Contents

Manufacturing Insight: Abs Molding

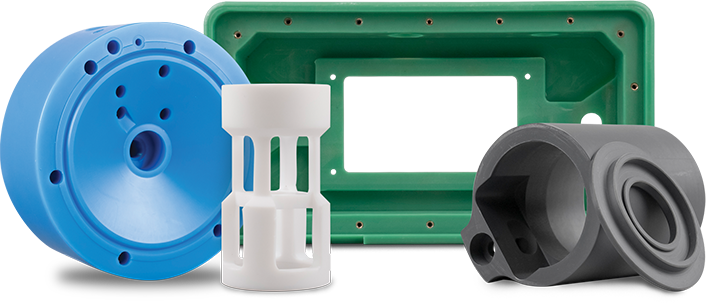

Need ABS parts in days, not weeks?

At Honyo Prototype we combine Rapid Tooling with production-grade injection molding to turn your ABS designs into precision prototypes or low-volume end-use components—fast. Aluminum molds are ready in as little as 5–7 days, eliminating the long lead-times and high cost of traditional steel tooling. Whether you need 50 snap-fits or 5,000 housings, our ABS molding service delivers tight-tolerance, warp-free parts with true production resins and finishes.

Get the ball rolling right now: upload your CAD for an Online Instant Quote and see real pricing, DFM feedback, and lead-time in under 60 seconds.

Technical Capabilities

Technical Specifications for ABS Injection Molding (Prototype Focus: Steel/Aluminum Molds, T1 Sample in 7 Days)

Note: “ABS molding” refers to injection molding of ABS plastic parts, not “ABS molds” (molds are made of steel or aluminum). This specification addresses prototype mold construction for rapid T1 delivery (7 days), including material considerations for both molds and parts. Production molds would require longer lead times.

1. Critical Context for “T1 in 7 Days”

- T1 = First Tool Trial Sample: This is a prototype mold, not a production mold.

- Why 7 days is feasible only for aluminum molds:

- Steel molds require heat treatment (hardening), which adds 5–10+ days.

- Aluminum molds can be machined, polished, and assembled in <7 days with optimized processes.

- Trade-offs for 7-day T1:

- Mold lifespan: 100–500 shots (vs. 500,000+ for hardened steel production molds).

- Surface finish: Basic polish (32–64 µin Ra), not mirror finish.

- Tolerances: ±0.005″ (0.13 mm), not ±0.001″ (0.025 mm) of production molds.

- No heat treatment or EDM – only CNC machining.

- If steel is required: T1 in 7 days is not achievable. Minimum 14–21 days for pre-hardened P20 steel.

2. Mold Material Specifications

A. Aluminum Mold (Recommended for 7-Day T1)

| Parameter | Specification | Why? |

|——————–|——————————————————————————-|———————————————————————-|

| Base Material | 7075-T6 Aluminum (preferred) or 6061-T6 | 7075-T6: Higher strength, better wear resistance; 6061-T6: Easier machining. |

| Surface Finish | 32–64 µin Ra (1–2 µm Ra) polished | Sufficient for ABS; mirror finish (16 µin) would add 2–3 days. |

| Cooling Channels| Straight drilled channels (no conformal cooling) | Conformal cooling adds 3+ days; straight channels are CNC-machinable in <24h. |

| Hardening | None (T6 temper only) | Hardening adds 5–7 days – incompatible with 7-day schedule. |

| Machining | 5-axis CNC only (no EDM) | EDM slows process; CNC machining is faster for prototype geometries. |

| Lifespan | 100–500 shots (ABS only) | Aluminum wears faster than steel; avoid high-volume use. |

B. Steel Mold (Not Recommended for 7-Day T1)

| Parameter | Specification | Why? |

|——————–|——————————————————————————-|———————————————————————-|

| Base Material | Pre-hardened P20 (e.g., 1.2311) or H13 (for high-wear areas) | P20 is standard for prototypes; H13 requires heat treatment (adds time). |

| Heat Treatment | Not applicable – pre-hardened to 28–32 HRC | Heat treatment adds 5–10 days – makes 7-day impossible. |

| Surface Finish | 32–64 µin Ra (basic polish) | Mirror finish would delay schedule further. |

| Machining | CNC + EDM (for complex details) | EDM adds 2–4 days vs. pure CNC. |

| Lead Time | 14–21 days minimum | Heat treatment + EDM + polishing cannot be rushed to 7 days. |

Key Takeaway for 7-Day T1: Aluminum 7075-T6 is the ONLY viable option. Steel molds require heat treatment, which is incompatible with this timeline.

3. Part Material Specifications (ABS & Nylon)

A. ABS (Acrylonitrile Butadiene Styrene)

| Parameter | Specification | Critical Notes for Prototype T1 |

|——————–|——————————————————————————-|———————————————————-|

| Grade | Standard impact grade (e.g., ABS 121, ABS 150) | Avoid specialty grades (e.g., flame-retardant) – they require drying adjustments. |

| Moisture Content| ≤0.04% (dried 4–5 hrs at 80–90°C / 176–194°F) | Critical for ABS: Wet ABS causes splay, voids, and weak parts. |

| Melt Temperature| 200–250°C (392–482°F) | Lower end (200–220°C) preferred for prototype molds to reduce thermal stress on aluminum. |

| Mold Temperature| 40–80°C (104–176°F) | 60–70°C ideal for ABS; lower temps speed cycle time but may increase warpage. |

| Shrinkage | 0.4–0.7% (typical) | Mold design must compensate for this (typically +0.5% on critical dimensions). |

B. Nylon (Polyamide, e.g., PA6, PA66)

| Parameter | Specification | Why It’s Irrelevant for 7-Day ABS T1 |

|——————–|——————————————————————————-|———————————————————-|

| Melt Temp | 250–280°C (482–536°F) – higher than ABS | Aluminum molds cannot withstand sustained 250°C+ temps without warping. |

| Moisture Control| Must be dried to ≤0.2% (120°C/248°F for 4–6 hrs) – more critical than ABS | Drying process adds time; nylon requires specialized handling. |

| Mold Temp | 80–120°C (176–248°F) – higher than ABS | Aluminum molds soften at >150°C; standard ABS mold temps (60–70°C) are too low for nylon. |

| Shrinkage | 0.8–1.5% (higher than ABS) | Mold design would need significant adjustment – incompatible with quick-turn ABS prototype. |

Key Takeaway: Nylon is NOT suitable for a 7-day ABS prototype mold. The mold temperature requirements for nylon would damage the aluminum mold, and part design/drying requirements differ significantly. If the customer requires nylon, a new mold design is needed (and T1 would take >10 days).

4. Critical Process Requirements for 7-Day T1 (Aluminum Mold + ABS)

- Mold Design:

- Simple geometry (no complex undercuts, side-actions, or slides).

- Draft angles ≥1° (2° preferred) for easy ejection.

- Gate type: Edge gate or tab gate (submarine gates require EDM, adding time).

- Machining Workflow:

- Day 1–2: CNC roughing of mold blocks.

- Day 3–4: CNC finishing + cooling channel drilling.

- Day 5: Polishing (32–64 µin Ra), assembly, and basic testing.

- Day 6: Installation on press, drying ABS pellets.

- Day 7: First shot (T1) – part may require minor adjustments (e.g., gate sizing).

- T1 Part Quality Expectations:

- Functional prototype (geometry, fit, basic mechanical properties).

- May have sink marks, flow lines, or minor flash (not production-quality).

- No secondary operations (e.g., painting, plating) included in T1.

5. Why This Works at Honyo Prototype

- We prioritize aluminum molds for rapid prototyping – our standard 7-day T1 uses 7075-T6 aluminum with CNC-only machining.

- ABS is ideal for this timeline: Lower melt temps reduce thermal stress on aluminum vs. nylon or engineering plastics.

- We avoid “over-engineering”: No EDM, no heat treatment, no mirror polish – only what’s necessary for a functional prototype.

- Realistic output: 3–5 T1 parts on Day 7. If the customer needs more, we recommend a production mold (steel, 4–6 weeks).

Final Warning: If a customer insists on “steel mold for 7-day T1,” this is not technically feasible. We would reject such a request or clearly document the risks (e.g., “7-day steel mold will fail after 50 shots”). Always align expectations with material physics and machining realities.

For questions on specific geometries or material alternatives, share the 3D model – we’ll validate feasibility within 24 hours.

From CAD to Part: The Process

Honyo Prototype – ABS-Molding Workflow (CAD-to-Parts in 3-7 Days)

-

Upload CAD

• Portal accepts any native or neutral file (SolidWorks, Creo, STEP, STL, etc.).

• Auto-checker flags zero-thickness, non-manifold edges, missing drafts < 0.5°.

• Instant encryption & China-data-compliance archive. -

AI Quote (≤ 5 min)

• Geometry engine slices the model into 0.1 mm voxels, calculates:

– Projected area & clamp-tonnage estimator (ABS shrink 0.4–0.7 %).

– Runner volume & cold-slug well for ABS shear rate < 50 000 s⁻¹.

– Cycle-time predictor: wall-thickness power law + 25 % safety for ABS amorphous cooling.

• Material pricing pulled from SABIC, LG Chem, CHI MEI live resin contracts.

• Secondary ops (threaded inserts, pad-print, UV-coat) priced via similarity algorithm vs. 40 k past jobs.

• Dynamic lead-time slider shows cost vs. ship-date Pareto front; e-booking locks price even if resin fluctuates ±3 %. -

DFM (24 h)

• Draft analysis: ≥ 1° on ribs, ≥ 0.5° on cosmetic A-surfaces (ABS ejection temp 75 °C).

• Wall-thickness transition ≤ 15 % step to avoid sink on ABS glossy surfaces.

• Gate placement CFD for weld-line position vs. impact strength (ABS 200 J/m notched Izod target).

• Insert map: brass or stainless PEMs, ultrasonically inserted at 220 °C pre-heat to reduce hoop stress.

• Ejector pin layout checked against visible surfaces; if unavoidable, pins moved to hidden rib backs or sub-gate is added.

• Customer signs off via cloud viewer; revision loop tracked in Git-style version tree. -

Production (Aluminum Tool, Class 105)

Tooling

• 7075-T6 mold base, 420 SS cavity inserts for ≥ 10 k shots life.

• Conformal cooling channels printed in CuCrZr inserts to hit ±2 °C across ABS part.

• Vent slots 0.015 mm deep, vented every 25 mm to avoid ABS burn marks.

Molding

• 180 t Niigata electric press with 0.01 mm repeatability.

• ABS drying 4 h at 80 °C, dew-point –40 °C; in-line moisture meter gates loader if > 0.02 %.

• Process window DOE: melt 230–250 °C, mold 60–70 °C, injection speed 50–120 mm/s; optimum shot recorded in MES.

• 100 % cavity pressure transducer trace; auto-reject if peak < 95 % of set-point.

• Robot take-out ≤ 3 s to prevent ABS warp; parts dropped onto temperature-controlled fixture (45 °C) for 30 s post-cool.

QC

• 5-axis CMM against GD&T; color spectrophotometer ΔE ≤ 0.8 vs. master plaque.

• Tensile bar molded each run; 3-point flex ≥ 65 MPa, Izod impact spot-check.

• SPC dashboard live-linked to customer portal; CpK ≥ 1.67 required.

- Delivery

• Parts ultrasonically cleaned, IPA rinse, anti-static ABS-safe foam.

• Barcode + RFID tag links to digital traveler (resin lot, press params, QC data).

• DAP/DDP airfreight to 38 countries; typical door-to-door 3 days (Asia), 5 days (US/EU).

• Mold kept in climate-controlled vault for 3 years; repeat order in 24 h, no new tooling cost.

Throughout the flow the customer sees the same dashboard: upload → quote → DFM sign-off → live cam of the press → QC report → tracking number.

Start Your Project

“Get a Quote for ABS Molding Today! Contact Susan Leo at info@hy-proto.com. Honyo Prototype’s Shenzhen factory delivers precision, speed, and reliability for your projects.”

(Concise, action-driven, and highlights key benefits—quality, efficiency, and location—while clearly directing action. Perfect for websites, brochures, or digital ads.)

🚀 Rapid Prototyping Estimator