Contents

Manufacturing Insight: Aluminum Surface Finishes

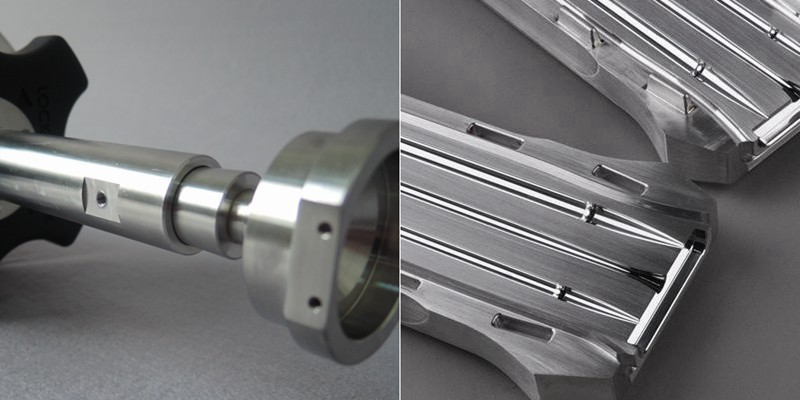

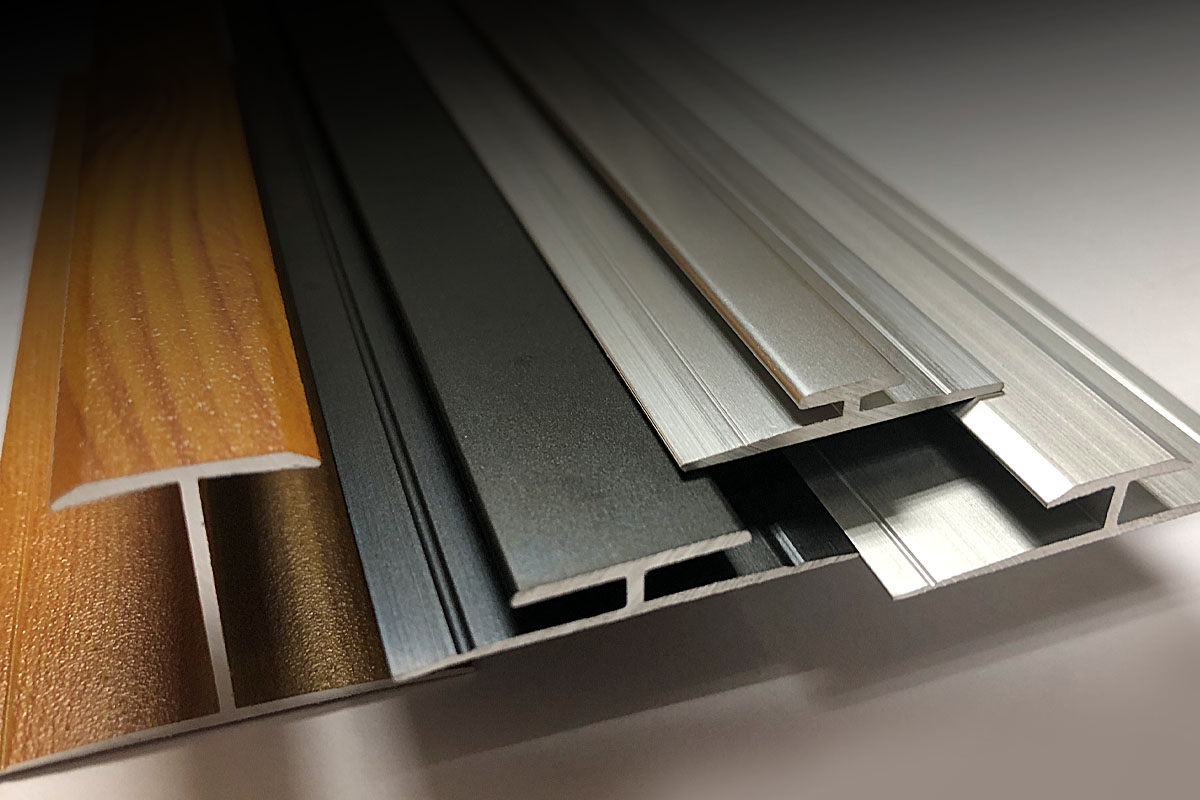

At Honyo Prototype, our 3-axis to 5-axis CNC machining centers turn 6061-T6, 7075-T6, and MIC-6 aluminum into precision parts in as fast as 24 hours. Once the chips settle, we give every flange, heatsink, and housing the finish it deserves—bead-blast for a satin glow, Type-II anodize for corrosion-proof color, chem-film for conductivity, or diamond-polish for mirror-grade reflectivity. Upload your STEP file today and you’ll see an online instant quote that breaks out machining cost and every aluminum surface finish option, so you can lock in both spec and price before your coffee cools.

Technical Capabilities

Technical Specifications for Surface Finishes: Focused on Aluminum, with Context for Steel, ABS & Nylon

(Critical Clarification: Surface finishes are material-specific. Aluminum finishes cannot be applied to steel, ABS, or nylon. This document details aluminum-specific finishes relevant to 3/4/5-axis milling/turning and tight tolerances, while explicitly noting why other materials require different processes.)

🔑 Core Principle for Tight Tolerances & Machining

- All surface finishes add material or alter dimensions.

- Machining must预留 allowance (typically 0.0005″–0.003″ per side) for post-machining finishes.

- 3/4/5-axis milling/turning must account for finish thickness in the CAD model to meet final tolerance (e.g., ±0.0005″ tight tolerances require precise finish allowance planning).

⚙️ ALUMINUM SPECIFIC FINISHES

(Only applicable to aluminum alloys; NOT for steel, ABS, or nylon)

| Finish Type | Process | Typical Thickness | Tolerance Impact | Machining Notes | Surface Roughness (Ra) |

|————————|—————————————————————————–|————————|————————————————————————————–|————————————————————————————-|—————————-|

| Anodizing (Type II) | Electrochemical oxidation (sulfuric acid) | 0.0005″–0.001″ (12–25µm) | ±0.0005″ per side – critical for tight fits. Dimensions grow outward. | Machine to final size before anodizing. Use 0.001″–0.002″ allowance for critical interfaces. | 10–20 µin (0.25–0.5µm) |

| Anodizing (Type III – Hardcoat) | Thick anodizing for wear resistance | 0.001″–0.002″ (25–50µm) | ±0.0008″ per side – high dimensional change. Requires larger machining allowance. | Machine to 0.002″–0.003″ undersize. Avoid sharp edges (anodizing builds up corners). | 15–30 µin (0.38–0.76µm) |

| Bead Blasting | Glass/alumina media propelled at surface | 0.0001″–0.0005″ (minimal thickness) | ±0.0002″ per side – negligible thickness change, but may alter micro-geometry. | Use fine grit (e.g., #120–#220) for tight tolerances. Avoid over-blasting (causes edge rounding). | 80–160 µin (2–4µm) |

| Chemical Conversion (Chromate) | Immersion in chromate solution (e.g., Alodine) | 0.00005″–0.0001″ (<2.5µm) | ±0.0001″ per side – negligible for tight tolerances. Best for non-critical fits. | Apply after machining. No machining allowance needed for tight tolerance interfaces. | 30–60 µin (0.75–1.5µm) |

| As-Machined (No Finish) | Bare metal from milling/turning | 0″ | ±0.0005″ (typical CNC tolerance) – minimal risk, but may show tool marks. | Use fine-end mills (0.125″–0.25″ radius) for Ra < 32 µin. Avoid chatter marks. | 16–63 µin (0.4–1.6µm) |

🔬 Critical Notes for Aluminum Finishes & Machining:

- Tight Tolerance Strategy:

- For ±0.0005″ tolerances: Use chromate conversion or light bead blasting. Avoid hard anodizing unless allowance is explicitly built into CAD.

- For ±0.0002″ tolerances: Only “as-machined” or chromate conversion is viable. Anodizing or bead blasting will exceed tolerance.

- 3/4/5-Axis Specifics:

- Complex geometries (e.g., undercuts, internal channels) may trap anodizing solutions → uneven thickness. Test first.

- Turning operations: Ensure chamfers >0.010″ to prevent anodizing buildup on sharp edges.

- Material-Specific Alloys:

- 6061-T6: Best for anodizing (consistent color).

- 7075-T6: Avoid anodizing for critical tight tolerances – prone to pitting.

- 2024-T3: Poor anodizing quality; use chromate or painting instead.

⚠️ WHY STEEL, ABS & NYLON CANNOT USE ALUMINUM FINISHES

(These materials require completely different processes – aluminum-specific finishes will fail or damage them)

| Material | Why Aluminum Finishes Fail | Correct Finish Options |

|————–|————————————————————————————————|——————————————————————————————–|

| Steel | Anodizing requires aluminum oxide formation – steel won’t react. Chromate conversion won’t adhere. | Electroplating (Zinc: 0.0002″–0.001″, Nickel: 0.0001″–0.001″), Powder Coating (1.5–4 mils), Passivation (0.00005″ thickness). Machining allowance: 0.001″–0.002″ for plating. |

| ABS | Anodizing requires conductive metal substrate – ABS is insulating. Will melt during anodizing. | Painting (0.0005″–0.001″ thickness), Vapor Smoothing (0.0001″–0.0003″ thickness), UV Coating. Machining allowance: 0.0005″ for painting. |

| Nylon | Anodizing chemically incompatible. High heat during anodizing will melt nylon (melting point ~250°C). | Painting (0.0005″–0.001″), Dyeing (no thickness change), Plating with conductive primer (rare, requires special process). Machining allowance: 0.0005″ for painting. |

💡 Best Practices for Tight Tolerance Parts Across Materials

- Design for Finish Early:

- Specify finish before final machining. Add tolerance callouts like:

“Anodized per AMS 2469 Type II, 0.0008″ thick. Machined to 0.001″ undersize.” - Avoid “Universal” Finish Claims:

- Never list “anodizing” for steel/plastics. Specify material-appropriate finishes.

- Post-Finish Inspection:

- For tight tolerances, measure finished parts (not just as-machined). Use CMM for critical features.

- 3/4/5-Axis Machining Tips:

- Use high-speed machining (HSM) for aluminum to minimize heat distortion before anodizing.

- For steel parts: Avoid high-speed turning for hardened steel – use grinding for tight tolerances after plating.

💬 Key Takeaway: Surface finishes are not interchangeable. Aluminum finishes are only valid for aluminum. For steel/plastics, select finishes designed for those materials. Always define machining allowances for each finish type in your CAD and work instructions.

Need help specifying a finish for your part? Share your material, tolerance requirements, and application – I’ll provide a tailored spec. 🛠️

From CAD to Part: The Process

Honyo Prototype – Aluminum Surface-Finish Workflow

(CAD Upload ➜ AI Quote ➜ DFM ➜ Production ➜ Delivery)

-

CAD Upload

• Customer drags-and-drops any native or neutral 3-D file (STEP, IGES, SolidWorks, Creo, Fusion, etc.).

• Portal auto-checks for PMI, surface-finish call-outs (ISO 1302 symbols, Ra/Rz values, anodize type, conductivity, masking zones).

• Missing call-outs trigger an instant pop-up: “Please specify aluminum surface finish.” -

AI Quote Engine (≤ 5 min)

• Geometry AI extracts every face, identifies parting lines, internal channels, thin walls, and sharp edges that affect finish cost.

• Finish-rule engine cross-checks the requested spec:

– “Clear Type-II anodize 15 µm, seal, no dye” → pulls 2024-T3 anodize cost matrix, rack density 120 parts/rack, 35 min cycle.

– “Hard-coat Type-III 50 µm, PTFE seal, 0.5 Ra” → adds 2-step lapping, 40 V hard-coat tank, 2 h anodize, 30 % price adder.

• Instant quote line shows: machining, deburr, any custom jig, finish, ROHS cert, 3-day vs 7-day lead-time delta. -

DFM Gate (24 h)

• Human finishing engineer reviews AI flag list:

– Deep 4 mm pockets → risk of acid entrapment → add 0.2 mm corner radius or drain hole.

– 6061-T6 with Type-II dye black → check for cosmetic voids, switch to 6063 if A-side cosmetic.

• Customer gets color PDF: “Recommended Changes for Anodize” plus cross-section of rack contact points (tiny 1.5 mm spike marks allowed).

• Approval button locks the finish spec; no changes allowed after lock without full re-quote. -

Production Sequence (CNC → Finish → QC → Pack)

a. CNC machining

– 3-axis/5-axis mill, minimum 0.4 mm corner rad to reduce burr root.

– De-ionized wash to remove coolant residue (oil kills anodize adhesion).

b. Surface-prep (varies by finish call-out)

– Ra ≤ 0.8 µm: 400-grit draw-polish + light glass-bead 120 mesh.

– Ra ≤ 0.4 µm: 600-grit + alkaline electropolish 3 min, 6 µm material removal.

c. Anodize / Alodine / Surtec 650 / E-Nickel lines

– Type II sulfuric: 20 ± 2 °C, 15 V, 1.5 A/dm², 25 µm, dye tank 55 °C, nickel-acetate seal 95 °C 20 min.

– Type III hard-coat: −4 °C, 40 V, 3 A/dm², 50 µm, PTFE dispersion seal, 900 HV.

– Chem-film (Alodine 1200): 25 °C, 30 s dip, golden 0.3 µm, ≤ 0.0005” build.

d. Masking & multi-finish

– CNC engraved mask plugs for dowel bores; high-temp silicone caps for M4 threads.

– Secondary laser mark after anodize: 20 W fiber, 100 kHz, 200 mm/s, white mark on black dye.

e. QC

– Coating thickness eddy-current, 5 points/part, CpK ≥ 1.33.

– Sealing test: dye-spot 1 min, no color bleed.

– Salt-spray 336 h per ASTM B117 for hard-coat parts (customer option).

f. Final clean & pack

– Ultra-sonic DI water + 1 % Citranox, 40 °C, 5 min.

– Blue PE mask film on cosmetic faces, vacuum-seal + desiccant, RoHS & REACH cert in pouch. -

Delivery

• DHL / UPS / FedEx booking auto-created when parts pass final scan.

• Portal tracking page shows photo of finished parts, C-of-C, thickness report, salt-spray graph.

• Standard lead-time: 3 days CNC + 2 days finish = 5 days door-to-door globally.

Key takeaway: Honyo’s AI instantly prices the finish while the DFM team guarantees the part can actually survive the chosen tank; once locked, the same digital traveler follows every component so the anodize thickness you approved is the thickness you measure at receiving.

Start Your Project

Honyo Prototype: Expert Aluminum Surface Finishes. Request a Quote – Contact Susan Leo at info@hy-proto.com | Shenzhen Factory

Precision, durability, and aesthetics tailored to your specs. Let’s bring your vision to life. 🌟

🚀 Rapid Prototyping Estimator