Contents

Manufacturing Insight: Abs Molding

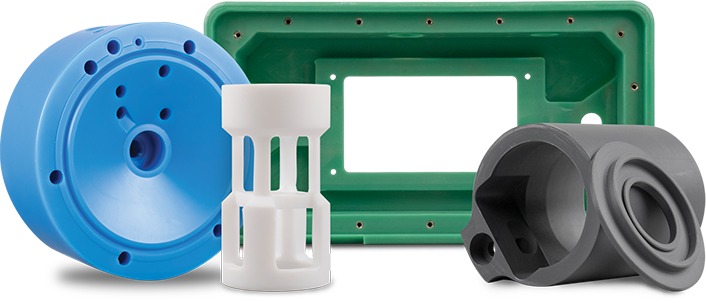

ABS Molding: Precision Engineering for Rapid Prototyping & Low-Volume Production

Acrylonitrile Butadiene Styrene (ABS) remains a cornerstone engineering thermoplastic for injection molding, particularly within the rapid prototyping and low-to-medium volume production landscape served by Shenzhen Honyo Prototype. Its enduring popularity stems from an exceptional balance of mechanical properties, including high impact resistance, dimensional stability, good rigidity, and ease of post-processing such as painting, plating, and bonding. These characteristics make ABS an ideal choice for functional prototypes, automotive interior components, consumer electronics housings, and medical device enclosures where durability and aesthetics are critical. At Honyo, we leverage ABS’s favorable melt flow and thermal properties to deliver parts that accurately validate design intent and meet near-production performance requirements, bridging the gap between concept and full-scale manufacturing efficiently.

Our rapid tooling expertise is specifically calibrated for ABS processing. We utilize high-precision CNC-machined aluminum molds, which offer significantly faster lead times compared to traditional steel tooling while providing excellent thermal conductivity for consistent cycle times and part quality. Aluminum molds are perfectly suited for ABS’s moderate processing temperatures and pressures, enabling us to produce robust prototypes and initial production runs of 100 to 10,000+ parts with exceptional fidelity. Honyo engineers meticulously optimize critical process parameters – melt temperature, injection speed, packing pressure, and cooling time – to minimize internal stresses, prevent sink marks, and ensure dimensional accuracy, directly addressing common challenges like warpage in complex ABS geometries. This optimization is grounded in deep material science understanding and our extensive in-house processing database.

Key ABS molding capabilities at Honyo Prototype are summarized below:

| Parameter | Typical Range for ABS at Honyo | Significance |

| :—————– | :————————— | :——————————————– |

| Material Grades | Standard, Flame Retardant (UL94 V-0), High Impact | Broad application suitability |

| Wall Thickness | 0.8 mm – 4.0 mm | Optimized for flow, strength, and aesthetics |

| Mold Temperature | 40°C – 80°C | Critical for surface finish and warpage control |

| Melt Temperature | 210°C – 250°C | Ensures proper flow without degradation |

| Typical Cycle Time | 30 – 90 seconds | Rapid turnaround for prototypes & low volume |

| Tooling Material | Aluminum (7075-T6, NAK80) | Fast lead times, cost-effective for volumes |

Beyond mold construction and process execution, Honyo integrates rigorous quality control throughout the ABS molding workflow. In-process monitoring tracks key parameters in real-time, while first-article inspection (FAI) and comprehensive dimensional reporting against customer CAD data ensure strict adherence to specifications. Our facility maintains stringent environmental controls for material drying – a non-negotiable step for ABS to prevent hydrolysis and surface defects like splay. By combining advanced machinery, material expertise, rapid aluminum tooling, and disciplined process control, Honyo Prototype delivers ABS molded parts that exceed expectations for functional validation and initial market launch, providing our clients with a reliable, high-fidelity path from design to tangible product.

Technical Capabilities

ABS Injection Molding Technical Capabilities at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, our expertise in rapid tooling and injection molding enables fast, high-quality ABS part production for prototyping and low-to-mid volume manufacturing. We specialize in delivering functional, dimensionally accurate components using both steel and aluminum molds, tailored to meet diverse client requirements across industries such as consumer electronics, automotive, and medical devices.

Our rapid tooling process leverages precision CNC machining to fabricate molds from either hardened steel or aluminum alloys, depending on production volume, part complexity, and durability needs. Aluminum molds are ideal for rapid prototyping and short production runs (up to 10,000 shots), offering faster lead times and lower costs. For higher volume applications requiring extended mold life (up to 100,000+ cycles), we utilize P20, 718H, or NAK80 steel molds with appropriate heat treatment and surface finishes.

One of our key differentiators is the ability to deliver T1 samples within 7 days from design approval. This accelerated timeline is made possible through in-house tool design, streamlined project management, and parallel processing of mold fabrication and material preparation. All molds undergo rigorous quality checks, including mold flow analysis and first-article inspection, to ensure optimal filling, cooling, and ejection performance before sample production.

We process high-grade ABS resins with excellent thermal stability, impact resistance, and surface finish characteristics. Material options include general-purpose, high-impact, heat-resistant, and flame-retardant ABS grades, all sourced from certified suppliers and dried properly prior to molding to prevent defects such as splay or voids.

Dimensional accuracy is maintained through strict process controls, including regulated melt temperature (210–250°C), injection pressure, and cooling time. Our molding machines feature closed-loop monitoring systems to ensure consistency across batches.

The following table outlines key technical specifications for our ABS molding capabilities:

| Parameter | Specification |

|——————————-|————-|

| Material | ABS (General Purpose, HI, Heat Resistant, FR) |

| Mold Material | Aluminum (7075, 6061), Steel (P20, 718H, NAK80) |

| Mold Life | 1,000–10,000 cycles (Aluminum), 50,000–100,000+ cycles (Steel) |

| Typical Lead Time (T1 Sample) | 7 days from design approval |

| Part Weight Range | 1 g – 1,000 g |

| Maximum Part Size | 400 mm × 300 mm × 200 mm |

| Tolerances (Standard) | ±0.1 mm (up to 50 mm), ±0.15 mm (50–100 mm), ±0.25 mm (>100 mm) |

| Surface Finishes | As-machined, Polished (SPI finishes), Textured, Grain |

| Secondary Operations | Degating, Ultrasonic Welding, Painting, Pad Printing, Assembly |

All ABS molded parts are inspected per ASME Y14.5 standards using CMM, optical comparators, and manual gauging as required. First article reports and process validation documentation are available upon request. By combining rapid tooling agility with industrial-grade molding precision, Shenzhen Honyo Prototype delivers reliable, scalable ABS solutions that accelerate product development and time to market.

From CAD to Part: The Process

ABS Injection Molding Production Workflow: From CAD to Finished Part

At Shenzhen Honyo Prototype, our ABS injection molding process integrates advanced digital tools with precision manufacturing to deliver rapid, high-quality prototypes and low-volume production parts. This structured workflow ensures efficiency, minimizes risk, and guarantees part integrity from initial concept to final shipment.

The process commences with the AI-Powered Quoting Engine. Upon receipt of the customer’s CAD file and technical requirements (including material grade, quantity, and surface finish), our proprietary AI system rapidly analyzes geometric complexity, part volume, and feature criticality. It cross-references this data against our extensive database of historical ABS molding cycles, material consumption rates, and machine utilization metrics. This generates an accurate, data-driven quote within hours, detailing estimated costs, lead times, and initial feasibility flags—providing immediate transparency without manual engineering intervention.

Following quote acceptance, the design enters the Critical DFM Validation Phase. Here, Honyo’s senior manufacturing engineers conduct a rigorous Design for Manufacturability review specific to ABS thermoplastics. We verify wall thickness uniformity to prevent sink marks, assess draft angles for seamless ejection, analyze gate location impact on weld lines, and confirm radii adequacy to reduce stress concentration. Crucially, we simulate ABS-specific behaviors like melt flow front progression and cooling-induced shrinkage using Moldflow software. Any identified risks—such as potential warpage from asymmetric cooling or ejection force exceeding part strength—are communicated via a detailed DFM report with actionable design recommendations. Customer approval of the DFM is mandatory before proceeding, ensuring alignment on manufacturability.

With DFM sign-off, Precision Production Execution begins. Honyo fabricates hardened steel or aluminum rapid tooling (depending on volume requirements) using CNC machining and EDM, achieving tight tolerances of ±0.05mm. The ABS molding phase utilizes calibrated all-electric injection machines, optimizing parameters for the selected ABS grade. Strict process control maintains consistent melt temperature, injection pressure, and cooling cycles to ensure dimensional stability and surface quality. Every batch undergoes in-process inspection for critical dimensions and final first-article inspection against the original CAD model. Finished parts receive thorough visual and metrology checks before packaging with full traceable documentation.

Key ABS processing parameters are meticulously controlled as follows:

| Parameter | Typical Range for ABS | Critical Impact |

|——————–|———————–|——————————————|

| Melt Temperature | 210°C – 250°C | Affects flow, surface finish, degradation |

| Mold Temperature | 40°C – 80°C | Influences cycle time, warpage, gloss |

| Injection Pressure | 50 – 150 MPa | Determines packing, sink, weld line strength |

| Cooling Time | 15 – 45 seconds | Directly impacts part crystallinity and ejection stability |

| Drying Requirement | 2 – 4 hours @ 80°C | Prevents hydrolysis, splay, and weakness |

This integrated workflow—AI quoting for speed, expert DFM for risk mitigation, and precision-controlled production—ensures Shenzhen Honyo Prototype consistently delivers ABS molded parts that meet stringent functional and aesthetic requirements on accelerated timelines. Our commitment to data-driven process validation underpins reliability in every component we manufacture.

Start Your Project

Start Your ABS Molding Project with Confidence at Shenzhen Honyo Prototype

When it comes to rapid tooling and injection molding for functional prototypes and low-to-mid volume production, ABS molding stands out for its durability, thermal stability, and excellent surface finish. At Shenzhen Honyo Prototype, we specialize in high-precision ABS injection molding, leveraging advanced rapid tooling technologies to deliver parts faster and more cost-effectively than traditional methods. Whether you’re developing consumer electronics enclosures, automotive components, or medical device housings, our engineering-driven approach ensures your design transitions seamlessly from concept to reality.

Our process begins with a thorough review of your 3D CAD files, where our manufacturing engineers analyze for moldability, draft angles, wall thickness, and material flow to optimize part quality and reduce cycle times. We utilize high-grade ABS resins—including standard, flame-retardant (FR), and high-impact formulations—tailored to your application’s mechanical and regulatory requirements. With in-house tooling capabilities using aluminum and steel molds, we support projects ranging from 50 to 10,000+ units, with turnaround times as fast as 7–12 days for mold fabrication.

What sets Honyo apart is our commitment to precision, consistency, and client collaboration. Every project is assigned a dedicated manufacturing engineer who acts as your technical liaison from quote to delivery. We conduct first-article inspections, perform dimensional validation using CMM equipment, and provide material certifications upon request. Our ISO 9001-compliant manufacturing floor ensures repeatability and quality control at every stage.

To help you evaluate feasibility and cost early in the design phase, we offer free design for manufacturability (DFM) feedback within 24 hours of submission. This proactive approach minimizes costly revisions and accelerates time-to-market.

Key ABS Molding Specifications at Honyo Prototype

| Parameter | Capability |

|—————————-|——————————————-|

| Material Options | ABS, ABS-PC, Flame Retardant ABS, High Impact ABS |

| Mold Materials | 7075 Aluminum, NAK80 Steel, H13 Steel |

| Tooling Life | 50–100,000 shots (based on mold type) |

| Part Weight Range | 1g – 1000g |

| Tolerance (Standard) | ±0.1 mm (up to ±0.05 mm with precision tuning) |

| Surface Finishes | As-molded, VDI3400 textures, SPI polish, painting, metallization |

| Lead Time (Mold + First Shot) | 7–15 days (varies by complexity) |

| Production Volume | 50 – 10,000+ units |

| Secondary Operations | Ultrasonic welding, insert molding, pad printing, assembly |

Starting your project is simple. Just send your 3D model (STEP, IGES, or native CAD) and any special requirements to Susan Leo, our Client Solutions Manager. With over a decade of experience in rapid manufacturing, Susan will guide you through material selection, tooling options, and production planning to ensure your project meets both technical and commercial goals.

Contact Susan Leo today at info@hy-proto.com to request a free quote and DFM analysis. Let Shenzhen Honyo Prototype be your trusted partner in turning innovative designs into high-quality, injection-molded reality.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.