Contents

Manufacturing Insight: Wire Edm Services

Manufacturing Insight: Wire EDM Services

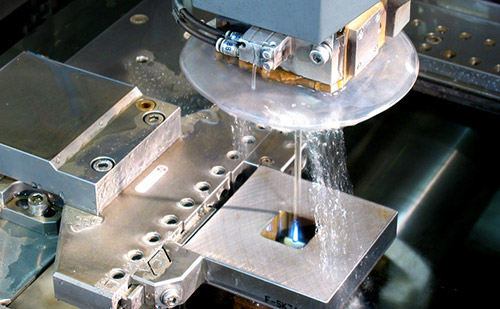

Wire Electrical Discharge Machining (EDM) is a non-contact, precision subtractive process that utilizes controlled electrical sparks between a thin brass or copper wire electrode and an electrically conductive workpiece. Submerged in deionized water, the wire erodes material through thermal energy, enabling the creation of intricate geometries, tight tolerances, and stress-free cuts impossible with conventional CNC milling or turning. This technology excels in machining hardened steels, exotic alloys, and delicate features—such as sharp internal corners, micro-slots, or complex contours—without inducing mechanical stress or distortion. For prototyping and low-volume production, wire EDM is indispensable when dimensional accuracy, surface integrity, and design complexity are paramount, particularly in tooling, aerospace components, and medical devices.

At Shenzhen Honyo Prototype, our wire EDM capabilities are engineered to meet the exacting demands of rapid prototyping and precision manufacturing. We deploy state-of-the-art CNC-controlled wire EDM systems with adaptive servo controls and advanced flushing technologies to ensure consistent repeatability and surface finishes down to Ra 0.4 µm. Our process eliminates the need for secondary operations in many applications, accelerating time-to-part while maintaining strict conformance to engineering specifications. Honyo specializes in handling challenging materials—including tool steels (D2, A2), titanium, Inconel, and tungsten carbide—where traditional machining struggles with hardness or thermal sensitivity.

Key Technical Specifications

| Parameter | Capability |

|————————-|————————————-|

| Tolerance | ±0.002 mm (standard) |

| Max Workpiece Size | 400 x 300 x 250 mm |

| Wire Diameter | 0.10–0.30 mm (brass/copper) |

| Surface Finish (Ra) | 0.4–1.6 µm |

| Taper Angle | Up to 30° per side |

| Material Hardness Limit | Up to 70 HRC (no pre-softening) |

Honyo’s engineering team collaborates closely with clients during the design-for-manufacturability (DFM) phase to optimize part geometry for wire EDM efficiency. We analyze electrode path strategies, kerf compensation, and fixture requirements to minimize lead times and eliminate potential pitfalls—such as wire breakage in deep cavities or excessive taper. Our facility maintains rigorous in-process inspection protocols using CMM and optical comparators, ensuring every prototype adheres to ISO 2768-mK geometric tolerances. For critical applications, we provide full first-article inspection reports (FAIR) with detailed dimensional validation.

Beyond technical execution, Honyo emphasizes agility in prototype workflows. Our wire EDM services integrate seamlessly with complementary processes like CNC milling, grinding, and surface treatment within a single facility, reducing logistics delays and quality handoffs. Whether producing injection mold cavities requiring mirror finishes or aerospace brackets with micron-level positional accuracy, we deliver solutions that balance precision, speed, and cost-effectiveness. Partner with Honyo to transform complex designs into high-fidelity prototypes, leveraging wire EDM’s unique capabilities to de-risk your development cycle and accelerate product validation.

Technical Capabilities

Technical Capabilities: Wire EDM Services at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, our Wire Electrical Discharge Machining (Wire EDM) services are engineered to deliver high-precision components for industries demanding tight tolerances, complex geometries, and superior surface finishes. Utilizing advanced CNC-controlled wire EDM systems, we specialize in machining conductive materials with exceptional accuracy, particularly where traditional cutting methods fall short. Our capabilities support 3-axis, 4-axis, and 5-axis wire EDM configurations, enabling us to produce intricate contours, tapers, and internal features with minimal distortion.

Our wire EDM process employs a continuously fed brass wire electrode—typically ranging from 0.1 mm to 0.3 mm in diameter—that precisely erodes material using controlled electrical discharges. This non-contact machining method eliminates mechanical stress on the workpiece, making it ideal for delicate, thin-walled, or hardened components. We support taper cutting up to ±15° per pass, depending on part geometry and material thickness, with consistent accuracy across workpieces up to 400 mm in height.

We serve a broad range of industries, including aerospace, medical device manufacturing, mold and die, and precision instrumentation, where tight tolerances and repeatable accuracy are critical. Our in-house metrology lab, equipped with high-resolution CMMs and optical comparators, ensures every component meets specified dimensional and geometric requirements before shipment.

The following table outlines our standard machining tolerances and compatible materials for wire EDM operations:

| Parameter | Specification |

|——————————-|———————————————-|

| Positional Accuracy | ±0.001 mm |

| Repeatability | ±0.001 mm |

| Surface Roughness (Ra) | 0.8 μm (standard), down to 0.4 μm (fine cut) |

| Taper Cutting Capability | Up to ±15° per side, depending on height |

| Maximum Workpiece Height | 400 mm |

| Wire Diameter Range | 0.1 mm – 0.3 mm |

| Axis Configuration | 3-axis, 4-axis, 5-axis (taper and rotation) |

| Material Type | Examples | Max Hardness Support |

|——————————-|———————————————-|————————|

| Tool Steels | D2, A2, H13, O1 | Up to 68 HRC |

| Stainless Steels | 304, 316, 17-4 PH, 440C | Up to 60 HRC |

| Titanium Alloys | Ti-6Al-4V, CP-Ti | Full compatibility |

| Aluminum Alloys | 7075, 6061 | Suitable with parameters|

| Exotic Alloys | Inconel 718, Monel, Hastelloy | Up to 55 HRC |

| Copper Alloys | Brass, Beryllium Copper | Full compatibility |

Our 5-axis wire EDM capability allows for complex rotational and tapered features in a single setup, reducing lead times and improving part consistency. All jobs undergo rigorous process planning, including CNC program simulation and first-article inspection, to ensure compliance with engineering drawings and quality standards. With a focus on tight tolerance machining—down to ±0.001 mm—we provide reliable, repeatable results for prototyping and low-to-mid volume production runs. Shenzhen Honyo Prototype combines technical expertise, advanced equipment, and strict quality control to deliver wire EDM solutions that meet the most demanding manufacturing requirements.

From CAD to Part: The Process

Wire EDM Production Process: From CAD to Precision Part

At Shenzhen Honyo Prototype, our Wire Electrical Discharge Machining (EDM) workflow is engineered for seamless transition from digital design to high-precision physical component, minimizing iteration and maximizing first-time yield. This integrated process leverages automation and engineering expertise specifically for complex geometries, tight tolerances, and hardened materials where conventional CNC machining reaches its limits. The submerged wire electrode, typically brass or coated, erodes material via controlled electrical sparks in a deionized water dielectric bath, enabling intricate cuts without mechanical force.

The journey begins with the AI-Powered Quoting System. Upon receiving your CAD file (STEP, IGES, X_T preferred), our proprietary AI engine performs an instant manufacturability scan. It analyzes critical factors like feature complexity, internal corner radii, aspect ratios, and material type against our machine capabilities and process libraries. This isn’t just a cost estimate; it flags potential production risks early, such as geometries requiring excessive skim cuts or sections prone to wire breakage, providing actionable feedback within minutes. This initial digital validation sets realistic expectations and accelerates project initiation.

Following quote acceptance, the design enters the Engineering-Led DFM (Design for Manufacturability) Review. Our senior manufacturing engineers conduct a deep dive, collaborating directly with your design team if necessary. We focus on optimizing the design for wire EDM physics, ensuring features are achievable within standard process parameters. Key considerations include verifying minimum inside corner radii (dictated by wire diameter), assessing taper requirements, confirming material suitability, and evaluating part stability during cutting. This proactive step prevents costly redesigns later and optimizes the cutting path strategy for speed and accuracy.

Critical Wire EDM DFM Parameters

| Parameter | Standard Capability | Enhanced Capability (Additional Cost) | Design Impact |

| :———————– | :—————— | :———————————- | :——————————————— |

| Minimum Corner Radius | 0.08 mm | 0.03 mm | Dictates smallest internal feature detail |

| Typical Tolerance (±) | 0.005 mm | 0.002 mm | Critical for mating surfaces & precision fits |

| Max Taper Angle (per side)| 15° | 30° | Enables complex draft angles & mold cavities |

| Surface Finish (Ra) | 0.8 – 1.6 µm | 0.4 µm | Affects part functionality & post-processing |

Production Execution commences only after DFM sign-off. The process involves meticulous setup: secure workpiece fixturing ensuring stability, precise wire threading (0.25mm standard diameter), and calibration of the dielectric fluid system. Cutting paths are generated using advanced CAM software, incorporating multiple skim passes for final dimensions and surface finish. Real-time monitoring tracks wire tension, spark conditions, and dimensional accuracy via in-process probing. For tapered features, our 4-axis machines dynamically adjust the upper guide. Final parts undergo rigorous CMM inspection against the original CAD model, with full dimensional reports provided. This closed-loop workflow, from intelligent quoting through expert DFM to tightly controlled production, ensures your complex wire EDM parts meet the most demanding specifications reliably and efficiently.

Start Your Project

Start Your Wire EDM Project with Precision and Confidence at Shenzhen Honyo Prototype

When it comes to high-precision manufacturing in complex geometries and tight-tolerance components, Wire Electrical Discharge Machining (Wire EDM) stands out as one of the most reliable and accurate processes available. At Shenzhen Honyo Prototype, we specialize in delivering top-tier Wire EDM services tailored to meet the demanding requirements of industries such as aerospace, medical devices, mold & die, and advanced electronics. Our state-of-the-art facilities, combined with decades of engineering expertise, ensure that your prototypes and production parts are manufactured to exact specifications—every time.

Whether you’re developing a one-off prototype or scaling to low-volume production, our Wire EDM capabilities support a broad range of materials including hardened steels, titanium, inconel, carbide, and other conductive alloys. With multi-axis control and ultra-fine wire technology, we achieve tolerances as tight as ±0.002 mm and surface finishes down to Ra 0.2 µm, enabling intricate cuts and superior edge quality without inducing mechanical stress.

Our process begins with a thorough review of your design to optimize cut paths, reduce lead times, and ensure dimensional accuracy. We support both .STEP/.IGES and 2D DXF/DWG file formats, and our engineering team is available to provide Design for Manufacturability (DFM) feedback before machining begins. This proactive approach minimizes errors, reduces costs, and accelerates time-to-market.

We understand that every project is unique. That’s why we offer fully customizable setups, including taper cutting up to ±30°, skived or square starts, and secondary operations integration. From small internal radii to complex contours, our Wire EDM solutions deliver repeatability and precision unmatched by conventional machining methods.

Below is an overview of our standard Wire EDM capabilities:

| Specification | Capability |

|————–|————|

| Maximum Workpiece Size | 400 mm × 300 mm × 200 mm |

| Maximum Weight | 500 kg |

| Tolerance | ±0.002 mm |

| Surface Finish | As fine as Ra 0.2 µm |

| Wire Diameter Range | 0.1 mm – 0.3 mm |

| Taper Cutting | Up to ±30° |

| Materials | Hardened steel, titanium, inconel, carbide, copper, brass, and more |

| Lead Time | As fast as 3–5 working days |

At Shenzhen Honyo Prototype, we are committed to being your trusted partner in precision manufacturing. Our ISO 9001-certified processes, rigorous quality control, and responsive customer service ensure that your project is handled with the highest level of professionalism.

Ready to bring your next precision component to life? Contact Susan Leo today to discuss your Wire EDM project. Send your design files and requirements to info@hy-proto.com for a fast, detailed quote and expert technical support. Let us help you achieve precision you can rely on.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.