Contents

Manufacturing Insight: 16 Gauge Thickness Stainless Steel

Manufacturing Insight: 16 Gauge Thickness Stainless Steel in CNC Machining

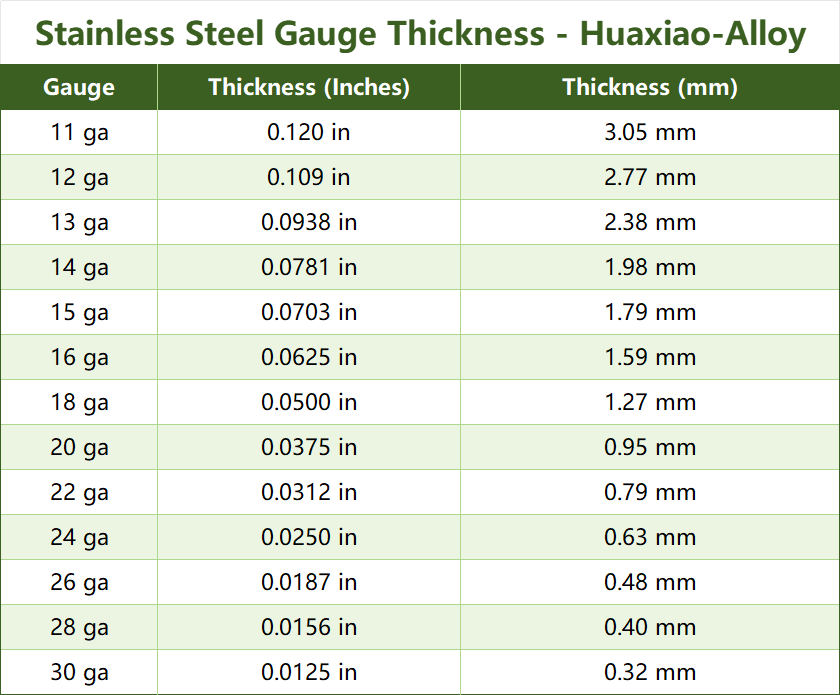

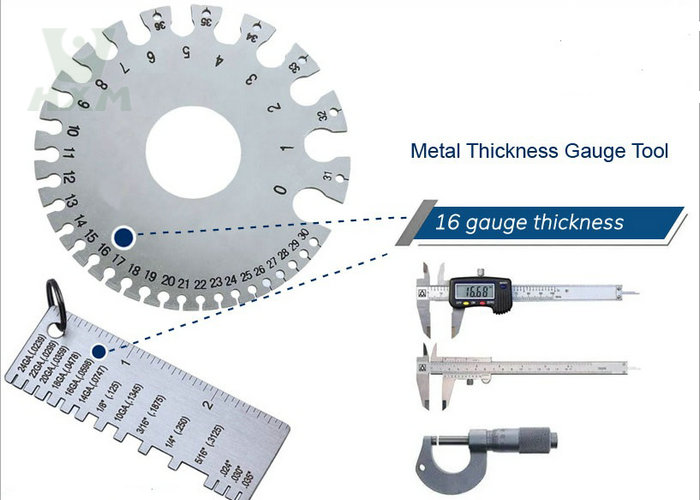

Shenzhen Honyo Prototype specializes in the precise CNC machining of challenging materials, including 16 gauge (approximately 1.50 mm or 0.0598 inches) stainless steel sheet and plate. This specific thickness represents a critical point in fabrication, balancing structural integrity with manufacturability for demanding applications across medical devices, aerospace components, and precision enclosures. Understanding the inherent properties of stainless steel at this gauge is paramount for achieving dimensional accuracy, surface finish, and functional performance in prototypes and low-volume production.

Machining 16 gauge stainless steel presents distinct technical challenges. Its high strength, work-hardening tendency, and low thermal conductivity necessitate specialized CNC strategies. Conventional machining parameters often lead to rapid tool wear, poor surface finish, thermal distortion, or even part failure due to induced stresses. Material grades like AISI 304 and 316 dominate this thickness range for prototyping, requiring careful consideration of cutting dynamics to prevent galling and maintain edge integrity. Honyo’s engineering team addresses these complexities through a foundation of material science expertise and advanced process control.

Our CNC machining capabilities for 16 gauge stainless steel are built upon optimized parameters rigorously validated through in-house testing. Key specifications and our implemented solutions are summarized below:

| Parameter Category | Key Specifications & Honyo Implementation |

| :———————– | :———————————————————— |

| Material Grades | AISI 304, 304L, 316, 316L; strict material certification verification |

| Cutting Speeds/Feeds | Significantly reduced vs. mild steel; dynamically adjusted based on real-time tool load monitoring to minimize heat generation and work hardening |

| Tooling Strategy | Carbide end mills with specialized PVD coatings (e.g., AlTiN); high positive rake geometry; rigid tool holders; mandatory frequent tool inspection/replacement |

| Machine Requirements | High-rigidity CNC mills (4-axis & 5-axis); consistent high-pressure coolant delivery (often through-spindle); thermal stability protocols |

Honyo leverages its Shenzhen-based facility’s advanced 5-axis machining centers, featuring sub-micron positioning accuracy and integrated probing systems, to maintain tolerances consistently within ±0.05 mm for critical features on 16 gauge stainless parts. We implement aggressive chip evacuation protocols and strategic use of cryogenic cooling or high-performance synthetic coolants to manage heat effectively, preventing distortion in thin sections. Our process includes post-machining stress relief techniques and stringent first-article inspection using CMM and optical comparators to verify geometric conformity and surface quality meeting Ra ≤ 1.6 µm standards.

This focused capability enables clients to develop robust prototypes and bridge-to-production components where corrosion resistance, strength-to-weight ratio, and precise form are non-negotiable. By mastering the nuances of 16 gauge stainless steel, Honyo Prototype delivers manufacturable designs that transition seamlessly from concept validation to functional testing, mitigating common production risks associated with this demanding material and thickness. Partner with Honyo to transform your stainless steel prototypes into reliable, high-performance solutions.

Technical Capabilities

Technical Capabilities: CNC Machining of 16 Gauge Stainless Steel

Shenzhen Honyo Prototype specializes in high-precision CNC machining of 16 gauge (approximately 1.5 mm) stainless steel components, delivering consistent quality and tight tolerances for mission-critical applications across aerospace, medical, automotive, and industrial sectors. Our advanced 3, 4, and 5-axis milling centers, combined with precision turning equipment, enable us to handle complex geometries and intricate features in thin-section stainless steel with exceptional accuracy and surface finish.

16 gauge stainless steel presents unique challenges due to its reduced thickness, which increases susceptibility to deformation, vibration, and thermal distortion during machining. At Honyo Prototype, we address these challenges through optimized toolpaths, low-deflection tooling, and specialized fixturing techniques that minimize workpiece movement and ensure dimensional stability. Our programming team utilizes high-efficiency machining (HEM) strategies to reduce cutting forces, enabling clean, burr-free edges and maintaining material integrity.

We routinely machine a range of stainless steel alloys, including 304/L, 316/L, 17-4 PH, and 430, each selected based on the application’s requirements for corrosion resistance, strength, and weldability. These materials are well-suited for 16 gauge fabrication and respond effectively to CNC processes when proper parameters are applied.

Our 5-axis milling platforms allow for single-setup machining of complex 3D contours, reducing cumulative error and improving positional accuracy. For rotational parts, our CNC turning centers integrate live tooling to perform mill-turn operations, enabling complete fabrication of turned components with cross-drilled holes, flats, or keyways—all within tight tolerance bands.

Tight tolerance machining is a core competency at Honyo Prototype. We maintain process control through in-process probing, laser tool measurement, and post-production inspection using coordinate measuring machines (CMM) and optical comparators. This ensures that every 16 gauge stainless steel part meets or exceeds specified tolerance requirements.

The following table outlines our standard and achievable tolerances for CNC machining 16 gauge stainless steel:

| Feature Type | Standard Tolerance | Achievable Tolerance (with process control) | Notes |

|———————–|——————–|———————————————|——-|

| Linear Dimensions | ±0.05 mm | ±0.025 mm | Up to 100 mm; beyond requires compensation |

| Hole Diameter | ±0.05 mm | ±0.015 mm | Reamed or honed features |

| Positional Tolerance | ±0.05 mm | ±0.02 mm | GD&T compliant; includes true position |

| Surface Roughness (Ra)| 3.2 µm | 0.8 – 1.6 µm | Achieved via finish passes and tool selection |

| Flatness | 0.1 mm | 0.05 mm | Critical for thin plates; vacuum or magnetic fixturing used |

| Angular Features | ±0.1° | ±0.05° | Verified with optical inspection |

All processes are supported by full documentation, first-article inspection reports (FAIR), and material certifications. At Shenzhen Honyo Prototype, we combine engineering expertise with advanced manufacturing technology to deliver reliable, high-precision 16 gauge stainless steel components tailored to our clients’ exact specifications.

From CAD to Part: The Process

CNC Machining Production Process: 16 Gauge Stainless Steel Parts

This workflow details Honyo Prototype’s integrated process for manufacturing precision components from 16 gauge (1.5 mm / 0.063 inch) stainless steel, ensuring optimal quality and efficiency from initial design submission to finished part delivery. Our focus on thin-gauge stainless steel necessitates specialized handling throughout to mitigate distortion risks inherent in this material thickness.

AI-Powered Quoting & Initial Assessment

Upon receipt of your CAD file (STEP, IGES, or native format preferred), our proprietary AI quoting engine performs an immediate preliminary analysis. This system rapidly evaluates geometric complexity, identifies potential thin-wall sections below 2.0 mm, checks for undercuts or deep cavities exceeding aspect ratio limits for 1.5 mm stock, and assesses overall manufacturability against standard CNC machining capabilities for thin stainless. The AI cross-references material properties of common grades like 304 and 316 stainless steel against our machine tool databases and historical production data. Within minutes, this generates a detailed, technically validated preliminary quote outlining estimated machining time, material requirements, critical process considerations specific to 16 gauge stock, and any immediate flags requiring designer attention before formal order placement. This step significantly reduces quoting lead time while providing actionable technical feedback early.

Comprehensive DFM Analysis & Process Planning

Following quote acceptance, our Senior Manufacturing Engineers conduct an in-depth Design for Manufacturability (DFM) review. This critical phase specifically addresses the challenges of machining 1.5 mm thick stainless steel. Engineers meticulously analyze wall stability, hole aspect ratios, feature isolation, and overall part rigidity. We identify areas prone to chatter or deflection during cutting and evaluate the necessity of specialized fixturing solutions like vacuum tables, low-force modular clamps, or sacrificial stock bonding to prevent workpiece movement and vibration-induced inaccuracies. Material grain direction and inherent stresses in thin sheet stock are factored into the machining sequence strategy. We provide specific, actionable recommendations to the client—such as minor radii adjustments, strategic relief cuts, or feature repositioning—to enhance manufacturability, reduce cycle time, and eliminate potential distortion without compromising core functionality. Client approval of the final DFM report and process plan is mandatory before production release.

Precision CNC Machining Execution

With DFM validation complete, production commences using optimized parameters validated for 16 gauge stainless steel. Parts are securely fixtured using the pre-determined low-distortion method. Machining employs high-precision CNC mills and lathes with rigid setups, utilizing sharp, polished carbide tooling specifically selected for stainless steel. Critical process parameters are strictly controlled as shown below to manage heat generation and cutting forces, preventing work hardening and part warpage.

| Parameter | Typical Value for 16ga SS | Rationale |

| :—————– | :———————— | :—————————————– |

| Spindle Speed | 4000 – 6000 RPM | Balances chip evacuation & heat control |

| Feed Rate | 100 – 250 mm/min | Minimizes deflection on thin features |

| Stepover (Roughing)| ≤ 30% of tool diameter | Reduces radial cutting forces |

| Coolant | High-pressure through-spindle | Critical for chip evacuation & cooling |

| Material Grade | 304, 316, or client spec | Standard austenitic stainless properties |

All critical dimensions undergo in-process verification using calibrated CMMs or optical comparators. Final parts receive thorough deburring, precision cleaning to remove ferrous contamination, and a comprehensive dimensional and visual inspection per AS9102 or client-specified standards before shipment. This integrated workflow ensures reliable, high-quality 16 gauge stainless steel components meeting stringent B2B requirements.

Start Your Project

Start Your Project with Precision CNC Machining for 16 Gauge Stainless Steel

When it comes to manufacturing high-performance components from 16 gauge stainless steel, precision, material integrity, and process consistency are non-negotiable. At Shenzhen Honyo Prototype, we specialize in CNC machining services tailored to meet the exacting demands of industries ranging from medical and aerospace to industrial equipment and consumer electronics. Our expertise in working with 16 gauge (approximately 1.5 mm thick) stainless steel ensures dimensional accuracy, superior surface finish, and reliable repeatability across both prototyping and low-to-mid volume production runs.

Stainless steel at 16 gauge thickness offers an optimal balance between structural rigidity and formability, making it ideal for enclosures, brackets, chassis components, and precision housings. Common grades such as 304 and 316 are routinely processed in our facility using advanced 3-, 4-, and 5-axis CNC milling and turning centers. These machines are calibrated to maintain tight tolerances—down to ±0.005 mm—ensuring that every part meets your engineering specifications without compromise.

Our end-to-end manufacturing workflow begins with a thorough review of your design files. Whether you provide 2D drawings or 3D CAD models, our engineering team evaluates material selection, feature feasibility, and potential optimization for manufacturability (DFM). We support a wide range of finishing options including passivation, electropolishing, bead blasting, and laser engraving to enhance corrosion resistance and aesthetic quality.

Below are the key technical specifications for CNC machining 16 gauge stainless steel at Honyo Prototype:

| Parameter | Specification |

|—————————-|—————————————————-|

| Material Thickness | 1.5 mm (16 gauge) |

| Common Grades | SS304, SS316, SS430 |

| Tolerance Capability | ±0.005 mm (standard), tighter upon request |

| Minimum Hole Diameter | 0.8 mm (drilled), 0.5 mm (laser) |

| Maximum Work Envelope | 1200 x 800 x 200 mm (for multi-axis milling) |

| Surface Roughness (Ra) | As low as 0.4 µm after polishing or grinding |

| Lead Time (Prototype) | 5–7 working days after design approval |

| Finishing Options | Passivation, bead blast, electropolish, engraving |

We understand that starting a new project requires confidence in your manufacturing partner. That’s why Honyo Prototype combines state-of-the-art equipment with rigorous quality control, including in-process inspections and final CMM verification. All materials are certified and traceable, and every production batch is documented for full accountability.

If you’re ready to move from concept to prototype—or scale to production—contact Susan Leo today. As your dedicated project manager, Susan will guide you through the onboarding process, answer technical questions, and ensure your timeline and quality expectations are met.

Contact Susan Leo

Email: info@hy-proto.com

Let us help you bring your 16 gauge stainless steel components to life with precision, speed, and engineering excellence.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.