Contents

Manufacturing Insight: Metal Turning Tools

Manufacturing Insight: Precision Metal Turning Capabilities at Honyo Prototype

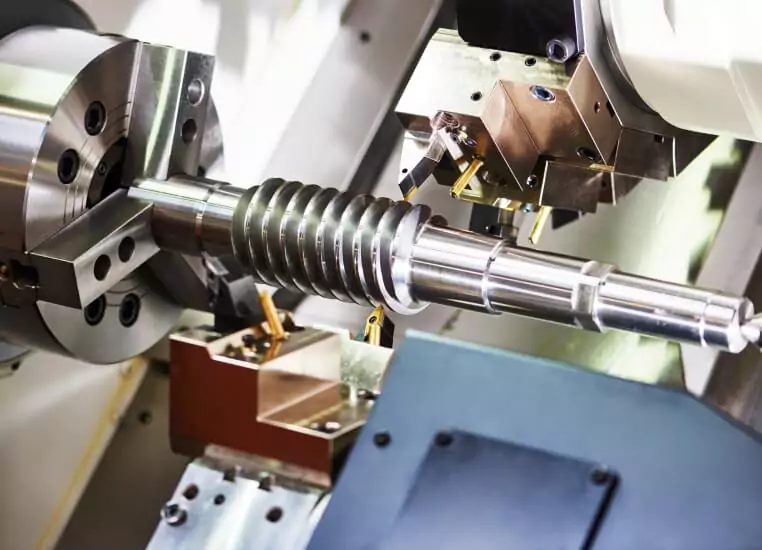

Metal turning represents a fundamental subtractive manufacturing process essential for producing precise cylindrical and axisymmetric components from solid bar stock. While sheet metal fabrication forms flat or bent structures, turning creates critical rotating parts such as shafts, bushings, fittings, and threaded components commonly integrated into assemblies alongside sheet metal elements. At Shenzhen Honyo Prototype, we leverage advanced CNC turning technology to deliver high-integrity prototypes and low-volume production parts with exceptional dimensional accuracy and surface finish, directly supporting complex product development cycles.

The core principle involves rotating the workpiece against a stationary cutting tool, precisely removing material to achieve the desired geometry. Modern CNC lathes automate this process using G-code instructions derived directly from CAD models, enabling complex contours, precise diameters, tight tolerances, and intricate features like grooves and threads. This capability is indispensable for functional prototypes requiring true rotational symmetry and mechanical integrity under load, where additive methods or sheet metal forming alone are insufficient. Honyo Prototype integrates turning seamlessly within our broader sheet metal and rapid prototyping ecosystem, ensuring clients receive fully assembled, test-ready units with all critical machined elements.

Honyo maintains a dedicated fleet of state-of-the-art CNC turning centers, optimized for the demanding requirements of rapid prototyping and bridge production. Our machines support a wide range of engineering materials including aluminum alloys (6061, 7075), stainless steels (303, 304, 17-4PH), brass, copper, and select engineering plastics. Critical to prototype validation is our consistent achievement of tight tolerances down to ±0.005 mm and surface finishes as fine as Ra 0.8 µm, verified through in-process and final CMM inspection. Material versatility combined with rapid setup procedures enables us to handle diverse project requirements efficiently, from single prototype iterations to small production batches of 50-500 units.

Our technical capabilities are rigorously defined by the performance parameters of our equipment, as detailed below:

| Parameter | Specification | Application Impact for Prototyping |

| :——————– | :——————— | :—————————————————– |

| Max Swing Diameter | 250 mm | Accommodates larger shafts and housings for industrial prototypes |

| Max Turning Length | 500 mm | Supports extended components like drive shafts |

| Spindle Speed Range | 50 – 6000 RPM | Optimizes cutting for diverse materials (aluminum to hardened steel) |

| Positioning Accuracy | ±0.003 mm | Ensures critical feature alignment in complex assemblies |

| Repeatability | ±0.002 mm | Guarantees consistency across prototype iterations |

| Standard Tolerance | ±0.01 mm (Typical) | Meets common engineering requirements for fit and function |

| Tightest Capability | ±0.005 mm | Enables precision mechanisms and sealing surfaces |

| Max Spindle Power | 15 kW | Handles aggressive cuts in tough materials efficiently |

Honyo Prototype’s turning expertise significantly accelerates time-to-prototype for clients developing electromechanical systems, fluid handling components, or precision instruments. By controlling the entire process in-house – from material sourcing and CNC programming to precision machining and finishing – we eliminate external dependencies and communication delays inherent in multi-vendor approaches. Our engineering team collaborates closely with clients during the design phase to provide actionable manufacturability feedback, optimizing part geometry for turnability while maintaining functional intent. This integrated capability ensures that prototypes accurately reflect final production intent, reducing costly design revisions and enabling faster validation of rotational components within the broader assembly context. Trust Honyo Prototype for turning solutions that deliver precision, speed, and technical partnership from concept to functional prototype.

Technical Capabilities

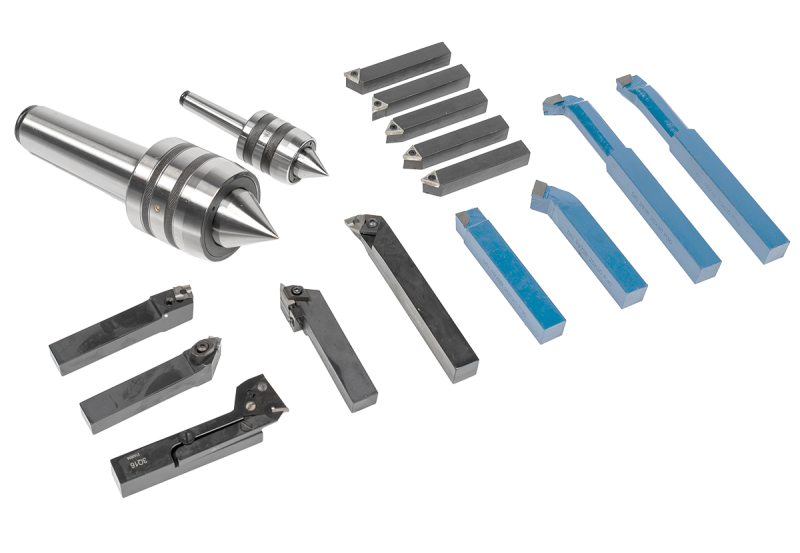

Technical Capabilities: Precision Metal Turning Tools at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, our expertise in sheet metal fabrication extends to the precision manufacturing of metal turning tools used across laser cutting, bending, and welding applications. These tools are engineered to meet the rigorous demands of high-speed, high-accuracy metal processing operations. Designed for durability and repeatability, our turning tools are fabricated using advanced CNC machining and supported by stringent quality control protocols to ensure performance consistency in industrial environments.

Our manufacturing process integrates high-grade tool steels and carbide materials, selected for their thermal resistance, wear performance, and mechanical strength. Each turning tool is customized to match the specific geometry, cutting force, and material removal rate required by the application. We support both external and internal turning operations, accommodating a range of diameters from 3 mm to 300 mm, with depth-to-diameter ratios optimized for stability and chip evacuation.

In laser cutting applications, our turning tools are used to fabricate precision guide components and rotary fixtures that ensure accurate beam alignment and material positioning. For bending operations, we produce mandrels and forming rollers that maintain tight angular tolerances and surface integrity across repeated cycles. In welding, we manufacture collets, chucks, and rotary joints that support automated orbital welding systems, ensuring consistent weld bead placement and joint strength.

All metal turning tools are finished with surface treatments such as TiN, TiCN, or Al₂O₃ coatings, enhancing tool life and reducing friction during high-load operations. We also offer micro-polishing and edge preparation services to minimize burr formation and improve cut quality.

The following table outlines the standard material options and achievable tolerances for our metal turning tools:

| Parameter | Specification |

|—————————-|————-|

| Material Options | |

| Tool Steel | AISI D2, H13, M2 |

| Carbide Grades | K10, K20, CBN |

| Stainless Steel | 304, 316, 17-4 PH |

| Aluminum Alloys | 6061-T6, 7075-T6 |

| Surface Coatings | TiN, TiCN, Al₂O₃, DLC |

| Machining Tolerances | |

| Diameter Tolerance | ±0.005 mm (for diameters < 50 mm) to ±0.02 mm (for diameters > 200 mm) |

| Length Tolerance | ±0.03 mm |

| Concentricity | ≤ 0.01 mm (TIR) |

| Surface Roughness (Ra) | 0.2 – 0.8 µm (depending on material and finish) |

| Angular Tolerance (for form tools) | ±0.1° |

| Runout (Rotary Tools) | ≤ 0.005 mm at operating speed |

All tolerances are verified using coordinate measuring machines (CMM) and laser interferometry to ensure compliance with ISO 2768 and customer-specific standards. We support rapid prototyping and low-to-medium volume production runs, enabling fast turnaround without compromising precision.

Shenzhen Honyo Prototype combines advanced toolpath simulation, in-process inspection, and material science expertise to deliver metal turning tools that enhance the performance of laser cutting, bending, and welding systems. Our engineering team works closely with clients to optimize tool geometry and material selection, ensuring maximum efficiency and longevity in real-world manufacturing environments.

From CAD to Part: The Process

Metal Turning Production Workflow: From CAD to Finished Component

Shenzhen Honyo Prototype specializes in precision CNC turning for rotational metal components. While metal turning differs fundamentally from sheet metal fabrication, our engineered workflow ensures optimal manufacturability and quality for turned parts. This guide details our standardized process from initial inquiry to final inspection.

AI-Powered Quoting Phase

Upon receiving your CAD model (STEP, IGES, or native formats), our proprietary AI quoting system performs an instant technical feasibility assessment. The algorithm analyzes geometric complexity, material specifications, critical tolerances, surface finish requirements, and feature accessibility. It cross-references this data against our machine capabilities, tooling library, and historical production metrics to generate an accurate lead time and cost estimate within minutes. This initial screening identifies potential red flags such as thin-wall sections prone to chatter, excessive overhangs, or non-standard thread forms requiring custom tooling, allowing for rapid client feedback before formal order placement.

Engineering-Driven DFM Analysis

Following quote acceptance, our manufacturing engineering team conducts a rigorous Design for Manufacturability (DFM) review. This is not an automated step but a critical human-led evaluation where senior engineers assess the design against real-world machining constraints. We identify opportunities to optimize wall thicknesses, suggest tolerance relaxation on non-critical features (e.g., changing ±0.05mm to ±0.1mm where functionally acceptable), recommend chamfer adjustments to prevent tool breakage, and propose efficient stock sizing to minimize material waste and machining time. Client collaboration is essential here; we provide a detailed DFM report with actionable recommendations via secure portal, ensuring alignment before production release.

Precision CNC Turning Production

Approved designs proceed to our CNC turning cell, primarily utilizing multi-axis lathes with live tooling (e.g., Okuma LB3000 EX-II, DMG MORI CTX beta 1250). Setup involves meticulous workholding selection (collets, chucks, or custom fixtures), tooling verification, and program validation via offline simulation. Machining parameters are optimized per material:

| Material | Machinability Index | Typical Tolerance (mm) | Max Spindle Speed (RPM) |

|——————-|———————|————————|————————-|

| Aluminum 6061-T6 | Excellent (100) | ±0.025 | 4500 |

| Stainless 304 | Moderate (40) | ±0.015 | 1800 |

| Brass C36000 | Excellent (120) | ±0.020 | 3500 |

| Titanium Gr5 | Poor (20) | ±0.030 | 800 |

In-process inspections occur at critical stages using calibrated CMMs and optical comparators, verifying diameters, concentricity, and thread accuracy against GD&T callouts. Final parts undergo full first-article inspection (FAI) per AS9102 standards, including surface roughness testing (Ra values) and material certification validation. All data is digitally archived for full traceability.

This integrated workflow—leveraging AI efficiency, engineering expertise, and precision execution—ensures Honyo Prototype delivers complex turned components with reduced lead times, minimized cost, and uncompromised quality. Contact our engineering team to discuss your specific turning requirements and CAD optimization.

Start Your Project

Start Your Metal Turning Project with Precision Engineering from Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, we specialize in delivering high-accuracy metal turning solutions tailored to your sheet metal fabrication needs. Whether you’re developing prototypes or scaling to low-volume production, our advanced CNC turning capabilities ensure tight tolerances, superior surface finishes, and consistent part quality across a wide range of materials. As a trusted partner in precision manufacturing, we combine cutting-edge technology with expert engineering support to bring your most demanding designs to life.

Metal turning is a critical process in modern manufacturing, enabling the creation of cylindrical components with exact dimensional control. From shafts and bushings to threaded fittings and custom connectors, our CNC lathes are equipped to handle complex geometries with ease. We support a broad spectrum of metals, including aluminum, stainless steel, brass, copper, and specialty alloys, ensuring compatibility with your application’s mechanical, thermal, and corrosion resistance requirements.

Our facility in Shenzhen is outfitted with multi-axis CNC turning centers that provide exceptional repeatability and efficiency. With live tooling and bar feeding options, we perform complete part fabrication in a single setup—reducing lead times and minimizing potential for error. Every component undergoes rigorous in-process and final inspection using precision metrology equipment, including CMMs and optical comparators, to verify conformance to your specifications.

We understand that every project begins with a vision. That’s why our engineering team collaborates closely with clients during the design phase to optimize for manufacturability, reduce costs, and accelerate time-to-market. Our design for manufacturing (DFM) feedback ensures that your parts are not only functional but also efficient to produce—without compromising on quality.

To help you get started, we’ve outlined key technical capabilities for our metal turning services:

| Specification | Detail |

|—————|——–|

| Maximum Turning Diameter | 300 mm |

| Maximum Turning Length | 500 mm |

| Spindle Speed | Up to 6,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Supported Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Brass (C3604), Copper, Titanium, and more |

| Secondary Operations | Milling, threading, knurling, drilling, tapping, surface finishing |

| Tolerances | As tight as ±0.01 mm (standard: ±0.05 mm) |

| Surface Finish | Ra 0.8 µm standard, down to Ra 0.4 µm with polishing |

All projects are managed with a focus on transparency, speed, and technical excellence. From initial inquiry to final delivery, we maintain clear communication and provide real-time updates to keep your development timeline on track.

Ready to turn your concept into reality? Contact Susan Leo, our dedicated manufacturing specialist, to discuss your project requirements, request a quote, or receive design feedback. At Shenzhen Honyo Prototype, we’re committed to delivering precision-engineered solutions that meet the highest standards of quality and performance.

Email Susan Leo at info@hy-proto.com to start your metal turning project today.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.