Contents

Manufacturing Insight: Cnc Steel Milling Machine

Manufacturing Insight: CNC Steel Milling Capabilities at Honyo Prototype

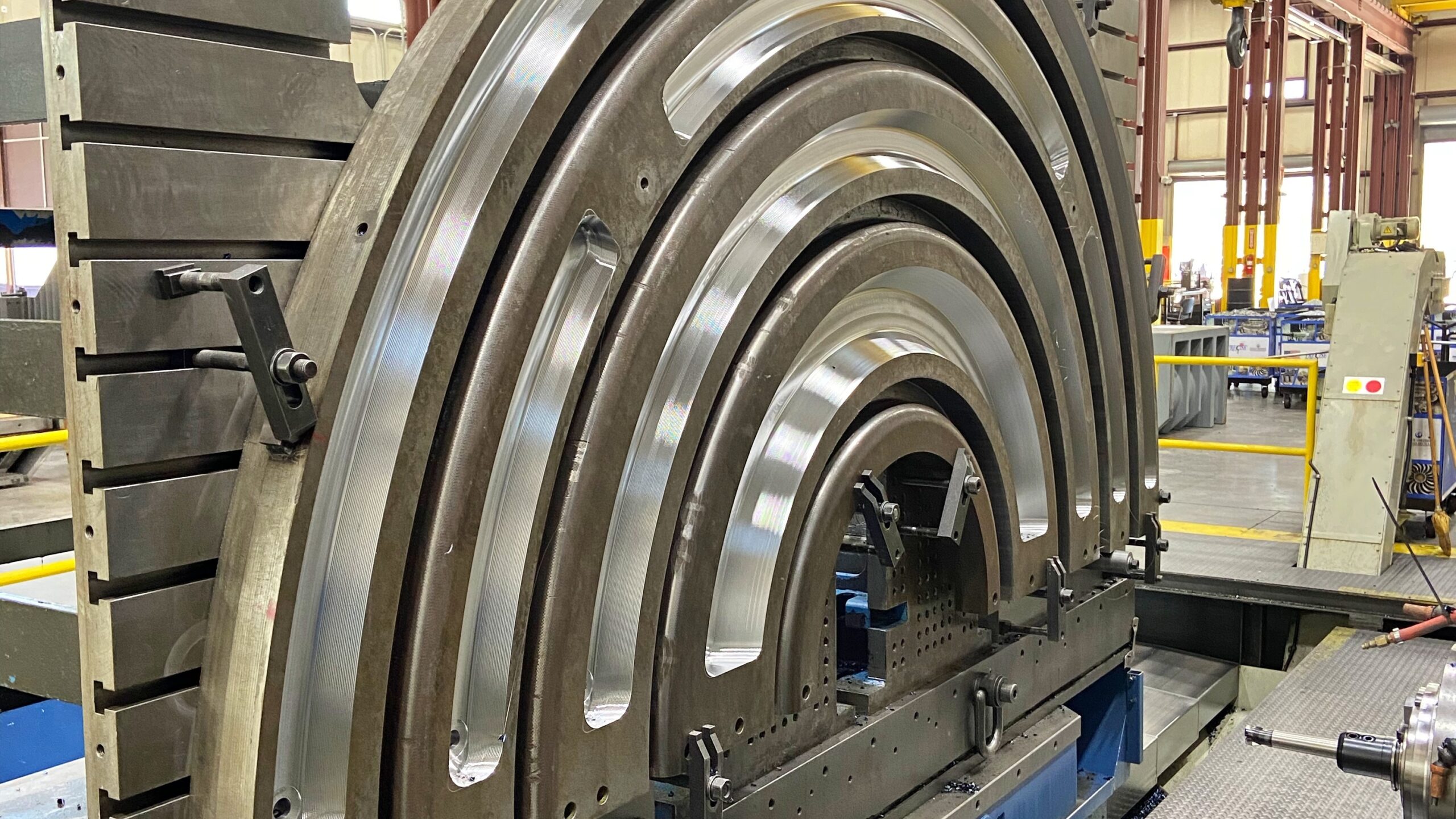

Precision steel milling represents a cornerstone of modern industrial manufacturing, demanding exceptional machine rigidity, thermal stability, and advanced process control to overcome the inherent challenges of machining this high-strength, abrasive material. Steel’s hardness and tendency to generate significant heat during cutting necessitate specialized CNC milling strategies to achieve tight tolerances, superior surface finishes, and dimensional stability, particularly for critical components in aerospace, automotive, and industrial machinery sectors. At Shenzhen Honyo Prototype, we leverage our deep expertise in ferrous material machining and state-of-the-art equipment to deliver complex steel parts with uncompromising quality and accelerated lead times, transforming demanding design concepts into fully functional, production-ready prototypes and low-volume production runs.

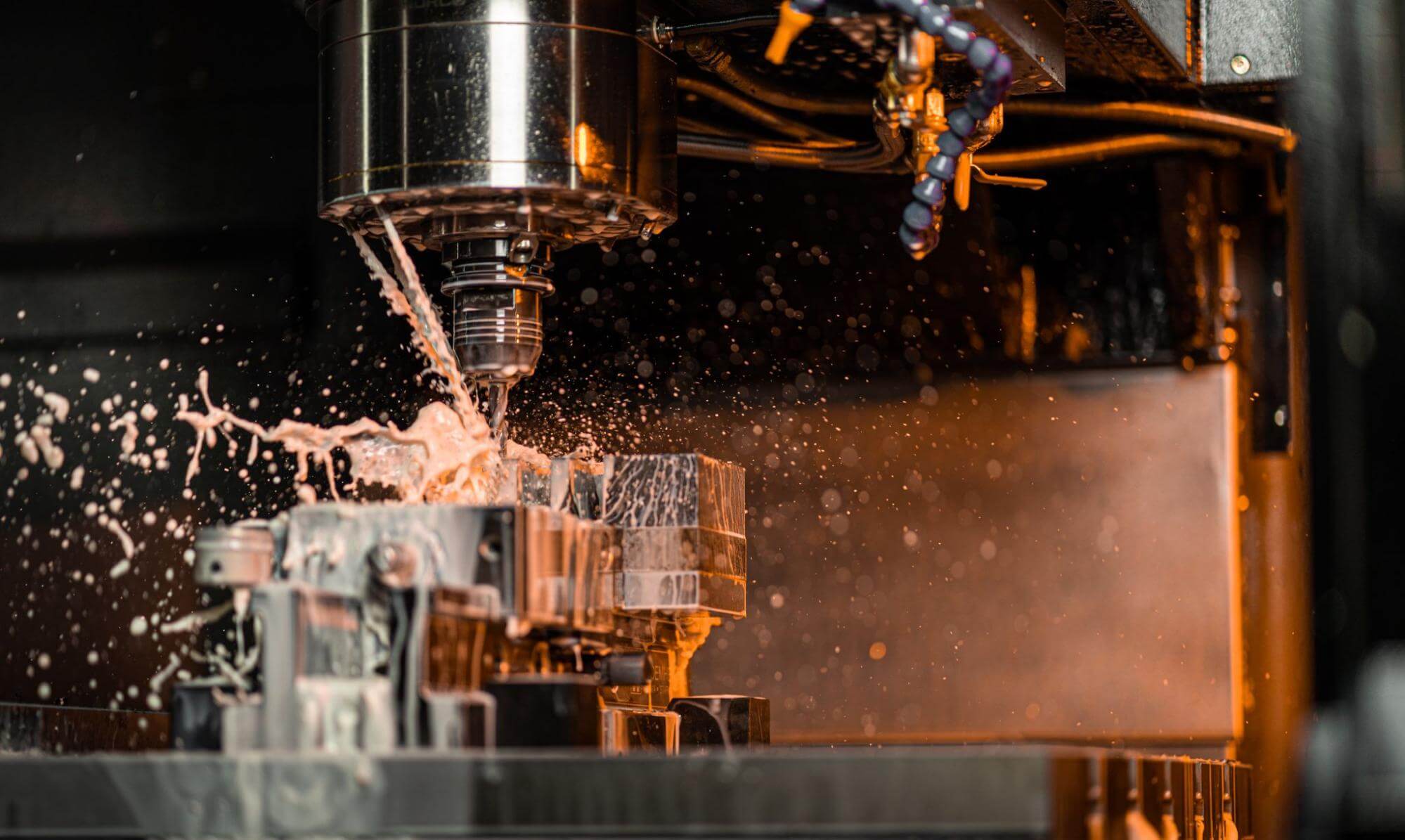

Our dedicated CNC steel milling operations utilize a strategically selected fleet of high-performance vertical and 5-axis machining centers, engineered specifically for the rigors of steel. These machines feature robust cast-iron frames, high-torque spindles capable of sustained heavy cutting, and advanced coolant delivery systems essential for managing thermal deformation and extending tool life. We employ proprietary cutting strategies, including optimized toolpath generation for minimal vibration, precise control of chip load to prevent work hardening, and strategic material removal sequences to maintain part integrity. This technical foundation is augmented by our rigorous process control protocols, encompassing in-process probing for real-time dimensional verification, stringent first-article inspection against ASME Y14.5 standards, and comprehensive final CMM reporting. Our engineering team possesses extensive knowledge of diverse steel alloys—from common 1018 and 4140 to exotic tool steels and stainless grades—enabling precise selection of cutting parameters, specialized tooling (including carbide and ceramic inserts), and optimal workholding solutions tailored to each unique material and geometry.

Honyo Prototype excels in translating complex steel component designs into reality, handling intricate features, thin walls, deep cavities, and critical geometric tolerances that challenge conventional machining. We prioritize minimizing secondary operations through integrated milling strategies, directly contributing to faster time-to-market for our clients’ most demanding applications. Our commitment extends beyond machining; we provide actionable Design for Manufacturability (DFM) feedback early in the process, identifying potential steel-specific manufacturability hurdles and suggesting optimizations to enhance part performance and reduce overall production cost without sacrificing functional requirements. This holistic approach ensures that every steel component we produce meets the exacting performance demands of its intended application.

Key technical capabilities for steel milling at Honyo Prototype are summarized below:

| Parameter | Capability Range | Significance for Steel Machining |

| :——————— | :———————————– | :——————————————— |

| Machine Types | 3-Axis, 4-Axis, 5-Axis Milling Centers | Enables complex geometries, reduced setups |

| Max Work Envelope | 1000 x 600 x 500 mm (XYZ) | Accommodates substantial prototype components |

| Positioning Accuracy | ±0.005 mm | Critical for tight-tolerance steel assemblies |

| Repeatability | ±0.002 mm | Ensures consistency in low-volume production |

| Spindle Speed Range | 20 – 24,000 RPM | Optimized for various steel grades & features |

Partnering with Honyo Prototype for your CNC steel milling requirements provides access to proven metallurgical expertise, cutting-edge technology, and a relentless focus on precision execution. We transform the challenges of steel machining into a strategic advantage for your product development cycle, delivering components that meet the highest standards of quality, reliability, and performance on schedule. Our integrated engineering and manufacturing approach ensures your steel prototypes and low-volume parts are not just accurate, but truly representative of final production intent.

Technical Capabilities

CNC Steel Milling Machine – Technical Capabilities

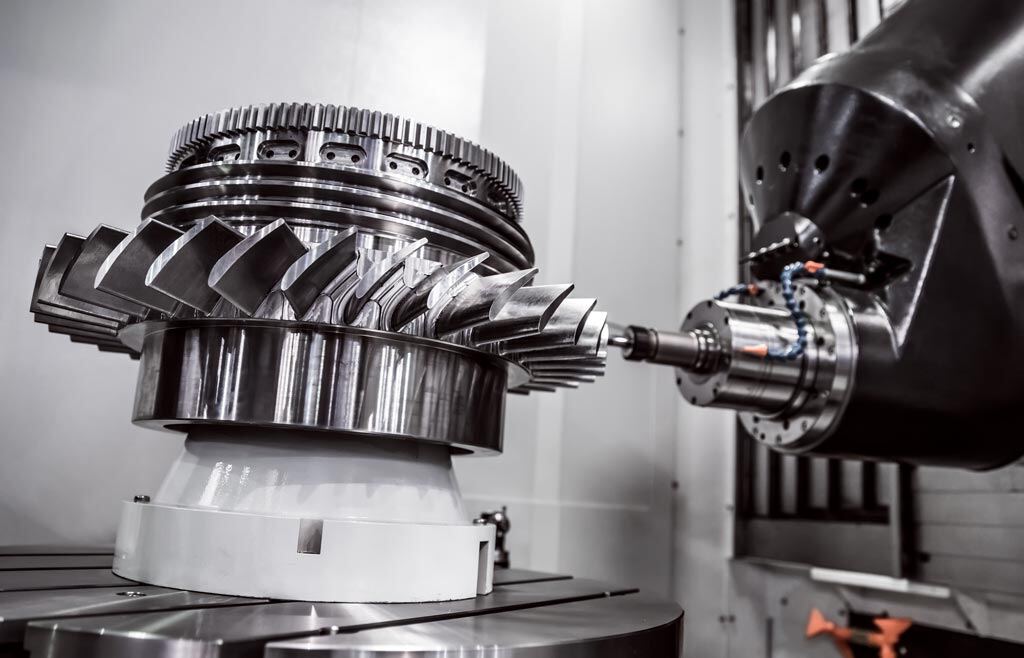

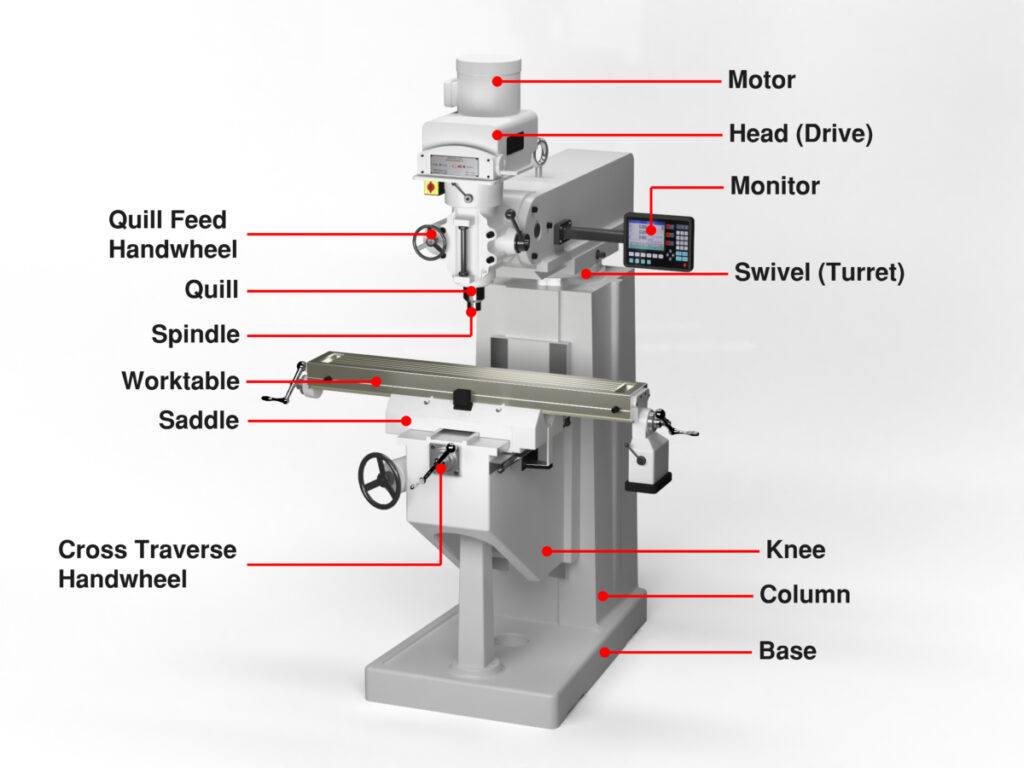

Shenzhen Honyo Prototype leverages advanced CNC steel milling machines to deliver high-precision machined components for demanding industrial applications. Our 3-axis, 4-axis, and 5-axis milling platforms are engineered to handle complex geometries, tight tolerances, and a wide range of steel alloys with consistent accuracy and surface integrity. These machines are integrated with high-rigidity spindles, automated tool changers, and real-time probing systems to ensure repeatability and process stability across both prototyping and low-to-mid volume production runs.

Our 3-axis milling centers are ideal for prismatic parts, flat surfaces, and standard cavity work, providing excellent material removal rates and dimensional accuracy. When rotational features or indexed angled surfaces are required, our 4-axis systems add a rotary table (A-axis) to enable efficient machining of components such as impellers, pump housings, and fixture plates. For the most complex geometries—such as aerospace brackets, medical instrument housings, and mold cores—we deploy our 5-axis simultaneous milling platforms. These machines allow tool access from multiple vectors in a single setup, minimizing part handling, reducing cumulative errors, and significantly improving surface finish and feature alignment.

In addition to multi-axis milling, our facility supports CNC turning for cylindrical steel components. This includes live tooling operations that combine turning with milling, drilling, and tapping, enabling complete part fabrication without secondary operations. All machines operate under strict environmental controls and are maintained to OEM standards, ensuring long-term precision and reliability.

A core strength at Honyo Prototype is our ability to consistently achieve tight tolerances across diverse steel materials. We routinely hold ±0.005 mm (±0.0002″) on critical dimensions, with surface finishes down to Ra 0.8 µm (32 µin) achievable through fine-tool finishing passes. Our quality assurance process includes first-article inspection (FAI), in-process probing, and final CMM validation to ensure full compliance with engineering specifications.

The table below outlines our standard tolerance capabilities and compatible steel materials:

| Material Type | Typical Grades | Tolerance (Linear) | Tolerance (Geometric) | Max Part Size (mm) | Surface Finish (Ra) |

|————————|——————————|——————–|————————|——————–|———————|

| Carbon Steel | S45C, 1045, 1018 | ±0.01 mm | ±0.02 mm (GD&T) | 800 x 500 x 400 | 1.6 – 3.2 µm |

| Alloy Steel | 4140, 4340 | ±0.008 mm | ±0.015 mm (GD&T) | 700 x 450 x 350 | 1.6 – 2.5 µm |

| Stainless Steel | 303, 304, 316, 17-4 PH | ±0.005 mm | ±0.01 mm (GD&T) | 600 x 400 x 300 | 0.8 – 1.6 µm |

| Tool Steel | H13, P20, S7, A2 | ±0.008 mm | ±0.015 mm (GD&T) | 500 x 400 x 300 | 0.8 – 2.5 µm |

| Free-Machining Steel | 12L14, 1215 | ±0.01 mm | ±0.02 mm (GD&T) | 750 x 500 x 400 | 1.6 – 3.2 µm |

All tolerances are achievable under stable thermal conditions and proper fixturing. Tighter tolerances down to ±0.002 mm are available upon engineering review for mission-critical applications.

From CAD to Part: The Process

CNC Steel Milling Production Workflow: From CAD to Finished Part

At Shenzhen Honyo Prototype, our CNC steel milling process transforms digital designs into precision-engineered components through a rigorously defined workflow. This structured approach ensures manufacturability, minimizes lead times, and guarantees part quality. The core sequence progresses from initial quotation through design validation to final production, integrating advanced automation with expert engineering oversight.

The process initiates with the AI-Powered Quotation System. Upon receipt of the client’s 3D CAD model (STEP, IGES, or native formats), our proprietary AI engine performs an immediate preliminary analysis. This system automatically assesses geometric complexity, identifies potential undercuts or thin walls, estimates raw material volume, and evaluates basic toolpath feasibility against standard machine capabilities. Crucially, it cross-references the geometry with material specifications provided (e.g., AISI 304, 4140, tool steel) to predict machining time and resource requirements. This enables Honyo to generate highly accurate, data-driven cost and lead time estimates within hours, significantly accelerating the project kickoff phase compared to manual review alone. The AI output forms the technical foundation for the formal quotation delivered to the client.

Following client approval, the project enters the critical Design for Manufacturability (DFM) Review stage. Here, Honyo’s senior manufacturing engineers conduct an in-depth manual analysis, building upon the AI assessment. We scrutinize the design for features that could compromise quality, increase cost, or cause production delays. Common focus areas include verifying adequate draft angles for deep pockets, confirming hole depths are achievable with standard tooling, assessing the necessity of tight tolerances on non-critical surfaces, and evaluating the feasibility of specified surface finishes on internal features. For instance, a design specifying a sharp internal corner might be flagged; our engineers will propose a practical corner radius improvement that maintains function while eliminating the need for slow, costly EDM processes. Client collaboration is essential here – we provide actionable DFM feedback and optimized design suggestions, often reducing part cost by 15-25% without sacrificing performance.

Upon DFM sign-off, the project transitions seamlessly into Production Execution. Our CAM team generates optimized, machine-specific toolpaths using Mastercam and Siemens NX, incorporating the validated design and agreed DFM modifications. Rigorous virtual machining simulation ensures collision avoidance and verifies path efficiency. Production begins with meticulous setup: raw steel stock is precisely fixtured, high-precision tooling is loaded and measured, and machine coordinate systems are calibrated. Throughout the machining cycle, in-process inspections using Renishaw probes verify critical dimensions after key operations. Final parts undergo comprehensive CMM inspection against the original CAD model, with full inspection reports provided. This integrated workflow – AI efficiency, expert DFM validation, and precise production control – is how Honyo consistently delivers complex steel millings with tolerances down to ±0.005mm and surface finishes to Ra 0.8μm.

Typical CNC Milling Parameters for Common Steels

| Material Grade | Spindle Speed (SFM) | Feed Rate (IPM) | Max Depth of Cut (mm) | Key Considerations |

|—————-|———————|—————–|————————|———————|

| AISI 304 Stainless | 200 – 400 | 5 – 15 | 2.0 | Requires sharp carbide tools, high pressure coolant essential to prevent work hardening |

| AISI 4140 Alloy Steel | 300 – 500 | 8 – 20 | 3.0 | Pre-heat recommended for large sections; controlled cooling avoids cracking |

| Tool Steel (A2/D2) | 150 – 300 | 3 – 10 | 1.5 | Slow speeds/feeds; frequent tool changes; strict thermal management critical |

Start Your Project

Start Your CNC Steel Milling Project with Honyo Prototype

When precision, reliability, and speed are critical to your product development, Shenzhen Honyo Prototype stands as your trusted partner in CNC steel milling. Our advanced manufacturing capabilities, combined with decades of engineering expertise, enable us to deliver high-tolerance steel components tailored to your exact specifications. Whether you’re prototyping a new design or scaling into low-volume production, our CNC milling services ensure superior surface finishes, tight tolerances, and consistent quality across every part.

At Honyo Prototype, we specialize in machining a wide range of steel alloys, including carbon steel, stainless steel (303, 304, 316), tool steel, and alloy steels. Our 3-axis and 4-axis CNC milling machines are equipped with high-precision spindles and automated tool changers, allowing us to handle complex geometries with ease. From intricate internal features to robust structural components, our machines deliver repeatability down to ±0.005 mm, ensuring your design intent is fully realized.

We understand that every project begins with a vision. That’s why our engineering team works closely with you from the earliest stages—reviewing your CAD models, offering design for manufacturability (DFM) feedback, and recommending optimal materials and finishes. Our goal is not just to manufacture your parts, but to help you refine your design for performance, cost-efficiency, and faster time to market.

To ensure transparency and control, we provide real-time project updates, material certifications, and comprehensive inspection reports—including first-article inspections and CMM reports upon request. With a streamlined workflow and in-house quality control, we consistently deliver lead times as fast as 5–7 business days for prototypes and 10–15 days for production runs.

Below are the key technical specifications of our CNC steel milling capabilities:

| Specification | Details |

|————-|——–|

| Machine Types | 3-axis and 4-axis CNC milling centers |

| Maximum Work Envelope | 1000 mm × 600 mm × 500 mm |

| Tolerance | ±0.005 mm (standard), tighter upon request |

| Spindle Speed | Up to 24,000 RPM |

| Tooling | Automatic tool changer (ATC), 24-tool capacity |

| Materials | Carbon steel, stainless steel (303/304/316), tool steel, alloy steel |

| Surface Finishes | As-machined, bead blast, anodizing (for applicable alloys), passivation |

| Quality Standards | ISO 9001:2015 compliant, full inspection reporting |

Starting your project is simple. Share your 3D CAD file (STEP, IGES, or SolidWorks format) and technical requirements with our team, and we’ll provide a detailed quote within 12 hours. Our responsive engineering support ensures your questions are answered quickly, and your project moves forward without delay.

Contact Susan Leo today at info@hy-proto.com to begin your CNC steel milling project. With Honyo Prototype, you gain more than a manufacturer—you gain a strategic partner committed to precision, speed, and engineering excellence. Let’s build your next innovation together.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.