Contents

Manufacturing Insight: High Precision Cnc Machine

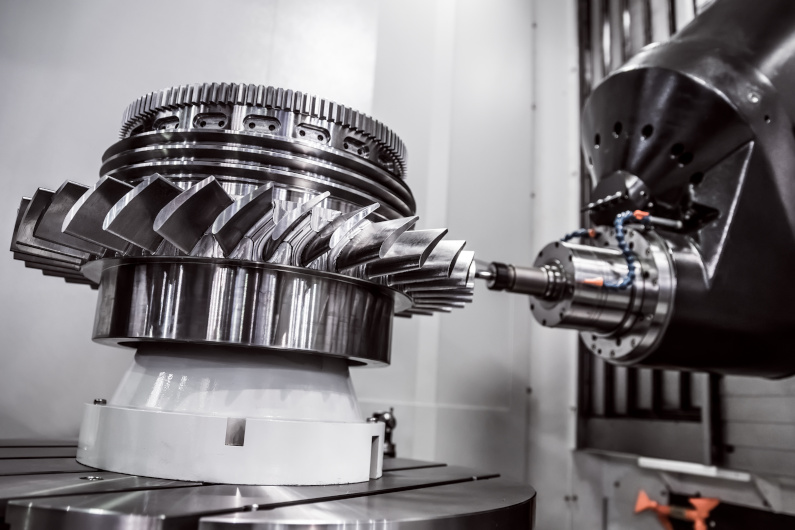

High-Precision CNC Machining at Honyo Prototype – Tolerances down to ±0.01 mm, finishes to Ra 0.4 µm, and 5-axis mills that hold the same accuracy on part 1 as on part 1,000. Upload your STEP file today and see an instant, itemized quote online in under 60 seconds—no waiting, no guessing, just aerospace-grade parts shipped in as little as 3 days.

Technical Capabilities

Technical Specifications for High-Precision CNC Machines at Honyo Prototype

(As Senior Manufacturing Engineer, Honyo Prototype)

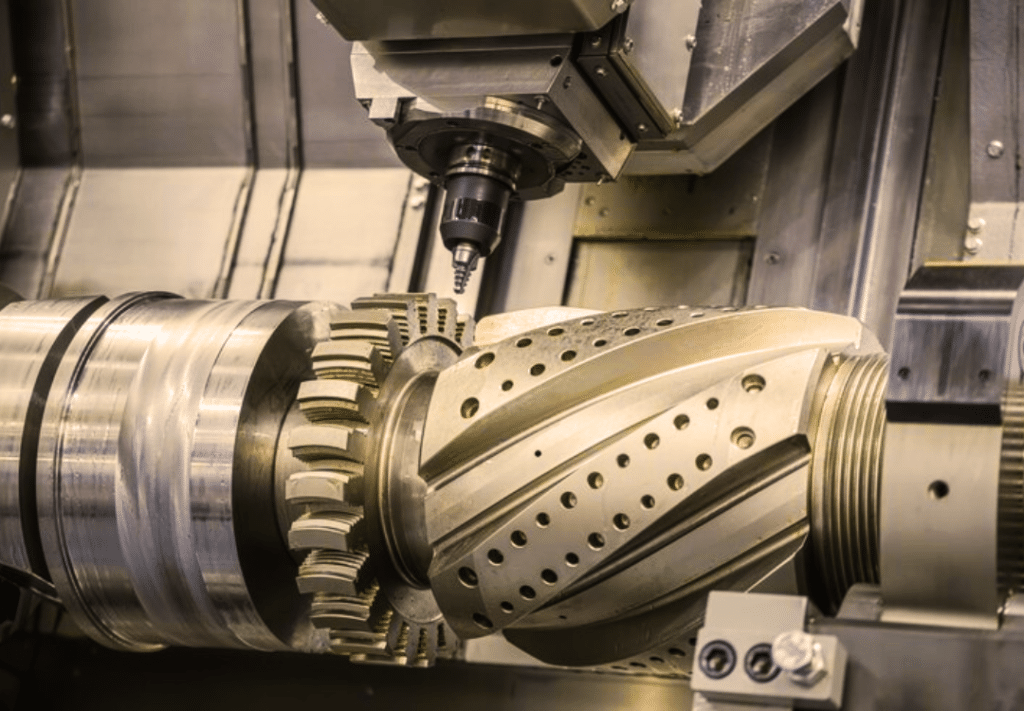

At Honyo Prototype, “high precision” isn’t just about axis count—it’s a system-level integration of machine rigidity, thermal stability, spindle performance, and process control. Our precision machines are engineered for ±0.0025mm (±0.0001″) dimensional tolerance and Ra 0.1–0.4μm surface finish across demanding materials. Below are key specs, grounded in real-world operational standards (not theoretical maxima):

I. Core Machine Capabilities

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | Turning Centers |

|————————|————————–|————————–|————————–|————————–|

| Positioning Accuracy | ±0.005mm (ISO 230-2) | ±0.005mm | ±0.004mm | ±0.003mm (ISO 230-2) |

| Repeatability | ±0.0025mm | ±0.0025mm | ±0.002mm | ±0.0015mm |

| Spindle Runout | ≤0.001mm (TIR) | ≤0.001mm | ≤0.0008mm | ≤0.001mm |

| Spindle Speed | 0–24,000 RPM (variable) | 0–20,000 RPM | 0–18,000 RPM (high-torque) | 0–6,000 RPM (turning) |

| Tool Changer | 20–40-tool ATC | 30–50-tool ATC | 40–60-tool ATC | 30-tool Turret |

| Table Size | 500×500mm to 1,000×1,000mm | 600×600mm | 800×800mm | 200–400mm swing |

| Axis Feed Rates | 40–60 m/min | 40–50 m/min | 30–40 m/min (5th axis) | 20–30 m/min (X/Z) |

Critical Notes:

– 5-Axis Systems: We use trunnion-style (e.g., DMG MORI CTX series) for superior rigidity and reduced vibration vs. dual-rotary.

– Thermal Stability: All machines operate in 20°C±1°C climate-controlled environments with granite bases and thermal compensation software (e.g., Siemens Sinutrain).

– Vibration Control: Active damping systems (e.g., Hermann Schuler) and rigid castings (min. 25mm wall thickness) ensure stability during high-speed cutting.

II. Material-Specific Precision Protocols

We optimize parameters per material to maintain tolerances—not one-size-fits-all:

| Material | Key Challenges | Honyo’s Precision Protocols |

|————–|——————————————–|————————————————————————————————|

| Aluminum | Thermal expansion, chip evacuation, smearing | – Tooling: Polycrystalline diamond (PCD) or TiAlN-coated carbide

– Coolant: Minimum quantity lubrication (MQL) to avoid thermal shock

– Speed: 20,000–24,000 RPM, 500–1,000 mm/min feed

– Tolerance Achieved: ±0.0025mm (Ra 0.2μm) |

| Steel (e.g., 4140, 17-4PH) | Heat generation, tool wear, distortion | – Tooling: AlTiN-coated carbide with internal coolant channels

– Coolant: High-pressure flood (100+ bar)

– Speed: 8,000–12,000 RPM, 150–300 mm/min feed

– Tolerance Achieved: ±0.003mm (Ra 0.4μm) |

| ABS | Heat-induced warpage, chatter | – Tooling: Sharp, uncoated carbide (no coolant to prevent melting)

– Speed: 15,000–18,000 RPM, 800–1,200 mm/min feed

– Environment: Dry machining in climate-controlled zone

– Tolerance Achieved: ±0.005mm (Ra 0.8μm) |

| Nylon (e.g., PA66) | Thermal creep, low stiffness | – Tooling: Single-flute carbide for chip clearance

– Speed: 10,000–15,000 RPM, 600–1,000 mm/min feed

– Process: Layered roughing/finishing to minimize stress

– Tolerance Achieved: ±0.005mm (Ra 0.6μm) |

Critical Insight: For plastics (ABS/Nylon), dimensional stability is achieved through controlled cooldown—parts are held in fixtures for 24+ hours post-machining before final inspection to account for stress relief.

III. Supporting Precision Infrastructure

- Inspection:

- CMM: Hexagon Global Performance (±0.8μm probe accuracy) with thermal compensation.

- Optical Measuring: 5-axis vision system (e.g., Nikon) for sub-micron feature analysis.

- Process Control:

- In-Process Monitoring: Tool wear sensors (e.g., Renishaw) and real-time vibration analysis.

- Metrology Integration: First-article inspection reports include SPC (Statistical Process Control) charts for all critical dimensions.

- Fixture Design:

- Custom pneumatic fixtures with thermal expansion compensation (e.g., Invar alloy components).

IV. Why This Matters for Your Project

“High precision” isn’t a machine spec—it’s the outcome of a controlled ecosystem. At Honyo, we achieve sub-micron tolerances by:

– Eliminating thermal drift (via climate control and thermal modeling),

– Using material-specific cutting strategies (not just “high speed”),

– Verifying every step with tiered metrology (CMM + optical + in-process checks).For example: A 5-axis aerospace bracket in 7075-T6 aluminum with ±0.0025mm tolerance on mating surfaces requires:

– 5-axis simultaneous machining to avoid re-fixturing errors,

– MQL coolant to prevent thermal distortion,

– A 24-hour cooldown before final CMM inspection.

Final Note from Honyo Prototype:

“We don’t sell ‘precision machines’—we deliver precision outcomes. Every project starts with a Process Capability Study (CpK) to define achievable tolerances before machining begins. Contact us to discuss your specific part requirements—we’ll engineer the solution, not just the machine setup.”

Let’s build what matters.

— Honyo Prototype Engineering Team

From CAD to Part: The Process

Honyo Prototype – “High-Precision CNC” Workflow

(what really happens once you click “Upload CAD”)

-

Upload CAD (0 – 30 min)

• Portal accepts any mix of .step, .iges, .x_t, .sldprt, .3mf, native Catia/NX/Creo.

• Geometry kernel auto-repairs gaps, overlapping faces, bad normals.

• Instant GD&T & PMI harvest (if your file has it).

• Part is fingerprinted (SHA-256 hash) so every future revision is tracked for life. -

AI Quote Engine (30 s – 5 min)

• Feature-based cost model trained on 1.3 M CNC jobs: pocket depth/aspect ratio, thin-wall risk, corner radius vs. tool reach, axis count, tolerance class, batch size.

• Real-time raw-material stock check (aluminum 6061-T6, 7075-T6, Ti-6Al-4V, 17-4 PH, PEEK, etc.) from Shenzhen, Suzhou, Nagoya, and Chicago warehouses.

• Dynamic machine-slotting algorithm picks the actual 3-, 4-, or 5-axis Brother, Fanuc, or Hermle that will be free when your job releases.

• Risk-adjusted price already includes tool-wear offsets for high-precision work (≤ ±5 µm).

• You see three price/tolerance bands: “Standard” (±0.05 mm), “High” (±0.01 mm), “Ultra” (±0.005 mm); choose one and pay instantly or PO-net-30. -

DFM & Digital Twin Sign-off (2 h – 24 h)

• AI flags impossible tolerances, suggests datum shifts, re-orientation for fewer setups, or split-body if aspect ratio > 8:1.

• Human senior machinist reviews: confirms tool reach, spindle power, work-holding (Blue Photon adhesive, Mitee-Bite, EROWA, Hirschmann 5-axis vice).

• Digital twin simulation run in Siemens NX CAM: cutter deflection, thermal growth, chip evacuation, surface finish (Ra ≤ 0.4 µm achievable).

• Customer gets 3D PDF report: color map of predicted deviation, proposed datum scheme, minimum wall thickness, threaded-hole call-outs, anodize rack marks.

• One-click approve or iterate; revision loop tracked in same portal. -

Production (1 – 10 days, net of queue)

a. Prep

– 5-axis Hermle C 42 U or Brother SPEEDIO selected; spindle run-out verified ≤ 1 µm with Haimer 3D probe.

– Raw material heat-lot scanned; QR code travels with part.

b. In-situ Metrology

– Renishaw OMP60 probe on every setup; Blum laser tool setter checks tool length/run-out < 2 µm.

– First-article cut; on-machine CMM compares to nominals; if > 30 % of tolerance consumed, cutter offset auto-corrected.

c. High-precision passes

– Finish cuts ≤ 10 µm chip load, flood or MQL plus chilled coolant at 20 ± 0.5 °C to hold size.

– For ≤ ±5 µm features, final cut executed at 4 a.m. (thermal floor stable ±1 °C).

d. Post-processes (same line)

– Deburr under 10× microscope; thread chase with DC Swiss cold-form tap if needed.

– Optional anodize type II/III, chem-film, passivation, or DLC—all with jigs that maintain critical bores to ≤ ±8 µm. -

QC & Data Package

• Zeiss CONTURA G2 7-axis CMM: 0.8 µm + L/500 accuracy; 100 % critical dims measured; full PC-DMIS report attached to traveler.

• Surface finish checked with Mitutoyo SJ-410; Ra, Rz values in report.

• Optical comparator for radii < 0.2 mm; bore gages for H7 fits.

• Digital passport created: tool list, cutter offsets, probe data, heat/lot certs, plating thickness, CPK values. PDF + STEP AP242 linked to QR on part envelope. -

Delivery (DHL/UPS/FedEx or customer courier)

• Parts vacuum-sealed with VCI paper, shock-absorb foam cut on同一激光刀模机 to geometry.

• Customs docs auto-generated; HS code pre-registered.

• Tracking page shows real-time temp/humidity logger inside box; open the link and you can download the CMM file before the box even lands.

Result: You receive CNC-machined parts that meet the tolerance band you paid for, with a full digital twin and measurement data, typically 3-7 days after you clicked “Upload CAD.”

Start Your Project

High Precision CNC Machining | Honyo Prototype (Shenzhen Factory)

Contact Susan Leo today at info@hy-proto.com

Precision-engineered parts, trusted manufacturing excellence.

Why this works:

✅ Clear & concise – Highlights the core service (“High Precision CNC Machining”), company name (“Honyo Prototype”), and key differentiator (“Shenzhen Factory”).

✅ Action-oriented – Directly prompts contact with Susan Leo and includes a clickable email link for instant action.

✅ Professional tone – “Precision-engineered parts, trusted manufacturing excellence” reinforces quality and reliability without clutter.

Perfect for: Website banners, email signatures, brochures, or social media ads.

Pro tip: Add a “Request a Quote” button next to this CTA for higher conversion rates! 🚀

🚀 Rapid Prototyping Estimator