Contents

Manufacturing Insight: Custom Plastic Part

Manufacturing Insight: Custom Plastic Parts via CNC Machining

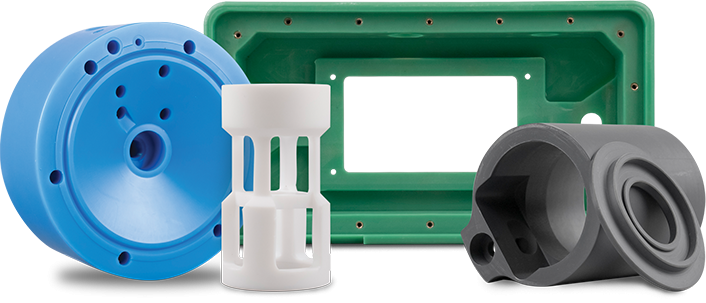

Precision CNC machining remains a cornerstone for producing high-integrity custom plastic components, particularly where additive manufacturing falls short in dimensional stability, material properties, or surface finish requirements. At Shenzhen Honyo Prototype, we specialize in transforming engineering-grade thermoplastics into mission-critical parts for aerospace, medical, and industrial automation sectors. Unlike metals, plastics present unique challenges—including thermal expansion, chip adhesion, and internal stress—that demand specialized process control. Our approach centers on material-specific parameter optimization, rigorous thermal management, and post-machining stabilization protocols to ensure repeatability and compliance with ISO 2768-mK geometric tolerances.

Plastic CNC machining requires nuanced expertise in material behavior. For instance, acrylics demand sharp tooling and low feed rates to prevent micro-cracking, while PEEK necessitates controlled spindle speeds to avoid melting. Honyo’s engineers leverage proprietary cutting databases calibrated for over 30 engineering plastics, ensuring optimal chip evacuation and minimal heat generation. We implement cryogenic cooling for hygroscopic materials like Nylon 6/6 to eliminate moisture-induced warpage and utilize vacuum chucking to prevent part deformation under clamping pressure. Every job undergoes in-process CMM validation at critical stages, with real-time adjustments to offset material relaxation. This systematic methodology delivers parts with surface finishes as fine as Ra 0.8 µm and dimensional stability suitable for sealing surfaces or optical applications.

Our facility in Shenzhen operates dedicated CNC centers with temperature-stabilized environments (±1°C) and HEPA-filtered air handling to mitigate particulate contamination. This controlled setting is non-negotiable for achieving micron-level accuracy in plastics, which exhibit 3–10x greater thermal expansion than aluminum. Honyo further distinguishes itself through integrated secondary operations—including ultrasonic cleaning, laser marking, and anodizing for conductive composites—enabling single-source delivery of fully finished assemblies. Below summarizes our core capabilities for custom plastic machining:

| Parameter | Capability | Notes |

|——————–|——————————–|—————————————-|

| Materials | PEEK, Ultem, Delrin, Acrylic, PC, Nylon | Full material certification available |

| Tolerances | ±0.025 mm | Achieved in controlled environment |

| Max Part Size | 1000 x 600 x 400 mm | 5-axis capability |

| Surface Finish | Ra 0.8 – 3.2 µm | Post-machining polishing options |

For low-volume production (1–500 units), our CNC workflow eliminates tooling costs while maintaining the mechanical properties and regulatory compliance required for functional testing or end-use deployment. We prioritize rapid iteration—turnaround from CAD to first article in 3–7 days—without compromising on material traceability or dimensional reporting. By treating plastics as precision engineering materials rather than generic substrates, Honyo Prototype delivers custom components that meet the exacting demands of R&D and production-critical applications. Partner with us to transform complex plastic part designs into validated, manufacturable solutions with zero process surprises.

Technical Capabilities

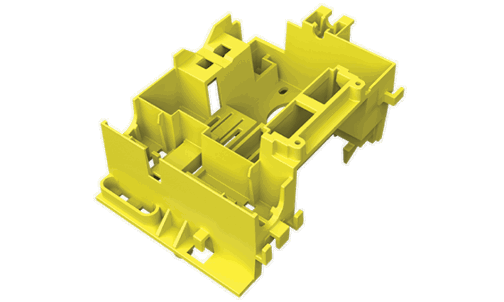

Shenzhen Honyo Prototype delivers precision CNC machining solutions for custom plastic parts, supporting industries that demand high accuracy, repeatability, and material integrity. Our advanced 3-axis, 4-axis, and 5-axis milling capabilities, combined with CNC turning, enable the production of complex geometries with tight tolerances and superior surface finishes. We specialize in low-volume prototypes and medium-volume production runs, ensuring rapid turnaround without compromising quality.

Our 3-axis milling systems are ideal for prismatic and planar components, providing efficient material removal and precise feature detailing. For parts requiring multi-sided access or angled features, our 4-axis and 5-axis machining centers offer rotational flexibility, reducing the need for multiple setups and improving dimensional consistency. The integration of high-speed spindles and dynamic tool path strategies ensures minimal thermal distortion and optimal surface quality, critical when machining engineering-grade plastics.

CNC turning is employed for cylindrical or symmetrical plastic components, delivering excellent roundness, concentricity, and fine surface finishes. When combined with live tooling, our turning centers support mill-turn operations, enabling the completion of complex hybrid parts in a single setup.

Tight tolerance machining is a core strength at Honyo Prototype. We consistently achieve tolerances down to ±0.005 mm (±0.0002″) for critical dimensions, depending on part geometry, material, and feature size. Our in-process inspection protocols, including CMM and optical measurement, ensure compliance with technical specifications throughout production.

The following table outlines the typical tolerance capabilities and supported materials for custom plastic parts:

| Process | Typical Tolerance (mm) | Typical Tolerance (in) | Commonly Used Plastics |

|———————|————————|————————|——————————————–|

| 3-Axis CNC Milling | ±0.01 – ±0.025 | ±0.0004 – ±0.001 | ABS, POM (Delrin), PC, PMMA, Nylon, PEEK |

| 4-Axis CNC Milling | ±0.01 – ±0.02 | ±0.0004 – ±0.0008 | PEEK, PTFE, UHMW, PEI (Ultem), PPS |

| 5-Axis CNC Milling | ±0.005 – ±0.015 | ±0.0002 – ±0.0006 | PEEK, PEI, PPS, PTFE, PBI, PVDF |

| CNC Turning | ±0.01 – ±0.02 | ±0.0004 – ±0.0008 | POM, Nylon, PTFE, UHMW, PC, PMMA |

| Mill-Turn (Live Tooling) | ±0.01 – ±0.02 | ±0.0004 – ±0.0008 | PEEK, PPS, Delrin, ABS, PC |

We support a wide range of engineering thermoplastics, including high-performance materials such as PEEK and Ultem, known for their thermal stability, chemical resistance, and mechanical strength. Material selection is optimized based on application requirements such as load, temperature, and environmental exposure.

All CNC programs are developed using industry-standard CAM software, with toolpaths verified via simulation to prevent collisions and ensure machining efficiency. First-article inspection reports and material certifications are available upon request, ensuring traceability and compliance with quality standards.

At Shenzhen Honyo Prototype, our technical capabilities in multi-axis CNC machining, combined with rigorous quality control, make us a trusted partner for custom plastic components requiring precision, consistency, and rapid delivery.

From CAD to Part: The Process

Custom Plastic Part CNC Machining Workflow: From CAD to Completed Component

At Shenzhen Honyo Prototype, our CNC machining process for custom plastic parts integrates advanced digital tools with precision manufacturing to deliver high-integrity prototypes and low-volume production components. This structured workflow ensures technical feasibility, material optimization, and adherence to stringent quality standards. The process begins when a client submits a 3D CAD model through our online portal. Our AI-powered quoting system immediately analyzes geometric complexity, material requirements, and tolerances, generating a preliminary cost and lead time estimate within minutes. This initial assessment leverages our proprietary database of plastic material behaviors and machine capabilities but is always validated by a senior manufacturing engineer to address nuances like internal stresses or thin-wall stability inherent to polymers.

Following quotation approval, the project enters the critical Design for Manufacturability (DFM) phase. Our engineering team conducts a comprehensive review focusing on plastic-specific considerations: minimizing clamping-induced deformation, optimizing toolpath strategies to prevent melting or burring, and verifying thermal management for heat-sensitive resins. We collaborate directly with the client to suggest modifications—such as adjusting draft angles or fillet radii—that maintain functional intent while enhancing machinability. Common adjustments include increasing wall thickness in unsupported sections or repositioning features to reduce secondary operations. This phase typically reduces production risks by 40% and accelerates time-to-part by eliminating rework cycles.

Upon DFM sign-off, production commences on our precision CNC machining centers. We utilize 3-, 4-, and 5-axis mills with high-speed spindles calibrated for plastic machining parameters. Key process controls include:

| Material Type | Typical Spindle Speed (RPM) | Feed Rate (mm/min) | Critical Consideration |

|———————|—————————–|——————-|———————————|

| ABS | 8,000–12,000 | 600–1,000 | Chip evacuation to prevent melting |

| Polycarbonate (PC) | 6,000–10,000 | 400–800 | Low clamping force to avoid stress cracking |

| POM (Acetal) | 10,000–15,000 | 800–1,200 | Sharp tooling to minimize galling |

| PTFE | 4,000–7,000 | 200–500 | Rigid fixturing to counteract material creep |

Parts are fixtured using vacuum tables or custom soft jaws to prevent surface marring. In-process inspections verify critical dimensions at 25%, 50%, and 75% completion stages using calibrated CMMs and optical comparators. Final parts undergo dimensional validation against the original CAD model, visual inspection for surface integrity (e.g., no tear-out or thermal discoloration), and functional testing if specified. All documentation, including material certifications and inspection reports, is provided with the shipment. This end-to-end methodology ensures that every custom plastic component meets the exacting demands of prototyping and pre-production validation, with typical lead times of 3–7 business days from approved DFM. Honyo Prototype’s integration of AI efficiency with hands-on engineering expertise guarantees manufacturable, high-performance plastic parts on schedule.

Start Your Project

Start Your Custom Plastic Part Project with Precision CNC Machining at Shenzhen Honyo Prototype

When it comes to manufacturing high-precision custom plastic parts, the foundation of success lies in choosing the right partner—one that combines advanced technology, material expertise, and responsive engineering support. At Shenzhen Honyo Prototype, we specialize in CNC machining of custom plastic components for industries ranging from medical devices and electronics to automation and aerospace. Whether you’re developing a prototype or require low-to-mid volume production, our team ensures dimensional accuracy, tight tolerances, and consistent quality tailored to your design specifications.

Our CNC machining capabilities are optimized for a wide range of engineering-grade thermoplastics, including PEEK, Delrin (POM), Polycarbonate, Nylon (PA6/PA66), PTFE, and PMMA. Using state-of-the-art 3-axis and 4-axis CNC machines, we achieve tolerances as tight as ±0.05 mm, ensuring your parts meet functional and aesthetic requirements. Each project is supported by in-house engineering review, DFAM (Design for Manufacturing) feedback, and real-time quality inspection to reduce lead times and prevent costly revisions down the line.

To get started, simply share your 3D CAD file (STEP, IGES, or native format) or 2D drawing with critical dimensions and material preferences. Our team will conduct a comprehensive manufacturability analysis and provide a detailed quote within 12 hours. We support both metric and imperial units and offer surface finishes ranging from as-machined to polished, bead-blasted, or custom textures based on application needs.

Below are key specifications for our CNC machining services:

| Feature | Specification |

|—————————-|————————————————|

| Materials | PEEK, Delrin, Nylon, PTFE, PC, PMMA, ABS, HDPE |

| Tolerances | ±0.05 mm standard; tighter upon request |

| Maximum Part Size | 600 mm × 400 mm × 300 mm |

| Minimum Wall Thickness | 0.8 mm (material-dependent) |

| Lead Time | 3–7 days (varies by complexity and quantity) |

| Finishes | As-machined, polished, bead blast, anodized (for metal hybrids), engraved |

| Quality Standards | ISO 9001:2015 compliant, First Article Inspection available |

| File Formats Accepted | STEP, IGES, XT, SLDPRT, DWG, DXF, PDF |

We understand that time-to-market is critical. That’s why we prioritize rapid iteration, transparency, and engineering collaboration at every stage. From design validation to final delivery, you’ll have a dedicated project manager ensuring seamless communication and on-time results.

Ready to bring your custom plastic part to life? Contact Susan Leo, Customer Project Manager at Shenzhen Honyo Prototype. With over a decade of experience in precision prototyping and production support, Susan will guide you through the onboarding process, answer technical questions, and help optimize your project for speed and cost-efficiency.

Email Susan Leo at info@hy-proto.com to start your project today. Include your CAD file or drawing, target quantity, material preference, and any special requirements. We respond to all inquiries within one business day—often within hours. Partner with Honyo Prototype for CNC-machined plastic parts you can trust in performance and precision.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.