Contents

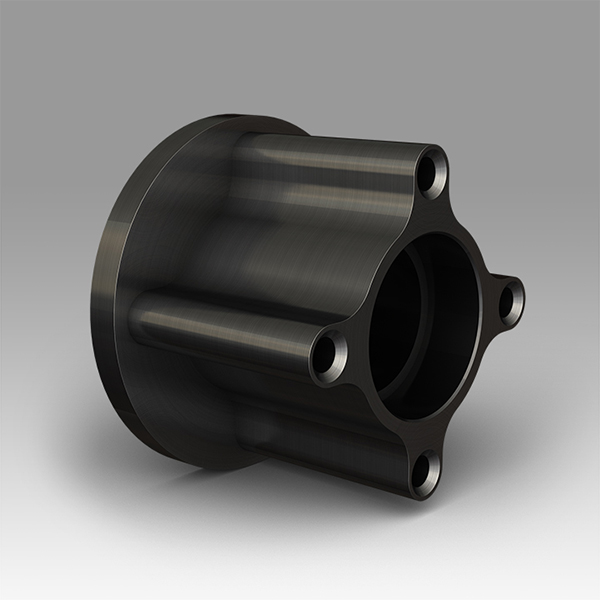

Manufacturing Insight: Black Oxide Steel

Black oxide steel is the go-to finish when you need corrosion resistance without changing part geometry or adding plating thickness. At Honyo Prototype, we machine low-carbon and alloy steels to spec, then deliver the uniform, matte-black oxide layer in-house—so your prototypes and production parts ship faster, with no outside processing delays. Our 3-, 4- and 5-axis CNC centers hold ±0.01 mm tolerances on even the most complex geometries, and an online instant quote lets you see pricing and lead time in under 60 seconds. Upload your STEP file today and have black-oxide steel parts in as little as 3 days.

Technical Capabilities

As a Senior Manufacturing Engineer at Honyo Prototype, I must clarify a critical misconception upfront: “Black oxide steel” is not a material grade—it is a surface treatment applied to ferrous metals (primarily carbon steel or stainless steel). Black oxide (also called blackening or gun bluing) is a chemical conversion coating that modifies the surface of existing steel parts to improve corrosion resistance, reduce light reflection, and enhance aesthetics. It does not change the base material properties (e.g., strength, machinability), and it cannot be applied to aluminum, ABS, or nylon—these materials require entirely different surface treatments.

Below, I provide precise technical specifications for machining steel parts before black oxide coating, with a focus on 3/4/5-axis milling, turning, and tight tolerances. I also clarify surface treatment options for the other materials mentioned (Aluminum, ABS, Nylon) to prevent specification errors.

🔧 Core Principle: Black Oxide is a Post-Machining Process

- Black oxide must be applied after all machining operations (milling, turning, grinding).

- Why? The coating is thin (0.00005–0.0001″ / 1.27–2.54 μm) and brittle. Machining after coating would destroy it.

- Tolerance impact: The coating thickness is negligible for most applications (typically <0.0001″), but for extremely tight tolerances (e.g., ±0.0002″ or tighter), you must machine to final dimensions before coating and specify coating tolerances in the drawing.

- Critical rule: Never machine parts after black oxide treatment—this will chip or remove the coating.

⚙️ Technical Specs for Machining Steel (Pre-Black Oxide)

Assuming base material is AISI 1018, 4140, or 430 Stainless Steel (common for black oxide applications).

| Parameter | Specification for Tight Tolerance Machining | Notes for Black Oxide Readiness |

|———————|———————————————|——————————–|

| Tolerance (Critical Dimensions) | ±0.0005″ (0.013 mm) for precision features; ±0.001″ (0.025 mm) for non-critical | Coat thickness (0.00005–0.0001″) is included in this tolerance. Always machine to final size before coating. |

| Surface Finish (Ra) | ≤32 μin (0.8 μm) for mating surfaces; ≤63 μin (1.6 μm) for general surfaces | Smooth finishes ensure uniform coating adhesion. Avoid rough surfaces (>125 μin) as they cause patchy black oxide. |

| Edge Breaks | 0.005–0.010″ chamfer on all sharp edges | Sharp edges chip during coating; chamfers prevent coating flaking. |

| Machining Process | 3/4/5-Axis Milling:

– Use rigid setups (e.g., vise + clamps, not just collet)

– Minimize vibration (high spindle speed, low feed rate)

– Critical for 5-axis: Avoid tool deflection on complex contours (use ball-nose end mills for tight radii)

Turning:

– Use carbide tools (e.g., CBN for hardened steel)

– Maintain consistent chip control (avoid built-up edge)

– Hold diameter tolerances to ±0.0005″ | 5-axis milling enables complex geometries without re-fixturing—critical for tight-tolerance aerospace/medical parts. Ensure all features are machined before coating. |

| Tooling | Carbide inserts (e.g., C6, C5 for steel); coated tools (TiAlN) for wear resistance | Avoid HSS tools—they dull quickly and cause surface defects that compromise coating quality. |

| Coolant | Flood coolant (water-soluble) or minimum quantity lubrication (MQL) | Dry machining causes thermal distortion; coolant must be clean to prevent contamination. |

| Deburring | Manual or vibratory deburring; avoid media blasting | Burrs trap coating chemicals, causing uneven black oxide. Deburr after machining, before coating. |

❌ Why Black Oxide Does NOT Apply to Other Materials

| Material | Can Be Black Oxide Coated? | Correct Surface Treatment | Key Machining Notes |

|———-|—————————-|—————————|———————|

| Aluminum (e.g., 6061, 7075) | ❌ No | Anodizing (Type II/III) or painting | – Anodizing adds 0.0002–0.001″ thickness; machine to size with allowance.

– Avoid excessive heat during machining (use high-speed cutting, flood coolant). |

| ABS (thermoplastic) | ❌ No | Dyeing, painting, or plating | – Machining: Use sharp tools, low feed rates (0.002–0.005″/tooth) to prevent melting.

– No surface treatment adds thickness—tight tolerances (±0.001″) are achievable. |

| Nylon (e.g., 6/6, 6/12) | ❌ No | Dyeing or painting | – Machining: Low cutting speeds (50–100 SFM) to avoid heat buildup.

– Tolerances: ±0.002″ typical (thermal expansion is high). |

💡 Critical Best Practices for Black Oxide Parts at Honyo Prototype

- Drawings Must Specify:

- “Machined to final dimensions before black oxide coating.”

- “Black oxide per ASTM D638 (or MIL-DTL-13924) for carbon steel.”

- “No machining after coating.”

- Tolerance Accounting:

- For fit-critical features (e.g., shafts/bearings), add the max coating thickness (0.0001″) to the tolerance band. Example: A 0.5000″ shaft with ±0.0005″ tolerance should be machined to 0.5000″ ±0.0004″ to account for coating.

- Avoid Common Mistakes:

- Never use black oxide on aluminum—it will not adhere and will flake off. Use anodizing instead.

- Never machine ABS/Nylon with high-speed steel tools—use carbide to prevent melting.

- Never skip deburring—burrs cause black oxide to peel.

✅ Summary for Honyo Prototype Work Instructions

- Black oxide is ONLY for steel. All other materials require different processes.

- Machining must be 100% complete before coating. Tight tolerances are achieved during machining—coating is a final, non-machining step.

- For 3/4/5-axis milling: Prioritize rigidity, tool path optimization, and surface finish to ensure coating uniformity.

- Document clearly in drawings: “BLACK OXIDE COATING APPLIED AFTER MACHINING. NO MACHINING PERMITTED POST-COATING.”

If you need specifications for a specific material (e.g., anodized aluminum for aerospace), I’m happy to provide detailed guidance. For black oxide steel parts, always confirm the base material (e.g., 1018 vs. 4140) and coating standard (e.g., MIL-DTL-13924 Class 1 vs. Class 2) upfront—this affects tolerances and machining strategy.

Let me know if you’d like a sample drawing callout or a tolerance checklist for your next project! 🔧

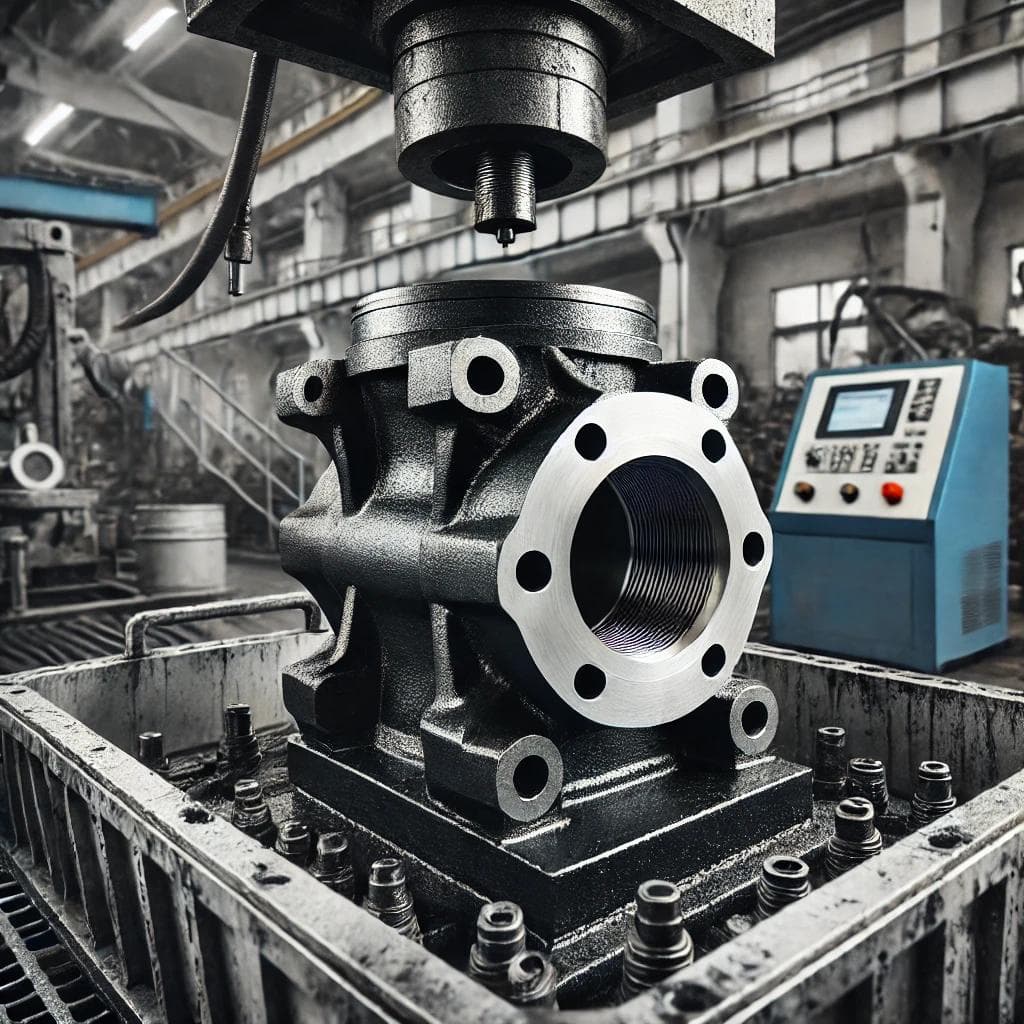

From CAD to Part: The Process

At Honyo Prototype the “black-oxide steel” workflow is the same 5-step digital thread we use for every machined part, but each gate has checks that are unique to the conversion coating. Here is what actually happens inside every box once you hit “Upload”.

-

Upload CAD

• Accepts any neutral format (STEP, Parasolid, IGES, 3D-MF) + PDF drawing.

• Auto-validator flags anything that will not accept black oxide:

– Non-steel alloys (303 SS, Al, Ti) are rejected or quoted with alternate finish.

– Blind, tapped or L/D > 8 holes are flagged for post-oxide tap-cleaning surcharge.

• Surface-area calculator feeds the oxide tank dwell-time model (0.75 µm/min at 142 °C). -

AI Quote (30 s)

• Combines machining time + black-oxide line time + fixturing for racking.

• Adds “no-rust” interim oil dip if shop queue > 72 h.

• Automatically selects 12L14 or 1215 free-machining steel unless you override.

• Price locks for 30 days; lead-time promise is FOB Shenzhen or Fremont, CA. -

DFM (human review ≤ 4 h)

• Black-oxide-specific rules:

– Edge-break ≥ 0.2 mm to avoid burn-through of the 0.5–1.0 µm Fe3O4 film.

– No stacked parts on the same rack wire; contact marks are cause for 100 % rework.

– Thread call-outs: if you spec “after-oxide,” we chase taps with a 2B oversized plug; if “before-oxide,” we mask with silicone stopper.

• You get a PDF report with a 3D snapshot showing rack points and masking plugs. -

Production

a. CNC machining – standard 3–5-axis; 16 µin Ra max as- machined (oxide will add ≈8 µin).

b. Vapor-degrease + alkaline clean (no acid pickle that would etch).

c. Black oxide line (Mil-DTL-13924, Class 1):

142 °C caustic-nitrate bath → 12 min dwell → 3× hot rinse → chromate seal 30 s → dewatering oil dip.

Salt-spray coupon run in parallel; must pass 96 h.

d. Final inspection – color delta E ≤ 2 vs. master tile, no red rust after 24 h ambient.

e. Pack with VCI paper + desiccant; nitrogen-back-flush option for long ocean freight. -

Delivery

• C of C includes salt-spray report, rack-contact map, and RoHS compliance for trivalent chromate seal.

• Parts leave Shenzhen in 5–7 days standard, Fremont in 3 days for North-America rush.

• Tracking link shows photo of the actual rack batch so you can verify color uniformity before the crate lands.

That is the entire digital path from your CAD file to black-oxide-finished steel parts on your dock.

Start Your Project

Transform your steel components with precision black oxide treatment—trusted by industry leaders.

Contact Susan Leo at info@hy-proto.com for expert solutions from our Shenzhen factory.

✅ Fast turnaround | ✅ Corrosion-resistant finish | ✅ Customized for your specs

Shenzhen-based manufacturing | ISO-certified processes | Competitive pricing

Ready to elevate your project? Email us today! 🔧

🚀 Rapid Prototyping Estimator