Contents

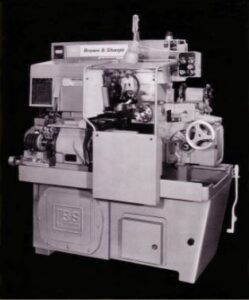

Manufacturing Insight: Brown & Sharpe Tooling

Manufacturing Insight: Brown & Sharpe Tooling in Precision CNC Machining

Brown & Sharpe (B&S) tooling represents a foundational standard in precision machining, originating from the iconic American instrument maker. While modern CNC systems predominantly utilize CAT, BT, or HSK toolholders, the B&S taper system (formally standardized under ISO 296) remains critically relevant for legacy equipment integration, specialized tooling, and high-accuracy applications requiring exceptional concentricity and rigidity. At Shenzhen Honyo Prototype, we maintain deep expertise in B&S tooling compatibility, enabling seamless support for clients utilizing this enduring standard within contemporary CNC workflows.

The B&S taper is defined by its unique 16.59° included angle (distinct from Morse tapers at 1.49°), coupled with a precision male taper on the tool shank and a matching female socket in the spindle. This design delivers superior concentricity (typically ≤ 0.0002″ TIR) and axial repeatability due to its self-holding characteristics and robust mechanical interface. Unlike steep-taper systems relying on drawbar force alone, B&S tooling achieves secure retention through precise friction fit, minimizing micro-vibration during light to medium cuts—critical for fine finishing and micro-machining tasks. Below outlines key specifications for common B&S sizes utilized in our facility:

| Size | Shank Diameter (mm) | Taper Angle (°) | Max Recommended Torque (Nm) | Typical Application Range |

|——|———————|—————–|—————————–|—————————|

| B&S 7 | 12.065 | 16.59 | 15 | Micro-drilling, engraving |

| B&S 10 | 17.480 | 16.59 | 35 | Precision milling, jig boring |

| B&S 12 | 23.000 | 16.59 | 65 | Small-part turning, grinding |

| B&S 15 | 29.000 | 16.59 | 110 | Multi-axis prototyping, mold work |

Honyo Prototype leverages B&S tooling’s inherent stability to solve complex manufacturing challenges where thermal growth or high-frequency chatter compromises newer systems. Our CNC machining centers are equipped with certified B&S spindle interfaces, maintained to ISO 2768-mK geometric tolerances. We specialize in adapting legacy tooling to modern CNC programs, including custom hybrid holders that convert B&S shanks to CAT40/BT30 spindles without sacrificing runout performance. This capability is particularly valuable for aerospace and medical clients restoring vintage tooling or requiring micron-level tolerances unattainable with standard steep tapers.

Our engineering team rigorously validates all B&S tool assemblies using laser interferometry and dynamic balancing to ensure ≤ 0.0001″ runout at operating speeds. This precision extends to workholding—our custom B&S collet chucks achieve 0.00008″ repeatability, enabling features like sub-5µm surface finishes on hardened steels. Crucially, Honyo maintains an extensive library of ISO 296-compliant tooling documentation, allowing rapid reverse-engineering of obsolete fixtures while guaranteeing interchangeability across global supply chains.

For manufacturers navigating mixed-technology environments, B&S tooling remains a strategic asset. Honyo Prototype bridges historical standards with next-generation CNC execution, delivering the geometric fidelity and process stability demanded by high-integrity prototypes and low-volume production. We invite engineering teams to engage our application specialists for feasibility assessments on B&S-integrated machining strategies.

Technical Capabilities

Brown & Sharpe Tooling Capabilities in Precision CNC Machining

Shenzhen Honyo Prototype leverages Brown & Sharpe tooling systems to deliver high-precision CNC machining services across 3-axis, 4-axis, and 5-axis milling platforms, as well as multi-axis turning operations. Brown & Sharpe tooling, known for its rigidity, repeatability, and metrological accuracy, enables our manufacturing team to maintain tight tolerances and superior surface finishes across a wide range of engineering materials. These tooling systems are integrated into our CNC workflows to ensure minimal runout, improved tool life, and enhanced dimensional consistency—critical for prototyping and low-to-mid volume production runs in aerospace, medical, and automation sectors.

Our 3-axis milling services utilize Brown & Sharpe collet chucks and precision v-blocks to secure workpieces during high-speed milling operations. These systems ensure excellent parallelism and squareness, especially when machining flat surfaces, pockets, and through-cuts in materials such as aluminum, stainless steel, and engineering plastics. For more complex geometries, our 4-axis and 5-axis CNC machining centers employ Brown & Sharpe rotary tables and precision indexing fixtures. These allow for simultaneous multi-face machining with minimal re-fixturing, reducing cumulative alignment errors and improving overall part accuracy.

In turning operations, Brown & Sharpe tool holders and precision ground inserts are used in conjunction with live tooling on CNC lathes to achieve high concentricity and surface integrity. This is particularly critical when producing shafts, bushings, and other rotational components requiring geometric tolerances such as runout, cylindricity, and positional accuracy.

Tight tolerance machining is a core competency at Honyo Prototype. With Brown & Sharpe tooling, we consistently achieve tolerances down to ±0.0002″ (±0.005 mm) on critical dimensions. Our metrology suite, including CMM and laser scanning, validates compliance with these tolerances across production batches. The rigidity and thermal stability of Brown & Sharpe components reduce deflection and thermal drift during prolonged machining cycles, ensuring long-term process reliability.

The following table outlines the achievable tolerances and compatible materials for our Brown & Sharpe-integrated CNC processes:

| Process | Typical Tolerance (±) | Geometric Tolerance | Materials Supported |

|———————-|————————|———————-|———————————————–|

| 3-Axis Milling | 0.0003″ (0.008 mm) | ±0.0004″ flatness | Aluminum 6061, 7075, Stainless Steel 303, 316, Titanium, PEEK, ABS, Delrin |

| 4-Axis Milling | 0.00025″ (0.006 mm) | ±0.0003″ true position | Aluminum, Steel Alloys, Brass, Polycarbonate |

| 5-Axis Milling | 0.0002″ (0.005 mm) | ±0.0002″ runout | Inconel, Titanium, Magnesium, PTFE, Nylon |

| CNC Turning | 0.0002″ (0.005 mm) | 0.0002″ concentricity| 17-4 PH, 4140, 6061-T6, PEEK, Acetal |

All processes are supported by advanced CAM programming, real-time tool wear compensation, and in-process inspection where required. By combining Brown & Sharpe’s legacy in precision tooling with modern CNC technology, Shenzhen Honyo Prototype delivers machined components that meet the most demanding engineering specifications.

From CAD to Part: The Process

CNC Machining Workflow for Brown & Sharpe Tooling Components

At Shenzhen Honyo Prototype, precision Brown & Sharpe tooling components—encompassing precision ground pins, bushings,_locator pins, and gage blocks essential for workholding and inspection—are manufactured through a rigorously defined CNC workflow. This process ensures dimensional accuracy, geometric conformity, and material integrity critical for downstream manufacturing applications. Our methodology systematically transforms customer CAD data into certified physical parts, minimizing iteration and maximizing first-pass yield. The core sequence integrates advanced digital tools with expert engineering oversight, starting with AI-driven quotation and culminating in validated production.

The workflow initiates upon receipt of validated 3D CAD geometry. Honyo’s proprietary AI quoting engine rapidly analyzes the model’s geometric complexity, material requirements, tolerance stringency, and feature density. This system cross-references our extensive machining database and real-time shop floor capacity to generate an accurate cost estimate and feasible lead time within minutes. Crucially, the AI pre-flags potential high-risk areas such as thin walls, deep cavities, or conflicting tolerances, providing immediate preliminary feedback to the client before formal order placement. This transparency accelerates project initiation and sets clear expectations.

Following order confirmation, the CAD model undergoes comprehensive Design for Manufacturability (DFM) analysis by our senior engineering team. This phase is non-negotiable for Brown & Sharpe tooling, where micron-level deviations compromise functionality. Engineers meticulously review geometric dimensioning and tolerancing (GD&T), material suitability, tool access, fixturing feasibility, and surface finish requirements. We identify opportunities to optimize part geometry without sacrificing function—such as modifying non-critical fillet radii or suggesting alternative stock sizes—to enhance machinability and reduce cycle time. The DFM report, delivered within 24 hours, details actionable recommendations and confirms manufacturability within Honyo’s certified process capabilities. Key DFM parameters are strictly governed as shown below.

| Parameter | Standard Tolerance | Critical Tolerance | Verification Method |

|——————–|——————–|——————–|—————————|

| Diameter (Ground) | ±0.005 mm | ±0.001 mm | CMM, Air Gaging |

| Length | ±0.01 mm | ±0.002 mm | CMM, Optical Comparator |

| Perpendicularity | 0.005 mm | 0.001 mm | CMM, Surface Plate |

| Surface Roughness | Ra 0.8 µm | Ra 0.2 µm | Profilometer |

Upon DFM sign-off, the part transitions to production. Programmers generate optimized CNC toolpaths using Mastercam, leveraging Honyo’s library of proven machining strategies for hardened steels and precision alloys common in tooling. All programs undergo rigorous virtual simulation to eliminate collisions and verify tool engagement. Machining occurs on our HAAS and DMG MORI 5-axis vertical mills and precision grinders, operating under strict environmental controls. In-process inspections at critical stages—using calibrated micrometers, height gauges, and vision systems—ensure conformance. Final inspection employs Zeiss CMMs and custom gaging fixtures to certify all critical dimensions against the approved drawing, with full traceability documentation provided. This integrated AI-DFM-Production pipeline guarantees Brown & Sharpe components meet the uncompromising standards demanded by precision manufacturing and quality assurance systems.

Start Your Project

Start Your Project with Precision: Partner with Honyo Prototype for Brown & Sharpe Tooling Solutions

When it comes to high-precision CNC machining, the integration of Brown & Sharpe tooling systems represents a gold standard in accuracy, repeatability, and operational efficiency. At Shenzhen Honyo Prototype, we specialize in leveraging this legacy of precision engineering to deliver prototype and low-volume production components that meet the most stringent industry requirements. Whether you’re developing aerospace components, medical devices, or complex industrial tooling, starting your project with the right manufacturing partner is critical to achieving success on time and within budget.

Brown & Sharpe tooling, originally developed by the pioneering American manufacturer, is renowned for its rigid, modular design and exceptional concentricity. These characteristics make it ideal for applications requiring micron-level tolerances and minimal runout. At Honyo Prototype, we have fully integrated Brown & Sharpe-compatible systems into our CNC machining centers, enabling us to maintain consistent tool alignment, reduce setup times, and enhance overall machining stability. Our technical team is trained in precision tooling calibration and performs regular system audits to ensure compliance with ISO 9001 standards.

We understand that every project begins with a vision. That’s why we offer a consultative approach to manufacturing—starting with a detailed review of your design specifications, material requirements, and performance expectations. Our engineers work closely with clients during the initial phase to identify potential design improvements, optimize for manufacturability, and recommend the most effective tooling strategy. This proactive collaboration minimizes iterations, reduces lead times, and ensures a seamless transition from concept to physical prototype.

To support a wide range of applications, we maintain a comprehensive inventory of Brown & Sharpe tool holders, collets, and adapters, compatible with both metric and imperial standards. Our CNC machining capabilities include 3-axis, 4-axis, and 5-axis milling, precision turning, and multi-tasking operations—all supported by advanced tool monitoring and automated tool changers calibrated for Brown & Sharpe systems.

Below is an overview of our core machining specifications:

| Specification | Capability |

|————–|————|

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Spindle Runout (with Brown & Sharpe tooling) | ≤ 0.003 mm TIR |

| Maximum Work Envelope (5-axis) | 800 x 600 x 500 mm |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Inconel, Plastics, Composites |

| Standard Tolerances | ±0.025 mm (tighter upon request) |

| Surface Finish | As low as Ra 0.4 µm (polishing available) |

Starting your project with Honyo Prototype means gaining access to a team that values precision as much as you do. We are committed to delivering components that not only meet but exceed expectations, backed by responsive communication and on-time delivery.

For immediate assistance with your next precision machining project, contact Susan Leo at info@hy-proto.com. Let us help you turn your design into a high-accuracy reality using proven Brown & Sharpe tooling and expert CNC machining capabilities.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.