Contents

Manufacturing Insight: Cnc Machine Vs 3D Printer

Manufacturing Insight: Strategic Selection Between CNC Machining and Industrial 3D Printing

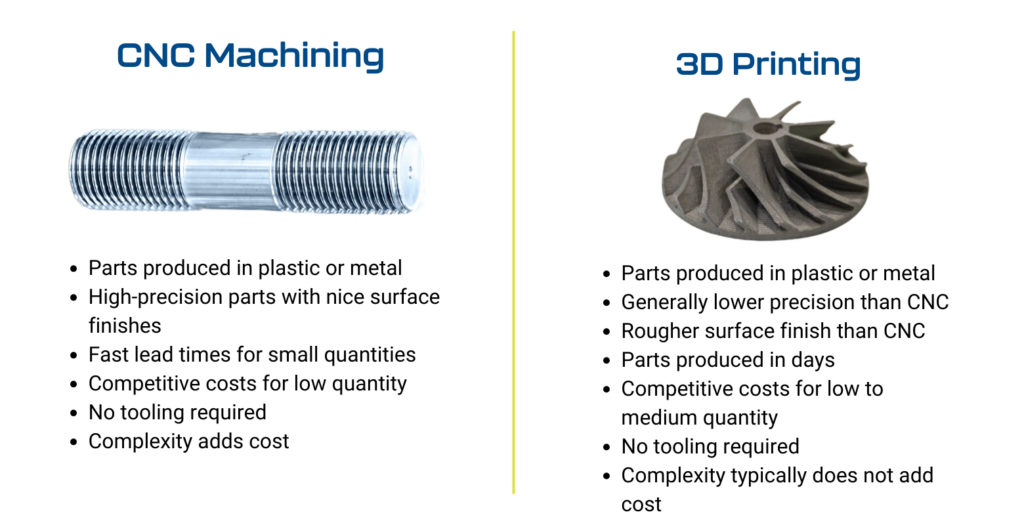

Selecting the optimal manufacturing process for rapid prototyping or low-volume production requires a precise understanding of the fundamental differences between Computer Numerical Control (CNC) machining and industrial 3D printing. Both technologies are indispensable within modern manufacturing ecosystems, yet their underlying principles dictate distinct applications and outcomes. CNC machining is a subtractive process, starting with a solid block of material and precisely removing stock via rotating cutting tools to achieve the final geometry. This method excels in producing parts with exceptional dimensional accuracy, superior surface finishes, and the ability to utilize a vast range of engineering-grade metals and plastics in their final, certified forms. Conversely, industrial 3D printing (additive manufacturing) builds parts layer by layer from digital models, adding material only where needed. This additive approach unlocks unprecedented geometric freedom, enabling complex internal structures, organic shapes, and consolidated assemblies impossible to machine, while significantly reducing material waste for intricate designs.

The decision between these processes hinges on specific project requirements. CNC machining remains the definitive choice for high-precision components demanding tight tolerances, critical mechanical properties matching bulk material specifications, and excellent surface quality without extensive post-processing – typical for functional prototypes, jigs, fixtures, and end-use parts in aerospace, automotive, and medical device sectors. Industrial 3D printing shines when design complexity is paramount, lead time for intricate geometries is critical, or when producing one-off custom parts where traditional tooling costs are prohibitive. It is particularly advantageous for lightweight structures, fluidics, conformal cooling channels, and highly customized medical implants.

Shenzhen Honyo Prototype leverages both technologies synergistically within its integrated manufacturing platform. Our engineering team rigorously evaluates each project against core parameters to determine the optimal process or strategic combination, ensuring clients receive the most cost-effective, time-efficient, and functionally appropriate solution. We do not advocate for one technology universally; instead, we apply deep material science and process expertise to match the method to the mission. Below is a comparative overview of key technical characteristics:

| Parameter | CNC Machining | Industrial 3D Printing (e.g., SLS, MJF, DMLS) |

| :—————– | :——————————– | :——————————————– |

| Accuracy | ±0.005 – 0.025 mm | ±0.1 – 0.3 mm (varies by process/material) |

| Materials | Wide range: Metals (Al, Ti, SS), Engineering Plastics (PEEK, Nylon), Composites | Polymers (Nylon, TPU), Metals (Ti, Al, SS, Inconel), Resins |

| Lead Time | Hours to days (setup/tooling dependent) | Hours to days (minimal setup, batchable) |

| Part Complexity| Limited by tool access/geometry | High complexity achievable (lattices, internal features) |

| Surface Finish | Excellent as-machined (Ra < 1.6 µm) | Typically requires post-processing (Ra 5-25 µm) |

| Best Applications | High-precision functional parts, metal components, smooth surfaces | Complex geometries, lightweight structures, custom/low-volume parts, rapid iteration |

At Honyo, our investment in advanced multi-axis CNC centers and industrial-scale polymer and metal 3D printing systems, coupled with expert process engineering, allows us to navigate this spectrum effectively. We provide clients not just with parts, but with validated manufacturing insights, ensuring the selected technology delivers the required performance, quality, and speed-to-market for their specific industrial application. Understanding these core distinctions is the first step toward optimized prototyping and production.

Technical Capabilities

When evaluating manufacturing technologies for rapid prototyping and low-volume production, understanding the technical capabilities of CNC machining versus 3D printing is essential. At Shenzhen Honyo Prototype, we leverage both subtractive and additive methods to meet diverse engineering requirements. CNC machining removes material from solid stock using precision cutting tools, delivering high accuracy, excellent surface finishes, and broad material compatibility. In contrast, 3D printing builds parts layer by layer, enabling complex geometries unachievable through traditional methods. Within industrial 3D printing, technologies such as Stereolithography (SLA), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), and Direct Metal Laser Sintering (DMLS) offer distinct advantages depending on application needs.

CNC machining achieves tight tolerances, typically within ±0.025 mm, and supports a wide range of metals and engineering plastics, including aluminum, stainless steel, titanium, and ABS. Surface finishes can reach Ra 0.8 μm or better with post-processing. However, CNC is limited by tool access, making internal cavities and undercuts challenging without multi-axis setups.

SLA uses ultraviolet lasers to cure photopolymer resins, producing highly detailed prototypes with smooth surfaces. It offers tolerances around ±0.1 mm and is ideal for visual models and master patterns, though mechanical properties are inferior to thermoplastics or metals. SLS fuses nylon-based powders using a laser, delivering functional parts with good mechanical strength and tolerances of ±0.1 to ±0.2 mm. It requires no support structures, enabling complex internal features. MJF, developed by HP, uses inkjet array and infrared energy to fuse nylon powder, achieving slightly better consistency and surface quality than SLS, with similar tolerances and material performance.

DMLS processes metal powders such as stainless steel, aluminum, and Inconel using a high-powered laser, producing fully dense metal components with tolerances of ±0.05 mm. It is well-suited for aerospace, medical, and tooling applications where strength and precision are critical. While build volumes are smaller than CNC, DMLS allows for topology-optimized designs that reduce weight without sacrificing performance.

The following table compares key technical specifications across these processes:

| Process | Typical Tolerance | Common Materials | Surface Finish (Ra) | Key Applications |

|—————|——————-|——————————————-|———————-|—————————————|

| CNC Machining | ±0.025 mm | Aluminum 6061/7075, Stainless Steel, Titanium, PEEK, ABS | 0.8 – 3.2 μm | Functional prototypes, end-use parts, jigs & fixtures |

| SLA | ±0.1 mm | Standard, Tough, Transparent, Castable Resins | 0.8 – 2.5 μm | Concept models, master patterns, fit testing |

| SLS | ±0.1 – ±0.2 mm | Nylon 12, Nylon 11, Glass-filled Nylon | 6.0 – 10.0 μm | Functional prototypes, enclosures, ducting |

| MJF | ±0.1 – ±0.2 mm | Nylon 12, Glass-filled Nylon | 4.0 – 8.0 μm | End-use parts, housings, mechanical components |

| DMLS | ±0.05 mm | Stainless Steel 316L, AlSi10Mg, Ti6Al4V, Inconel 718 | 10.0 – 20.0 μm (as-built) | Aerospace, medical implants, tooling |

Selecting between CNC and 3D printing depends on part geometry, material requirements, production volume, and performance criteria. At Honyo Prototype, we guide clients through this decision matrix to ensure optimal manufacturability and cost-efficiency.

From CAD to Part: The Process

From CAD to Part: CNC Machining vs. Industrial 3D Printing Workflow at Honyo Prototype

At Shenzhen Honyo Prototype, transforming your CAD model into a functional part begins with precise technology selection between CNC machining and industrial 3D printing. This decision, critical for cost, lead time, and part performance, is systematically guided through our integrated workflow: AI-Powered Quoting, Design for Manufacturability (DFM) analysis, and production execution. Understanding the distinct paths for each technology ensures optimal results for your prototyping or low-volume production needs.

The process initiates with our AI-driven quoting system. Upon CAD file upload, the AI instantly evaluates geometric complexity, material requirements, and requested quantity. For CNC machining, the AI assesses feature accessibility, required tool changes, and raw stock utilization. For industrial 3D printing (primarily SLS, MJF, SLA, or metal PBF), it analyzes part orientation, support structure needs, and build volume efficiency. This provides an immediate, data-backed estimate of cost and lead time, highlighting the inherent trade-offs: CNC excels for high-precision metal parts with tight tolerances but incurs higher per-part costs for complex geometries, while 3D printing offers unrivaled design freedom for complex organic shapes and internal features with lower setup costs, though surface finish and material properties may require specific post-processing.

Following quoting, rigorous DFM analysis is mandatory. Our engineering team scrutinizes the design specifically for the chosen process. For CNC, DFM focuses on minimizing setups, avoiding deep cavities with small radii, ensuring adequate wall thickness, and optimizing toolpath strategies to reduce machining time. For 3D printing, DFM emphasizes designing for self-supporting angles, minimizing overhangs to reduce support structures, optimizing part orientation for strength and surface quality, and leveraging topology optimization unique to additive manufacturing. This phase often involves collaborative feedback with the client to refine the design, ensuring manufacturability without compromising functional intent, whether the part requires the metallurgical integrity of machined aluminum or the lightweight lattice structures achievable only through printing.

Production execution then leverages Honyo’s dedicated expertise. CNC machining utilizes multi-axis mills and lathes with strict in-process metrology, producing parts with exceptional dimensional stability and surface finishes achievable through secondary operations like polishing or anodizing. Industrial 3D printing employs calibrated systems within controlled environments, building parts layer by layer, followed by essential post-processing such as depowdering, thermal treatment, or vapor smoothing. The final output is a part meeting the agreed specifications, with CNC delivering superior mechanical properties for demanding applications and 3D printing enabling rapid iteration of complex designs impossible via subtractive methods.

Key Process Comparison for Technology Selection

| Process Parameter | CNC Machining | Industrial 3D Printing |

| :———————- | :————————————- | :—————————————– |

| Typical Lead Time (Prototype) | 3-7 days (complex setups longer) | 2-5 days (build + post-processing) |

| Material Range | Metals (Al, SS, Ti), Engineering Plastics | Polymers (Nylon, TPU), Metals (Ti, Al, SS), Resins |

| Dimensional Accuracy | ±0.025mm (achievable) | ±0.1% (typical, varies by technology) |

| Surface Finish (As-Built)| Superior (Ra 0.8 – 3.2 µm) | Granular/Textured (Ra 5 – 20+ µm, post-process dependent) |

| Geometric Complexity | Limited by tool access (undercuts challenging) | High (internal channels, lattices, organic shapes) |

| Scalability (Low Volume)| Higher per-part cost for complexity | Lower per-part cost for complex designs |

| Primary Post-Processing | Deburring, polishing, finishing | Support removal, depowdering, thermal cure, surface treatment |

Start Your Project

Start Your Project with the Right Manufacturing Choice: CNC Machining or 3D Printing?

When launching a new product development cycle, selecting the appropriate manufacturing method is critical to achieving precision, speed, and cost-efficiency. At Shenzhen Honyo Prototype, we specialize in industrial 3D printing and CNC machining services, empowering engineers, designers, and R&D teams to make informed decisions based on part complexity, material requirements, production volume, and lead time constraints.

CNC machining delivers high-precision, tight-tolerance components from solid blocks of metal or plastic, making it ideal for end-use parts requiring superior mechanical properties and surface finish. It excels in applications where dimensional accuracy and repeatability are non-negotiable—such as in aerospace, automotive, and medical device manufacturing. However, CNC is often more expensive for low-volume or highly complex geometries due to tooling costs and material waste.

In contrast, industrial 3D printing offers unparalleled design freedom, enabling rapid prototyping and production of complex, lightweight, and topology-optimized parts that would be impossible—or extremely costly—to machine. Technologies like SLS, SLA, and MJF allow for quick iteration, reduced assembly needs, and on-demand manufacturing with minimal setup. This makes 3D printing the preferred choice for functional prototypes, custom tooling, and small-batch production.

To help you determine the best path for your next project, we’ve summarized key performance characteristics of both technologies:

| Feature | CNC Machining | Industrial 3D Printing |

|————————–|————————————|————————————-|

| Material Options | Metals, engineering plastics | Nylon, TPU, resins, composites |

| Dimensional Accuracy | ±0.005 mm | ±0.1 mm (varies by technology) |

| Surface Finish | Excellent (machined finish) | Good (may require post-processing) |

| Lead Time (Prototype) | 3–7 days | 1–3 days |

| Design Complexity | Limited by tool access | High (no tooling constraints) |

| Minimum Viable Quantity | 1–100+ | 1–500+ |

| Cost Efficiency | High for mid-to-high volumes | Optimal for low volumes, complex parts |

At Honyo Prototype, we support both subtractive and additive workflows, offering seamless transitions from concept to prototype to production. Our team evaluates each project holistically, recommending the most suitable process based on your technical specifications and business goals.

Ready to move forward? Let us help you choose the right technology for your application. Contact Susan Leo, Customer Project Manager at Shenzhen Honyo Prototype, to discuss your project requirements, request a quote, or receive technical consultation.

Susan Leo

Email: info@hy-proto.com

Shenzhen Honyo Prototype – Precision. Innovation. Delivered.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.