Contents

Manufacturing Insight: 3D Printed Wax Mold

Manufacturing Insight: 3D Printed Wax Molds for Precision Casting

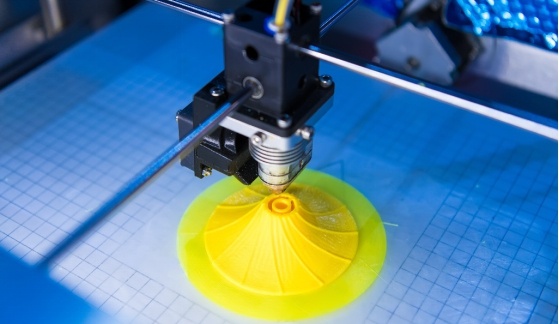

Investment casting remains a cornerstone for producing complex, high-integrity metal components across aerospace, medical, and automotive sectors. The critical initial step – creating the precise sacrificial pattern – has been transformed by industrial 3D printing of wax molds. Traditional wax injection tooling involves significant time and cost for complex geometries, creating bottlenecks in prototyping and low-volume production. 3D printed wax molds eliminate this barrier, enabling direct digital fabrication of intricate patterns with exceptional fidelity, drastically reducing lead times from weeks to days while maintaining the dimensional accuracy and surface finish required for high-quality castings. This technology is particularly advantageous for rapid iteration, complex internal features, and bespoke part production where tooling economics are prohibitive.

The core process leverages vat photopolymerization technologies, primarily Digital Light Processing (DLP) or high-resolution Stereolithography (SLA), using specialized casting wax photopolymers. These materials are engineered to mimic traditional injection waxes in burnout characteristics – cleanly vaporizing without residue during the shell firing process – while offering the design freedom of additive manufacturing. Parts are built layer by layer from a digital CAD model, capturing fine details, undercuts, and organic shapes impossible with conventional tooling. Post-processing involves careful support removal, thorough cleaning to eliminate uncured resin, and a controlled UV curing cycle to achieve full material properties and dimensional stability before proceeding to the standard investment casting shell building and burnout stages.

At Shenzhen Honyo Prototype, we specialize in industrial-grade 3D printed wax mold production, integrating this capability seamlessly into our end-to-end rapid casting services. Our investment focuses on high-precision DLP platforms operating within stringent environmental controls to ensure consistent part quality and repeatability. We utilize only certified, high-purity casting wax resins rigorously tested for optimal ash content, thermal decomposition behavior, and compatibility with common shell systems. Our engineering team possesses deep expertise in optimizing build orientation, support structures, and post-cure parameters specifically for wax patterns, ensuring minimal distortion and maximizing as-printed accuracy critical for the casting outcome. This mastery allows us to deliver patterns meeting tight tolerances essential for demanding applications.

Key technical capabilities underpinning our wax mold service are summarized below:

| Parameter | Specification |

| :—————– | :—————————————– |

| Technology | Industrial DLP (High-Resolution) |

| Layer Resolution | 25µm – 50µm |

| Max Build Volume | 192 x 108 x 300 mm |

| Material Type | Certified Investment Casting Wax Resin |

| Typical Accuracy | ±0.05mm + 0.05% per 100mm (as-printed) |

| Surface Finish (Ra)| 2.0 – 4.0 µm (post-processed) |

| Lead Time (Molds) | 3-5 Business Days (from approved CAD) |

Leveraging 3D printed wax molds through Honyo Prototype provides manufacturers a decisive competitive edge. We enable rapid validation of casting designs, facilitate complex geometry realization without tooling constraints, and accelerate time-to-market for critical metal components. Our commitment to process control, material science, and casting expertise ensures the patterns we produce translate directly into successful, high-yield investment casting runs, making us a trusted partner for innovation in metal component manufacturing.

Technical Capabilities

Technical Capabilities: 3D Printed Wax Molds at Shenzhen Honyo Prototype

Shenzhen Honyo Prototype specializes in advanced industrial 3D printing solutions for high-precision wax mold applications, serving industries such as investment casting, jewelry, dental, and aerospace. Our expertise spans multiple additive manufacturing technologies—Stereolithography (SLA), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), and Direct Metal Laser Sintering (DMLS)—enabling us to produce wax molds with exceptional dimensional accuracy, surface finish, and thermal performance. These capabilities ensure seamless integration into downstream casting processes, minimizing post-processing and maximizing yield.

SLA remains our primary method for wax mold production due to its superior resolution and smooth surface quality. Using high-performance photopolymer resins engineered to mimic traditional wax behavior, SLA enables the fabrication of intricate geometries with fine features down to 0.1 mm. This technology is ideal for prototypes and low-volume production runs requiring aesthetic fidelity and precise detail replication.

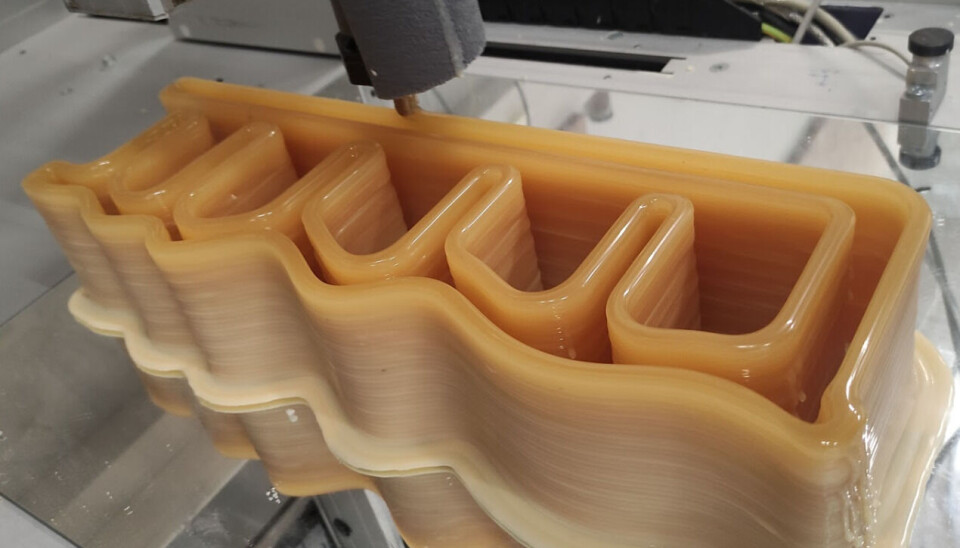

For applications demanding higher thermal stability or compatibility with automated casting lines, we utilize SLS and MJF with specialized wax-like polymer powders. These powder-based systems offer excellent part strength and consistency across larger batch sizes. While surface finish is slightly less smooth than SLA, both SLS and MJF provide robust molds suitable for high-temperature dewaxing cycles. Additionally, their support-free nature allows for complex internal channels and undercuts without sacrificial structures.

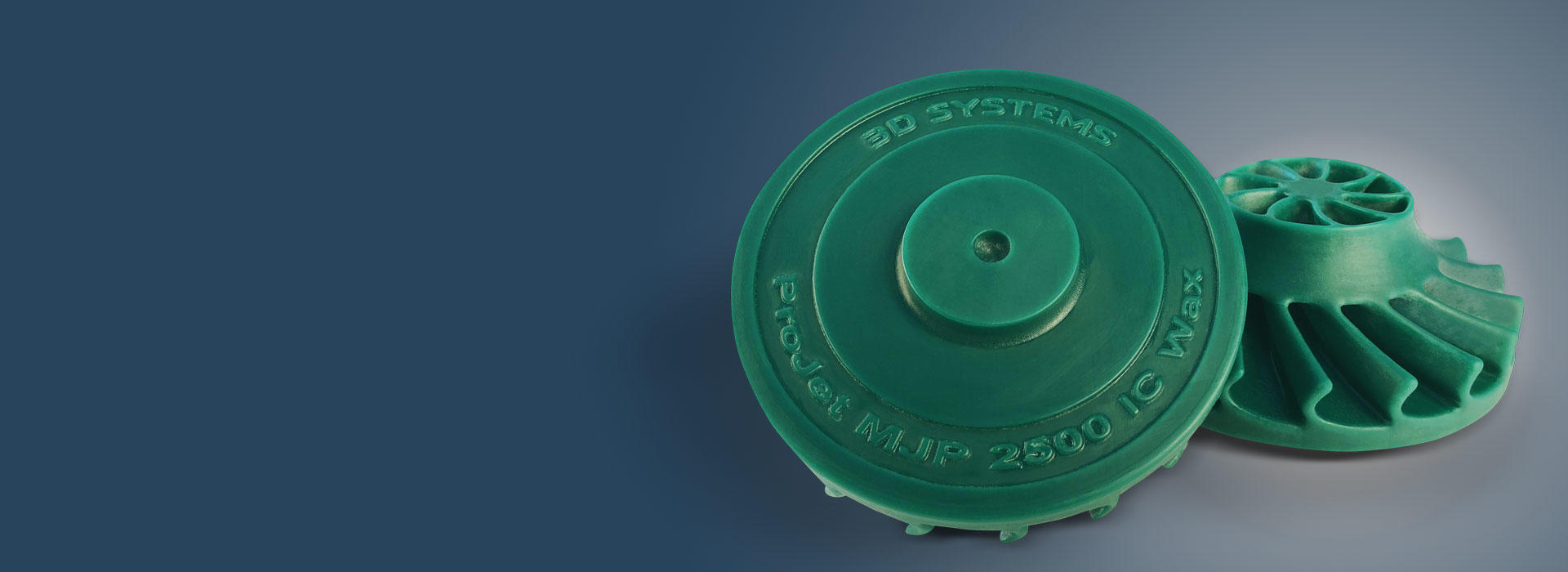

In select cases where direct metal patterns are required, DMLS is employed using low-thermal-conductivity metal alloys treated to simulate wax burnout characteristics. Though not a true wax process, DMLS enables ultra-durable molds for high-repetition investment casting, particularly in aerospace turbine blade manufacturing. This approach is reserved for mission-critical components where longevity and repeatability outweigh cost considerations.

All 3D printed wax molds undergo rigorous quality control, including first-article inspection and coefficient of thermal expansion (CTE) validation to ensure compatibility with ceramic shell systems. Post-processing options include vapor smoothing, autoclave dewaxing testing, and infiltration for enhanced green strength.

Below is a comparative summary of key technical specifications across our platforms:

| Technology | Material Type | Layer Thickness | Typical Tolerance | Surface Roughness (Ra) | Max Build Volume (mm) |

|———–|—————|——————|——————–|————————–|————————|

| SLA | Photopolymer Wax-Resin | 25–100 µm | ±0.1 mm (first 100 mm), ±0.05 mm thereafter | 0.8–1.6 µm | 140 x 140 x 180 |

| SLS | Wax-Composite Polyamide | 80–120 µm | ±0.2 mm | 3.0–5.0 µm | 250 x 250 x 300 |

| MJF | Wax-Filled Thermoplastic | 80 µm | ±0.2 mm | 2.5–4.0 µm | 380 x 280 x 380 |

| DMLS | Inconel 718 / Stainless Steel 17-4 PH (pattern use) | 20–50 µm | ±0.05 mm | 10–15 µm (as-built) | 250 x 250 x 325 |

Our multi-technology approach ensures optimal process selection based on client requirements for accuracy, volume, and thermal performance. Shenzhen Honyo Prototype maintains ISO 9001-certified workflows and collaborates closely with foundries to validate mold performance in real-world casting environments.

From CAD to Part: The Process

End-to-End Workflow for 3D Printed Wax Molds

Honyo Prototype delivers precision investment casting patterns through a streamlined digital manufacturing workflow. Our process eliminates traditional tooling delays by integrating AI-driven analysis with industrial-grade additive production. Starting from your CAD file, we ensure dimensional accuracy and casting integrity through three critical phases: AI Quote, Design for Manufacturability (DFM), and Production. This approach reduces lead times by up to 70% compared to conventional methods while maintaining strict aerospace and medical industry tolerances.

AI-Powered Quoting System

Upon CAD file submission, our proprietary AI engine instantly analyzes geometry complexity, material requirements, and build orientation. The system evaluates over 200 parameters—including wall thickness distribution, undercuts, and thermal stress points—to generate a precise cost and timeline estimate within 90 seconds. This eliminates manual quoting errors and provides immediate feedback on manufacturability constraints. Clients receive actionable insights such as recommended minimum feature sizes and optimal part orientation before formal order placement, ensuring alignment with casting foundry requirements from the outset.

Design for Manufacturability Analysis

All approved designs undergo rigorous DFM review by our engineering team. We focus on critical wax mold considerations: draft angles (minimum 1° for vertical walls), uniform wall thickness (1.5–5.0 mm standard), and strategic venting channels to prevent air entrapment during shell building. The DFM phase identifies potential thermal degradation zones during burnout and validates compliance with ISO 2768-mK geometric tolerances. Clients receive a detailed DFM report with suggested modifications—such as adding support structures for thin ribs or adjusting fillet radii—to eliminate casting defects like shrinkage or surface roughness. This collaborative step ensures the final mold withstands standard steam autoclave and kiln cycles without distortion.

Production Execution

Production begins with slicing the validated CAD model using calibrated parameters for castable photopolymer resins. Parts are built layer-by-layer on industrial DLP printers with 0.025–0.1 mm resolution, followed by automated support removal and solvent cleaning. Critical post-processing includes UV curing to stabilize the wax structure and vapor smoothing for Ra < 5 μm surface finish—essential for high-fidelity metal castings. Each mold undergoes dimensional verification via CMM against the original CAD file, with full traceability from digital build logs to final inspection reports.

Technical Specifications

| Parameter | Specification |

|————————-|———————————–|

| Material | ISO 10993-certified castable wax resin |

| Layer Resolution | 0.025–0.1 mm |

| Typical Accuracy | ±0.1 mm for features < 50 mm |

| Max Build Volume | 140 x 75 x 175 mm |

| Burnout Compatibility | Full compatibility with 600–900°C cycles |

Honyo Prototype’s integrated workflow transforms digital designs into production-ready wax molds in 3–5 business days. By unifying AI analysis, casting-specific DFM, and precision additive manufacturing, we deliver molds that consistently produce defect-free metal castings for demanding industrial applications. This end-to-end control ensures your prototype or low-volume production meets exacting quality standards on schedule.

Start Your Project

Start Your Project with Precision-Engineered 3D Printed Wax Molds from Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, we specialize in delivering high-accuracy 3D printed wax molds tailored for investment casting and rapid prototyping applications. As a trusted partner in industrial 3D printing, our advanced manufacturing capabilities ensure your projects transition seamlessly from concept to functional prototype—fast, reliably, and with unmatched detail.

Our wax mold 3D printing process leverages state-of-the-art materials and precision layering technology to produce molds with excellent surface finish and dimensional stability. These molds are ideal for creating intricate metal components used in aerospace, automotive, medical devices, and precision engineering industries. Whether you’re developing a single prototype or preparing for low-volume production, our solutions are engineered to meet rigorous industry standards.

We understand that time-to-market is critical. That’s why our streamlined workflow—from digital model to physical mold—can be completed in as little as 3–5 business days, depending on complexity and order volume. Our in-house quality control ensures every mold meets your exact specifications, with feature resolution down to 0.1 mm and a typical surface roughness (Ra) of 3.2 µm, minimizing post-processing requirements.

To get started, simply provide your 3D CAD file in STL, STEP, or IGES format. Our engineering team will conduct a comprehensive design for manufacturability (DFM) review to optimize geometry, support structures, and material selection. We support maximum build dimensions of 250 × 250 × 200 mm, making us suitable for both small, detailed components and larger assemblies requiring high fidelity.

Below are our key technical specifications for 3D printed wax molds:

| Parameter | Specification |

|———|—————|

| Technology | Material Jetting (Wax) |

| Layer Thickness | 16–32 µm |

| Dimensional Accuracy | ±0.1 mm (up to 50 mm), ±0.15% (>50 mm) |

| Minimum Feature Size | 0.1 mm |

| Surface Roughness (Ra) | 3.2 µm (as-printed) |

| Build Envelope | 250 × 250 × 200 mm (L×W×H) |

| Supported File Formats | STL, STEP, IGES, X_T |

| Lead Time | 3–5 days (standard), expedited options available |

All molds are compatible with standard dewaxing and shell-building processes in investment casting, ensuring smooth integration into your existing production pipeline. We also offer post-printing services such as vapor smoothing, support removal, and dimensional inspection reports upon request.

Your next breakthrough begins with a single step. Let Shenzhen Honyo Prototype be your partner in turning innovative designs into high-performance physical models.

Contact Susan Leo today at info@hy-proto.com to start your project. Include your CAD file and any specific requirements, and our team will respond within 4 business hours with a detailed quote and production timeline. With Honyo, precision, speed, and reliability are built into every mold we deliver.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.