Contents

Manufacturing Insight: Milling Machine Operation

Manufacturing Insight: Milling Machine Operation at Honyo Prototype

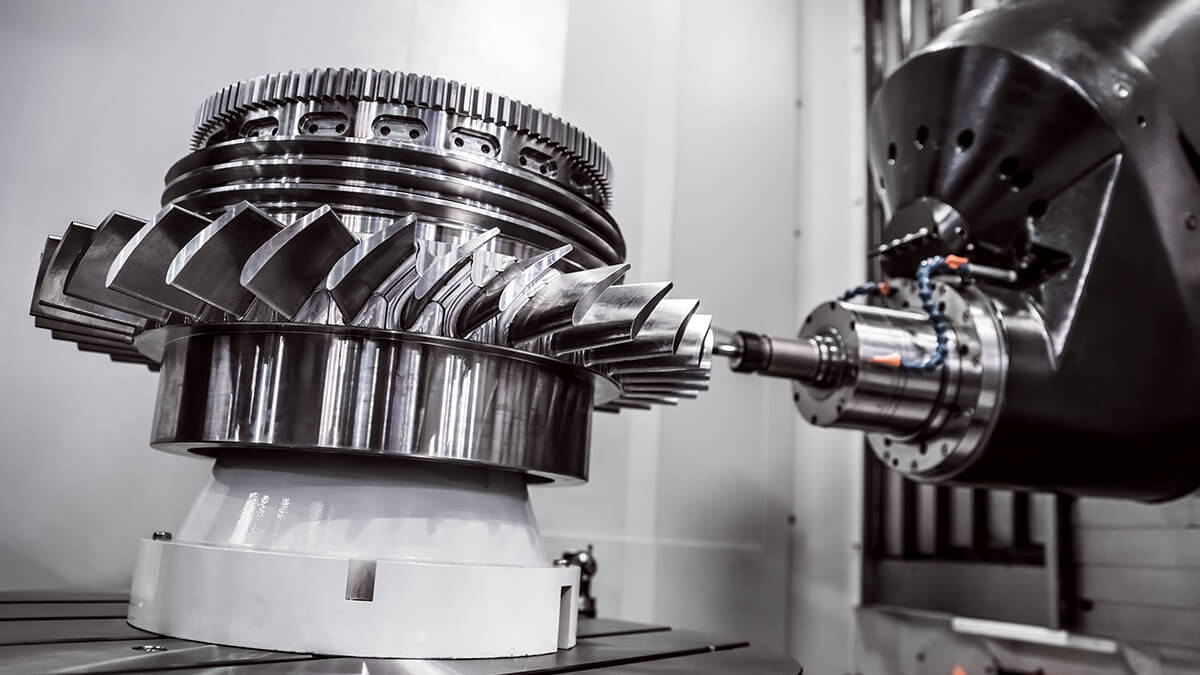

Milling remains a cornerstone subtractive manufacturing process for creating complex, high-precision components across aerospace, medical, automotive, and consumer electronics industries. At Shenzhen Honyo Prototype, we leverage advanced CNC milling technology as a fundamental capability for rapid prototyping and low-volume production. This process utilizes rotating multi-point cutting tools to systematically remove material from a solid workpiece, enabling the fabrication of intricate geometries, tight tolerances, and superior surface finishes essential for functional validation and end-use parts. Our mastery of milling operations ensures clients receive dimensionally accurate, structurally sound prototypes that reliably mirror final production intent.

Honyo Prototype operates a modern fleet of CNC milling centers, strategically selected to handle the diverse demands of rapid prototyping. Our infrastructure balances high-speed capability for aluminum and plastics with robust torque for challenging materials like hardened steels and titanium alloys. Key machine specifications underpinning our service delivery are detailed below.

| Parameter | Typical Range at Honyo Prototype | Application Impact |

| :—————– | :——————————- | :————————————- |

| Machine Axes | 3-Axis, 4-Axis, 5-Axis | Complex geometry access, reduced setups |

| X/Y/Z Travel (mm) | 500 x 400 x 300 to 1000 x 600 x 500 | Accommodates part sizes up to 1m³ |

| Spindle Speed (RPM)| 8,000 – 24,000 | Optimized for metals, composites, plastics |

| Positioning Accuracy (µm) | ±3 to ±5 | Ensures micron-level dimensional fidelity |

| Rapid Traverse (m/min) | 30 – 48 | Minimizes non-cutting time, accelerates delivery |

Our operational excellence extends beyond machine hardware. Honyo integrates rigorous process planning with each project. Experienced manufacturing engineers collaborate directly with client design teams during the Design for Manufacturability (DFM) phase, identifying potential milling challenges early and suggesting optimizations to reduce lead times and costs without compromising functionality. We utilize industry-leading CAM software to generate highly efficient toolpaths, minimizing cycle times while maximizing tool life and surface quality. Material selection guidance is a critical service component; our technicians possess deep knowledge of machining characteristics for aluminum alloys (6061, 7075), stainless steels (303, 316), tool steels, titanium (Grade 5), and engineering plastics (PEEK, Delrin), ensuring optimal cutting parameters and fixturing strategies.

Stringent quality control is non-negotiable. Every milled component undergoes comprehensive dimensional verification using calibrated CMMs, optical comparators, and surface roughness testers against client specifications, typically holding tolerances to ±0.025mm and surface finishes down to Ra 0.8µm. This commitment to precision, combined with our Shenzhen location within a dense manufacturing ecosystem for rapid material sourcing and secondary operations, positions Honyo Prototype as a strategic partner for clients requiring technically demanding, time-sensitive prototypes. We transform digital designs into tangible, high-fidelity components with the speed and accuracy demanded by modern product development cycles.

Technical Capabilities

Shenzhen Honyo Prototype delivers precision CNC machining services tailored for rapid prototyping and low-to-medium volume production. Our technical capabilities in milling machine operations are built around advanced 3-axis, 4-axis, and 5-axis CNC milling centers, complemented by multi-axis turning systems. These platforms enable us to produce complex geometries with high repeatability, surface accuracy, and dimensional consistency across a broad range of engineering materials.

Our 3-axis milling systems are ideal for prismatic parts with straightforward features, offering fast cycle times and excellent surface finish. For components requiring access to multiple faces or deeper complexity, our 4-axis and 5-axis machining centers provide simultaneous rotary motion, enabling the production of intricate contours, undercuts, and organic shapes without requiring multiple setups. This reduces cumulative error and improves overall part accuracy. All milling operations are supported by high-speed spindles, rigid tooling systems, and real-time tool length compensation to maintain cutting precision throughout production runs.

We integrate CNC turning with live tooling to support mill-turn operations, allowing us to machine fully featured rotational parts in a single setup. This hybrid capability is particularly effective for components with both cylindrical and off-axis features, such as valve bodies, shafts with flats, or sensor housings.

A core strength of our milling operations is the ability to achieve tight tolerances consistently. Standard machined parts are held to ±0.05 mm, while critical features can be controlled to ±0.005 mm when required by design. These tolerances are maintained through continuous process validation, in-process inspections using CMM and optical comparators, and thermal compensation systems within our machining centers.

The following table outlines our achievable tolerances and compatible materials:

| Feature | Tolerance Range | Notes |

|——–|——————|——-|

| Standard Dimensional Tolerance | ±0.05 mm | Typical for most machined features |

| Tight Tolerance Machining | ±0.005 mm | Available on critical features with proper GD&T |

| Positional Tolerance | ±0.012 mm | With fixture optimization and alignment |

| Surface Roughness (Ra) | 0.8 – 3.2 µm | Adjustable based on tooling and finish passes |

| Angular Tolerance | ±0.1° | For milled angles and beveled edges |

| Material Category | Examples | Machinability Notes |

|——————|———|———————-|

| Engineering Plastics | PEEK, Delrin, Nylon, PC, PTFE | Low thermal conductivity; requires sharp tooling |

| Aluminum Alloys | 6061, 7075, 2024 | High machinability; excellent for prototypes |

| Stainless Steels | 303, 304, 316, 17-4 PH | Good corrosion resistance; moderate tool wear |

| Carbon & Alloy Steels | 1018, 4140, 4340 | High strength; suitable for functional parts |

| Brass & Copper | C36000, C110 | Excellent finish; high thermal conductivity |

| Titanium Alloys | Grade 2, Grade 5 (Ti-6Al-4V) | High strength-to-density; slower cutting speeds |

All milling operations are supported by CAD/CAM-driven toolpath generation, ensuring optimal tool engagement and surface quality. At Shenzhen Honyo Prototype, we combine technical precision with rapid turnaround to deliver machined components that meet the highest standards of form, fit, and function.

From CAD to Part: The Process

From CAD to Part: CNC Milling Workflow at Shenzhen Honyo Prototype

Achieving precision machined prototypes requires a rigorously defined workflow that bridges digital design intent with physical reality. At Shenzhen Honyo Prototype, our CNC milling process integrates advanced planning, engineering validation, and meticulous execution to ensure parts meet stringent quality and timeline requirements. This workflow begins well before the machine spindle engages the material.

The process initiates with the AI-Driven Quotation System. Upon receiving a client’s CAD model (typically STEP or IGES format), our proprietary algorithm analyzes geometric complexity, feature tolerances, material specifications, and surface finish requirements. This system rapidly generates an accurate cost estimate and lead time projection by correlating the model against our extensive database of machining parameters, tooling costs, and machine utilization rates. This initial step provides clients with transparent, data-backed expectations while highlighting potential high-cost or high-risk features early.

Critical engineering validation follows via Design for Manufacturability (DFM) Analysis. Honyo’s senior manufacturing engineers conduct a comprehensive review of the CAD model, focusing explicitly on milling feasibility. We identify and resolve issues such as inadequate wall thicknesses prone to deflection, internal radii too small for standard tooling, deep cavities requiring specialized long-reach tools, and features lacking proper tool access. Material selection is scrutinized against machinability characteristics and client performance needs. This phase is non-negotiable; unresolved DFM issues directly cause tool breakage, extended cycle times, or part rejection. Client collaboration during DFM is essential to implement necessary design refinements without compromising functional intent.

Upon DFM sign-off, Production Execution commences. CNC programmers generate optimized toolpaths using Mastercam and Fusion 360, selecting appropriate tooling, speeds, feeds, and stepovers based on the validated design and material. Key machining parameters are strictly controlled as shown below:

| Parameter | Typical Range (Aluminum 6061) | Critical Consideration |

| :—————– | :—————————- | :—————————————– |

| Spindle Speed | 8,000 – 15,000 RPM | Balance material removal rate vs. vibration |

| Feed Rate | 500 – 2000 mm/min | Chip load optimization to prevent tool wear |

| Depth of Cut (Rough) | 1.5 – 3.0 mm | Machine rigidity and material hardness |

| Depth of Cut (Finish)| 0.1 – 0.5 mm | Surface finish and dimensional accuracy |

Material is securely fixtured, and the first article undergoes machining with in-process verification using touch probes for critical datums. Final inspection employs CMMs and optical comparators to validate all geometric tolerances per the original drawing. Only after rigorous first-article inspection approval does full production batch machining proceed, ensuring every part shipped meets Honyo’s zero-defect prototyping standard. This integrated workflow minimizes rework, accelerates time-to-part, and delivers the precision expected from a leading rapid prototyping partner.

Start Your Project

Start Your CNC Milling Project with Precision and Confidence

At Shenzhen Honyo Prototype, we specialize in high-precision CNC milling operations tailored to meet the demanding requirements of modern engineering and product development. Whether you’re prototyping a new design or scaling into low-volume production, our advanced CNC machining capabilities ensure accuracy, repeatability, and material integrity across a wide range of applications.

Our milling services leverage state-of-the-art 3-axis, 4-axis, and 5-axis CNC machining centers, enabling us to produce complex geometries with tight tolerances as tight as ±0.005 mm. We support a broad spectrum of materials, including aluminum alloys, stainless steel, brass, titanium, engineering plastics, and more—ensuring your part performs under real-world conditions.

All milling operations are supported by rigorous quality control protocols, including in-process inspections and final dimensional verification using coordinate measuring machines (CMM) and optical comparators. Our manufacturing engineers work closely with your team to review designs for manufacturability (DFM), helping to optimize tool paths, reduce lead times, and minimize costs—without compromising on quality.

To get started, simply provide your 3D CAD model (in STEP, IGES, or native formats) along with any specific tolerances, surface finishes, or material requirements. Our team will generate a detailed quotation within 24 hours, including manufacturability feedback and delivery timeline.

Below are the key technical specifications for our CNC milling capabilities:

| Feature | Specification |

|—————————-|————————————————|

| Machine Types | 3-axis, 4-axis, 5-axis CNC milling centers |

| Maximum Work Envelope | 1200 × 600 × 500 mm (47 × 23.6 × 19.7 in) |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Standard Surface Finish | Ra 3.2 µm (other finishes available on request)|

| Supported Materials | Aluminum (6061, 7075), Stainless Steel (303, 316), Brass, Titanium, PEEK, ABS, PC, and more |

| Lead Time | As fast as 3–5 days for prototypes |

| Quality Standards | ISO 9001:2015 compliant processes |

We understand that speed, precision, and communication are critical when bringing a new product to life. That’s why we prioritize responsive customer service and transparent project tracking from quote to delivery.

Ready to move forward? Contact Susan Leo, our dedicated manufacturing solutions specialist, to discuss your project requirements. Whether you need a single prototype or a small production run, we’re equipped to support your goals with expert engineering insight and reliable execution.

Email Susan Leo at info@hy-proto.com today to receive a fast, detailed quote and DFM analysis. Let Shenzhen Honyo Prototype be your trusted partner in precision CNC milling.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.