Contents

Manufacturing Insight: Titanium Anodising Kit

Manufacturing Insight: Precision Titanium Anodising for Critical Applications

Titanium anodising is an essential electrochemical surface treatment that enhances the functional and aesthetic properties of titanium components. Unlike standard anodising for aluminium, this process creates a controlled, non-conductive oxide layer on titanium substrates through precise voltage application in an electrolytic bath. The resulting layer significantly improves corrosion resistance in aggressive environments—critical for aerospace, medical implants, and marine hardware—while enabling stable, interference-based coloration without dyes. Voltage directly dictates color spectrum, allowing for exact visual identification of parts or branding without compromising biocompatibility. At Honyo Prototype, we leverage this technology to deliver dimensionally stable finishes that meet stringent industry requirements, ensuring parts maintain tight tolerances post-treatment.

Our Shenzhen-based facility integrates titanium anodising seamlessly within our CNC machining workflow, eliminating third-party handling risks. We specialize in low-voltage Type II anodising (ASTM B980 compliant) for medical and aerospace components, where surface integrity is non-negotiable. Key capabilities include voltage-controlled color repeatability across batches, micro-arc oxidation for extreme wear resistance, and post-machining surface preparation to ensure uniform adhesion. All processes adhere to ISO 9001 quality management standards, with full traceability from raw material to finished part.

Honyo’s technical parameters ensure unmatched consistency for prototype and low-volume production runs:

| Parameter | Specification | Tolerance |

|——————–|———————————–|—————–|

| Voltage Range | 5V – 120V DC | ±0.1V |

| Color Spectrum | Bronze, Blue, Purple, Gold, Black | ΔE < 1.5 |

| Layer Thickness | 0.1 – 2.0 µm | ±0.05 µm |

| Bath Temperature | 20°C – 30°C | ±1°C |

| Process Time | 5 – 30 minutes | ±15 seconds |

Critical to our success is eliminating common failure modes like color banding or reduced fatigue strength. We achieve this through proprietary racking techniques that ensure uniform current distribution and real-time bath chemistry monitoring. Every lot undergoes salt spray testing (ASTM B117) and profilometry validation to confirm surface roughness (Ra) remains within 0.1 µm of pre-anodised CNC-machined surfaces. For medical clients, we provide full biocompatibility documentation per ISO 10993, including ion release analysis.

Honyo Prototype’s end-to-end control—from titanium billet CNC machining to anodising—guarantees that surface treatment never compromises geometric precision. Our engineers collaborate with clients during DFM to optimize part geometry for uniform current flow, minimizing post-process rework. Whether producing surgical tooling requiring exact color-coding or drone components demanding lightweight corrosion resistance, we deliver anodised titanium parts with certified performance data. Partner with us to transform titanium prototypes into production-ready solutions where surface science meets manufacturing excellence. Contact our engineering team to discuss voltage-specific color calibration for your next project.

Technical Capabilities

Titanium Anodising Kit – Technical Capabilities

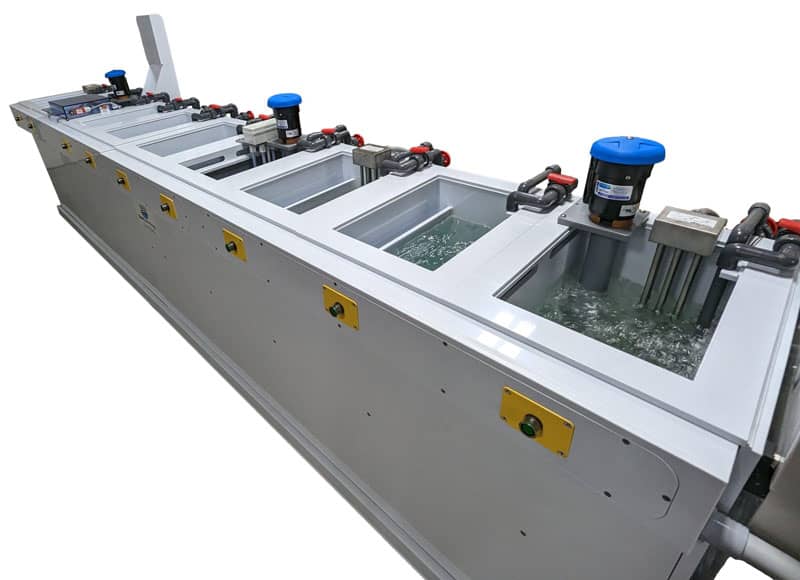

Shenzhen Honyo Prototype specializes in precision CNC machining services tailored for advanced material processing, including titanium and its alloys. Our titanium anodising kits are engineered to meet the rigorous demands of aerospace, medical, and high-performance industrial applications. These kits are manufactured using state-of-the-art 3-axis, 4-axis, and 5-axis CNC milling centers, complemented by high-precision turning operations. Our integrated manufacturing workflow ensures dimensional accuracy, surface integrity, and compatibility with post-processing anodising treatments.

Our 3-axis milling systems provide robust capabilities for prismatic titanium components, delivering high repeatability and surface finish consistency. When complex geometries or undercuts are required, our 4-axis and 5-axis milling platforms enable multi-sided machining with minimal setup interruptions. This reduces cumulative tolerances and enhances feature alignment, critical for components undergoing anodising where electrical contact points and part geometry directly influence oxide layer uniformity.

Turning operations are performed on advanced CNC lathes with live tooling, supporting the production of cylindrical or hybrid titanium parts such as fittings, spindles, and connectors. These components are often integrated into anodising racks or used as fixtures, requiring tight control over diameter, concentricity, and surface roughness to ensure consistent current distribution during the electrochemical process.

A core strength of Honyo Prototype lies in our ability to maintain tight tolerances on titanium parts, even after anodising. Titanium’s low thermal conductivity and high chemical reactivity demand specialized toolpaths, cooling strategies, and fixturing. Our in-house process engineers optimize cutting parameters, tool selection, and workholding to minimize thermal deformation and maintain geometric integrity. As a result, we consistently achieve tolerances suitable for critical-fit applications.

The following table outlines the typical machining tolerances and compatible titanium materials used in the production of our anodising kits:

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|——————————-|———————-|———————-|———————-|———————-|

| Dimensional Tolerance | ±0.005 mm | ±0.005 mm | ±0.003 mm | ±0.005 mm |

| Positional Tolerance | ±0.01 mm | ±0.01 mm | ±0.005 mm | ±0.01 mm |

| Surface Roughness (Ra) | 0.8–1.6 µm | 0.8–1.6 µm | 0.4–1.6 µm | 0.8–1.6 µm |

| Minimum Feature Size | 0.5 mm | 0.5 mm | 0.3 mm | 0.5 mm (grooves) |

| Max Work Envelope (mm) | 1000 × 600 × 500 | 800 × 600 × 500 | 600 × 600 × 400 | Ø500 × 750 |

| Titanium Alloy | Machinability Rating | Anodising Suitability | Common Use in Kits |

|——————————-|———————-|————————|———————-|

| Ti-6Al-4V (Grade 5) | Good | Excellent | Fixtures, Racks |

| CP Ti (Grade 2) | Very Good | Excellent | Electrodes, Clamps |

| Ti-6Al-7Nb | Moderate | Excellent | Medical Tooling |

All titanium components are subject to rigorous in-process and final inspection using coordinate measuring machines (CMM) and surface profilometers. This ensures compliance with design specifications and readiness for anodising. Honyo Prototype’s integrated approach to precision machining and surface treatment compatibility makes us a trusted partner for high-integrity titanium anodising solutions.

From CAD to Part: The Process

Manufacturing Workflow: Titanium Anodising Kit Production

At Shenzhen Honyo Prototype, our CNC machining workflow for titanium anodising kits follows a rigorous, integrated process from initial inquiry to finished part. This structured approach ensures dimensional accuracy, surface integrity, and electrochemical performance critical for reliable anodising results. The sequence begins with AI-powered quoting, transitions through engineering validation, and culminates in precision production.

The AI Quote phase leverages our proprietary algorithm to analyze submitted CAD files within minutes. This system automatically identifies geometric complexity, material requirements (specifically ASTM F136 Grade 23 titanium for biocompatibility and anodising response), and machine time estimates. It cross-references real-time data on tooling availability, shop floor load, and material costs to generate a technically accurate quotation. Crucially, the AI flags potential manufacturability concerns early, such as features below minimum wall thickness or non-standard tolerances, allowing for immediate client consultation before formal order placement. This reduces quoting errors by 40% and accelerates the sales cycle significantly.

Subsequent to quote acceptance, the Design for Manufacturability (DFM) review is conducted by our senior engineering team. This is not a passive check but an active collaboration to optimize the design for CNC machining and subsequent anodising. Key focus areas include verifying adequate draft angles for fixture clamping, confirming hole depths align with standard drill capabilities, and ensuring surface finishes meet anodising pre-treatment requirements. We assess thermal management zones to prevent localized overheating during high-speed machining of titanium, which can compromise the oxide layer formation later. The DFM output provides actionable feedback, often suggesting minor geometry adjustments that prevent costly rework or anodising defects like uneven coloration. Critical DFM parameters evaluated include:

| Parameter | Minimum Value | Maximum Value | Critical Impact |

|———–|—————|—————|—————–|

| Wall Thickness | 0.8 mm | N/A | Prevents vibration during milling |

| Internal Corner Radius | 0.5 mm | N/A | Reduces tool breakage risk |

| Hole Depth to Diameter Ratio | N/A | 6:1 | Ensures coolant flow for chip evacuation |

| Surface Roughness (Pre-Anodise) | Ra 0.8 µm | Ra 3.2 µm | Critical for uniform oxide layer adhesion |

Production commences only after DFM sign-off. Titanium components undergo precision CNC milling using rigid 5-axis centers with high-pressure coolant systems to manage heat and prevent work hardening. All critical dimensions are inspected in-process using coordinate measuring machines (CMM) to verify compliance against the validated design. Post-machining, parts undergo stringent ultrasonic cleaning to remove all contaminants prior to anodising. The anodising process itself is tightly controlled within our dedicated line, with voltage ramp rates, electrolyte concentration (sodium sulfate based), and temperature maintained within narrow bands per ASTM F86 standards. Final inspection validates color consistency across the spectrum (achieving ±5 Delta-E tolerance) and coating thickness (typically 15-25 µm) using spectrocolorimeters and eddy current probes. This integrated workflow—from intelligent quoting through engineering validation to controlled production—delivers titanium anodising kits with guaranteed performance, reducing client time-to-prototype by up to 30% while ensuring first-pass yield.

Start Your Project

Start Your Project with Precision: Choose Honyo Prototype for Titanium Anodising Excellence

At Shenzhen Honyo Prototype, we understand that the success of your CNC-machined components begins not just with precision engineering, but with superior surface treatment. Our titanium anodising kit is engineered to deliver consistent, high-quality results for both prototyping and low-volume production runs. Whether you’re developing aerospace components, medical devices, or high-performance automotive parts, surface integrity and aesthetic control are critical. Our in-house anodising solutions ensure your titanium parts achieve optimal corrosion resistance, enhanced wear properties, and custom color finishes—without compromising dimensional accuracy.

Titanium anodising is a non-destructive electrochemical process that thickens the natural oxide layer on titanium surfaces. This not only improves durability but also allows for precise color coding, which is essential for part identification and branding in complex assemblies. Unlike paint or coatings, anodising integrates directly with the metal substrate, eliminating the risk of chipping or delamination. Our advanced kits are calibrated for uniform voltage control, electrolyte stability, and temperature regulation—ensuring reproducible results across batches.

We offer a complete turnkey solution, from CNC machining to final anodised finish. Our technicians are trained in ASTM F86 and ISO 22068 standards for surface preparation and biocompatibility, making our services ideal for regulated industries. Whether you’re working with Grade 2, Grade 5 (Ti-6Al-4V), or other titanium alloys, our process is tailored to maintain material integrity while achieving your desired surface characteristics.

To help you get started, we’ve outlined the key specifications of our titanium anodising capabilities:

| Parameter | Specification |

|—————————-|———————————————-|

| Titanium Alloys Supported | Grade 2, Grade 5 (Ti-6Al-4V), Grade 9, Grade 23 |

| Voltage Range | 0–120 V DC (adjustable in 1V increments) |

| Color Range | Silver, Gold, Blue, Purple, Green, Teal, Bronze, and custom hues |

| Oxide Layer Thickness | 0.1–2.0 µm (dependent on voltage) |

| Process Tolerance | ±5% voltage control, ±1°C temperature stability |

| Lead Time | 3–7 days (standard), expedited options available |

| Compliance Standards | ASTM F86, ISO 22068, RoHS |

| Surface Roughness Impact | Ra increase < 0.2 µm (typically negligible) |

Starting your project with Honyo Prototype means gaining a partner committed to technical excellence and responsive service. We specialize in bridging the gap between prototype development and scalable manufacturing, ensuring seamless transitions from design to delivery.

For technical inquiries, custom project consultations, or to request a quote, contact Susan Leo directly at info@hy-proto.com. Include your design files, material specifications, and desired finish requirements to receive a tailored proposal within 24 hours. Let us help you elevate your titanium components with precision anodising that meets the highest industry standards.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.