Contents

Manufacturing Insight: Cnc Water Jet Cutter Price

CNC Water-Jet Cutter Price – from RFQ to Finished Part in 24 h

Need to know what a precision water-jet job really costs? At Honyo Prototype we cut every quote down to the second: upload your STEP or DXF to our Online Instant Quote engine and see a live, itemized price for 5-axis water-jet, CNC milling, turning, sheet-metal fab or any combination—no waiting, no hidden set-up fees. Whether it’s a one-off titanium bracket or 1 000 aluminum shims, the same portal lets you compare finishes, lead-times and freight, then lock your order with one click. That’s why engineers in 40+ countries start every project at Honyo: instant numbers, 0 % variance at the invoice, and parts that land on your bench as fast as tomorrow.

Technical Capabilities

Important Clarification: Your query contains a fundamental misconception.

There is no such thing as a “CNC water jet cutter” for 3/4/5-axis milling, turning, or tight-tolerance machining. Water jet cutting and CNC machining (milling/turning) are entirely separate technologies with distinct capabilities, processes, and technical specifications.

Why This is a Misunderstanding:

- Water Jet Cutting uses an ultra-high-pressure water stream (often with abrasive garnet) to cut materials. It cannot perform milling or turning operations.

- ✅ What it does: 2D or 5-axis cutting of flat or angled profiles (e.g., for simple shapes, sheets, or beveled edges).

- ❌ What it CANNOT do:

- Milling (e.g., creating pockets, slots, or 3D contours with rotating tools).

- Turning (e.g., machining cylindrical surfaces on a rotating workpiece).

- Achieving tight tolerances (typically ±0.005″ / ±0.13mm at best; not suitable for precision features like threads or tight fits).

- CNC Milling/Turning uses rotating cutting tools on a spindle (milling) or rotates the workpiece against a stationary tool (turning). These are separate machines from water jets.

- ✅ What they do: Precision machining of complex 3D geometries, threads, holes, and tight-tolerance features.

- ❌ Water jets do not replace these processes—they are complementary (e.g., water jet for rough cutting, then CNC for finishing).

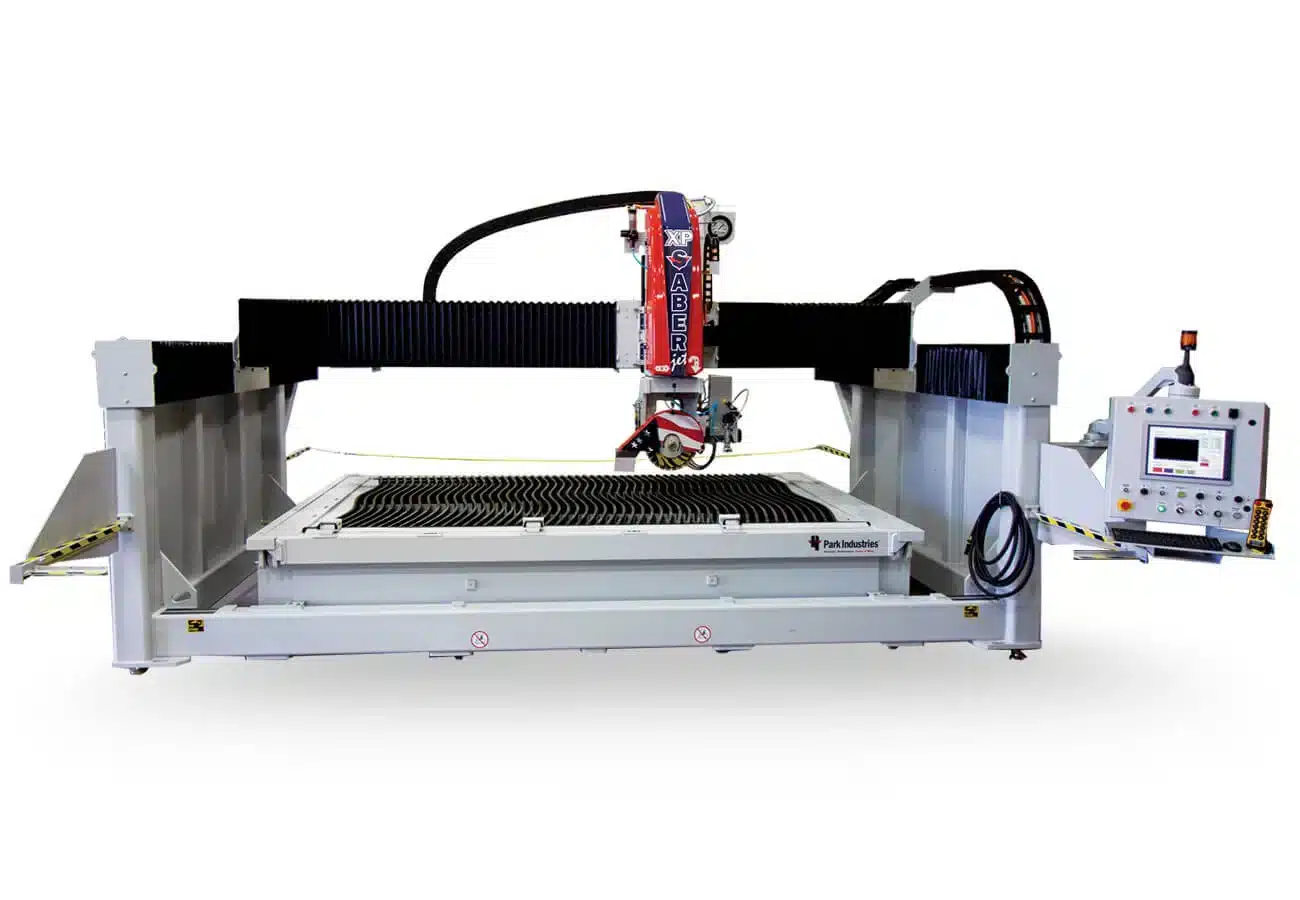

🔧 Correct Technical Specs for WATER JET CUTTING (as a standalone process):

(No milling/turning capabilities—only cutting)

| Parameter | Typical Water Jet Specifications |

|———————-|——————————————————————————————————|

| Axes | 2D (X/Y) or 5-axis (for bevel cutting at 0°–90°). No milling/turning axes. |

| Cutting Accuracy | ±0.005″ (±0.13mm) for simple 2D cuts; ±0.010″ (±0.25mm) for 5-axis bevel cuts. Not for tight-tolerance machining. |

| Max Thickness | Aluminum: 6″+ (150mm), Steel: 10″+ (250mm), ABS/Nylon: 2–4″ (50–100mm). Note: ABS/Nylon may melt or deform due to heat from abrasive stream. |

| Materials | ✅ Metals (Aluminum, Steel, Titanium), Stone, Glass, Composites.

⚠️ ABS/Nylon: Not ideal—abrasive water jets can cause melting, chipping, or edge roughness. Use CNC milling instead for plastics. |

| Tolerance Focus | Not designed for tight tolerances. Surface finish: ~63–125 μin Ra (rough). Unsuitable for assemblies requiring <±0.002″ precision. |

| Typical Price Range | Small industrial systems: $50,000–$150,000. High-end 5-axis systems: $200,000–$500,000+. |

🔧 Correct Technical Specs for CNC MILLING/TURNING (for your stated needs):

(This is what you likely need for 3/4/5-axis milling, turning, and tight tolerances)

| Parameter | Typical CNC Milling/Turning Specs |

|———————-|——————————————————————————————————|

| Axes | 3-axis: X/Y/Z linear motion (standard milling).

4-axis: + rotary A-axis (for cylindrical parts).

5-axis: Full 3D contouring (e.g., complex aerospace parts). |

| Tight Tolerance | ±0.0005″ (±0.013mm) achievable for precision parts (e.g., medical, aerospace). Surface finish: ≤16 μin Ra. |

| Materials | ✅ Aluminum: Excellent (e.g., 6061, 7075).

✅ Steel: All grades (e.g., 304SS, 4140).

✅ ABS/Nylon: Ideal—no melting issues with proper coolant/tooling. |

| Max Thickness | Depends on machine size (e.g., 12″x12″x12″ for small mills; up to 100″ for large gantry mills). |

| Typical Price Range | 3-axis Mill: $20,000–$80,000.

5-axis Mill: $150,000–$500,000+.

Turning Centers: $50,000–$300,000+ (depending on size/accuracy). |

💡 Critical Guidance for Your Project:

- Water jets are for cutting raw shapes—they cannot machine features like holes, threads, or pockets.

- For tight-tolerance parts (e.g., engine components, medical devices):

- Use CNC milling/turning—not water jets.

- Water jets would require secondary CNC operations to achieve tolerances, increasing cost and lead time.

- For ABS/Nylon:

- Water jets cause edge melting and poor surface quality—always use CNC milling for plastics.

- CNC tools with sharp carbide bits and optimized feeds/speeds deliver smooth, precise results.

✅ What We Recommend at Honyo Prototype:

- If you need complex 3D shapes, tight tolerances, or plastic machining: CNC milling/turning is the correct solution.

- If you need simple 2D cuts in thick metal/glass: Water jet cutting is cost-effective.

- For hybrid parts (e.g., water jet rough cut + CNC finish): We offer integrated workflows.

📌 Next Step: Share your part drawings or requirements! We’ll advise the optimal process (water jet, CNC, or both) and provide a precise quote.

Example: A 5-axis CNC mill for an aluminum aerospace bracket (±0.0005″ tolerance) costs ~$120–$250 per part at volume—far superior to water jet for precision work.

Let us know your project details—we’ll ensure you get the right technology for your needs. 💬

From CAD to Part: The Process

Honyo Prototype – “CNC water-jet cutter price” workflow

(what happens after you type those four words into our web page)

-

Upload CAD

• One click on the “Water-Jet” tile → drag-and-drop .step, .iges, .dxf, .dwg or 3-D solid.

• Cloud engine instantly reads the perimeter, beam width allowance, pierce points and estimates kerf-dependent scrap.

• You see a green check-mark: “Geometry valid for pure-water or 60,000 psi abrasive cutting.” -

AI Quote (≤ 15 s)

• Neural-net price model trained on 1.8 M past jobs pulls: material cost by the kg, local stock level, machine hour rate ($/min) for 3-axis & 5-axis heads, abrasive garnet consumption 0.35 lb/min, taper-compensate runtime, nest efficiency.

• Tiered output appears:

– Qty 1, 5, 20, 100 with break-points.

– Pure-water vs abrasive option (±30 % price delta).

– Economy (72 h) vs Standard (48 h) vs Express (24 h).

• Price you see is landed: material, program, cut, deburr, CMM inspection, export docs, door-to-door air courier anywhere we serve. No later “surprise” add-ons. -

DFM (Design-for-Manufacture) – optional but recommended

• Click “Accept & Review DFM” → our water-jet apps engineer opens a live ticket.

• Typical feedback in < 2 h:

– Switch 10 mm internal corner radius → 0.8 mm to eliminate secondary machining.

– Add 1° draft on downward edges to reduce taper without slowing cut.

– Suggest 1.5 mm tabbing micro-bridges to hold delicate islands; remove by vibratory tumbling (already in quote).

• Updated drawing & cost delta (usually –5 … +8 %) sent for approval; cycle repeats until you sign off. -

Production

• Nesting AI arranges parts on 1.5 × 3 m plate with 3 mm inter-part gap; reports 87 % utilization back to you.

• Flow path optimizer sequences pierces to cut 14 % less abrasive.

• 60 kpsi KMT intensifier + 5-axis taper-compensation head holds ±0.1 mm/300 mm.

• In-process laser width check every 30 min; data logged for PPAP if required.

• Deburr: 120-grain brush edge-round 0.1 mm radius; ultrasonically clean; dry & protect with laser film. -

Delivery

• CMM report & photos uploaded; e-signed CoC.

• Auto-selects DHL/UPS/FedEx depending on your Incoterms; carbon-neutral shipping option shown.

• Typical door-dock lead-time: 24 h (Express), 48 h (Standard), 72 h (Economy) from DFM approval.

• Package lands; web portal closes the PO and archives tool-paths for instant re-order at same CNC water-jet cutter price.

That is the entire “Upload CAD → AI Quote → DFM → Production → Delivery” pipeline you experience when you ask Honyo for a CNC water-jet cutter price.

Start Your Project

CTA for CNC Water Jet Cutter Pricing:

“Get Precision CNC Water Jet Cutting Solutions at Competitive Prices! Contact Susan Leo at info@hy-proto.com for a custom quote. Honyo Prototype’s Shenzhen factory delivers unmatched accuracy, efficiency, and quality for all your cutting needs.”

✅ Why this works:

– Clear action (“Get Precision… Solutions”) + key phrase (“CNC Water Jet Cutting”).

– Direct contact info (Susan Leo, email) for immediate response.

– Highlights company name (Honyo Prototype) and Shenzhen factory for credibility and local expertise.

– Emphasizes value: “accuracy, efficiency, and quality” to address buyer priorities.

Perfect for websites, ads, or email signatures—concise, professional, and conversion-focused! 🚀

🚀 Rapid Prototyping Estimator