Contents

Manufacturing Insight: Plasma Cutting Services

Plasma Cutting: Precision Thermal Processing for Industrial Applications

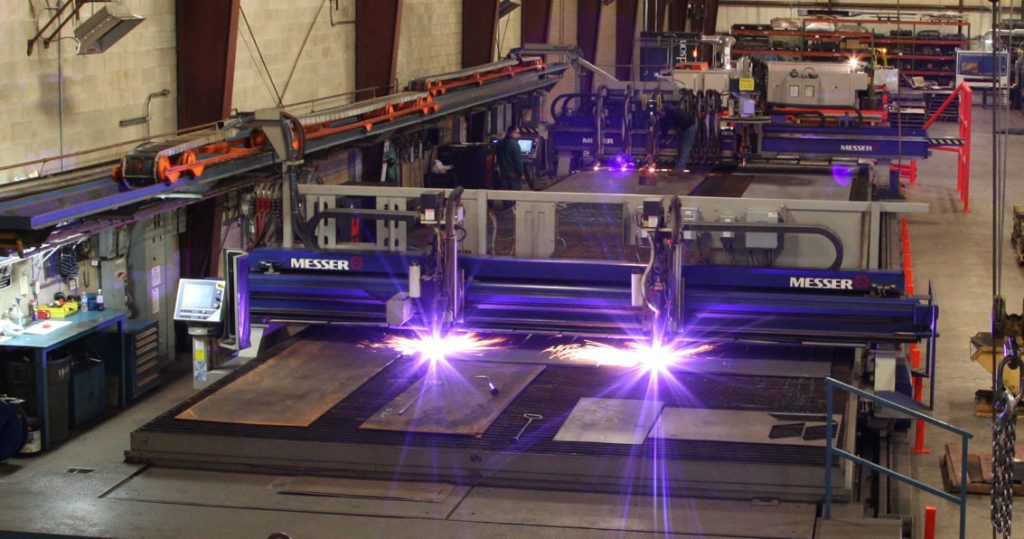

Plasma cutting represents a critical thermal fabrication process where ionized gas (plasma) conducts electrical energy to melt and eject conductive materials. This technology leverages a high-velocity jet of superheated plasma, generated by forcing gas through a constricted nozzle while applying an electrical arc. The resulting 20,000°C+ stream cleanly severs metals with exceptional speed, making it indispensable for rapid prototyping and low-volume production of structural components, enclosures, and chassis. Unlike laser cutting, plasma excels at processing thicker conductive materials while maintaining cost efficiency, though it typically achieves lower precision than fiber lasers on thin sheets. Its versatility across ferrous and non-ferrous alloys ensures broad applicability in aerospace, automotive, and industrial equipment manufacturing where material thickness exceeds 6mm.

At Shenzhen Honyo Prototype, plasma cutting is integrated into our end-to-end CNC machining ecosystem to accelerate prototype development cycles. Our automated systems utilize high-definition plasma torches controlled by precision-motion CNC routers, enabling complex 2D geometries with minimal thermal distortion. This approach reduces lead times by up to 70% compared to traditional milling for plate fabrication, while maintaining strict geometric tolerances. We prioritize material utilization efficiency through nested part programming, minimizing waste for both client cost savings and sustainable manufacturing practices.

Honyo’s plasma cutting capabilities are engineered for demanding industrial prototyping:

| Parameter | Specification |

|————————|—————————————-|

| Material Thickness | Mild Steel: 1–50 mm; Stainless Steel: 1–35 mm; Aluminum: 1–25 mm |

| Max Cutting Speed | 8,000 mm/min (at 10 mm mild steel) |

| Positional Accuracy | ±0.2 mm over 2,000 x 4,000 mm bed |

| Compatible Materials | Carbon steel, stainless steel, aluminum, copper, brass |

| Surface Finish (Ra) | 12.5–25 μm (as-cut) |

Our facility operates 24/7 with dual plasma workcells, accommodating sheet sizes up to 4,000 x 2,000 mm. Advanced height control systems dynamically adjust torch standoff distance to compensate for material warpage, ensuring consistent cut quality across imperfect stock—critical for prototype validation where material consistency may vary. All processes adhere to ISO 9001 standards, with in-line verification of critical dimensions via CMM spot checks. For clients requiring secondary operations, Honyo seamlessly transitions plasma-cut blanks to our milling, bending, and finishing departments under one roof, eliminating supply chain delays. This integrated workflow ensures that plasma-cut prototypes meet functional testing requirements while accelerating time-to-market. By combining industrial-grade plasma technology with agile manufacturing protocols, Honyo delivers production-intent metal components with the speed essential for modern product development cycles.

Technical Capabilities

Plasma Cutting Services – Technical Capabilities

Shenzhen Honyo Prototype delivers precision plasma cutting services as part of our advanced CNC machining portfolio. Engineered for high-speed, high-accuracy metal fabrication, our plasma cutting technology efficiently processes conductive materials with tight dimensional control and clean edge finishes. Utilizing modern CNC-guided plasma systems, we support complex 2D and 3D cutting geometries across a range of industrial applications, from rapid prototyping to low-to-mid volume production runs.

Our facility is equipped with multi-axis plasma cutting workstations capable of synchronized 3-axis, 4-axis, and 5-axis motion, enabling intricate contouring and beveled edge preparation for welding. This multi-axis capability ensures superior flexibility in handling complex components, particularly in structural, automotive, aerospace, and heavy equipment manufacturing sectors. Integrated with high-definition plasma torches and real-time arc control systems, our machines maintain consistent cut quality across variable thicknesses and material types.

A key strength of our plasma cutting process lies in tight tolerance achievement. Through precision motion control, adaptive height sensing, and optimized kerf compensation algorithms, we maintain dimensional accuracy critical for downstream assembly and fitment. All cutting paths are generated from validated CAD/CAM programs, ensuring repeatability and adherence to engineering specifications. Our in-house quality assurance team performs first-article inspections and periodic in-process checks using coordinate measuring machines (CMM) and optical comparators to verify compliance.

Material selection is a critical factor in plasma cutting performance, and we support a broad range of conductive metals. The table below outlines our standard material compatibility and achievable tolerances:

| Material Type | Thickness Range (mm) | Typical Tolerance (mm) | Max Cutting Speed (mm/min) |

|———————|————————|————————–|—————————–|

| Mild Steel | 1 – 50 | ±0.2 | 6,000 |

| Stainless Steel | 1 – 40 | ±0.3 | 4,500 |

| Aluminum Alloys | 1 – 35 | ±0.3 | 5,000 |

| Tool Steel | 1 – 45 | ±0.25 | 3,800 |

| Brass | 1 – 25 | ±0.3 | 4,200 |

For critical applications requiring tighter control, we offer precision plasma and hybrid plasma-laser configurations capable of achieving tolerances down to ±0.15 mm on selected geometries and materials. Edge quality is optimized through parameter tuning, minimizing dross, taper, and heat-affected zones. All components undergo post-cut de-slagging and surface inspection to ensure readiness for secondary operations such as bending, welding, or coating.

At Shenzhen Honyo Prototype, our plasma cutting services are fully integrated with broader CNC milling and turning capabilities, enabling seamless transition from cutting to high-precision machining. This vertical integration allows us to deliver fully finished components with tight overall tolerances, reducing lead times and supply chain complexity for our clients. Whether producing one-off prototypes or batch production parts, we maintain consistent quality, traceability, and on-time delivery across all projects.

From CAD to Part: The Process

Plasma Cutting Production Process: From CAD to Finished Part

At Shenzhen Honyo Prototype, our plasma cutting workflow is engineered for precision, efficiency, and seamless integration within your CNC machining project lifecycle. We transform your digital CAD files into high-quality metal components through a rigorously defined three-stage process: AI-Powered Quoting, Design for Manufacturability (DFM) Analysis, and Controlled Production Execution. This structured approach minimizes errors, optimizes lead times, and ensures dimensional accuracy from the initial design concept to the final shipped part.

The process initiates upon receipt of your CAD file, typically in DXF, DWG, or STEP format. Our proprietary AI quoting engine rapidly analyzes the geometry, material specifications, and required quantities. This system instantly calculates precise material utilization, machine runtime, labor, and secondary operation costs, generating a detailed technical quotation within minutes. Crucially, the AI cross-references the design against our established plasma cutting capability matrix, flagging potential issues like minimum feature sizes or excessive kerf that could impact cost or feasibility before human review, accelerating the initial feedback loop significantly compared to manual quoting methods.

Following quote acceptance, the design undergoes mandatory DFM analysis by our senior manufacturing engineering team. This is not a simple validation step but a proactive collaboration. Engineers scrutinize the CAD model for plasma-specific manufacturability: verifying internal corner radii against torch capabilities, assessing cut path sequencing to minimize thermal distortion, confirming hole diameters relative to material thickness, and evaluating the need for lead-ins/lead-outs to prevent edge defects. We provide actionable feedback, suggesting geometric adjustments where necessary to enhance cut quality, reduce dross, or lower costs – for instance, recommending slight chamfers on sharp internal corners instead of accepting slow, high-dross cuts. Client approval of the DFM report is required prior to programming, ensuring alignment on any design refinements.

Production commences only after DFM sign-off. Our CNC plasma cutting systems, featuring high-definition plasma sources (40A to 150A) and precision motion control, utilize the final, optimized CAD/CAM program. Material preparation involves rigorous verification of grade, thickness, and flatness against the job specifications. The cutting sequence executes with controlled gas flows (oxygen for mild steel, nitrogen for stainless/aluminum), amperage, and travel speeds, dynamically adjusted based on real-time pierce and cut parameters. Critical quality checkpoints occur throughout: initial part verification against the CAD model using calibrated measurement tools, in-process checks for edge squareness and dross levels, and final inspection confirming all dimensions per the engineering drawing and surface finish requirements. Parts are deburred, labeled, and prepared for integration into downstream machining or assembly processes.

Shenzhen Honyo Prototype Plasma Cutting Capabilities

| Parameter | Capability Range | Typical Tolerance | Notes |

| :—————– | :———————————– | :—————- | :————————————- |

| Material Types | Mild Steel, Stainless Steel, Aluminum | – | Optimized gas selection per material |

| Thickness Range | 1mm – 25mm (Mild Steel) | ±0.2mm (≤10mm) | Up to 50mm possible with specific setup |

| | 1mm – 12mm (Stainless/Aluminum) | ±0.3mm (>10mm) | |

| Kerf Width | 1.0mm – 2.5mm | Varies by amperage| Compensated in CAM programming |

| Edge Quality | ISO 9013 Class F2 (Fine) achievable | – | Depends on material/thickness/speed |

| Minimum Hole Size | 1.0 x Material Thickness | – | Smaller possible with specialized tech |

| Max. Cutting Area | 1500mm x 3000mm | – | Standard bed size |

This integrated workflow, combining AI efficiency with deep engineering expertise in plasma dynamics, ensures your parts are produced right the first time, maximizing value and minimizing time-to-market for your prototypes and low-volume production runs.

Start Your Project

Start Your Plasma Cutting Project with Shenzhen Honyo Prototype

When precision, speed, and reliability are critical to your fabrication needs, Shenzhen Honyo Prototype delivers expert plasma cutting services tailored to your specifications. As a trusted partner in CNC machining, we specialize in transforming raw metal into high-accuracy components using advanced plasma cutting technology. Whether you’re developing prototypes, low-volume production runs, or full-scale fabrication projects, our capabilities support a wide range of materials and geometries with consistent repeatability and tight tolerances.

Plasma cutting at Honyo Prototype leverages high-velocity jets of ionized gas to melt and sever conductive materials, enabling clean, burr-free edges on steel, stainless steel, aluminum, and other alloys. Our CNC-controlled plasma systems ensure dimensional accuracy down to ±0.005 inches, making them ideal for industrial enclosures, brackets, frames, and structural components. We integrate your CAD files directly into our production workflow, minimizing setup time and reducing lead times without sacrificing quality.

We understand that every project begins with a clear vision and detailed requirements. To ensure seamless execution, our engineering team reviews your design for manufacturability, offering feedback on material selection, cut tolerances, and edge quality to optimize both performance and cost-efficiency. With a maximum cutting bed size of 4,000 mm × 2,000 mm and the ability to process materials from 0.5 mm up to 25 mm in thickness, we accommodate diverse project scales and complexities.

Our plasma cutting services are supported by secondary operations including CNC bending, welding, surface finishing, and assembly—providing a full-spectrum manufacturing solution under one roof. This integrated approach reduces supply chain dependencies and accelerates time-to-market for your product development cycle.

To initiate your project, simply provide your 2D vector files or technical drawings in DXF, DWG, or STEP format. Our system automatically performs a preliminary review for file integrity and nesting efficiency, allowing us to generate accurate quotes within 4 hours of submission. Once approved, typical turnaround time ranges from 3 to 7 business days, depending on complexity and volume.

Below are key technical specifications for our plasma cutting capabilities:

| Parameter | Specification |

|—————————-|———————————————-|

| Material Types | Mild Steel, Stainless Steel, Aluminum |

| Thickness Range | 0.5 mm – 25 mm |

| Maximum Cutting Area | 4,000 mm × 2,000 mm |

| Positioning Accuracy | ±0.05 mm |

| Repeatability | ±0.02 mm |

| Edge Quality | Smooth, minimal dross, ready for finishing |

| Supported File Formats | DXF, DWG, STEP, IGES |

| Lead Time (Standard) | 3–7 working days after approval |

Begin your next fabrication project with confidence. Contact Susan Leo at info@hy-proto.com to submit your design files, request a quote, or discuss your technical requirements. At Shenzhen Honyo Prototype, we combine advanced technology with engineering expertise to deliver precision plasma-cut components—on time, every time.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.