Contents

Manufacturing Insight: Kc Precision Machining

Manufacturing Insight: K&C Precision Machining Capabilities at Honyo Prototype

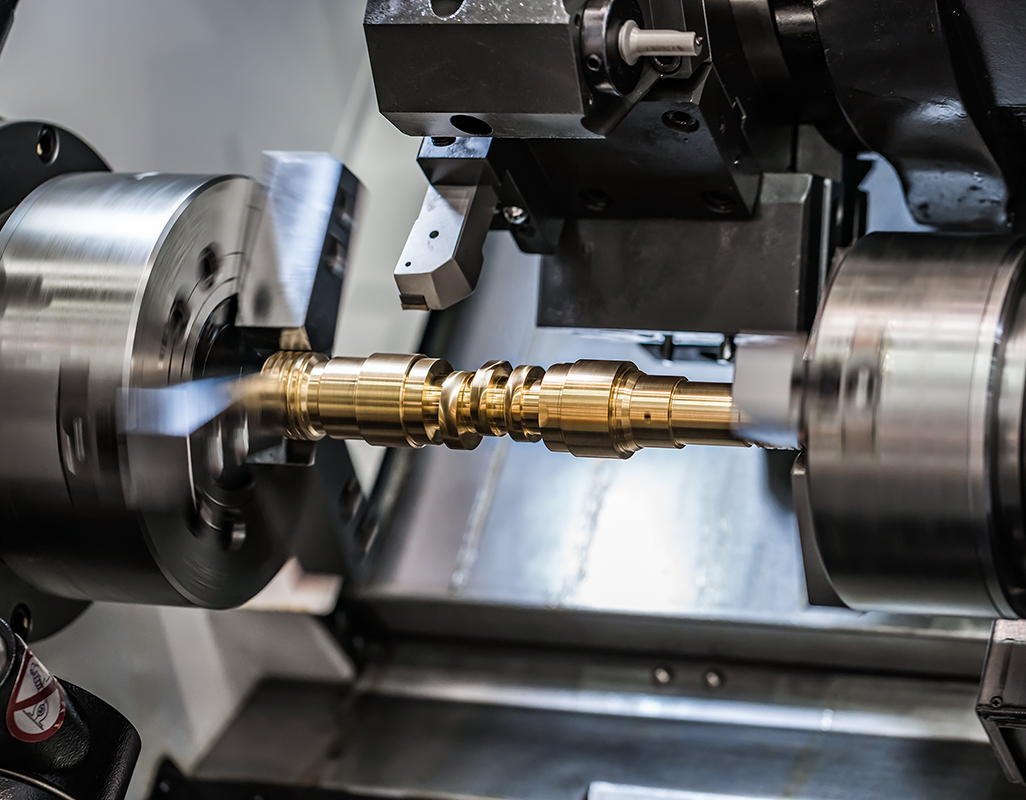

K&C Precision Machining represents the critical intersection of kinetic motion control and cutting-edge toolpath strategies essential for producing complex, high-integrity components, particularly within rapid prototyping and low-volume production environments. At Shenzhen Honyo Prototype, this methodology transcends basic CNC operations, focusing on achieving micron-level tolerances and superior surface finishes required for functional validation, aerospace components, medical devices, and precision instrumentation. The inherent challenge lies in maintaining dimensional stability and geometric accuracy across diverse materials while accelerating time-to-part – a challenge met through integrated process engineering and advanced machine capabilities. For prototype development, where design iteration is frequent and material costs are significant, K&C precision directly impacts the reliability of test data and the speed of product refinement.

Honyo Prototype leverages a dedicated fleet of multi-axis CNC machining centers specifically optimized for K&C workflows. Our infrastructure combines high-rigidity spindles, thermal compensation systems, and in-process probing to minimize error sources inherent in complex machining sequences. This technical foundation enables us to consistently deliver on stringent client specifications, as detailed in our core machining capabilities:

| Capability | Tolerance Range | Key Materials Supported | Typical Applications |

| :———————- | :——————- | :——————————- | :————————————— |

| 3-Axis Milling | ±0.005 mm (±0.0002″) | Aluminum, Steel, Plastics | Structural brackets, housings, jigs |

| 4/5-Axis Milling | ±0.003 mm (±0.0001″) | Titanium, Inconel, PEEK, Brass | Aerospace fittings, medical implants |

| Precision Turning | ±0.002 mm (±0.00008″)| Stainless Steel, Copper Alloys | Shafts, connectors, fluidic components |

| Micro-Machining | ±0.001 mm (±0.00004″)| Specialty Alloys, Ceramics | Sensor elements, optical mounts |

| Surface Finish (Ra) | As low as 0.4 µm | All supported materials | Sealing surfaces, optical interfaces |

Our technical differentiators stem from a closed-loop manufacturing philosophy. Every K&C process begins with DFM analysis focused on minimizing setup complexity and thermal distortion risks. Toolpath generation utilizes adaptive high-speed strategies to reduce cycle times while maintaining surface integrity, crucial for prototypes requiring immediate functional testing. In-process inspection via Renishaw probes verifies critical features mid-operation, preventing scrap on high-value materials like Ti-6Al-4V or medical-grade PEEK. Final verification employs calibrated CMMs and optical comparators traceable to NIST standards, with full inspection reports provided for critical features. This integrated approach ensures first-article parts meet specifications, reducing the need for costly design re-spins during prototyping.

For engineering teams developing next-generation products, Honyo’s K&C Precision Machining capability delivers more than dimensional accuracy; it provides actionable data confidence. By eliminating manufacturing-induced variables early in the development cycle, clients accelerate validation, mitigate downstream production risks, and achieve faster market entry. We specialize in transforming complex CAD models into physically precise, functionally representative prototypes within compressed timelines – turning design intent into tangible, test-ready reality without compromising on the fidelity required for critical engineering decisions. Partner with Honyo to leverage precision as a strategic asset in your innovation pipeline.

Technical Capabilities

Shenzhen Honyo Prototype delivers advanced CNC machining services tailored to meet the rigorous demands of industries requiring high-precision components, including aerospace, medical, automotive, and industrial equipment. Our technical capabilities in 3-axis, 4-axis, and 5-axis milling, combined with precision turning and tight-tolerance machining, enable us to produce complex geometries with exceptional accuracy and repeatability. Our state-of-the-art CNC equipment is supported by a skilled engineering team and rigorous quality control processes, ensuring every component meets or exceeds customer specifications.

Our 3-axis milling services are ideal for parts with simple geometries and flat surfaces, providing fast turnaround times for high-volume production runs. For more complex designs involving undercuts and multi-sided features, our 4-axis and 5-axis CNC machining centers offer enhanced flexibility and precision. The addition of rotational axes allows for machining from multiple angles in a single setup, minimizing part handling and improving dimensional consistency. Our 5-axis simultaneous machining capability supports the production of intricate contours, organic shapes, and freeform surfaces commonly found in turbine blades, impellers, and custom molds.

In addition to milling, Honyo Prototype offers CNC turning for cylindrical and axially symmetric components. Our turning centers are equipped with live tooling, enabling mill-turn operations that combine turning with milling, drilling, and tapping in one setup. This integrated approach reduces cycle times and enhances accuracy, especially for complex turned parts requiring secondary features.

Tight-tolerance machining is a core strength at Honyo Prototype. We consistently achieve tolerances down to ±0.005 mm (±0.0002″) for critical dimensions, supported by precision metrology tools such as CMMs, optical comparators, and laser scanners. Our quality management system ensures full traceability and compliance with ISO 9001 standards.

The table below outlines our standard machining tolerances and compatible materials:

| Process | Typical Tolerance | Max Tolerance | Common Materials |

|———————–|——————-|—————|——————|

| 3-Axis CNC Milling | ±0.01 mm | ±0.005 mm | Aluminum (6061, 7075), Steel (1018, 4140), Stainless Steel (303, 304, 316), Titanium (Grade 5), PEEK, Delrin |

| 4-Axis CNC Milling | ±0.01 mm | ±0.005 mm | Same as above, with added capability for complex indexing |

| 5-Axis CNC Milling | ±0.01 mm | ±0.005 mm | Aluminum, Stainless Steel, Titanium, Inconel, PEEK |

| CNC Turning | ±0.01 mm | ±0.005 mm | Aluminum, Steel, Stainless Steel, Brass, Plastics |

| Mill-Turn Machining | ±0.01 mm | ±0.005 mm | Aluminum, Stainless Steel, Titanium, Brass |

All materials are sourced from certified suppliers and are fully traceable. Material certifications and RoHS compliance documentation are available upon request. At Shenzhen Honyo Prototype, we combine technical expertise, advanced equipment, and rigorous quality assurance to deliver precision-machined components that meet the most demanding engineering requirements.

From CAD to Part: The Process

From CAD to Part: KC Precision Machining Workflow at Shenzhen Honyo Prototype

Shenzhen Honyo Prototype delivers exceptional CNC machined prototypes and low-volume production parts through a rigorously defined workflow, ensuring precision, efficiency, and cost-effectiveness from initial concept to final component. Our KC Precision Machining process is engineered for seamless integration, starting with your digital model and culminating in a fully validated physical part. The core sequence integrates advanced digital tools with expert engineering oversight: AI-Powered Quoting, Comprehensive Design for Manufacturability (DFM) Analysis, and Precision Production Execution.

The process initiates with our proprietary AI-Powered Quoting Engine. Upon receiving your CAD file (accepted formats: STEP, IGES, Parasolid, native SOLIDWORKS), the system performs an instant geometric analysis. It automatically identifies critical features, material requirements, dimensional complexity, and surface finish specifications. This deep analysis, combined with real-time machine availability and material cost databases, generates an accurate, detailed quote within minutes. This initial step provides immediate clarity on cost and lead time feasibility, significantly accelerating your project kick-off compared to manual estimation methods. Key inputs driving the AI analysis include part geometry complexity, specified material grade, required tolerances, and surface finish class.

Following quote acceptance, your project enters the mandatory and value-driven Design for Manufacturability (DFM) Analysis phase. Our senior manufacturing engineers conduct a thorough review, moving beyond basic geometry to assess practical manufacturability. We proactively identify potential challenges such as excessive thin walls prone to deflection, deep internal cavities requiring specialized tooling, unnecessarily tight tolerances increasing cost, or features difficult to machine without complex fixturing. This collaborative stage involves direct consultation; we provide specific, actionable recommendations to optimize your design for CNC machining. Typical suggestions address minimizing setups, improving tool access, adjusting radii for standard tooling, or resolving potential tolerance stack-up issues. Implementing these DFM insights before production begins is critical for mitigating delays, reducing scrap rates, and achieving optimal cost efficiency without compromising functional intent.

With an optimized design approved, production commences under stringent quality protocols. Your CAD model is meticulously programmed using industry-leading CAM software (Mastercam, Fusion 360) by our certified programmers. Toolpaths are generated, simulated for collision avoidance, and optimized for material removal rate and surface finish. Material is selected and inspected per your specification. Machining occurs on our high-precision CNC equipment, with rigorous in-process inspections at critical stages using calibrated CMMs, optical comparators, and surface roughness testers. Final parts undergo comprehensive First Article Inspection (FAI) against all drawing requirements, including critical dimensions and GD&T. Traceability is maintained throughout via our digital MES system. The table below summarizes key capabilities within our production cell:

| Machine Type | Typical Applications | Max Work Envelope (mm) | Standard Accuracy (mm) | Surface Finish (Ra µm) |

| :—————– | :——————————————– | :——————— | :——————— | :——————— |

| 3-Axis Vertical Mill | Prismatic parts, plates, housings | 1000 x 600 x 500 | ±0.010 | 0.8 – 3.2 |

| 4-Axis Mill/Turn | Complex rotational parts, off-center features | Ø300 x 500 | ±0.005 | 0.4 – 1.6 |

| 5-Axis Mill | Organic shapes, deep cavities, single-setup | 800 x 500 x 400 | ±0.005 | 0.4 – 1.6 |

This integrated workflow—AI Quote for speed and transparency, expert DFM for risk mitigation and cost optimization, and controlled Production Execution for guaranteed quality—ensures Shenzhen Honyo Prototype consistently delivers KC Precision Machined parts that meet the highest standards of accuracy and reliability, directly translating your CAD model into a flawless physical component.

Start Your Project

Start Your CNC Machining Project with Confidence at Shenzhen Honyo Prototype

When precision, speed, and reliability are critical to your product development cycle, partnering with an experienced CNC machining provider makes all the difference. At Shenzhen Honyo Prototype, we specialize in high-accuracy, low-volume CNC-machined components tailored to meet the exacting demands of engineers, designers, and R&D teams across industries including medical devices, automation, aerospace, and consumer electronics.

Our state-of-the-art CNC machining capabilities support a wide range of materials—from aluminum and stainless steel to engineering plastics such as PEEK and PTFE—ensuring your prototype or bridge production parts perform exactly as intended. Whether you’re validating a design, preparing for pilot testing, or requiring functional components under tight deadlines, our in-house 3-axis and 4-axis machining centers deliver repeatability, tight tolerances down to ±0.005 mm, and exceptional surface finishes.

We understand that every project begins with a concept. That’s why our engineering team collaborates closely with clients from the earliest stages, offering design for manufacturability (DFM) feedback to optimize part geometry, reduce costs, and accelerate turnaround. With a typical lead time of 5–7 business days for most machined parts, we combine rapid prototyping agility with production-grade quality.

To ensure seamless communication and project tracking, each order is assigned a dedicated project manager who oversees every phase—from material sourcing and machining to finishing and inspection. All parts undergo rigorous quality control using calibrated CMMs and optical measurement systems, with first-article inspection (FAI) reports available upon request.

Below are key specifications for our CNC machining services:

| Feature | Specification |

|——–|—————-|

| Machining Types | 3-Axis, 4-Axis (Indexing), Milling, Turning |

| Tolerances | Standard: ±0.01 mm; Precision: ±0.005 mm |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Steel (4140, 1018), Brass, Copper, PEEK, ABS, Nylon, PTFE |

| Max Work Envelope | 600 × 400 × 300 mm |

| Surface Finishes | As machined, Anodizing (Type II & III), Plating, Powder Coating, Bead Blasting, Polishing |

| Lead Time | 5–7 days average (varies by complexity and quantity) |

| Quality Standards | ISO 9001:2015 compliant, Full inspection reporting available |

Starting your project is simple. Upload your 3D CAD file in STEP, IGES, or native formats, and our team will provide a comprehensive quote within 12 hours. We accept orders for single prototypes up to small-batch production runs of several hundred units.

For immediate assistance, contact Susan Leo, Customer Project Manager at Shenzhen Honyo Prototype. She will guide you through the submission process, answer technical questions, and ensure your project is on track from day one.

Email: info@hy-proto.com

Let’s turn your design into a precision-engineered reality—quickly, accurately, and reliably.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.