Contents

Manufacturing Insight: 032 Aluminum Sheet

Manufacturing Insight: 032 Aluminum Sheet Fabrication

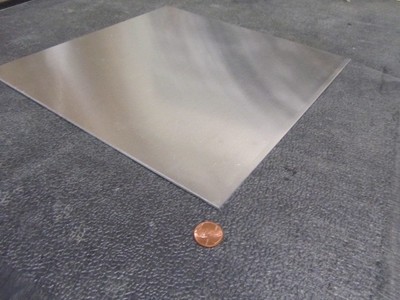

Aluminum sheet designated as “032” refers to a nominal thickness of 0.032 inches (0.81 mm), a critical dimension frequently encountered in precision sheet metal prototyping and low-volume production. This thin gauge presents unique manufacturing considerations distinct from thicker materials, demanding specialized expertise to achieve dimensional accuracy, structural integrity, and surface quality. At Shenzhen Honyo Prototype, we recognize that mastering 032 aluminum fabrication is essential for clients developing intricate enclosures, heat sinks, brackets, and aerospace components where weight savings and formability are paramount. Understanding the inherent properties and processing challenges of this specific gauge is fundamental to successful project execution.

The behavior of 032 aluminum sheet is heavily influenced by its alloy composition and temper. Common alloys like 3003 H14 and 5052 H32 offer a balance of moderate strength, excellent formability, and good corrosion resistance, making them prevalent choices for prototypes. However, the thin cross-section amplifies challenges such as springback during bending, susceptibility to warpage from residual stresses, and increased difficulty in handling without surface marring. Precise control over tooling geometry, bending sequences, and clamping forces becomes non-negotiable to maintain tight tolerances and prevent part distortion. Surface finish requirements also necessitate careful process selection and tool maintenance to avoid scratches or oil canning effects inherent in thin materials.

Honyo Prototype leverages deep material science knowledge and advanced manufacturing infrastructure specifically optimized for thin-gauge aluminum work. Our capabilities extend beyond standard forming to address the nuances of 032 sheet:

| Key Parameter | Specification/Value | Relevance for 032 Aluminum Sheet |

| :——————— | :———————— | :————————————————— |

| Typical Thickness | 0.032 in (0.81 mm) | Defines handling sensitivity and forming challenges |

| Common Alloys | 3003 H14, 5052 H32 | Balance of formability, strength, weldability |

| Key Challenge | Springback & Warpage | Requires precise compensation and stress management |

| Critical Tolerance | ±0.05 mm typical | Demands high-precision tooling and process control |

| Surface Sensitivity | High | Requires meticulous handling and clean tooling |

Our CNC press brakes utilize adaptive control systems with real-time feedback to dynamically adjust for springback, ensuring bend angles consistently meet specifications. Precision laser cutting minimizes heat-affected zones and edge deformation, while our specialized welding protocols for thin sheets prevent burn-through and distortion. In-process metrology, including coordinate measuring machines (CMM) and optical comparators, verifies flatness and critical features at multiple stages, not just post-fabrication. Furthermore, our experienced technicians employ custom fixtures and handling protocols designed explicitly for sub-1mm materials to prevent dents and scratches during processing.

Partnering with Honyo Prototype for 032 aluminum sheet projects means accessing a manufacturing partner who treats thin-gauge intricacies not as obstacles, but as core engineering challenges we are uniquely equipped to solve. We translate material understanding into robust, repeatable processes, ensuring your prototype or low-volume part meets stringent functional and aesthetic requirements right from the first iteration. This capability is fundamental to accelerating your product development cycle while maintaining the highest standards of quality inherent in Shenzhen’s advanced manufacturing ecosystem.

Technical Capabilities

Technical Capabilities: 0.032″ Aluminum Sheet Fabrication

Shenzhen Honyo Prototype specializes in precision sheet metal fabrication, with extensive experience handling thin-gauge aluminum materials, including 0.032″ (0.813 mm) aluminum sheets. This thickness is frequently used in enclosures, brackets, heat shields, and lightweight structural components across aerospace, electronics, and industrial equipment sectors. Our manufacturing processes are optimized for high accuracy, repeatability, and surface integrity, ensuring consistent part quality for both prototypes and low-to-mid volume production runs.

Laser cutting is the primary method used for 0.032″ aluminum sheet due to its precision, edge quality, and minimal material distortion. At Honyo Prototype, we utilize fiber laser technology capable of achieving fine features and tight tolerances. The process supports complex geometries, including intricate cutouts, slots, and registration features. For 0.032″ aluminum, kerf widths are typically maintained between 0.15 mm and 0.20 mm, depending on beam focus and assist gas parameters. Nitrogen is used as the assist gas for clean, oxide-free edges suitable for subsequent finishing or welding operations.

Bending operations on 0.032″ aluminum are performed using precision CNC press brakes equipped with narrow V-die tooling. Given the thin gauge, special attention is paid to minimizing deformation and ensuring consistent bend angles. The recommended minimum bend radius for 0.032″ aluminum is 0.5 mm (0.020″), which helps prevent cracking in the material, particularly for alloys with lower ductility. Our standard bend tolerance is ±0.25°, with positional accuracy of ±0.1 mm per bend. Coordinated bend sequencing ensures dimensional stability across multi-bend components.

Welding of 0.032″ aluminum is performed using pulsed DC TIG or micro plasma arc welding techniques, both of which offer precise heat input control to avoid burn-through and warpage. These methods are ideal for thin sheets where joint strength and cosmetic appearance are critical. We commonly weld 5052, 6061, and 3003 aluminum alloys, all of which exhibit good weldability at this thickness. Post-weld cleaning and inspection are standard, with optional post-weld machining or finishing available upon request.

The following table summarizes key technical specifications and tolerances for 0.032″ aluminum sheet fabrication at Honyo Prototype:

| Process | Material Compatibility | Typical Tolerance | Minimum Feature Size | Notes |

|—————–|——————————|————————-|————————|——-|

| Laser Cutting | 5052, 6061, 3003, 1100 | ±0.1 mm | 0.5 mm hole diameter | Nitrogen assist; burr < 0.05 mm |

| Bending | 5052, 6061, 3003 | ±0.25° / ±0.1 mm | 5.0 mm flange width | Min. bend radius: 0.5 mm |

| Welding | 5052, 6061 (TIG/Micro Plasma) | ±0.5 mm positional | 3.0 mm weld length | Full penetration; minimal distortion |

All fabricated components undergo in-process and final inspection to ensure compliance with customer drawings and industry standards. Honyo Prototype maintains ISO 9001-certified quality systems, supporting reliable and repeatable manufacturing outcomes for demanding applications.

From CAD to Part: The Process

From CAD to Finished Part: Streamlined Workflow for 0.032″ Aluminum Sheet Fabrication

At Shenzhen Honyo Prototype, we execute a rigorously defined workflow for transforming customer CAD models into precision 0.032″ aluminum sheet metal parts. This integrated process, spanning AI-powered quoting through final production, ensures manufacturability, cost efficiency, and rapid turnaround, critical for prototyping and low-volume production demands. Our methodology minimizes iteration and maximizes first-pass yield.

AI-Powered Quoting System

The workflow initiates when a customer uploads a native CAD file (STEP, IPT, SLDPRT) or high-fidelity 2D drawing to our portal. Honyo’s proprietary AI engine performs instant geometric analysis, identifying key parameters: material specification (defaulting to 3003-H14 for 0.032″ sheet unless otherwise specified), flat pattern area, feature count (holes, bends, notches), and overall geometric complexity. The system cross-references real-time material costs, machine availability, and historical production data to generate a highly accurate quote within minutes. This eliminates manual estimation delays and provides immediate cost visibility, allowing for rapid project initiation or design adjustment before formal commitment.

Engineering-Driven Design for Manufacturability (DFM)

Following quote acceptance, our Senior Manufacturing Engineers conduct a mandatory DFM review, treating it as a collaborative value-engineering step, not merely a checkpoint. We scrutinize the CAD model against the stringent capabilities and limitations of thin-gauge aluminum fabrication. Critical focus areas include bend radii feasibility (ensuring minimum internal radius ≥ 0.03″ for 0.032″ 3003-H14 to prevent cracking), hole-to-edge/bend spacing, feature density impacting laser cutting speed, and part nesting efficiency on the sheet. Material properties directly influence these assessments, as shown below.

| Parameter | Value for 0.032″ Aluminum 3003-H14 | Significance in DFM |

| :—————– | :——————————— | :————————————– |

| Thickness | 0.032″ ± 0.003″ | Drives bend allowance & force calcs |

| Tensile Strength | 17 KSI min | Impacts forming loads & springback |

| Yield Strength | 16 KSI min | Critical for bend radius prediction |

| Elongation | 10% min | Indicates formability limit |

| Common Bend Radius | 0.03″ – 0.06″ | Must exceed min to avoid material failure |

Engineers provide actionable feedback, often suggesting minor feature relocation or tolerance adjustments that significantly reduce cost or lead time without compromising function. Customer approval of the DFM report is required before production release.

Precision Production Execution

With DFM sign-off, the part enters our high-mix production cell. The CAD model drives direct programming for our fiber laser cutting systems, achieving ±0.005″ positional accuracy on features and clean edges essential for thin aluminum. Automated material handling loads 4’x8′ sheets of certified 3003-H14. Post-cutting, parts undergo meticulous deburring to remove micro-burrs inherent in laser processing of aluminum, preventing handling injuries and ensuring smooth assembly. Bending occurs on CNC press brakes with coining tooling optimized for 0.032″ gauge, utilizing real-time angle feedback for consistent 90-degree bends within ±0.5° tolerance. Final inspection verifies critical dimensions against the approved drawing using calibrated CMMs or optical comparators before packaging. This seamless integration of digital quoting, collaborative DFM, and tightly controlled production ensures your 0.032″ aluminum prototype arrives on time, within specification, and ready for validation.

Start Your Project

Start Your Project with Precision: Choose 032 Aluminum Sheet Fabrication at Shenzhen Honyo Prototype

When it comes to high-performance, lightweight, and corrosion-resistant materials in sheet metal fabrication, 032 aluminum sheet stands out as a preferred choice across aerospace, electronics, automotive, and industrial equipment sectors. At Shenzhen Honyo Prototype, we specialize in precision manufacturing of aluminum components using 032 aluminum sheet—a material known for its excellent strength-to-weight ratio, good formability, and reliable weldability. Whether you’re developing a prototype or scaling into low-volume production, our advanced fabrication capabilities ensure your design is translated into a high-quality physical product with accuracy and speed.

Our expertise in sheet metal fabrication includes laser cutting, CNC punching, precision bending, and automated welding, all optimized for 032 aluminum sheet thickness. This specific gauge—approximately 0.032 inches (0.81 mm)—offers an ideal balance between structural integrity and flexibility, making it suitable for enclosures, brackets, heat sinks, and intricate chassis components. We understand that even minor deviations in thickness or tolerances can impact final performance, which is why every stage of production is monitored under strict quality control standards.

We support a wide range of aluminum alloys compatible with the 032 sheet specification, including 5052, 6061, and 3003, each selected based on your project’s mechanical, thermal, and environmental requirements. Our engineering team collaborates closely with clients to recommend the optimal alloy, surface finish (such as anodizing, powder coating, or chem film), and fabrication approach to meet both functional and aesthetic goals.

Below are key technical specifications for 032 aluminum sheet commonly processed at Honyo Prototype:

| Property | Value |

|—————————–|———————————-|

| Thickness | 0.032 in (0.81 mm) |

| Common Alloys | 5052-H32, 6061-T6, 3003-H14 |

| Tolerance (Cutting) | ±0.005 in (±0.13 mm) |

| Minimum Bend Radius | 1× material thickness |

| Max Sheet Size Processed | 48 in × 96 in (1219 mm × 2438 mm) |

| Surface Finishes Available | Anodizing, Powder Coating, Passivation, Brushing |

At Shenzhen Honyo Prototype, we pride ourselves on rapid turnaround times without compromising quality. Our facility in Shenzhen is equipped with state-of-the-art machinery and staffed by experienced technicians who adhere to international manufacturing standards. From DFM analysis to final assembly, we ensure seamless project execution.

Ready to bring your next design to life? Contact Susan Leo, our dedicated Project Coordinator, to discuss your 032 aluminum sheet fabrication needs. We offer free quotes, technical consultation, and prototype support to help you move quickly from concept to production.

Email Susan Leo at info@hy-proto.com today and take the first step toward precision manufacturing excellence.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.