Contents

Manufacturing Insight: 6061 T6 Aluminum Vs 7075 T6

6061-T6 or 7075-T6?

The choice can make or break your next aerospace bracket, robotics arm, or mold insert. At Honyo Prototype, we machine both alloys every day on our fleet of 5-axis DMG-Mori and Brother CNC centers—holding ±0.01 mm true position so you don’t have to over-design. Upload your STEP file today for an online instant quote: in under 60 seconds you’ll see real pricing for 6061-T6, 7075-T6, or any grade you specify, with lead times as short as 3 days. Let’s put the right aluminum to work, faster.

Technical Capabilities

Technical Specifications Comparison: 6061-T6 vs. 7075-T6 Aluminum for Precision Machining

(Focus: 3/4/5-Axis Milling, Turning, Tight Tolerance)

Prepared by: Senior Manufacturing Engineer, Honyo Prototype

Key Material Properties & Machining Implications

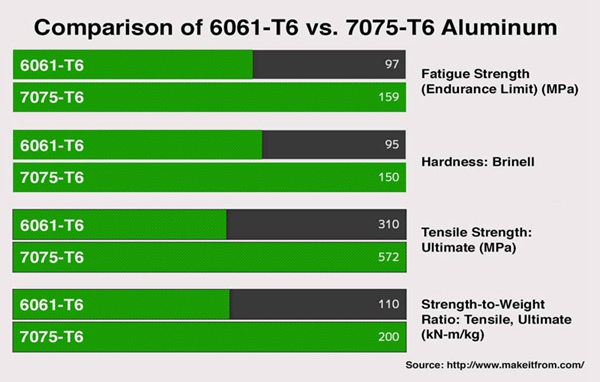

| Property | 6061-T6 Aluminum | 7075-T6 Aluminum | Why It Matters for Precision Machining |

|—————————-|———————————————–|———————————————–|——————————————–|

| Tensile Strength | 310 MPa (45 ksi) | 572 MPa (83 ksi) | 7075-T6 handles higher loads but requires aggressive tooling to avoid chatter. |

| Yield Strength | 276 MPa (40 ksi) | 503 MPa (73 ksi) | Critical for structural parts; 7075-T6 demands tighter control of cutting forces to prevent deflection. |

| Machinability Rating | 100% (ASTM standard reference) | 70–80% (Compared to 6061) | 6061-T6 cuts smoothly with minimal tool wear; 7075-T6 is harder, gummier, and prone to work hardening—requires slower speeds, high-pressure coolant, and PCD/diamond tools. |

| Thermal Conductivity | 167 W/m·K | 130 W/m·K | 6061 dissipates heat faster during milling/turning, reducing thermal warpage. 7075-T6 retains heat, increasing risk of dimensional drift in tight-tolerance features. |

| Thermal Expansion | 23.6 μm/m·°C | 23.2 μm/m·°C | Negligible difference, but both require strict temperature control for tolerances ≤±0.0005″ (±12.7 μm). |

| Work Hardening Tendency| Low | Very High | 7075-T6 rapidly hardens during machining—must avoid dwell times and use sharp tools with high feed rates. 6061-T6 is far more forgiving. |

| Typical Tight Tolerance Capability | ±0.0005″ (±12.7 μm) achievable consistently | ±0.001″ (±25.4 μm) achievable with extreme care | 6061-T6 is ideal for complex 5-axis contours (e.g., aerospace brackets). 7075-T6 requires stress-relief annealing before final machining to minimize distortion. |

Critical Machining Considerations

3/4/5-Axis Milling

- 6061-T6:

- Optimal Parameters: 800–1,200 SFM, 0.002–0.005″ per tooth feed, high-pressure coolant (≥1,000 psi).

- Advantages: Minimal chatter, excellent surface finish (Ra 0.4 μm achievable), ideal for thin walls and intricate features (e.g., heat exchangers, drone frames).

-

Tolerance Control: Stable during machining; minimal tool deflection. No post-machining stress relief needed for most parts.

-

7075-T6:

- Optimal Parameters: 400–600 SFM, 0.001–0.003″ per tooth feed, cryogenic coolant (LN₂) recommended to combat work hardening.

- Challenges: Rapid tool wear (carbide tools last 30–50% shorter), high risk of chatter on complex 5-axis paths. Avoid high-speed roughing—use slow, light passes.

- Tolerance Control: Requires pre-machining stress relief (300°F/150°C for 1–2 hours) and post-machining stress relief for critical aerospace parts. Tolerances ≤±0.0005″ demand in-process laser metrology.

Turning Operations

- 6061-T6:

- Smooth chip formation; can run at 1,000+ SFM with carbide inserts.

-

Tolerances ≤±0.0002″ achievable with steady rests and minimal vibration.

-

7075-T6:

- Tooling must be coated (TiAlN, AlCrN) or diamond-coated; uncoated carbide fails rapidly.

- Critical: Use positive rake angles, high feed rates to “skip” work hardening, and rigid setups (hydraulic chucks).

- Tolerance Risk: Thermal distortion from cutting heat can cause out-of-tolerance diameters if coolant isn’t optimized.

Comparison with Other Materials (for Context)

| Material | Machinability | Tight Tolerance Capability | Key Challenges | Best For |

|————–|——————-|——————————–|——————–|————–|

| Steel (e.g., 4140, 17-4PH) | 30–60% of 6061-T6 | ±0.0002″ achievable | High tool wear, significant heat generation, requires hardened tooling (HSS, CBN). Thermal expansion ~11.7 μm/m·°C (better stability than Al). | High-strength, wear-resistant parts (e.g., shafts, molds). |

| ABS Plastic | 150–200% of 6061-T6 | ±0.001″ achievable | Extreme thermal expansion (70–80 μm/m·°C); warps easily. Requires sharp tools, low speeds (200–400 SFM), and ambient temperature control. | Prototypes, jigs, non-critical housings. |

| Nylon (e.g., 6/6) | 120–150% of 6061-T6 | ±0.002″ achievable | Moisture absorption (dimensional drift), low melting point. Must be machined dry or with air blast—no coolant. | Wear-resistant parts, low-friction components. |

Critical Note: For tight-tolerance parts (≤±0.0005″), aluminum alloys require climate-controlled machining environments (20–22°C). Plastics like ABS/Nylon are unsuitable for precision aerospace/medical parts due to thermal instability. Steel offers better dimensional stability but at higher cost/lead time.

Honyo Prototype Engineering Recommendations

- Choose 6061-T6 for:

- Most prototypes, fixtures, and non-critical structural parts.

- Complex 5-axis contours, thin walls, or high-volume runs where cost and speed matter.

- When tight tolerances (±0.0005″) are needed without stress-relief steps.

- Choose 7075-T6 only when:

- Ultimate strength-to-weight ratio is critical (e.g., aircraft fittings, military components).

- You can invest in specialized tooling, cryogenic cooling, and in-process metrology.

- Always stress-relieve before final machining—never skip this step for 7075-T6.

- Avoid 7075-T6 for:

- Parts with intricate internal features (risk of tool breakage), low-volume prototypes, or budget-sensitive projects.

💡 Pro Tip: For 5-axis milling of 7075-T6, use simultaneous 5-axis adaptive clearing (not 3+2) to minimize dwell time and reduce work hardening. For 6061-T6, leverage high-speed machining (HSM) strategies to maximize throughput.

Final Thought: 6061-T6 is the default choice for 90% of precision aluminum parts at Honyo Prototype. 7075-T6 is reserved for niche applications where strength outweighs machining complexity. Always validate tolerances with CMM data during first-article inspection—especially for 7075-T6.

— Honyo Prototype Engineering Team

Precision Machining Since 1998

From CAD to Part: The Process

At Honyo Prototype the same 6-step digital thread is used whether you pick 6061-T6 or 7075-T6.

The alloy choice only changes the parameters inside each step, not the flow itself.

-

Upload CAD

• Portal accepts any format; alloy is declared in the drop-down.

• AI immediately flags the “strength-to-weight” slider: 7075 raises the cost index ≈1.8× and machining-time index ≈1.4× vs 6061. -

AI Quote (30–60 s)

6061-T6 baseline:

– Material: $3.20/kg

– Machinability rating: 90 % → high speed, 4 000–9 000 rpm, 0.05 mm/tooth.

– Tool wear factor: 1.0

7075-T6 override:

– Material: $7.50/kg

– Machinability: 60 % → 30 % slower feed, 20 % lower RPM, tool-wear factor 2.3.

– Special notes: 7075 chips are flammable; vacuum extraction & fire-suppression surcharges added.

– Lead-time identical (stocked in 6 mm–100 mm plate), but part cost ↑ 35–70 % depending on pocket volume.

- DFM (24 h)

6061-T6 focus:

– Thin-wall threshold 0.5 mm (end-mill Ø0.8 mm).

– Weld tabs OK if customer later welds (6061 is weld-friendly).

– Anodize type II or III recommended; no post-bake stress relief needed.

7075-T6 focus:

– Thin-wall limit 0.8 mm (material is more notch-sensitive).

– Sharp internal corners require 0.2 mm minimum radius to avoid stress-corrosion.

– No welding permitted (hot-short & strength loss).

– Anodize type II only; type III causes micro-cracks. Alodine or Surtec 650 for electrical conductivity.

– Stress-corrosion relief: 24 h room-temp age after machining; added 0.5 d in router.

- Production (3-day std)

6061-T6:

– Carbide tool life ~1 200 min; flood coolant.

– Typical cutting speed 600 m/min, feed 0.12 mm/tooth.

7075-T6:

– Carbide tool life ~500 min; micro-drop 7 % coolant to reduce ignition risk.

– Speed 350 m/min, feed 0.08 mm/tooth.

– Chips collected in sealed steel drums, disposed daily.

– In-process CMM every 10 pcs instead of every 25 pcs (higher value material).

-

QA & finishing

– Both alloys pass identical CMM, RoHS, and material-cert (EN 10204-3.1) gates.

– 7075 parts receive extra dye-penetrant inspection if tensile > 480 MPa region is machined. -

Delivery

– Packaging: 6061 = ESD foam; 7075 = VCI film + desiccant (prevents pitting in transit).

– Cert pack includes alloy-specific mechanical test coupon (attached to remnant tab).

Bottom line: the Honyo digital thread stays the same; 7075-T6 simply triggers tighter machining rules, longer cycle times, and higher quoted price inside the identical Upload ➜ AI Quote ➜ DFM ➜ Production ➜ Delivery sequence.

Start Your Project

Get expert advice on 6061 T6 vs 7075 T6 aluminum.

Contact Susan Leo at info@hy-proto.com for tailored material selection, cost optimization, and precision manufacturing.

Shenzhen-based factory delivering fast turnaround and high-quality prototyping & production.

🚀 Rapid Prototyping Estimator