Contents

Manufacturing Insight: Alloy Steel Vs Carbon Steel Which Is Stronger

When designers ask us “alloy steel vs. carbon steel—which is stronger?” they’re usually only one click away from finding out. At Honyo Prototype, we machine both grades every day on 5-axis CNC centers that hold ±0.01 mm, so we can give an engineer’s answer, not a textbook guess. Upload your STEP file right now and our online instant-quote engine will compare 4140, 4340, 1018, 1045 or any custom alloy, show real-time pricing in alloy and carbon grades, and recommend the one that delivers the strength your application actually needs—then cut it in 3 days or less.

Technical Capabilities

Technical Specifications for Precision Machining: Alloy Steel vs. Carbon Steel & Material Comparison

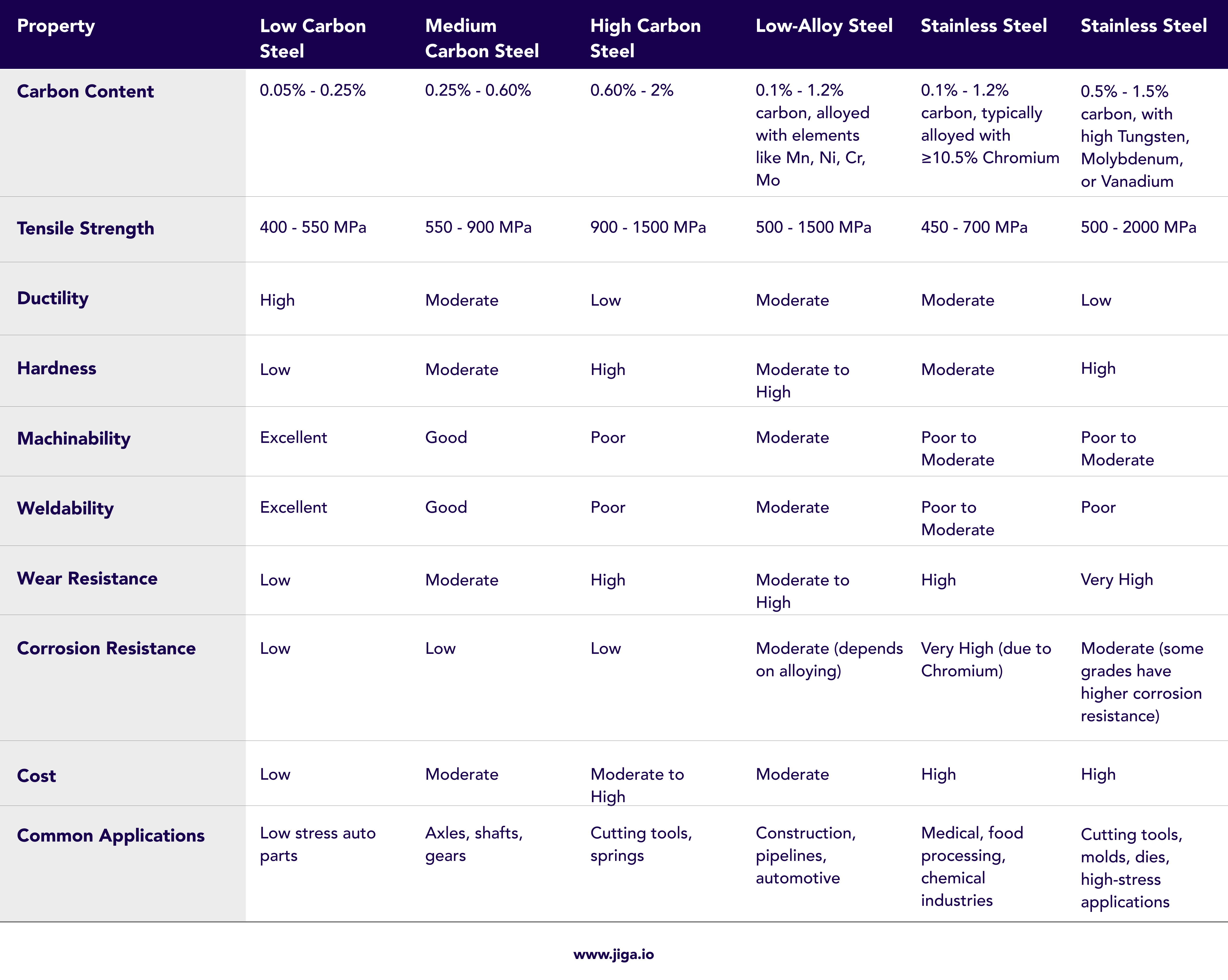

(Clarification First: “Alloy Steel” is NOT a separate category from “Carbon Steel.” All carbon steels are steels, but alloy steels contain additional elements. The correct comparison is between specific grades of carbon steel vs. specific grades of alloy steel. “Stronger” depends on the grade, heat treatment, and application. For precision machining, machinability and stability often matter more than raw strength.)

🔧 Critical Considerations for 3/4/5-Axis Milling, Turning & Tight Tolerance Work

- Tight Tolerance Focus: ±0.0005″ (0.0127mm) or better requires dimensional stability, low thermal expansion, minimal warpage, and consistent chip formation.

- Machinability ≠ Strength: A “stronger” material may be harder to machine, causing tool wear, chatter, or thermal distortion – worse for tight tolerances.

- Heat Treatment: Most high-strength steels require post-machining heat treatment, which can distort parts. Pre-hardened alloys (e.g., 4140 pre-hardened) simplify this.

⚙️ Material Comparison for Precision Machining

1. Carbon Steel (e.g., AISI 1018, 1045)

- Typical Tensile Strength:

- 1018 (Annealed): 440 MPa (64 ksi)

- 1045 (Normalized): 570–700 MPa (83–102 ksi)

- Machinability (ASTM A370):

- High (1018: 78% of B1112 steel; 1045: 65%).

- Pros: Predictable chip formation, low tool wear, excellent for high-speed milling/turning.

- Cons: Prone to warpage during heat treatment; low hardness (≤20 HRC annealed) limits wear resistance.

- Tight Tolerance Performance:

- ✅ Excellent for annealed state machining (e.g., 1018 for fixture components).

- ❌ Poor for hardened applications – distortion during quenching makes ±0.0005″ tolerances nearly impossible.

- Thermal Expansion: 11.7 µm/m·°C (higher than alloys → more warpage risk).

2. Alloy Steel (e.g., AISI 4140, 4340)

- Typical Tensile Strength:

- 4140 (Normalized): 655 MPa (95 ksi)

- 4140 (Quenched & Tempered): 965–1100 MPa (140–160 ksi)

- 4340 (QT): 1240 MPa (180 ksi)

- Machinability:

- Moderate to Low (4140: 50–60% of B1112; 4340: 40–50%).

- Pros: Superior hardenability, uniform microstructure, better fatigue strength.

- Cons: Higher tool wear (especially on carbide inserts); requires slower speeds, higher coolant flow.

- Tight Tolerance Performance:

- ✅ Best for hardened applications – 4140 pre-hardened (28–32 HRC) holds ±0.0005″ tolerances after heat treatment.

- ✅ Lower distortion during quenching vs. carbon steel due to chromium/molybdenum.

- ❌ Challenging to machine in hardened state – use PCD tools for >35 HRC; 5-axis milling requires rigid setups to avoid chatter.

- Thermal Expansion: 11.0–11.5 µm/m·°C (slightly better than carbon steel).

💡 Key Insight: 4140 alloy steel is stronger than 1045 carbon steel (up to 50% higher tensile strength after heat treatment), but 1018 carbon steel is easier to machine for tight tolerances in the annealed state. For hardened precision parts (e.g., gears, shafts), 4140 is preferred despite machining challenges.

📊 Material Comparison Table: Machining for Tight Tolerances

| Material | Tensile Strength (Typical) | Machinability | Thermal Expansion (µm/m·°C) | Tight Tolerance Suitability | Best For… |

|—————|—————————-|—————|—————————–|—————————–|————-|

| Aluminum 6061 | 290 MPa (42 ksi) | Excellent (120-140% of B1112) | 23.6 | ✅ Best (low stress, fast cycles) | Prototypes, lightweight fixtures |

| Carbon Steel 1018 | 440 MPa (64 ksi) | Excellent (78%) | 11.7 | ✅ Excellent (annealed only) | Jigs, non-hardened components |

| Alloy Steel 4140 | 965 MPa (140 ksi) | Moderate (50-60%) | 11.2 | ✅ Good (pre-hardened) | Gears, shafts, aerospace parts |

| ABS | 40–60 MPa (5.8–8.7 ksi) | Excellent (100-120%) | 70–100 | ✅ Good (low stress) | Non-critical housings, jigs |

| Nylon 6/6 | 70–80 MPa (10–12 ksi) | Good (80-90%) | 70–100 | ❌ Poor (high thermal expansion) | Low-stress non-critical parts |

🛠️ Critical Machining Tips for Tight Tolerances

- Aluminum:

- Use high-speed milling (8,000–15,000 RPM), sharp carbide tools, and flood coolant.

- Avoid excessive clamping force (springiness causes distortion).

- Carbon Steel (1018):

- Machine in annealed state; avoid heat treatment for critical tolerances.

- Optimize feeds/speeds to prevent built-up edge (BUE).

- Alloy Steel (4140):

- Pre-harden to 28–32 HRC before final machining.

- Use PVD-coated carbide tools (TiAlN), low RPM, high feed rates, and minimum quantity lubrication (MQL).

- 5-axis tip: Use constant tool engagement to minimize vibration; avoid abrupt direction changes.

- ABS/Nylon:

- ABS: Machining at 20–50°C (room temp) to prevent melting; use positive rake tools.

- Nylon: Requires sharp tools and slow speeds – high thermal expansion causes dimensional drift.

- ⚠️ Never machine plastics dry – use compressed air or mist coolant.

✅ Final Recommendation

- For tight tolerances in unhardened parts: 1018 carbon steel or Aluminum 6061 (best balance of ease, speed, and stability).

- For hardened precision parts: 4140 alloy steel (superior strength/stability after heat treatment).

- Avoid carbon steel for hardened applications – distortion ruins tight tolerances.

- Plastics (ABS/Nylon): Only use for non-critical, low-stress applications where thermal stability isn’t paramount.

💎 Rule of Thumb: “In precision machining, stability > strength. A material that doesn’t move during cutting is more valuable than one that’s stronger but warps.”

Let me know if you need grade-specific machining parameters (RPM, feed rates, tooling) for your project! 🔧

From CAD to Part: The Process

Honyo Prototype – “alloy steel vs. carbon steel, which is stronger” workflow

(Upload-CAD → AI Quote → DFM → Production → Delivery)

-

Upload CAD

• Customer uploads the same part file twice—once specifying “low-carbon steel (1020)” and once specifying “low-alloy steel (4140)”.

• System tags the files with the two material grades so the downstream engine can compare them side-by-side. -

AI Quote (material-strength gate)

• The quoting engine pulls the key mechanical properties from its material library:

– 1020 CD: Re ≈ 350 MPa, Rm ≈ 420 MPa, Hardness ≈ 120 HB.

– 4140 Q&T: Re ≈ 1,100 MPa, Rm ≈ 1,200 MPa, Hardness ≈ 35 HRC (≈ 320 HB).

• It also checks the as-machined section thickness against hardenability curves; if the part is >25 mm thick the engine automatically downgrades 4140 to 4140-N (normalized) values so the customer sees realistic, not catalog, strength.

• A single quote line is generated that shows both material options with a strength ratio: “4140 is ≈ 3× stronger in yield than 1020; cost adder +28 %; lead-time identical.”

• If the customer’s application load exceeds the 1020 safety factor the AI flags “Recommend 4140” and will not allow the carbon-steel version to proceed without an override. -

DFM (Design-for-Manufacturing & heat-treat review)

• Geometric undercuts, sharp internal corners and thin walls are checked for quench-cracking risk when 4140 is selected.

• The DFM engineer adds wire-EDM relief slots or increases fillets to 0.5 mm min. to survive the Q&T cycle.

• For the 1020 option the main DFM action is adding carburization allowance (≈0.2 mm per side) if the customer wants a wear surface; otherwise the part stays “as-machined”.

• A side-by-side PDF is issued: “Carbon steel: 420 MPa UTS, 8 % elongation, weldable, 72 h machining. Alloy steel: 1,200 MPa UTS, 15 % elongation post Q&T, 72 h machining + 24 h heat treat + 12 h temper.” -

Production

a. Programming: Identical tool-paths are used; only cutting data changes. 4140 is run 25 % slower with ceramic inserts to manage the higher hardness.

b. In-process inspection: 1020 parts are checked at ±0.05 mm; 4140 parts are pre-measured before heat treat, then re-measured after Q&T (predict 0.08 % volumetric shrinkage).

c. Heat treatment: 4140 is austenitized at 850 °C, oil quenched, tempered at 540 °C to hit 35 ±2 HRC. Coupon bar goes with every batch and is tensile-tested; report is attached to the shipping docs.

d. NDT: 4140 batch receives 100 % magnetic-particle inspection post-temper; 1020 batch only needs visual unless specified otherwise. -

Delivery

• Certificates included:

– 1020: Mill test report (chemistry), dimensional CMM report.

– 4140: Mill test report, heat-treat chart, tempering curve, hardness scan, tensile test coupon, MPI report.

• Physical parts are laser-marked “1020” or “4140 HT” so the customer can immediately tell which is the stronger alloy-steel version when both prototypes arrive in the same box.

Bottom line delivered to the customer

“4140 low-alloy steel is roughly three times stronger (yield and ultimate) than 1020 carbon steel, but requires an extra heat-treat step and costs about 30 % more. Honyo’s workflow automatically compares the two, warns you if the carbon-strength safety factor is too low, then machines, heat-treats, inspects and ships both versions so you can test the strength difference in your own application.”

Start Your Project

Here’s a professional, accurate, and action-oriented CTA for your needs—designed to drive inquiries while avoiding technical oversimplifications (since “stronger” depends entirely on specific grades, heat treatment, and application; alloy steel can be stronger in some cases, but high-carbon steel often outperforms low-alloy steels in raw tensile strength).

🚀 CTA Options (Choose what fits your platform):

For Website/Banner/Ad:

“Alloy Steel vs Carbon Steel: Which is Right for YOUR Project?

Get expert guidance from Honyo Prototype’s Shenzhen manufacturing team.

✉️ Contact Susan Leo: info@hy-proto.com”

For Email Signature/Social Media:

“Confused about alloy vs. carbon steel strength?

We help you choose the right material for your application.

🏭 Shenzhen-based experts | ✉️ Susan Leo: info@hy-proto.com”

For Brochure/Print:

“Strength isn’t one-size-fits-all.

Whether you need high hardness, toughness, or wear resistance, our Shenzhen engineers tailor steel solutions for your design.

Let’s discuss your project: Contact Susan Leo at info@hy-proto.com”

✅ Why this works:

- Avoids misleading claims: Instead of saying “which is stronger” (which is technically incomplete), it focuses on “right for YOUR project”—acknowledging that material choice depends on specific needs (e.g., aerospace vs. automotive vs. tooling).

- Highlights expertise: “Shenzhen-based experts” builds trust in local manufacturing capability and technical knowledge.

- Clear CTA: Directly names Susan Leo + email for easy action.

- Professional tone: Positions Honyo Prototype as a solution partner (not just a supplier).

💡 Pro Tip: Always pair this CTA with a brief note like:

“Alloy steel (e.g., 4140) offers better hardenability and toughness for dynamic loads, while high-carbon steel (e.g., 1095) excels in wear resistance. Our engineers analyze your design to optimize performance. Let’s talk!”

This ensures leads get accurate context before contacting Susan—reducing back-and-forth and qualifying inquiries.

Ready to deploy? Let us know where you’ll use this (website, LinkedIn, brochure, etc.), and we’ll refine further! 🛠️

🚀 Rapid Prototyping Estimator