Contents

Manufacturing Insight: Automated Cnc Machine

Manufacturing Insight: Automated CNC Machining at Honyo Prototype

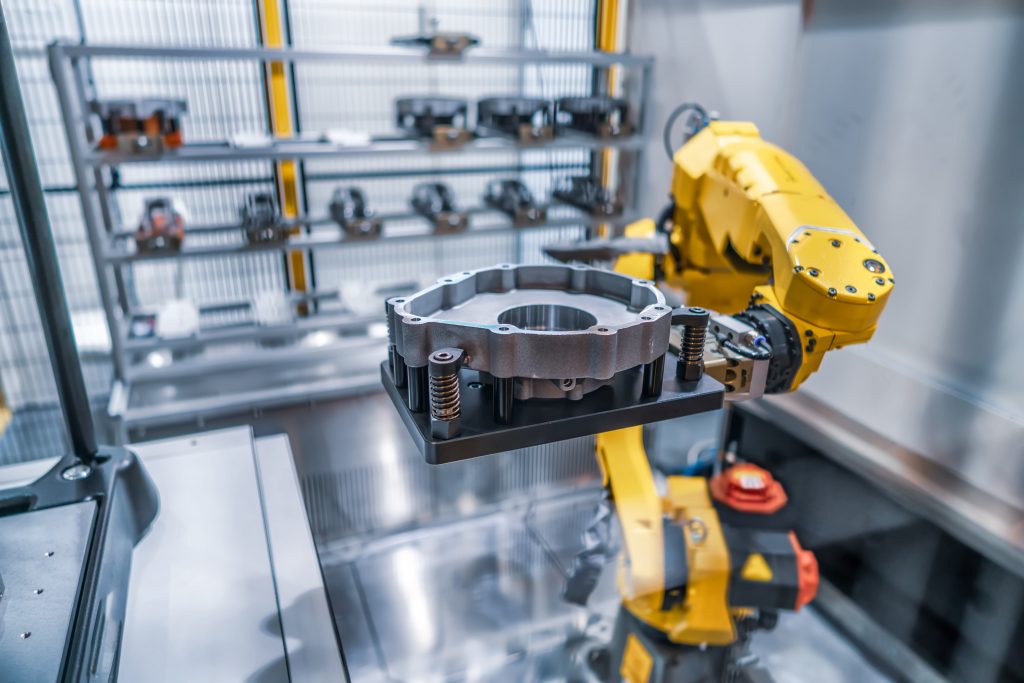

Automated CNC machining represents a critical evolution in precision manufacturing, moving beyond traditional manual oversight to integrate robotics, advanced software, and real-time monitoring for uninterrupted production. At Shenzhen Honyo Prototype, we leverage this technology to deliver complex, high-tolerance components with exceptional repeatability and efficiency—essential for industries demanding rapid prototyping and low-to-mid volume production. Unlike conventional CNC setups requiring constant operator intervention, our automated systems utilize robotic arms for part loading/unloading, AI-driven tool wear compensation, and closed-loop feedback to maintain micron-level tolerances across extended runs. This eliminates human variability while optimizing machine utilization, directly addressing client pain points like extended lead times and inconsistent quality in multi-part batches.

Honyo Prototype’s automated CNC capability centers on a flexible FMS (Flexible Manufacturing System) infrastructure. Our facility integrates 5-axis milling and turning centers with palletized workholding systems, enabling true “lights-out” operation for up to 72 hours. Key differentiators include predictive maintenance algorithms that preempt downtime and in-process metrology via integrated touch probes, ensuring dimensional compliance without interrupting the machining cycle. We support materials ranging from aerospace-grade titanium and Inconel to engineering plastics, maintaining ±0.005 mm accuracy even in complex geometries. This system is particularly advantageous for clients requiring iterative design validation, as it accelerates iteration cycles while preserving data integrity for design-for-manufacturability analysis.

The strategic value of automation extends beyond speed. For prototypes demanding strict regulatory compliance (e.g., medical or defense sectors), our systems generate full traceability logs—capturing spindle load, temperature, and tool path data for every component. This audit trail satisfies stringent documentation requirements while providing actionable insights for scaling to volume production. Crucially, Honyo’s approach prioritizes scalability: the same programming and fixturing used for a single prototype seamlessly transition to automated batch runs, eliminating requalification costs.

Below is a comparison highlighting how Honyo’s automated CNC systems outperform standard CNC setups in critical operational metrics:

| Parameter | Standard CNC Operation | Honyo Automated CNC System |

|————————-|————————|—————————|

| Max Continuous Runtime | 8–12 hours (shift-based) | 72+ hours (unattended) |

| Labor Dependency | High (1 operator per machine) | Low (1 operator per cell) |

| Typical Positional Accuracy | ±0.01 mm | ±0.005 mm |

| Changeover Time | 30–60 minutes | < 10 minutes (palletized) |

| OEE (Overall Equipment Effectiveness) | 40–60% | 85–92% |

By embedding automation into our core prototyping workflow, Honyo Prototype transforms CNC from a mere fabrication tool into a strategic advantage. Clients gain faster time-to-part, reduced unit costs for batches of 10–500 pieces, and unwavering quality—proven by our ISO 9001-certified processes. Whether validating a next-gen drone component or producing end-use brackets for autonomous vehicles, our automated systems ensure your design intent is realized with manufacturing excellence. Partner with Honyo to harness precision engineering where innovation meets execution.

Technical Capabilities

Technical Capabilities: Automated CNC Machining at Shenzhen Honyo Prototype

Shenzhen Honyo Prototype leverages state-of-the-art automated CNC machining systems to deliver high-precision, repeatable, and scalable manufacturing solutions for complex components across aerospace, medical, automotive, and industrial sectors. Our facility integrates advanced 3-axis, 4-axis, and 5-axis milling centers with automated pallet systems and robotic part handling, enabling lights-out machining and reduced cycle times without compromising accuracy. These systems are supported by real-time tool monitoring, in-process probing, and closed-loop quality feedback, ensuring consistent output across both prototype and low-to-mid volume production runs.

Our 5-axis simultaneous milling platforms provide superior geometric flexibility, allowing for the machining of intricate contours, deep cavities, and compound angles in a single setup. This eliminates cumulative alignment errors and significantly improves surface finish and dimensional consistency. The 4-axis configurations are ideal for rotational symmetry and indexed multi-face machining, while 3-axis systems remain optimal for prismatic parts requiring high-speed precision. All systems operate under stringent environmental controls and are calibrated monthly to maintain ISO 2768 and ASME Y14.5 standards.

In addition to multi-axis milling, our automated turning centers support live tooling and Y-axis capabilities, enabling complete machining of complex turned components without secondary operations. These CNC lathes are integrated with bar feeders and part catchers, allowing for continuous production of shafts, bushings, connectors, and other rotational parts with tight concentricity and surface integrity.

Tight tolerance machining is a cornerstone of our service offering. We consistently achieve tolerances down to ±0.002 mm (±0.0001″) on critical dimensions, supported by CMM validation, optical comparators, and on-machine touch probes. Our metrology lab is certified to ISO 9001:2015, ensuring traceable and repeatable quality assurance across every production batch.

The table below outlines our standard tolerance capabilities and compatible materials for automated CNC machining:

| Feature | Standard Tolerance | Typical Materials |

|——–|——————–|——————-|

| Linear Dimensions | ±0.025 mm (±0.001″) | Aluminum 6061, 7075, 2024 |

| Hole Diameter | +0.03 / 0 mm | Stainless Steel 303, 304, 316, 17-4PH |

| Flatness | 0.02 mm per 100 mm | Titanium Grade 2, Grade 5 (Ti-6Al-4V) |

| Perpendicularity | 0.03 mm | Brass C36000, C26000 |

| Positional Tolerance | ±0.02 mm | Engineering Plastics (PEEK, Delrin, Nylon) |

| Surface Roughness (Ra) | 0.8 μm (32 μin) standard, down to 0.2 μm (8 μin) | Magnesium, Carbon Steel, Inconel 718 |

All materials are sourced from certified suppliers and subjected to incoming material verification. First-article inspection reports (FAIR) and PPAP documentation are available upon request.

With full digital integration from CAD/CAM to machine toolpath execution, Shenzhen Honyo Prototype ensures rapid turnaround, minimal human intervention, and maximum repeatability—delivering precision-engineered components that meet the most demanding technical specifications.

From CAD to Part: The Process

CNC Production Workflow: From CAD File to Precision Part at Shenzhen Honyo Prototype

Shenzhen Honyo Prototype utilizes an integrated, technology-driven workflow to transform customer CAD models into high-precision CNC machined prototypes and low-volume production parts efficiently. This process ensures manufacturability, cost-effectiveness, and adherence to stringent quality standards, minimizing iteration and accelerating time-to-market. The core sequence involves AI-Powered Quoting, Collaborative DFM Analysis, and Automated Production Execution.

The workflow initiates upon receipt of a validated CAD file (STEP, IGES, Parasolid, or native formats preferred). Our proprietary AI quoting engine immediately analyzes the 3D geometry, extracting critical features, material requirements, tolerances, and surface finish specifications. This AI system cross-references Honyo’s extensive manufacturing database, including machine capabilities, tooling libraries, material costs, and historical cycle times, to generate an accurate, detailed quote within minutes. This initial AI assessment provides customers with rapid cost and lead time visibility while identifying potential high-level manufacturability flags requiring further engineering review.

Following quote acceptance, the project enters the critical Design for Manufacturability (DFM) phase. Honyo’s experienced manufacturing engineers conduct a thorough, collaborative DFM analysis. This is not a passive checklist but an active engineering dialogue aimed at optimizing the design for CNC efficiency and part integrity without compromising function. Engineers evaluate feature geometry, wall thicknesses, hole depths, undercuts, tolerance stack-ups, and material suitability against CNC machining constraints. Key considerations during DFM are summarized below:

| Parameter | Critical Threshold | Recommended Action |

| :—————– | :———————— | :————————————- |

| Minimum Wall Thickness | < 0.5mm (Aluminum) | Increase thickness or suggest alternative material |

| Internal Corner Radius | Sharp (R0) | Specify minimum tool radius (e.g., R0.5mm) |

| Feature Depth | > 4x Diameter (Holes) | Consider alternative machining strategy or design modification |

| Tolerance (General) | < ±0.025mm (Standard) | Confirm necessity; tighter tolerances increase cost/time |

| Surface Finish | Ra < 0.4µm (Non-critical) | Specify only on functional surfaces |

Upon DFM sign-off, the part transitions to automated production. Honyo leverages a modern fleet of multi-axis CNC machining centers (3-axis, 4-axis, 5-axis) integrated with robotic pallet systems for lights-out manufacturing capability. CAM programming, optimized during DFM, generates efficient toolpaths. The process involves meticulous material selection and preparation, followed by precision fixturing. Machining proceeds under continuous automated monitoring for tool wear, vibration, and dimensional accuracy via in-process probing. Critical dimensions are verified at defined stages using CMMs or optical comparators. Final parts undergo comprehensive first-article inspection against the original CAD model and customer specifications before packaging and shipment. This seamless integration of AI, engineering expertise, and advanced automation ensures Honyo delivers complex, high-quality CNC machined components reliably and rapidly for demanding prototyping and production applications. Material selection significantly impacts the process; common options include:

| Material | Typical Machinability | Key Considerations for CNC Prototyping |

| :—————- | :——————– | :————————————- |

| Aluminum 6061-T6 | Excellent | Fast cycle times, good strength, anodizing compatible |

| Stainless Steel 303 | Good | Requires sharp tools, slower speeds, potential for work hardening |

| POM (Acetal/Delrin)| Very Good | Low friction, excellent dimensional stability, minimal burring |

| ABS Plastic | Excellent | Very fast machining, low heat generation, suitable for visual prototypes |

Start Your Project

Start Your Project with Precision CNC Machining at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, we specialize in high-precision automated CNC machining services designed to meet the demanding requirements of modern manufacturing. Whether you are developing a prototype for validation or scaling up for low- to mid-volume production, our state-of-the-art CNC capabilities ensure accuracy, repeatability, and fast turnaround times. Our advanced automation systems integrate seamlessly with tight-tolerance machining processes, enabling consistent part quality across all stages of your project lifecycle.

Our automated CNC machining center is equipped with multi-axis milling and turning systems, robotic part handling, and real-time monitoring to minimize human error and maximize efficiency. This allows us to support complex geometries, tight tolerances down to ±0.005 mm, and a wide range of engineering-grade materials—from aluminum and stainless steel to titanium, brass, and high-performance plastics such as PEEK and Delrin.

We understand that every project begins with a concept. That’s why our engineering team works closely with clients from the initial design phase to ensure manufacturability, reduce lead times, and optimize costs without compromising performance. Our Design for Manufacturability (DFM) analysis is provided free of charge, helping you identify potential issues early and streamline the path from CAD model to finished part.

To get started, simply upload your 3D model or 2D drawing, and our team will provide a comprehensive quote within 12 hours. We support all major file formats, including STEP, IGES, SolidWorks, and DWG. Once the design is approved, production can begin immediately—with typical lead times ranging from 3 to 7 days depending on complexity and quantity.

Below are the key specifications of our automated CNC machining capabilities:

| Specification | Details |

|—————————-|————————————————————————-|

| Machining Types | 3-axis, 4-axis, 5-axis CNC milling; CNC turning; mill-turn machining |

| Automation Level | Fully automated with robotic loading/unloading and in-process inspection|

| Materials Supported | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium, Brass, PEEK, Delrin, ABS, PC |

| Tolerances | Standard: ±0.025 mm; Tight: ±0.005 mm available upon request |

| Maximum Work Envelope | 1000 x 600 x 500 mm (39″ x 23.6″ x 19.7″) |

| Surface Finishes | As-machined, bead blast, anodizing (Type II & III), passivation, powder coating |

| Lead Time | 3–7 days for most prototypes; production runs scalable based on volume |

| Quality Standards | ISO 9001:2015 compliant; full inspection reports available |

Every project at Honyo Prototype is treated with the highest level of technical care and confidentiality. We serve industries ranging from aerospace and medical devices to robotics and consumer electronics, delivering parts that meet stringent performance and regulatory standards.

Ready to bring your design to life? Contact Susan Leo today at info@hy-proto.com to discuss your project requirements, request a DFM review, or receive a competitive quote. Let Shenzhen Honyo Prototype be your trusted partner in precision CNC manufacturing.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.