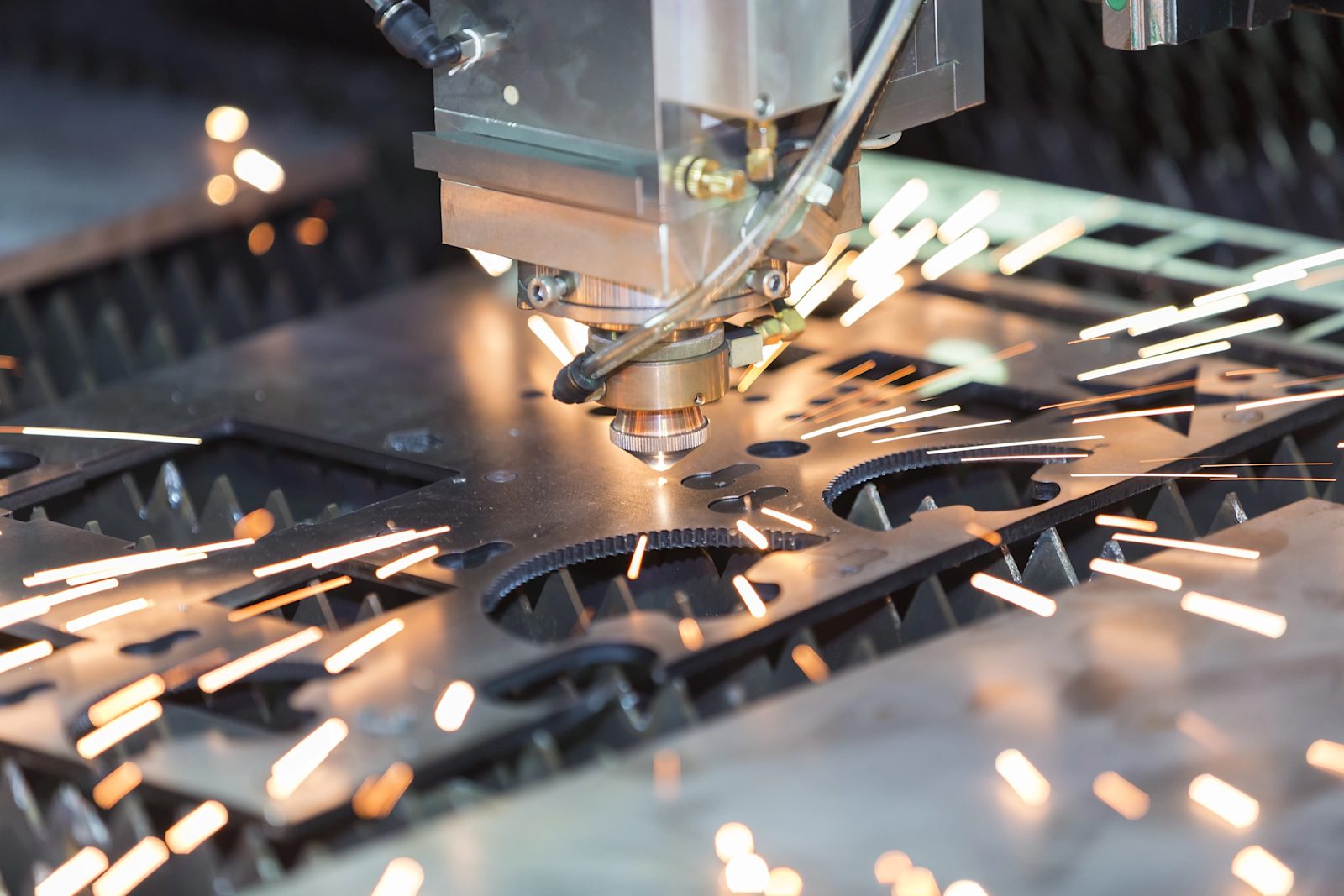

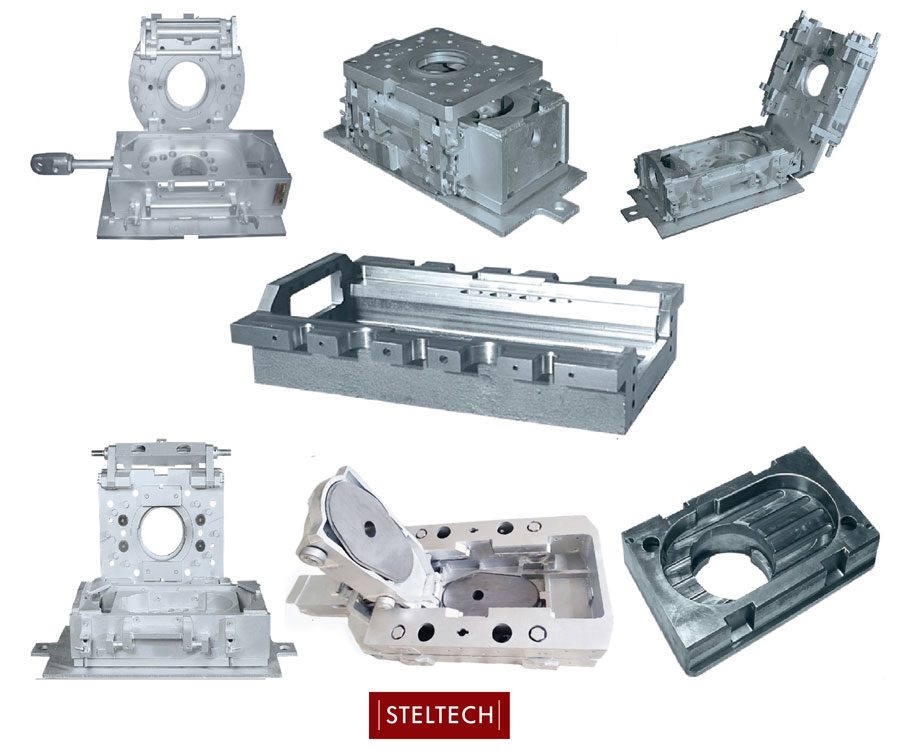

Steel remains the cornerstone material for industrial machinery due to its exceptional strength, wear resistance, and thermal stability. However, its demanding metallurgical properties—particularly high hardness and work-hardening tendencies—require advanced CNC machining expertise to achieve tight tolerances and functional reliability. At Shenzhen Honyo Prototype, we specialize in transforming raw steel alloys into mission-critical machinery components through rigorously controlled processes that address inherent challenges like thermal distortion and tool wear. Our approach leverages high-rigidity machining centers, optimized toolpath strategies, and real-time process monitoring to ensure dimensional integrity across complex geometries, from gear housings to hydraulic manifolds.

CNC machining excels for steel machinery by enabling precise material removal under high cutting forces, which is essential for maintaining structural integrity in load-bearing applications. Unlike softer materials, steel demands slower feed rates, specialized carbide tooling, and meticulous coolant management to prevent micro-fissures and surface degradation. Honyo’s protocols include pre-machining stress-relief annealing for critical components and in-process inspections using CMMs to mitigate residual stress effects. This focus on process stability ensures parts meet stringent industry standards for fatigue resistance and assembly compatibility, reducing field failures in end-use machinery.

Honyo Prototype operates a dedicated steel machining division equipped with 5-axis vertical and horizontal machining centers, capable of handling both prototyping and low-volume production runs. Our technical capabilities are engineered to exceed typical industry benchmarks for steel fabrication, as demonstrated below:

| Parameter | Specification | Honyo Capability |

|——————–|———————|——————————|

| Material Grades | 4140, 4340, 304/316 Stainless, A36 | Full certification traceability |

| Tolerance Range | ±0.01mm standard | ±0.005mm achievable |

| Max Work Envelope | 1200 x 800 x 600 mm | 1500 x 1000 x 750 mm |

| Surface Finish | Ra 1.6 µm standard | Ra 0.4 µm with polishing |

| Secondary Operations | Heat treatment, Passivation, Welding | In-house coordination with NADCAP-certified partners |

Beyond machining, Honyo integrates finishing services critical for machinery longevity, including precision grinding for bearing seats and electroless nickel plating for corrosion-prone components. Our engineering team collaborates early in the design phase to recommend manufacturability improvements—such as optimizing wall thickness or eliminating undercuts—that reduce cycle times by up to 30% without compromising structural performance. This proactive DFM analysis, combined with our ISO 9001-certified quality system, ensures steel machinery parts transition seamlessly from prototype validation to production readiness.

For OEMs developing industrial equipment, partnering with a specialist in steel CNC machining mitigates risk in performance-critical applications. Honyo Prototype delivers the technical rigor and scalability needed to transform steel’s inherent advantages into reliable machinery, backed by decades of metallurgical expertise and a commitment to on-time delivery. Engineers can achieve optimal balance between cost efficiency and operational durability through our end-to-end steel fabrication ecosystem.

Technical Capabilities

Shenzhen Honyo Prototype delivers precision CNC machining services tailored for steel machinery components used in industrial automation, power generation, heavy equipment, and high-performance manufacturing systems. Our advanced 3-axis, 4-axis, and 5-axis milling capabilities, combined with precision turning, enable us to produce complex geometries with tight tolerances and excellent surface finishes. We specialize in machining a wide range of steel alloys, ensuring structural integrity, wear resistance, and long-term reliability under demanding operational conditions.

Our 3-axis milling systems are ideal for prismatic parts with straightforward geometries, offering high-speed material removal and consistent accuracy. For components requiring indexing or rotational features, our 4-axis CNC mills provide enhanced flexibility with A-axis rotation, enabling efficient machining of features such as grooves, slots, and off-center holes. For the most complex steel parts—such as turbine housings, gearboxes, and structural brackets—our 5-axis simultaneous milling centers deliver unparalleled precision. These systems eliminate the need for multiple setups, reduce cumulative error, and improve surface finish on contoured surfaces and deep cavities.

Complementing our milling capabilities, our CNC turning centers handle bar stock up to Ø300 mm and lengths of 800 mm, supporting both chucker and bar-fed operations. Multi-axis turning with live tooling allows us to produce turned-milled components in a single setup, reducing lead times and improving dimensional consistency. Our machines are equipped with high-pressure coolant systems and tool monitoring for optimal performance when machining hard steels.

Tight tolerance control is a hallmark of our steel machining process. We maintain standard tolerances of ±0.025 mm on critical dimensions, with the ability to achieve ±0.005 mm on customer-requested features through precision finishing and in-process inspection. Our metrology suite includes coordinate measuring machines (CMM), optical comparators, and surface roughness testers to verify compliance at every stage.

The following table outlines our key machining capabilities and tolerance specifications by process and material type:

| Material Type | Process | Max Work Envelope (mm) | Standard Tolerance (±mm) | Achievable Tolerance (±mm) | Surface Roughness (Ra µm) |

|———————|——————-|————————-|—————————|—————————–|—————————-|

| Mild Steel (A36, 1018) | 3-Axis Milling | 1000 × 600 × 500 | 0.025 | 0.010 | 3.2–1.6 |

| Stainless Steel (304, 316) | 4-Axis Milling | 800 × 500 × 400 | 0.025 | 0.008 | 1.6–0.8 |

| Tool Steel (D2, A2) | 5-Axis Milling | 600 × 500 × 400 | 0.015 | 0.005 | 0.8–0.4 |

| Alloy Steel (4140, 4340) | CNC Turning | Ø300 × 800 | 0.020 | 0.008 | 1.6–0.8 |

| Hardened Steel (HRC 50–58) | 5-Axis Milling | 500 × 400 × 300 | 0.020 | 0.010 | 0.8–0.4 |

We support a full range of post-machining treatments, including annealing, stress relieving, nitriding, and various coating options, to meet the mechanical and environmental demands of steel machinery applications. All processes are controlled under ISO 9001:2015 standards, ensuring repeatability and quality across prototype, bridge, and low-volume production runs.

From CAD to Part: The Process

Shenzhen Honyo Prototype: CNC Machining Production Process Guide for Steel Machinery Components

This section details the standardized workflow for transforming customer CAD models into precision steel machinery components at Shenzhen Honyo Prototype. Our integrated process ensures manufacturability, quality, and efficiency from initial inquiry through final part delivery, specifically optimized for the challenges of steel machining including material hardness, thermal management, and stringent geometric tolerances.

AI-Powered Quoting (0-24 Hours)

Upon receipt of a validated CAD model (STEP, IGES, or native formats), our proprietary AI quoting engine performs an initial geometric and material analysis. For steel components, the system automatically identifies critical factors such as alloy grade implications (e.g., 4140 vs. 304 SS), estimated machining time based on feature complexity, and raw material requirements. The AI cross-references real-time data on tooling availability, machine center loads, and material costs specific to steel stock. This generates a preliminary quote with accurate lead time estimates and flags potential high-risk features requiring immediate engineering review, significantly reducing traditional quoting latency while providing clients with actionable data before formal commitment.

Engineering-Driven DFM Analysis (24-72 Hours Post-Quote Acceptance)

Following client approval of the quote, our manufacturing engineering team conducts a rigorous Design for Manufacturability (DFM) review focused explicitly on steel machinability. This phase is critical for preventing costly errors and ensuring first-pass yield. Engineers evaluate feature geometry against steel’s properties, assessing risks like thin-wall deflection during milling, hole depth-to-diameter ratios exceeding drill capabilities, and surface finish requirements achievable with standard steel cutting parameters. We collaborate directly with the client to propose optimized solutions, such as adjusting fillet radii to reduce tool stress or modifying non-critical tolerances to standard machining capabilities. The DFM report provides clear justification for any required design modifications, ensuring transparency and shared understanding of manufacturability constraints.

Precision CNC Production Execution

Once DFM is finalized and approved, parts enter controlled production on our multi-axis CNC machining centers. Steel components undergo strict process controls:

Critical Steel Machining Parameters

| Parameter | Standard Capability | High-Precision Capability | Notes for Steel |

|——————–|———————|—————————|————————————-|

| Tolerance (Linear) | ±0.05 mm | ±0.025 mm | Tighter tolerances require slow finish passes, stress relief |

| Surface Finish (Ra)| 3.2 µm | 0.8 µm | Achieved with fine carbide tools, controlled feeds/speeds |

| Max Feature Depth | 5x Diameter | 3x Diameter | Deep pockets require specialized tooling, peck strategies |

| Material Removal | Optimized HSM Paths | High-Pressure Coolant | Essential for heat dissipation, chip evacuation in steel |

Raw material certification is verified prior to machining. Programs incorporate adaptive clearing strategies to manage tool wear and thermal distortion inherent in steel. In-process inspections at critical stages (e.g., after roughing, before finish passes) validate dimensional stability. Final inspection utilizes calibrated CMMs and surface testers against the approved drawing, with full traceability linking the part to its specific machine, operator, and inspection data. This closed-loop process guarantees that every steel machinery component meets Honyo’s stringent quality standards for performance and reliability in demanding industrial applications.

Start Your Project

Start Your Steel Machinery Project with Precision CNC Machining from Shenzhen Honyo Prototype

When it comes to manufacturing high-performance steel machinery, precision, durability, and consistency are non-negotiable. At Shenzhen Honyo Prototype, we specialize in CNC machining services tailored to the demanding requirements of industrial steel components. Whether you’re developing heavy-duty gear systems, structural frames, or custom transmission parts, our advanced machining capabilities ensure every piece meets exact engineering specifications.

Our CNC machining center is equipped with state-of-the-art 3-axis, 4-axis, and 5-axis milling machines, complemented by high-precision lathes and turning centers. This allows us to handle complex geometries, tight tolerances, and large-scale steel components with ease. We work with a wide range of steel alloys, including stainless steel (303, 304, 316), carbon steel (1018, 1045), and tool steels (D2, A2, O1), ensuring material compatibility with your application’s mechanical and environmental demands.

We understand that steel machinery projects often require rapid turnaround without compromising quality. That’s why our streamlined workflow—from CAD/CAM programming to in-process inspection—delivers fast prototyping and scalable production runs. Our team of experienced manufacturing engineers applies deep domain knowledge in material behavior, toolpath optimization, and post-processing techniques such as heat treatment, surface grinding, and passivation to enhance part performance.

To ensure seamless project initiation, we provide comprehensive DFM (Design for Manufacturability) feedback early in the process. This collaborative approach identifies potential challenges in design, material selection, or assembly, reducing costly revisions and minimizing lead time. Every component is inspected using calibrated CMMs, optical comparators, and surface roughness testers to guarantee compliance with ISO 9001 standards.

Below are key technical specifications for our CNC machining services for steel machinery components:

| Parameter | Capability |

|——————————-|———————————————|

| Materials | Stainless Steel, Carbon Steel, Tool Steel |

| Tolerance | ±0.005 mm (standard), up to ±0.002 mm |

| Surface Finish | Ra 0.8 µm (standard), down to Ra 0.2 µm |

| Maximum Part Size | 1200 x 800 x 600 mm (5-axis) |

| Machining Types | Milling, Turning, Drilling, Threading |

| Lead Time | 5–7 days (prototype), 10–15 days (batch) |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI) |

| Post-Processing Options | Anodizing, Plating, Powder Coating, Passivation |

Starting your project with Honyo Prototype is simple. Share your 3D CAD files, technical drawings, and production requirements, and our engineering team will provide a detailed quotation and DFM report within 24 hours. We support STEP, IGES, SolidWorks, and PDF formats for drawings.

For immediate assistance, contact Susan Leo, Customer Project Manager, at info@hy-proto.com. She will guide you through material selection, volume planning, and timeline optimization to ensure your steel machinery components are manufactured to the highest industry standards. At Shenzhen Honyo Prototype, we don’t just machine parts—we engineer solutions. Let’s build your next-generation machinery together.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.