Contents

Manufacturing Insight: Cnc Mill For Steel

Need a CNC mill for steel that actually cuts like it means business?

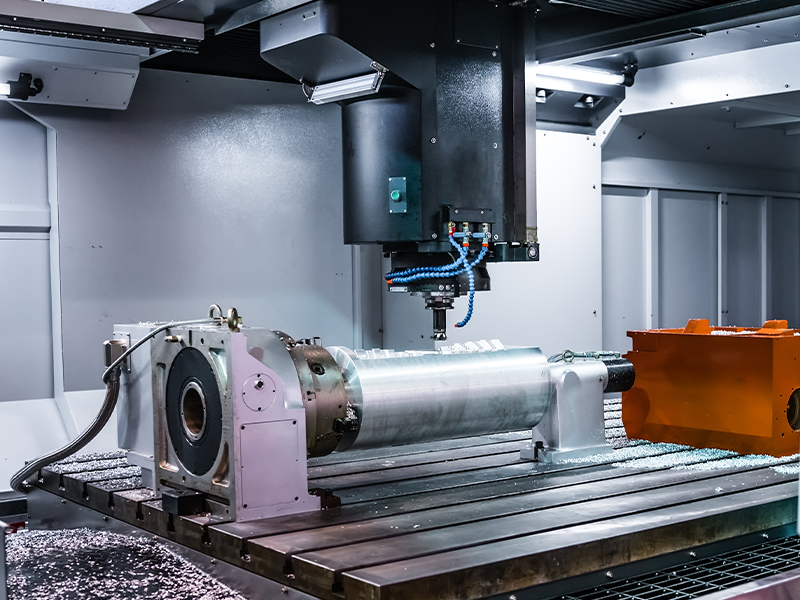

At Honyo Prototype, our 3- to 5-axis CNC machining centers are loaded with through-spindle coolant, 20,000-rpm geared heads and ceramic-coated tooling that chew through 4140, 17-4 PH, D2 and even hardened H13 without flinching. Tolerances down to ±0.01 mm, Ra 0.4 µm finishes and full 5-sided machining in a single setup mean your steel parts leave the floor ready for assembly—no bench hand-finish required.

Upload your STEP or IGES file now and see an instant, itemized quote in under 60 seconds; hit “Accept” and we’re cutting steel the same day. That’s Honyo Prototype: steel-grade CNC milling at digital speed.

Technical Capabilities

Technical Specifications for Precision CNC Mill-Turn Center (Steel-Focused, Multi-Material Capable)

Designed for High-Accuracy Prototyping at Honyo Prototype – Emphasizing Tight Tolerances, Rigidity, and Multi-Material Flexibility

As a Senior Manufacturing Engineer at Honyo Prototype, I emphasize that “cnc mill for steel” in a prototyping context requires a mill-turn center – not a standalone mill. This integrates 5-axis milling with live-tool turning capability, critical for complex, high-precision parts in steel while accommodating aluminum, ABS, and nylon. Below are the critical specs for a machine suitable for ±0.0025mm (±0.0001″) tolerance work on steel, with material-specific considerations:

Core Machine Specifications

| Category | Specification | Why It Matters for Steel & Tight Tolerances |

|————————|———————————————————————————–|—————————————————————————————————————|

| Machine Type | 5-Axis Mill-Turn Center (e.g., DMG MORI CTX beta 1250, DMG Mori CTX 500) | Combines milling, turning, and full 5-axis simultaneous motion in one setup – eliminates part re-fixturing errors. |

| Frame & Base | High-grade cast iron with constrained-layer damping; thermal isolation design | Critical for steel: Minimizes vibration during heavy cuts and thermal drift. Steel machining generates high heat; this maintains micron-level stability. |

| Spindle (Milling) | – Power: 22–37 kW (30–50 HP)

– Max RPM: 12,000–18,000 RPM

– Torque: 150–250 Nm

– HSK-E63 or BBT50 taper | High torque (not just RPM) is essential for steel. HSK-E63 provides rigidity for heavy cuts while allowing high-speed finishing. |

| Spindle (Turning) | – Live Tooling: 10,000–15,000 RPM

– Torque: 80–120 Nm

– C-Axis Resolution: ≤0.0001° | Enables precise turning operations (e.g., diameters, threads) without part re-mounting. C-axis resolution ensures contouring accuracy. |

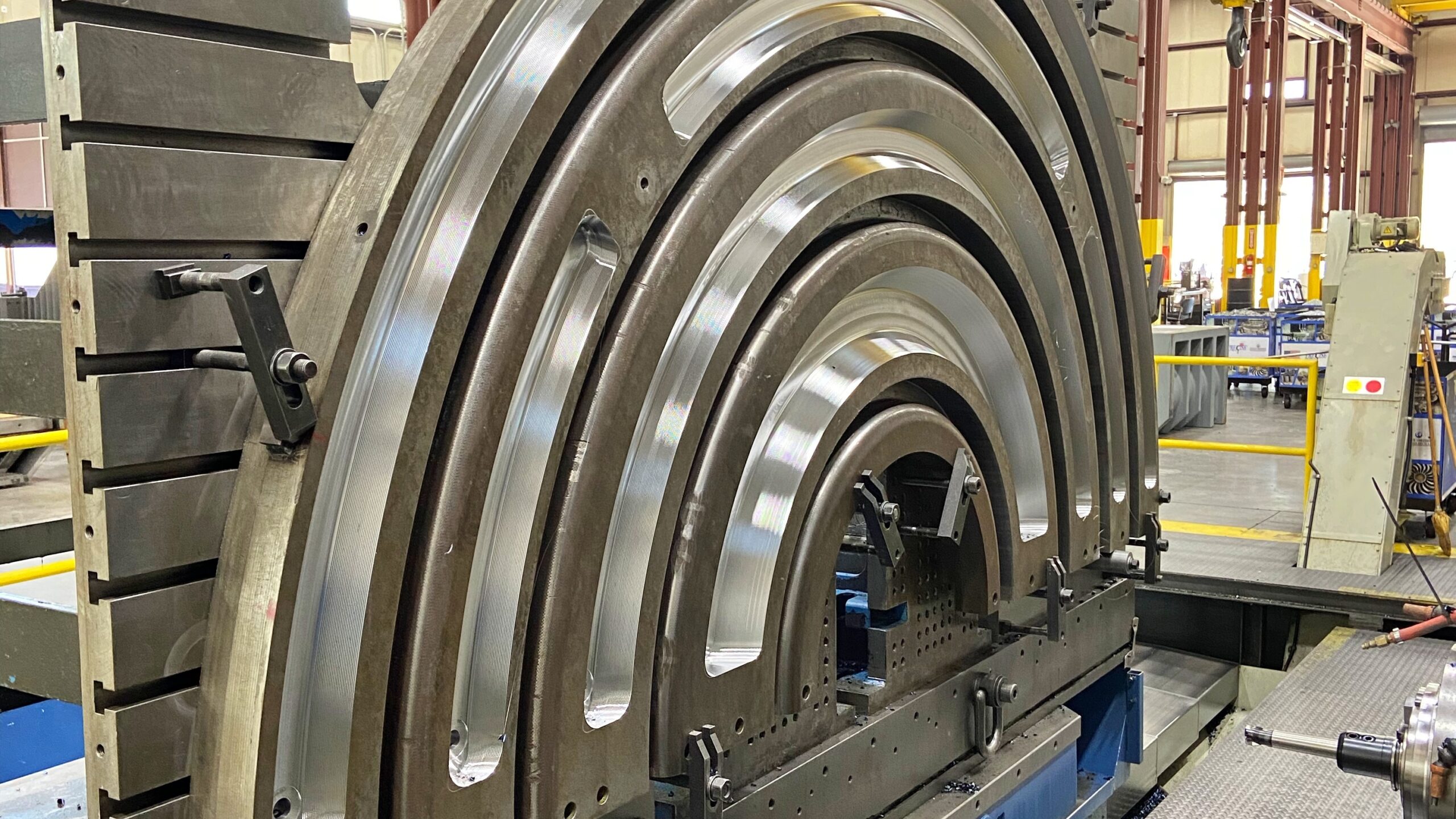

| Axis Travel | X: 600mm, Y: 500mm, Z: 500mm

A-C-axis: ±110° (5-axis simultaneous)

C-axis: 360° continuous | Adequate travel for complex steel components. 5-axis capability allows single-setup machining of intricate geometries (e.g., aerospace brackets, medical implants). |

| Positioning Accuracy | ISO 230-2 Certified:

– Linear Axes: ≤0.005mm/m

– Angular Axes: ≤15 arc-sec | Tight tolerance foundation: ISO 230-2 is the industry standard for geometric accuracy. This ensures parts meet ±0.0025mm tolerances consistently. |

| Repeatability | ≤0.0025mm (X/Y/Z), ≤8 arc-sec (A/C) | Critical for batch consistency in prototyping. Steel parts require this level of repeatability for fit/assembly. |

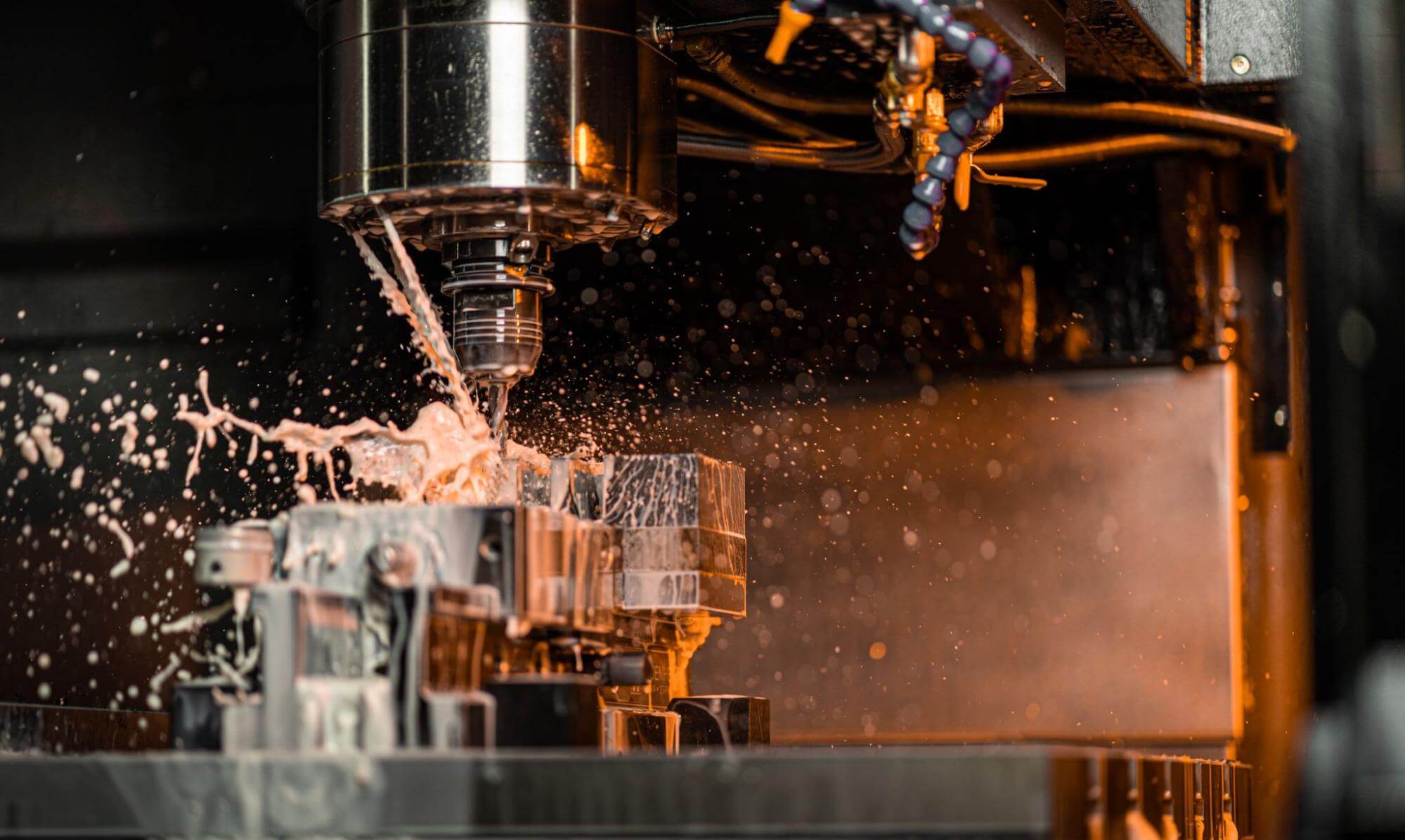

| Coolant System | High-pressure (30–50 bar) through-spindle coolant; chip evacuation (500+ L/min) | Steel machining generates heat and long chips. High-pressure coolant prevents thermal distortion and chip welding. |

| Control System | Siemens 840D sl or Heidenhain TNC 640 with adaptive control & thermal compensation | Real-time compensation for thermal expansion (critical for steel). Adaptive feed rate adjusts for material hardness variations. |

Material-Specific Processing Considerations

| Material | Critical Machine Requirements | Typical Tolerance Achievable |

|————–|—————————————————————————————————|———————————-|

| Steel (e.g., 4140, 17-4 PH, 316 SS) | – High spindle torque & rigidity

– High-pressure coolant

– Thermal stability (≤0.005mm/m accuracy)

– Durable tooling (TiAlN-coated carbide) | ±0.0025mm (0.0001″) for critical features; ±0.005mm for general features |

| Aluminum (e.g., 6061, 7075) | – Higher RPM capability (18,000+ RPM)

– Air blast cooling (for fine chips)

– Reduced cutting forces (lower torque needed) | ±0.0025mm (easier than steel due to lower heat generation) |

| ABS/Nylon | – Low cutting forces (1–5 Nm torque)

– High RPM (15,000+ RPM) for smooth finishes

– Dust extraction (not coolant)

– Thermal management (avoid melting) | ±0.005mm (plastics are dimensionally unstable if overheated) |

Note on Plastics: ABS/Nylon require no coolant – it would cause warping. Instead, use dry cutting with air blasts and optimized feed rates to prevent heat buildup. A machine with precise spindle speed control is essential to avoid melting.

Why This Matters for Honyo Prototype

- Steel Focus: Steel demands rigidity and thermal stability. A standard “light-duty” mill will drift under heavy cuts, causing tolerance failures. The specs above ensure consistent results on hardened steel (e.g., ±0.0025mm on a 50mm feature).

- Tight Tolerance Reality: ±0.0025mm is achievable only with:

- ISO 230-2-certified geometric accuracy

- Thermal compensation (not just a “high-precision” claim)

- Vibration-damped frame (steel cuts generate 5–10x more force than aluminum)

- Multi-Material Flexibility: The same machine handles steel, aluminum, and plastics – but process parameters must change. For example:

- Steel: 150 RPM, 0.1mm/tooth feed, 30 bar coolant

- ABS: 5,000 RPM, 0.3mm/tooth feed, no coolant

- Turning Integration: Live tooling allows drilling, tapping, and turning operations without re-fixturing – critical for complex steel parts (e.g., valve bodies with internal features). C-axis resolution of ≤0.0001° ensures helical threads or contour turns meet tight tolerances.

Key Takeaway for Prototyping

“For steel in a prototype environment, the machine must prioritize thermal stability and geometric accuracy over raw power. A 5-axis mill-turn center with ISO 230-2 certification, thermal compensation, and high-pressure coolant is non-negotiable for achieving ±0.0025mm tolerances. Plastic materials (ABS/Nylon) are secondary – they require different setups but can be handled on the same platform with parameter adjustments.”

At Honyo Prototype, we specify machines like the DMG MORI CTX 500 or Haas TM-1 for such work – they balance rigidity, precision, and multi-material flexibility while meeting ISO 230-2 standards for tight-tolerance steel parts. Always validate machine specs with a geometric accuracy test (ISO 230-2) before purchase – theoretical “high precision” claims are meaningless without certified proof.

Let me know if you need details on tooling strategies, fixturing, or process validation for specific steel alloys!

From CAD to Part: The Process

Honyo Prototype – “CNC Mill for Steel” Workflow

(what happens to your part from the moment you drop the file until the courier leaves our gate)

-

Upload CAD

• Portal accepts any neutral format (STEP, IGES, Parasolid) plus native SolidWorks/Creo/Catia.

• Geometry is immediately scanned for IP theft, ITAR or EAR flags, then encrypted at rest.

• Pre-validator checks for fatal errors (zero-thickness, non-manifold edges, missing faces).

• You pick “Steel” class (low-carbon, pre-hard, stainless, tool steel, maraging, etc.) and quantity.

• Optional: add drawing, GD&T, coating call-outs, material cert level (3.1 / 3.2 / 3.1 with X-ray). -

AI Quote (≤60 s)

• Feature-based cost engine extracts every mill-accessible face, pocket depth, internal corner R, under-cut, thread, bore tolerance.

• Machine-match algorithm decides 3-axis, 3+2, or full 5-axis workflow based on steel grade and complexity index.

• Tool-life model pulls historic carbide wear curves for the selected steel; adjusts cycle time and insert cost.

• Dynamic lead-time scheduler looks at spindle hours already sold on our 40 steel-dedicated DMG-Mori & Brother Speedio cells, then returns three lanes:

– Express (1-2 days)

– Standard (3-5 days)

– Economy (6-8 days)

• Price you see is landed: material, machining, deburr, CMM sampling, RoHS-compliant oil rust preventative, export docs, air freight to 46 countries. No later add-ons. -

DFM (Design-for-Manufacture) – Human + AI hybrid

Approval route:

a. AI red-flags impossible tolerances (e.g., 5 µm true-position on a 120 mm long P20 block).

b. Senior steel mill planner (10 yr+ experience) opens your file, proposes:

– Split bodies to eliminate deep slotting,

– Add relief grooves for thread mills,

– Change 90° internal corner to Ø1 mm R to let us run Ø2 mm end-mill at full flute length,

– Switch from 316L to 17-4PH if you need 40 HRC without post heat-treat.

c. You receive an interactive 3D PDF; click “Accept” or chat live with the planner.

d. Final manufacturability score must hit ≥92 % before release to production—internal rule for steel jobs. -

Production

4.1 Material prep

– Incoming 6061-T6 aluminium is never mixed with steel; separate section of warehouse.

– Plate or round bar cut on Amada carbide saw with flood coolant to avoid decarburised skin.

– Each blank laser-marked with job QR; photo logged.

4.2 Fixturing & set-up

– Modular Mitee-Bite aluminium fixtures for proto runs; hardened A2 fixture plates for 50+ qty.

– Datum is probed on Heidenhain TS460; offset auto-uploaded to central Offset-Cloud so sister machines can reload without re-probing.

4.3 Roughing

– Prefer 3/4” 4-flute variable-helix TiAlN-coated carbide, 250 m/min SFM, 0.06” IPT, 55 % step-over, high-pressure 70 bar through-spindle coolant to evacuate chips and avoid work-hardening (critical in 316L).

– Trochoidal paths generated by HyperMill Maxx-Machining; keeps constant tool engagement <30 %.

4.4 Semi & finish

– For 0.8 µm Ra or better we leave 0.15 mm stock then take 0.05 mm finish pass at 8 000 rpm, 0.005” IPT with 6 mm 5-flute end-mill, tilt +1° to avoid witness marks.

– 5-axis continuous motion for tapered ribs; eliminates secondary EDM in most cases.

4.5 In-process control

– On-machine Renishaw OMP60 probing every 3rd part; dimensions auto-logged to SPC dashboard.

– If Cpk < 1.33 machine pauses, tool replacement triggered; you get an alert plus updated ship date.

4.6 Deburr & surface

– Thermal deburr (Kalamazoo) for intersecting cross-holes in stainless; removes 0.02 mm burr in 3 ms.

– Vibro-finish with 5 mm conic ceramic for 20 min to break 0.1 mm edge radius if drawing calls out “no sharp edges”.

– Optional: black-oxide, passivation, or 25 µm electroless nickel (all in-house).

4.7 Final CMM & material certs

– Zeiss CONTURA G2 scans critical features; report attached to shipment.

– Mill-test certificates (EN 10204 3.1) printed and packed with parts; 3.2 cert available if witnessed by TÜV/SGS (add 24 h).

- Delivery

• Parts ultrasonically washed, dipped in Shell Ensis rust preventative, vacuum-sealed with VCI film.

• Desiccant pack + impact indicator on inner box; outer carton UN3480-certified for lithium-battery aircraft (same crash-proof standard we use for steel).

• Courier choices:

– DHL Express (next-flight-out 10:30 a.m.)

– FedEx Economy (2-day)

– Your own UPS account.

• Tracking number pushes to portal; photos of packed boxes uploaded so you can see how each part is oriented before you open at receiving.

• Digital traveller (tool list, offsets, CMM report, heat number) archived 10 yr for ITAR traceability.

Typical calendar time for a 150 mm × 100 mm × 40 mm 17-4PH block, 0.05 mm general tolerance, qty 10:

Upload → AI quote 45 s → DFM approval 4 h → production 3 days → DHL 1 day = 4-5 days door-to-door anywhere on the planet.

That is the complete “CNC mill for steel” path at Honyo Prototype.

Start Your Project

Precision CNC Milling for Steel – Engineered in Shenzhen.

Contact Susan Leo at Honyo Prototype for high-accuracy, cost-effective solutions:

info@hy-proto.com

✅ Trusted by global manufacturers

✅ ISO-certified facility in Shenzhen

✅ Fast turnaround, competitive pricing

Ready to transform your steel designs? Reach out today! 🔧

🚀 Rapid Prototyping Estimator