Contents

Manufacturing Insight: Laser Cnc Machine For Metal

Manufacturing Insight: Laser CNC Technology for Precision Metal Fabrication

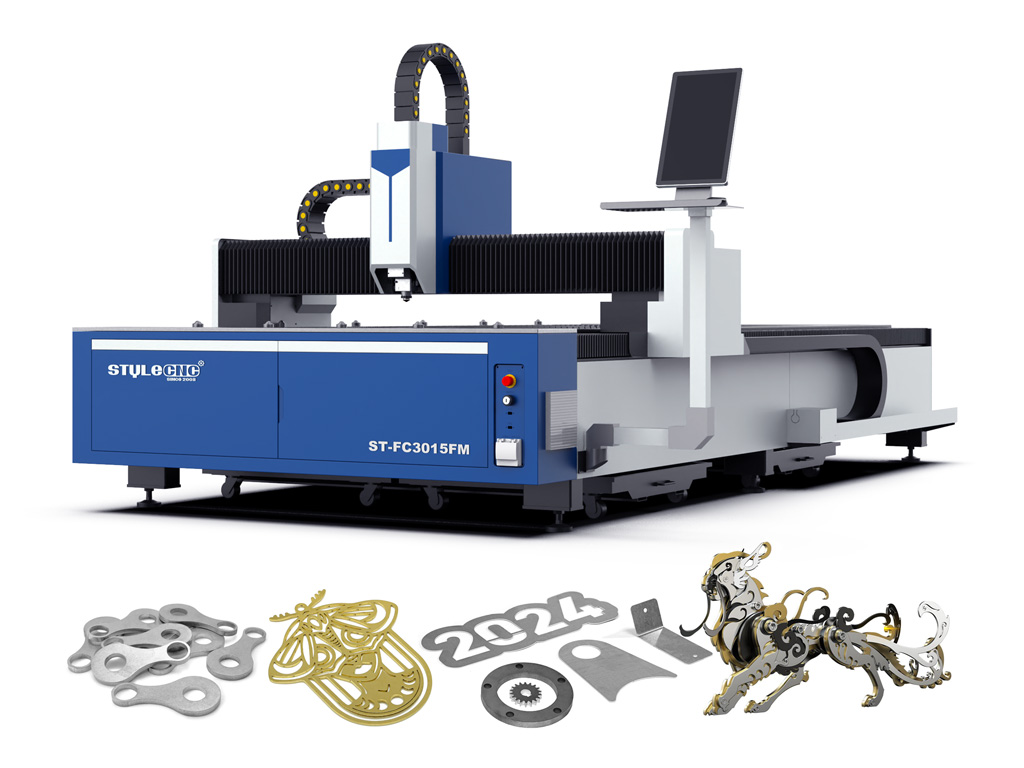

Laser CNC cutting represents a cornerstone technology in modern sheet metal fabrication, offering unparalleled precision and versatility for metal components. At Shenzhen Honyo Prototype, we utilize advanced fiber laser systems engineered specifically for metals, including stainless steel, carbon steel, aluminum, and brass. Unlike traditional mechanical cutting methods, laser CNC employs a focused high-energy beam to melt, burn, or vaporize material along programmed paths, eliminating tool wear and mechanical stress on delicate parts. This non-contact process ensures clean edges, minimal burr formation, and the ability to produce intricate geometries—such as micro-perforations, tight-radius contours, and complex lattice structures—that are unattainable with punch presses or saws. Crucially, fiber lasers deliver superior energy efficiency and faster processing speeds for thin to medium-thickness metals compared to legacy CO2 lasers, while maintaining exceptional edge quality and dimensional repeatability critical for prototyping and low-volume production.

Our facility integrates state-of-the-art 500W to 3000W fiber laser CNC systems, calibrated for the exacting demands of rapid prototyping and precision sheet metal work. Honyo’s process begins with rigorous material validation, ensuring optimal laser parameters are applied based on alloy type, thickness, and desired edge finish. Real-time monitoring systems track beam focus, gas assist pressure, and motion control to maintain tolerances within ±0.05 mm. Every cut undergoes automated edge quality inspection, with adaptive algorithms compensating for thermal distortion during high-speed operations. This integrated approach enables us to consistently achieve burr-free cuts on materials up to 20 mm thick while supporting rapid design iterations—turning CAD files into functional metal prototypes within 24–72 hours.

Key technical capabilities of Honyo’s laser CNC platform are summarized below:

| Parameter | Specification Range | Precision Standard |

|————————–|——————————|————————|

| Material Thickness | 0.5 mm – 20 mm | Optimized per alloy |

| Positioning Accuracy | ±0.02 mm | ISO 2768-mK compliant |

| Maximum Cutting Speed | Up to 40 m/min (1mm stainless)| Varies by material |

| Minimum Feature Size | 0.3 mm holes / slots | Burr-free finish |

| Working Area | 1500 mm × 3000 mm | Seamless nesting |

| Supported File Formats | DXF, DWG, STEP, IGES | Native CAD integration |

Honyo Prototype leverages this technology to solve critical client challenges in aerospace, medical devices, and electronics enclosures. Our systems excel at producing low-stress components with tight tolerances, eliminating secondary finishing operations and accelerating time-to-test for validation prototypes. By maintaining N₂ and O₂ gas assist options, we tailor cut quality for reflective materials like copper or aluminum, preventing oxidation and ensuring weld-ready edges. This capability, combined with our in-house bending and finishing services, provides a seamless single-source solution for metal prototypes demanding industrial-grade accuracy and repeatability. For engineering teams prioritizing speed without compromise, Honyo’s laser CNC platform delivers the fidelity to transform conceptual designs into mission-ready metal components.

Technical Capabilities

Shenzhen Honyo Prototype specializes in precision sheet metal fabrication using state-of-the-art laser CNC machinery. Our integrated manufacturing capabilities encompass laser cutting, press brake forming, and automated welding processes, enabling us to deliver high-accuracy metal components for prototyping and low-to-mid volume production. Each process is optimized for repeatability, edge quality, and dimensional consistency across a broad range of ferrous and non-ferrous materials.

Our fiber laser cutting systems are engineered for high-speed, high-precision contour cutting of sheet and tube metal. These machines utilize advanced 3-kW to 6-kW laser sources, delivering clean cuts with minimal heat-affected zones. The non-contact cutting method ensures no tooling marks or material deformation, making it ideal for complex geometries and tight-tolerance features. Cut edges exhibit excellent surface finish, often eliminating the need for secondary deburring.

For forming operations, we deploy CNC-controlled press brakes equipped with automated backgauging and angle measurement systems. These machines support air bending, bottoming, and coining methods, allowing precise control over bend angles and radii. Our bending capacity spans from thin 0.5 mm sheets up to 6 mm thick plates, depending on material type. Tooling is selected dynamically based on part geometry and material specifications to maintain consistency and avoid surface marring.

Laser welding is performed using pulsed and continuous-wave fiber lasers, enabling deep penetration welds with low distortion. This process is particularly effective for joining dissimilar metals, thin-walled components, and heat-sensitive assemblies. Weld seams are characterized by high strength, minimal spatter, and excellent cosmetic finish—critical for both structural and visible applications.

The following table outlines the technical capabilities and tolerances achievable across our core processes:

| Process | Material Types | Thickness Range | Tolerance (Cutting) | Tolerance (Bending) | Max Part Size |

|—————–|———————————-|———————|———————|———————|——————-|

| Laser Cutting | Mild Steel, Stainless Steel, Aluminum, Brass, Copper | 0.5 – 25 mm | ±0.1 mm | – | 1500 x 3000 mm |

| CNC Bending | Mild Steel, Stainless Steel, Aluminum | 0.5 – 6 mm | – | ±0.2° / ±0.1 mm | 1200 x 1000 mm |

| Laser Welding | Mild Steel, Stainless Steel, Aluminum (dissimilar joints supported) | 0.8 – 8 mm | ±0.15 mm (joint fit-up) | – | 800 x 800 mm |

All operations are supported by in-house CAD/CAM programming and real-time process monitoring. We adhere to ISO 2768-mK for general tolerances and apply geometric dimensioning and tolerancing (GD&T) when specified. Material certifications and first-article inspection reports are available upon request. Shenzhen Honyo Prototype’s laser CNC capabilities ensure rapid turnaround without compromising on precision, making us a trusted partner for demanding industrial applications.

From CAD to Part: The Process

From CAD to Part: Laser CNC Production Workflow at Honyo Prototype

At Shenzhen Honyo Prototype, our sheet metal fabrication process for laser CNC machining is engineered for precision, efficiency, and seamless client integration. We transform digital designs into high-quality metal components through a rigorously defined workflow, minimizing lead times while maximizing part integrity. This structured approach ensures manufacturability from the earliest stages and guarantees consistent output meeting stringent industry standards.

AI-Powered Quoting Acceleration

The process initiates upon receipt of a client’s CAD file. Our proprietary AI quoting engine instantly analyzes the geometry, material specifications, and requested quantities. It cross-references this data against our comprehensive database of machine capabilities, material costs, and historical production metrics. This automation delivers an accurate, detailed quotation within minutes, not hours, providing immediate cost and timeline visibility. The system flags potential complexities requiring engineering review, setting clear expectations before formal order placement and significantly reducing quotation bottlenecks.

Engineering-Driven DFM Analysis

Following order confirmation, the CAD model undergoes mandatory Design for Manufacturability (DFM) review by our senior manufacturing engineering team. This critical phase identifies and resolves potential production hurdles before machine setup. Engineers scrutinize minimum feature sizes, bend radii relative to material thickness, hole spacing, kerf compensation requirements, and nesting efficiency. We assess potential for warpage, heat-affected zones, and tolerance stack-up, proposing actionable optimizations to the client. This collaborative DFM step prevents costly rework, ensures optimal material yield, and guarantees the design aligns perfectly with our advanced laser cutting capabilities, directly enhancing your part’s quality and reducing time-to-market.

Precision Laser CNC Production Execution

Approved designs move directly into production on our state-of-the-art fiber laser CNC systems. The validated CAD file is converted into precise machine code (G-code), incorporating all DFM refinements and material-specific cutting parameters. High-power laser beams, guided by CNC motion control, vaporize material along programmed paths with exceptional accuracy and minimal thermal distortion. Our process includes rigorous in-process inspection at key stages, verifying critical dimensions and feature placement against the original CAD model. Post-cutting operations, such as deburring, bending, welding, or surface finishing as specified, are performed under controlled conditions. Each component undergoes final quality assurance, including first-article inspection (FAI) for new runs and batch sampling, ensuring full conformance to your dimensional and functional requirements before shipment.

Key Laser CNC System Capabilities

| Parameter | Specification | Impact on Production |

| :—————– | :—————— | :————————————— |

| Laser Type | Fiber Laser | Superior cut quality on reflective metals, lower operating cost |

| Max Power | 6 kW | Enables cutting of thicker mild/stainless steel efficiently |

| Cutting Area | 3015 mm x 1510 mm | Accommodates large sheet formats, reducing nesting constraints |

| Positioning Accuracy | ±0.05 mm | Ensures tight tolerances and feature repeatability |

| Max Material Thickness | Mild Steel: 25mm, Stainless: 20mm | Broad capability for diverse sheet metal applications |

| Edge Quality (Ra) | < 12.5 μm (as-cut) | Minimizes need for secondary finishing operations |

This integrated workflow—from AI quote generation through expert DFM validation to precise CNC execution—forms the core of Honyo Prototype’s commitment to delivering complex sheet metal components with unmatched speed, reliability, and technical excellence for your prototyping and low-volume production needs.

Start Your Project

Start Your Project with Precision Laser CNC Machining for Metal

When it comes to high-precision sheet metal fabrication, Shenzhen Honyo Prototype delivers unmatched expertise in laser CNC machining for metal. Our state-of-the-art facilities and rigorous quality control processes ensure that your project is manufactured to exact specifications—on time and within budget. Whether you’re developing prototypes or scaling to low-volume production, our laser CNC capabilities are engineered to meet the demands of modern manufacturing.

Our laser CNC machines are optimized for cutting, engraving, and shaping a wide range of metals, including stainless steel, aluminum, carbon steel, and copper alloys. With tight tolerances and clean edge finishes, we eliminate the need for secondary finishing in most applications, reducing lead times and lowering overall production costs. At Honyo Prototype, we understand that every project begins with a vision—our role is to turn that vision into a high-quality, functional reality.

We invite you to start your next fabrication project with confidence. Our engineering team is available to review your designs, recommend material selections, and provide expert feedback to optimize manufacturability. From initial concept to final delivery, we are committed to supporting you at every stage of production.

To ensure seamless collaboration, contact Susan Leo, your dedicated project coordinator at Shenzhen Honyo Prototype. With extensive experience in international client support and technical project management, Susan will guide you through the onboarding process, clarify technical requirements, and ensure your timelines are met without compromise.

Reach out today via email at info@hy-proto.com to discuss your project specifications, request a quote, or schedule a technical consultation. We respond to all inquiries within 12 business hours and offer rapid prototyping services with turnaround times starting at just 3–5 working days, depending on complexity.

Below is an overview of our standard laser CNC machining capabilities for metal sheet fabrication:

| Specification | Details |

|—————|——–|

| Laser Type | Fiber Laser |

| Max Power | 6 kW |

| Material Thickness Range | 0.5 mm – 25 mm (varies by material) |

| Cutting Accuracy | ±0.1 mm |

| Maximum Work Envelope | 1500 mm × 3000 mm |

| Supported Materials | Stainless Steel, Aluminum, Carbon Steel, Brass, Copper |

| Surface Finish | Burr-free, minimal dross |

| Lead Time (Prototype) | 3–5 working days |

| File Formats Accepted | DWG, DXF, STEP, IGES, PDF |

At Shenzhen Honyo Prototype, we combine advanced technology with engineering excellence to deliver precision sheet metal solutions tailored to your needs. Don’t let design complexity or tight deadlines slow you down—partner with a team that values accuracy, speed, and reliability.

Contact Susan Leo at info@hy-proto.com and take the first step toward seamless, high-quality metal fabrication.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.