Contents

Manufacturing Insight: Alloy Steel Vs Metal

Manufacturing Insight: Alloy Steel vs Carbon Steel in Precision Sheet Metal Fabrication

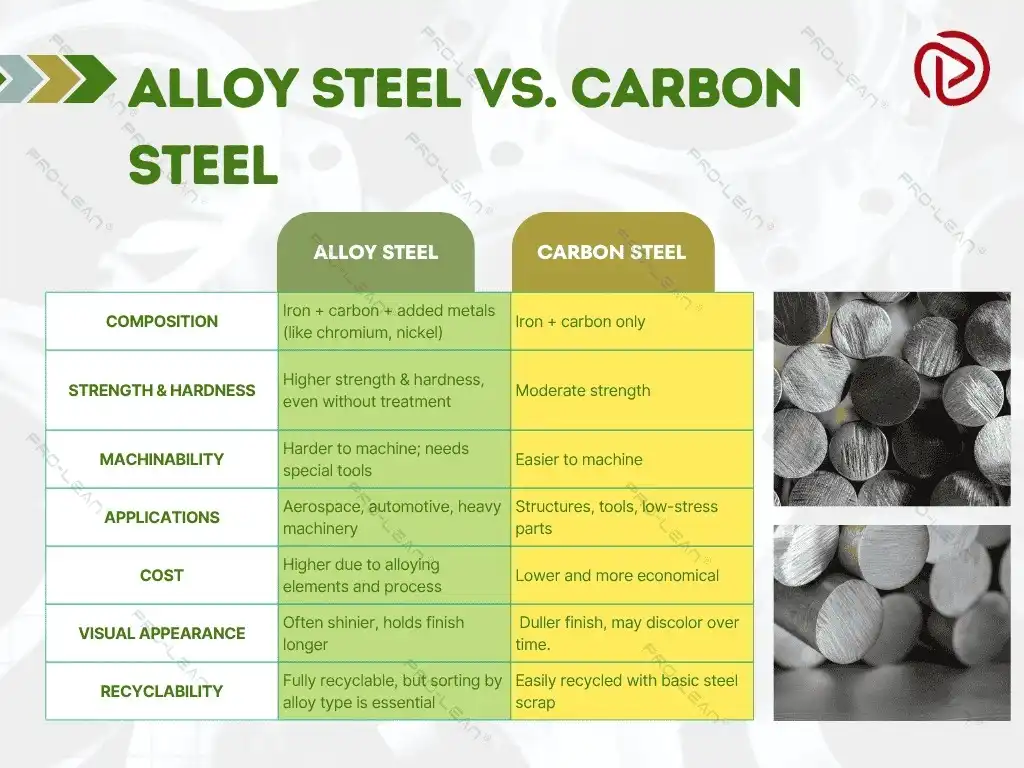

A frequent point of confusion in sheet metal fabrication involves the comparison between “alloy steel” and “metal.” It is critical to clarify that alloy steel is a specific category of metal, falling under the broader ferrous metal family. The meaningful technical comparison for manufacturing decisions is typically alloy steel versus carbon steel, both subcategories of steel (an iron-carbon alloy). Understanding their distinct properties is paramount for selecting the optimal material for demanding prototyping and low-volume production applications, directly impacting manufacturability, performance, and cost at Shenzhen Honyo Prototype.

Carbon steels, like 1018 or 1020, contain primarily iron and carbon (up to 2.1%), with minimal other alloying elements. They offer good formability, weldability, and cost-effectiveness for structural components where extreme strength or hardness isn’t required. Alloy steels, such as 4140, 4340, or 8620, incorporate significant additions of elements like chromium, nickel, molybdenum, or vanadium. These additions dramatically enhance specific properties—yield strength, hardness, toughness, hardenability, and wear or corrosion resistance—compared to plain carbon steels. However, these improvements often come with increased material cost and potential challenges in machining or welding that require specialized process control.

The selection between carbon steel and alloy steel hinges entirely on the functional requirements of the end part. Carbon steel suffices for brackets, enclosures, or frames where moderate strength and ease of fabrication are priorities. Alloy steel becomes essential for high-stress components like gears, shafts, aerospace fittings, or tooling where superior strength-to-weight ratio, fatigue resistance, or surface durability under load is non-negotiable. Misapplication can lead to premature failure or unnecessary expense.

Honyo Prototype leverages deep material science expertise to guide clients through this critical selection phase. Our engineering team evaluates your design intent, load conditions, environmental exposure, and lifecycle requirements to recommend the most suitable grade, ensuring optimal performance without over-engineering. We possess extensive experience processing both material types across our advanced sheet metal fabrication suite.

Below is a comparative overview of key properties relevant to fabrication:

| Property | Typical Carbon Steel (e.g., 1018) | Typical Alloy Steel (e.g., 4140) | Honyo Application Note |

| :——————– | :——————————– | :——————————- | :—————————————————— |

| Yield Strength (MPa) | 300 – 400 | 600 – 1000+ | Alloy steel enables thinner, lighter high-stress parts. |

| Machinability | Good to Excellent | Fair to Moderate | Alloy steel often requires slower speeds/feeds; Honyo optimizes toolpaths. |

| Weldability | Generally Excellent | Requires Pre/Post-Heat Treatment | Honyo implements strict welding procedures for alloy steels. |

| Hardenability | Low (Surface only) | High (Through hardening) | Critical for wear surfaces; Honyo manages heat treat integration. |

| Relative Cost | Lower | Moderate to Higher | Honyo minimizes waste via precise nesting & efficient processes. |

Shenzhen Honyo Prototype excels in transforming complex designs in both carbon and alloy steels into high-integrity prototypes and production parts. Our integrated capabilities—from precision laser cutting, CNC punching, and bending to expert welding (including TIG for critical alloy joints) and finishing—ensure material properties are preserved throughout the prototyping lifecycle. We utilize advanced simulation to predict formability and springback, particularly crucial for high-strength alloy grades, reducing iteration time. Partner with Honyo to navigate material selection confidently and achieve optimal manufacturability for your next sheet metal fabrication project. Consult our engineering team early in the design phase for the most cost-effective and robust solution.

Technical Capabilities

Shenzhen Honyo Prototype delivers precision sheet metal fabrication services, specializing in advanced processing of alloy steel and various metal materials. Our technical capabilities in laser cutting, bending, and welding are engineered to meet stringent industrial standards, ensuring dimensional accuracy, structural integrity, and repeatability across production runs. We maintain rigorous process controls and utilize state-of-the-art equipment to accommodate the distinct metallurgical behaviors of different materials.

Alloy steel, composed of iron with added elements such as chromium, nickel, molybdenum, or vanadium, offers enhanced strength, hardness, and wear resistance compared to mild steel and many non-ferrous metals. This makes it ideal for high-stress applications in automotive, aerospace, and industrial machinery. However, its increased hardness and thermal sensitivity require precise parameter control during fabrication. In contrast, common metals such as mild steel, stainless steel, aluminum, and copper exhibit varying levels of ductility, thermal conductivity, and oxidation resistance, necessitating material-specific processing strategies.

Our fiber laser cutting systems are optimized for both alloy steel and a wide range of metals, delivering clean, burr-free edges with minimal heat-affected zones. For alloy steels, we adjust laser power, assist gas (typically nitrogen or oxygen depending on grade), and cutting speed to prevent hardening and cracking. Aluminum and copper materials require specialized settings due to high reflectivity and thermal conductivity.

Bending operations are performed using CNC press brakes equipped with precision tooling. Alloy steels typically require higher tonnage and controlled bend radii to avoid cracking, particularly in high-strength grades. Springback compensation is actively managed through real-time feedback systems. Softer metals like aluminum and mild steel allow for tighter bend radii but require careful handling to prevent surface marring.

Welding processes, including TIG, MIG, and spot welding, are selected based on material compatibility and joint requirements. Alloy steels often require preheating and post-weld heat treatment to mitigate brittleness, while aluminum demands AC TIG welding with high-frequency cleaning to break down oxide layers. Stainless steel welding is performed under inert shielding gas to preserve corrosion resistance.

The following table outlines key material specifications and achievable tolerances across our core fabrication processes:

| Material Type | Thickness Range (mm) | Laser Cutting Tolerance (±mm) | Bending Tolerance (±°) | Welding Distortion Control | Max. Part Size (mm) |

|——————–|———————-|——————————-|————————|—————————-|———————|

| Alloy Steel | 0.8 – 12.0 | 0.1 | 0.5° | High (pre/post-heat) | 1500 x 3000 |

| Mild Steel | 0.5 – 15.0 | 0.1 | 0.3° | Moderate | 1500 x 3000 |

| Stainless Steel | 0.5 – 12.0 | 0.1 | 0.4° | High (argon shielding) | 1500 x 3000 |

| Aluminum Alloys | 0.8 – 10.0 | 0.15 | 0.5° | Moderate (chill blocks) | 1500 x 3000 |

| Copper & Brass | 0.8 – 6.0 | 0.2 | 0.6° | Low to Moderate | 1000 x 2000 |

All fabrication parameters are validated through in-process inspection and first-article testing, ensuring compliance with ISO 9001 standards. Shenzhen Honyo Prototype remains committed to delivering high-integrity metal components with consistent quality across diverse material platforms.

From CAD to Part: The Process

Shenzhen Honyo Prototype: Sheet Metal Fabrication Production Process Guide

Understanding the distinction between alloy steel and other metals is critical in sheet metal fabrication. Alloy steel specifically refers to carbon steel enhanced with elements like chromium, nickel, or molybdenum to improve strength, hardness, or corrosion resistance. It is a subset of metals, which encompass broader categories including non-ferrous options like aluminum or copper. Material selection directly impacts manufacturability, cost, and final part performance. Our streamlined workflow ensures precision from digital design to physical component, integrating material science with advanced manufacturing.

The process initiates with AI-Powered Quoting. Upon receiving a CAD file (STEP, IGES, or native formats), our proprietary AI engine analyzes geometric complexity, material specifications, and required tolerances. For alloy steels such as 4140 or 4340, the system factors in higher machinability challenges and thermal processing needs compared to materials like 304 stainless steel or 6061-T6 aluminum. This stage generates a preliminary cost estimate and lead time within minutes, highlighting potential material-driven cost drivers like increased tool wear or secondary heat treatments.

Next, Design for Manufacturability (DFM) Analysis commences. Our engineering team conducts a rigorous review, focusing on material-specific constraints. For alloy steel components, we assess minimum bend radii to prevent cracking, kerf width adjustments for laser cutting due to higher reflectivity and thermal conductivity variations, and weldability considerations. Features such as tight tolerances in high-strength alloys may necessitate post-machining stress relief. DFM feedback is provided within 24 hours, offering actionable recommendations—such as modifying internal radii or adjusting hole placement—to optimize yield and reduce scrap rates, particularly crucial for costly alloy steels.

Finally, Precision Production executes the validated design. Material sheets undergo rigorous incoming inspection to verify grade, thickness, and mechanical properties against ASTM or EN standards. Laser cutting, CNC punching, or waterjet processes are deployed based on the material’s characteristics; for instance, 4130 alloy steel may require slower cutting speeds and specialized assist gases versus softer aluminum alloys. Forming operations use custom tooling calibrated for the material’s springback properties. Secondary operations like heat treating (e.g., quenching and tempering for 4340) or precision machining follow, with in-process metrology ensuring conformance to GD&T requirements. All alloy steel parts undergo mandatory post-heat-treat dimensional verification.

Material selection profoundly influences each phase. The table below summarizes key fabrication considerations:

| Material Type | Typical Grades | Laser Cutting Speed | Minimum Bend Radius (vs. Thickness) | Critical DFM Consideration |

|———————|———————|———————|———————————–|———————————–|

| Low-Alloy Steel | 4140, 4340, 4130 | 30-50% of Mild Steel| 2.5x – 3.0x | Pre-heat required for thick sections; stress relief post-welding |

| Austenitic Stainless| 304, 316 | 60-75% of Mild Steel| 1.5x – 2.0x | Slag adhesion; controlled heat input to avoid warping |

| Aluminum Alloy | 6061-T6, 5052-H32 | 100-120% of Mild Steel | 1.0x – 1.5x | Burr formation; clamping to prevent distortion |

| Carbon Steel | A36, 1018 | Baseline (100%) | 1.0x – 1.5x | Zinc flash for weldability; oxide removal pre-painting |

This integrated workflow—AI quoting, engineering-led DFM, and material-optimized production—ensures Shenzhen Honyo Prototype delivers complex sheet metal parts with exceptional accuracy, minimizing iterations and accelerating time-to-market. Material expertise remains foundational to navigating the trade-offs between performance, cost, and manufacturability in every project.

Start Your Project

Start Your Project with Confidence: Expert Guidance in Alloy Steel vs Metal Selection

When initiating a sheet metal fabrication project, one of the most critical decisions you’ll make is material selection—particularly when weighing alloy steel against other metal options. At Shenzhen Honyo Prototype, we specialize in providing precision manufacturing solutions tailored to your design requirements, engineering constraints, and production goals. Whether your project demands the high strength and wear resistance of alloy steel or the lightweight versatility of alternative metals, our team ensures optimal material pairing for performance, cost-efficiency, and manufacturability.

Alloy steel combines iron with elements such as chromium, nickel, molybdenum, or vanadium to enhance mechanical properties including tensile strength, hardness, and resistance to impact and fatigue. This makes it ideal for applications in demanding environments—industrial machinery, automotive components, and structural systems where durability is non-negotiable. In contrast, other metals like aluminum, stainless steel, or copper alloys offer unique advantages such as corrosion resistance, electrical conductivity, or reduced weight, making them better suited for aerospace, electronics, or consumer-facing products.

Understanding these differences is essential, but equally important is how the chosen material behaves during fabrication processes such as laser cutting, CNC punching, bending, and welding. Each metal reacts differently under stress and heat, affecting tolerances, surface finish, and overall part integrity. For instance, while alloy steel offers exceptional strength, it may require more robust tooling and slower machining speeds compared to softer metals like aluminum.

To help you make an informed decision, we’ve outlined key comparative specifications:

| Property | Alloy Steel | Aluminum 6061 | Stainless Steel 304 | Copper C110 |

|————————-|————————-|———————-|————————|————————|

| Tensile Strength (MPa) | 750–1200 | 310 | 505–520 | 210–260 |

| Yield Strength (MPa) | 600–1000 | 276 | 215–310 | 60–120 |

| Density (g/cm³) | 7.85 | 2.70 | 8.03 | 8.94 |

| Machinability Rating | 45–65% | 90% | 45% | 80% |

| Common Applications | Gears, shafts, tooling | Enclosures, frames | Food equipment, marine | Electrical connectors |

At Honyo Prototype, we go beyond material supply—we partner with engineers and product developers to optimize designs for manufacturability, recommend suitable finishes, and support rapid prototyping to validate performance before full-scale production. Our advanced CNC press brakes, fiber laser cutters, and skilled fabrication team ensure tight tolerances and consistent quality across both low-volume prototypes and high-volume runs.

Don’t leave your project’s success to guesswork. Let our experts guide you through the selection process and help you achieve the ideal balance of strength, cost, and functionality.

Contact Susan Leo today at info@hy-proto.com to discuss your project requirements and receive personalized support from our manufacturing team.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.