Contents

Manufacturing Insight: Cost Of Titanium Vs Steel

Material Cost Analysis: Titanium versus Steel in Precision CNC Machining

Material selection directly impacts both project economics and manufacturability in CNC machining. At Shenzhen Honyo Prototype, we routinely guide clients through the cost-performance trade-offs between titanium and steel alloys. While raw material costs provide an initial benchmark, the total machining expense often tells a more complex story. Titanium alloys like Ti-6Al-4V command a base material cost 3–5 times higher per kilogram than common stainless steels such as 304 or 17-4 PH. However, this differential alone misrepresents the true production burden. Titanium’s low thermal conductivity, high strength-to-weight ratio, and tendency toward work hardening significantly increase machining time and tooling consumption. Cutting speeds for titanium typically run 30–50% slower than steel under comparable conditions, requiring specialized toolpaths and rigid setups to prevent chatter or part distortion.

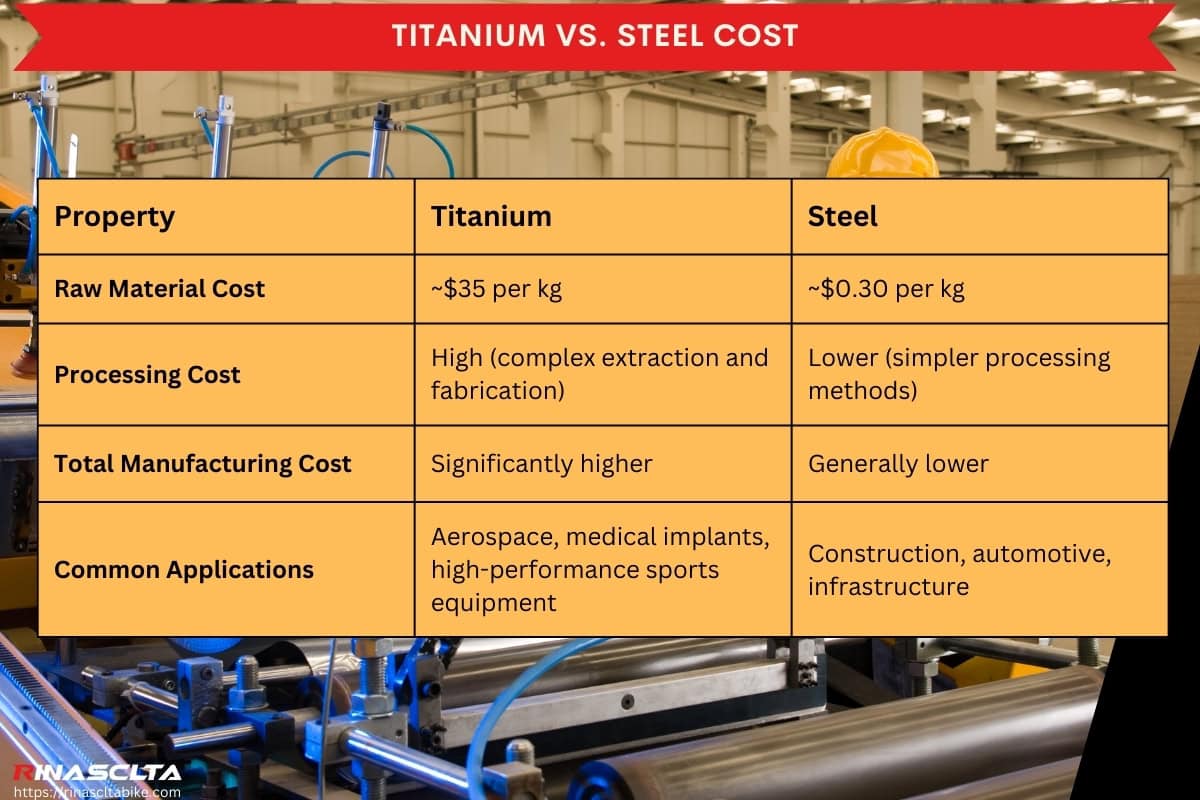

The following table summarizes critical cost drivers for both material families in CNC environments:

| Property | Titanium (Ti-6Al-4V) | Steel (304 Stainless) |

|————————-|—————————-|—————————-|

| Raw Material Cost | $80–$120/kg | $20–$30/kg |

| Machinability Rating | Poor (20–30% of B1112) | Moderate (50–60% of B1112) |

| Tool Wear Impact | High (3–5x steel) | Moderate |

| Typical Machining Time | 30–50% longer | Baseline |

| Common Applications | Aerospace, medical implants | Fluid systems, brackets |

Steel’s superior machinability reduces cycle times and extends tool life, lowering per-part costs for high-volume runs. Titanium, while expensive, becomes economically justifiable when its unique properties—corrosion resistance, biocompatibility, or strength-to-weight—are mission-critical. At Honyo, we mitigate titanium’s cost challenges through optimized CNC protocols. Our engineers leverage high-pressure coolant systems, carbide tooling with polished flutes, and adaptive milling strategies to minimize thermal buildup and tool deflection. This approach reduces scrap rates by up to 25% compared to standard machining practices for titanium.

Our Shenzhen facility maintains dedicated CNC workcells for reactive and hard-to-machine materials, featuring 5-axis milling centers with through-spindle coolant and real-time thermal monitoring. We hold ISO 9001:2015 and AS9100D certifications, ensuring strict adherence to material traceability and process validation—particularly vital for aerospace-grade titanium. By analyzing your part geometry, volume, and performance requirements, we identify opportunities to balance material costs with manufacturability. For instance, we may recommend near-net-shape casting for titanium components to reduce machining allowances or propose steel alternatives with PVD coatings for wear resistance where weight savings are non-critical.

Honyo Prototype transforms material cost complexity into strategic advantage. Partner with us to navigate the titanium-steel decision with data-driven insights and precision manufacturing expertise that protects your timeline and budget.

Technical Capabilities

Cost Comparison of Titanium vs Steel in CNC Machining at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, precision CNC machining of high-performance materials is central to our manufacturing capabilities. When selecting between titanium and steel for prototyping or low-volume production, cost considerations are driven by material properties, machinability, tool wear, and required tolerances. Understanding these factors enables optimal material selection for performance, durability, and cost-efficiency across 3-axis, 4-axis, and 5-axis milling, as well as precision turning operations.

Titanium, particularly Grade 5 (Ti-6Al-4V), offers an exceptional strength-to-density ratio, corrosion resistance, and performance at elevated temperatures, making it ideal for aerospace, medical, and high-performance automotive applications. However, titanium’s low thermal conductivity results in localized heat buildup during machining, accelerating tool wear and requiring slower cutting speeds. This directly impacts machining time and tooling costs. Additionally, its high chemical reactivity with cutting tools increases the risk of galling and necessitates the use of specialized carbide or coated tooling, further elevating production expenses.

In contrast, alloy steels such as 4140, 4340, and tool steels like H13 or P20 are generally more cost-effective to machine. These materials exhibit better thermal conductivity and chip evacuation characteristics, allowing higher cutting speeds and feed rates. While certain high-hardness steels require pre- or post-heat treatment, they are less aggressive on tooling than titanium, resulting in longer tool life and reduced downtime. Stainless steels (e.g., 304, 316) fall between carbon steels and titanium in terms of machinability, with work hardening tendencies requiring careful process control.

For tight-tolerance components—especially those requiring ±0.005 mm or better—material stability becomes critical. Titanium’s lower elastic modulus can lead to deflection under cutting forces, demanding conservative machining strategies and multiple finishing passes. Steel, with higher stiffness and dimensional stability, typically achieves tight tolerances more predictably and with fewer iterations.

Below is a comparative overview of tolerances and material characteristics relevant to CNC machining at Honyo Prototype:

| Material Type | Typical Tolerance Range (Milling) | Typical Tolerance Range (Turning) | Machinability Rating (Relative) | Common Applications |

|——————–|———————————–|———————————–|———————————-|———————————|

| Titanium (Ti-6Al-4V)| ±0.010 mm – ±0.005 mm | ±0.010 mm – ±0.008 mm | Low (20-30% of free-machining steel) | Aerospace, Medical Implants |

| Alloy Steel (4140) | ±0.005 mm – ±0.003 mm | ±0.005 mm – ±0.004 mm | Medium | Automotive, Industrial Shafts |

| Stainless Steel (316)| ±0.008 mm – ±0.005 mm | ±0.008 mm – ±0.006 mm | Medium-Low | Marine, Chemical Processing |

| Tool Steel (H13) | ±0.005 mm – ±0.003 mm | ±0.005 mm – ±0.004 mm | Medium (pre-hardened) | Molds, Dies |

At Honyo Prototype, we optimize machining strategies for each material, leveraging advanced 5-axis platforms for complex titanium geometries and high-speed steel machining for cost-sensitive production runs. Our process planning includes adaptive toolpaths, high-pressure coolant systems, and in-process inspection to maintain tight tolerances while managing overall project cost. Clients benefit from our material expertise, enabling informed decisions between performance and manufacturability.

From CAD to Part: The Process

From CAD to Part: Titanium vs Steel CNC Production Workflow at Honyo Prototype

At Shenzhen Honyo Prototype, our CNC machining workflow rigorously integrates material-specific considerations from initial quotation through final production. This ensures optimal cost efficiency and part integrity, particularly critical when comparing titanium alloys like Ti-6Al-4V against common steels such as 304 stainless or 4140. The process begins with an AI-driven quotation system that analyzes CAD geometry alongside material properties. For titanium, the algorithm flags higher raw material costs (typically 3–5x steel per kg) and factors in extended machining times due to lower thermal conductivity and higher strength. Steel quotations benefit from faster cycle times and lower material premiums but may include allowances for secondary finishing if corrosion resistance is required.

Following quotation, every design undergoes mandatory Design for Manufacturability (DFM) review. Titanium demands aggressive DFM intervention: sharp internal corners are redesigned to reduce tool deflection and heat buildup, while thin walls require strategic support features to prevent chatter-induced distortion. Steel parts generally tolerate tighter tolerances with fewer modifications, though complex geometries still necessitate feature simplification. Our engineers use material-specific simulation tools to predict stress concentrations—titanium’s lower elastic modulus increases springback risk, requiring overbending compensation not needed in steel. This phase often identifies 15–20% cost savings by eliminating non-essential features that disproportionately impact titanium machining.

Production execution highlights the steepest divergence. Titanium machining requires rigid setups, specialized carbide tooling with polished flutes, and reduced cutting parameters to manage heat. Typical spindle speeds for titanium are 30–50% lower than steel, with feed rates 20–40% slower, directly inflating machine hours. Tool wear monitoring is continuous; a single titanium part may consume 3–5x more inserts than an equivalent steel component. Steel leverages higher MRR (Material Removal Rates), allowing aggressive roughing passes and fewer tool changes. Crucially, titanium’s reactivity necessitates strict coolant purity control to prevent surface embrittlement—a step rarely critical for steel.

Material property differences fundamentally drive cost structures. The table below summarizes key production variables:

| Parameter | Titanium (Ti-6Al-4V) | Steel (304 Stainless) |

|——————–|———————-|———————–|

| Raw Material Cost | $80–$120/kg | $15–$25/kg |

| Typical MRR | 5–10 cm³/min | 20–40 cm³/min |

| Tooling Cost/Part | $12–$18 | $3–$6 |

| Cycle Time Factor | 1.8–2.5x steel | Baseline (1.0x) |

| Scrap Rate Risk | High (15–25%) | Moderate (5–10%) |

Final cost outcomes hinge on holistic workflow management. While titanium’s material cost dominates early estimates, inefficient DFM or unoptimized production can escalate steel part costs unexpectedly through secondary operations. Honyo’s integrated approach—leveraging AI quotation precision, material-aware DFM, and adaptive CNC strategies—minimizes these variables. We consistently deliver titanium prototypes within 10–15% of steel part lead times by front-loading engineering analysis, ensuring clients pay only for necessary performance advantages, not avoidable process penalties. This disciplined workflow transforms material cost challenges into predictable, value-driven manufacturing outcomes.

Start Your Project

Understanding the Cost of Titanium vs Steel in CNC Machining

When planning a CNC machining project, one of the most critical decisions you’ll make is material selection. Two of the most commonly used metals—titanium and steel—offer distinct advantages and trade-offs, particularly when it comes to cost, performance, and manufacturability. At Shenzhen Honyo Prototype, we help engineering teams and product developers make informed decisions by providing accurate cost analysis and precision manufacturing services tailored to your project’s requirements.

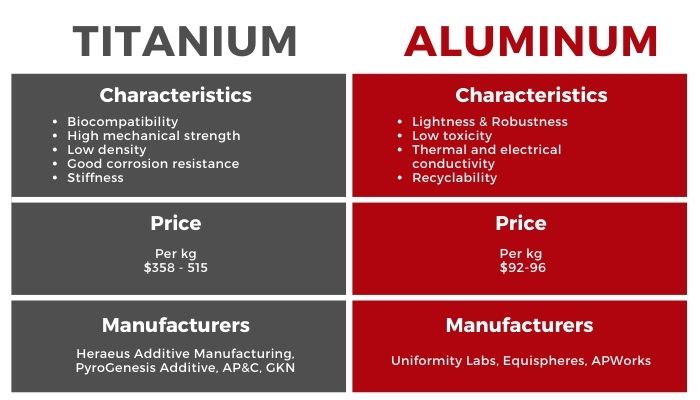

Titanium is renowned for its exceptional strength-to-density ratio, corrosion resistance, and performance in extreme environments. These properties make it a preferred choice for aerospace, medical implants, and high-performance automotive applications. However, titanium’s benefits come at a premium. Raw material costs for titanium are significantly higher than those of most steels—often 5 to 10 times more per kilogram. Additionally, titanium’s low thermal conductivity and high chemical reactivity increase tool wear and reduce machining speeds, which raises labor and tooling expenses during CNC processing.

Steel, particularly alloy and stainless varieties, offers excellent mechanical properties, good machinability, and lower raw material costs. Common grades like 4140, 304, and 17-4 PH stainless steel provide robust performance across industrial, automotive, and consumer applications. Steel is generally faster to machine than titanium, resulting in shorter cycle times and reduced production costs. For projects where extreme weight savings or corrosion resistance isn’t a primary concern, steel remains a cost-effective and reliable option.

To help you evaluate the financial and functional implications of your material choice, we’ve summarized key comparative data:

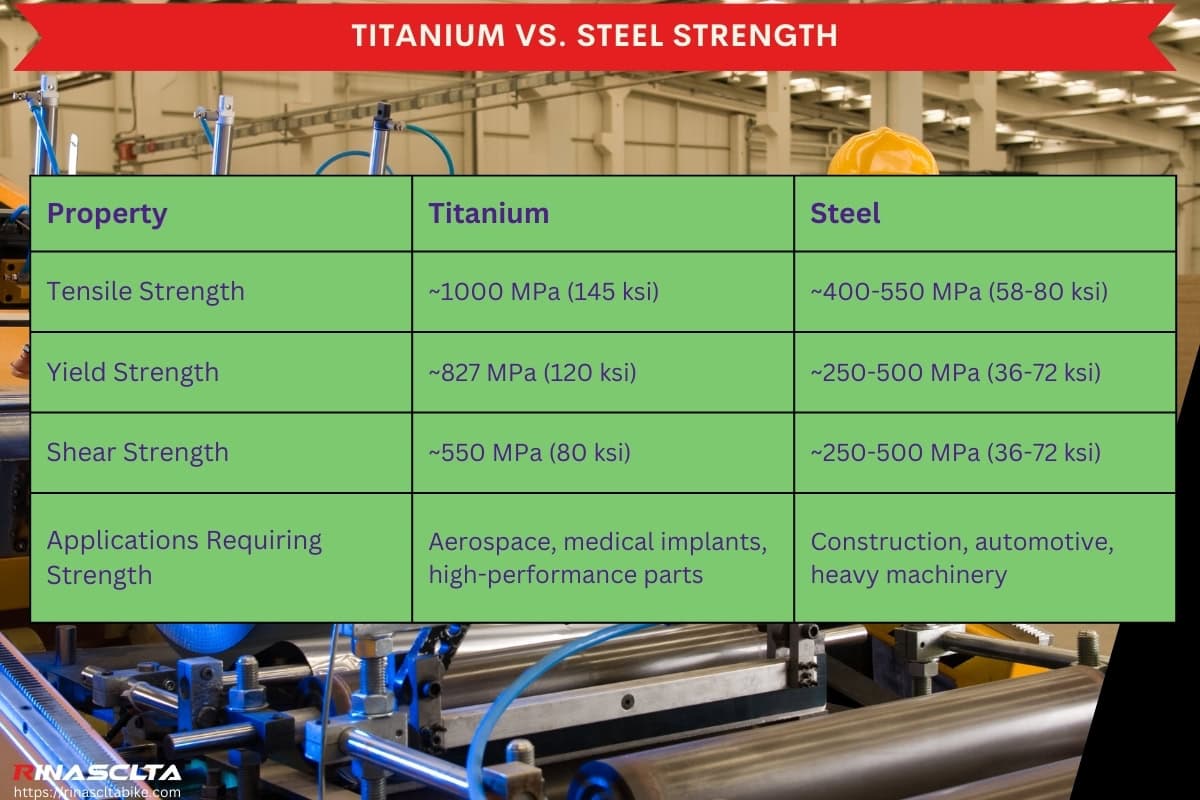

| Property | Titanium (Grade 5, Ti-6Al-4V) | Steel (4140 Alloy) | Stainless Steel (304) |

|—————————–|——————————-|——————–|————————|

| Density (g/cm³) | 4.43 | 7.85 | 8.00 |

| Tensile Strength (MPa) | 900–1,100 | 655–1,000 | 505–860 |

| Machinability Rating | 22% (Poor) | 70% (Good) | 45% (Moderate) |

| Approx. Material Cost ($/kg)| $80–$120 | $8–$12 | $10–$15 |

| Common Applications | Aerospace, Medical, Racing | Industrial, Tooling| Food, Chemical, Marine |

Ultimately, the decision between titanium and steel should balance performance needs with budget constraints. While titanium delivers unmatched performance in demanding environments, steel often provides a more economical solution without sacrificing durability.

At Shenzhen Honyo Prototype, we specialize in high-precision CNC machining for both metals, with in-house expertise to optimize toolpaths, reduce waste, and control costs—no matter your material choice.

Ready to start your project? Contact Susan Leo today at info@hy-proto.com for a detailed quote and material consultation. Let us help you turn your design into a high-quality, cost-efficient prototype or production part.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.