Guide Contents

Project Insight: Brown And Sharpe Tooling

Manufacturing Insight: Brown & Sharpe Tooling

Why Precision is Non-Negotiable in Product Development

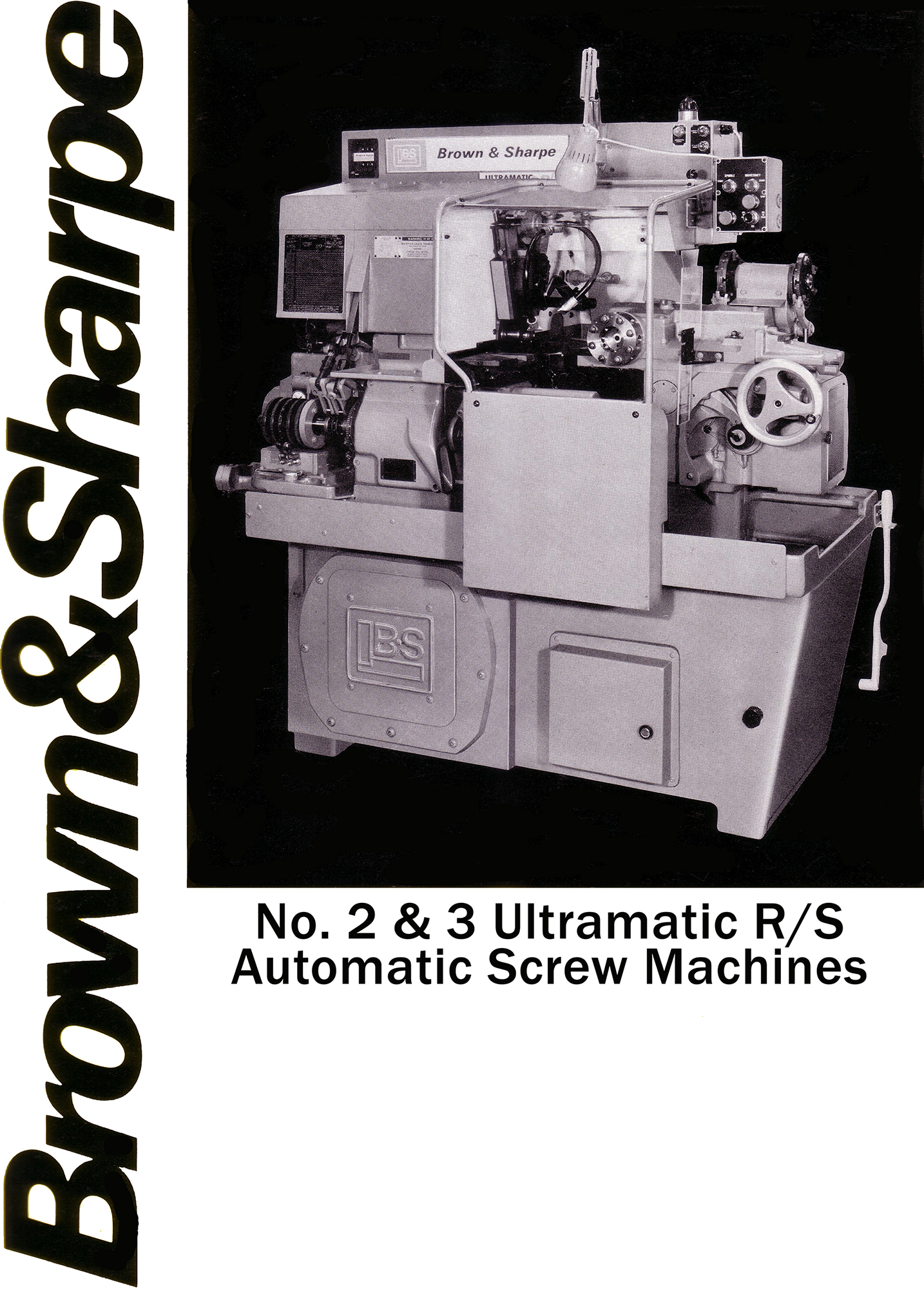

Brown & Sharpe’s legacy in precision machining (e.g., MICROXCEL PFX CMMs, 7107CM CNC machines) sets the industry gold standard for micron-level accuracy.

In injection molding, tooling tolerances of ±0.001″ directly impact part consistency—minor deviations cause flash, warpage, or functional failures, derailing product launches.

Startups investing in precision tooling avoid costly rework, accelerate validation cycles, and ensure reliable performance at scale.

Honyo Prototype: Modern Precision, Digital Speed

Online Instant Quote: Receive real-time pricing and lead times in <60 seconds—no manual quotes, no delays.

AI-Powered Platform: Automated Design for Manufacturing (DFM) analysis and simulation to eliminate errors before production begins.

Fast Turnaround: Bridge tooling delivered in 7–10 days for low-volume production (100–10,000+ parts), enabling rapid MVP iteration.

Advanced Capabilities: High-precision steel/aluminum molds, overmolding, and insert molding solutions engineered for your unique product needs.

At Honyo Prototype, we fuse Brown & Sharpe’s legacy of precision with cutting-edge digital innovation—turning your designs into reality faster, smarter, and with uncompromising reliability.

Honyo Capabilities & Technology

Precision Tooling Powered by Brown & Sharpe Excellence

Advanced Machinery for Unmatched Precision

Steel/Aluminum Mold Manufacturing: Leveraging Brown & Sharpe 7107CM CNC Turning Centers and high-speed milling for micron-level accuracy in cavity/core machining.

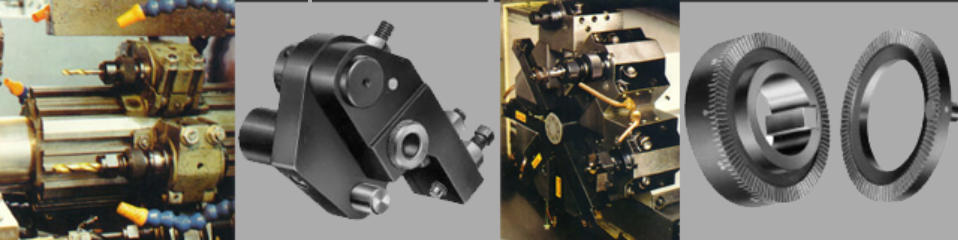

Specialized Overmolding & Insert Molding: Seamless integration of multi-material components with Brown & Sharpe screw machine capabilities for high-precision inserts and functional prototypes.

CMM-Verified Tolerances: Final quality checks using Brown & Sharpe MICROXCEL PFX Coordinate Measuring Machines to ensure ±0.001mm dimensional compliance.

Bridge Tooling for Scalable Production

Cost-Effective Low-Volume Runs: Perfect for 100–10,000+ parts – no need for expensive production molds during product validation or early-stage scaling.

50% Faster Lead Times: Rapid tooling workflows reduce mold production time from weeks to days, accelerating time-to-market.

Seamless Transition to Mass Production: Design flexibility ensures your bridge tooling adapts effortlessly to full-scale manufacturing requirements.

Digital-First Manufacturing Experience

AI-Powered Instant Quotes: Get real-time pricing and lead time estimates in <60 seconds via our intuitive online platform.

Automated DFM Analysis: AI-driven design validation catches potential issues before production, eliminating costly rework.

24/7 Project Transparency: Track progress, access documentation, and collaborate on revisions through our secure cloud portal – anytime, anywhere.

ISO-Certified Quality Assurance

End-to-End Traceability: Every step documented per ISO 9001 standards, with customizable QC reports for compliance-critical applications.

In-Process Monitoring: Real-time sensor feedback during machining ensures consistent quality across all production batches.

Zero-Defect Commitment: Rigorous inspection protocols and root-cause analysis for every component – because precision isn’t optional.

“At Honyo Prototype, we don’t just build molds – we engineer solutions that turn your prototypes into market-ready products faster, smarter, and with unmatched precision.”

– Susan Leo, Founder

Materials & Surface Finishes

Material Options & Finishes for High-Performance Injection Molding

Thermoplastic Material Selection

Choose the right thermoplastic to balance performance, cost, and aesthetics for your application. Our expert team curates materials optimized for your specific needs:

ABS (Acrylonitrile Butadiene Styrene)

Why choose it? Exceptional impact resistance, smooth surface finish, and easy post-processing. Ideal for consumer electronics (e.g., housings, knobs) and automotive interior components.

Innovation tip: Use for prototypes requiring rapid iteration—ABS responds seamlessly to painting and bonding.

PC (Polycarbonate)

Why choose it? High strength-to-weight ratio, heat resistance (up to 135°C), and optical clarity. Perfect for medical devices, automotive lenses, and safety equipment.

Innovation tip: Pair with UV-stabilized grades for outdoor applications where clarity and durability are critical.

PP (Polypropylene)

Why choose it? Chemical resistance, flexibility, and FDA-compliant for food contact. Commonly used in medical syringes, reusable containers, and automotive fluid systems.

Innovation tip: Leverage its fatigue resistance for living hinge designs—no secondary assembly needed.

TPE (Thermoplastic Elastomer)

Why choose it? Soft-touch flexibility, shock absorption, and seamless overmolding capability. Ideal for grips, seals, and ergonomic handles in consumer products.

Innovation tip: Combine with rigid plastics for dual-shot molding—eliminate assembly steps while enhancing user experience.

💡 Pro insight: We optimize material selection using real-world testing data—no guesswork. Tell us your application, and we’ll recommend the perfect thermoplastic for your project’s lifecycle.

Surface Finishing Options

Elevate your parts with finishes tailored to function and form—whether for plastic components or metal inserts in overmolding/insert molding:

For Plastic Parts:

High-Gloss Polishing: Achieve mirror-like clarity for optical lenses, medical instruments, or premium consumer products.

Custom Texturing: Add functional or aesthetic patterns (e.g., matte, leather grain, or geometric designs) for grip, scratch resistance, or brand identity.

Painted Surfaces: Durable, color-matched coatings for branding, UV protection, or color-coding—available in matte, satin, or metallic finishes.

UV-Resistant Coatings: Essential for outdoor applications to prevent fading, cracking, or degradation under sunlight.

For Metal Inserts (Insert Molding):

Anodizing: Enhance corrosion resistance and add vibrant colors to aluminum inserts—ideal for aerospace or automotive components.

Electroplating: Apply chrome, nickel, or gold finishes for conductivity, wear resistance, or luxury aesthetics.

Passivation: Boost stainless steel insert durability by removing surface contaminants and improving corrosion resistance.

💡 Pro insight: Our AI-driven finish simulation tool lets you visualize outcomes before production. See how textures, colors, and coatings interact with your design—no physical samples needed.

Optimizing Material Selection for Your Project

Selecting materials isn’t just about specs—it’s about solving your unique challenges. Here’s how we make it effortless:

Mechanical Requirements: Need toughness? Choose PC. Flexibility? TPE. Chemical resistance? PP. We map your functional needs to material properties.

Environmental Factors: Outdoor exposure? UV-stabilized ABS. High-temp environments? PC or PEEK. We account for real-world conditions.

Cost vs. Performance: Balance budget constraints with longevity—e.g., ABS for prototypes, PC for end-use parts.

Aesthetics & Compliance: FDA-compliant materials for medical devices, food-safe PP for packaging, or high-gloss finishes for retail products.

✨ Innovate Faster with Our AI-Powered Platform

– Instant Quotes: Get material recommendations and pricing in seconds—no email chains or delays.

– Smart Design Guidance: Our AI analyzes your CAD file and suggests optimal materials/finishes for manufacturability and cost efficiency.

– 7-Day Turnaround: From quote to production—accelerate your prototyping-to-production cycle without compromising quality.

Ready to build smarter? Get Your Instant Quote Now and let data-driven insights turn your vision into reality—faster, cheaper, and with zero compromise.

From Quote to Part: Our Process

How It Works: From CAD to Part

Step 1: Upload Your CAD File

Submit your 3D model in any standard format (STEP, STL, IGES, etc.) via our secure online portal—no software required.

Our system automatically validates file integrity and compatibility within seconds, ensuring seamless processing.

Step 2: AI-Powered Instant Quote

Receive an accurate, real-time quote in under 60 seconds with our proprietary AI engine—no manual estimates, no hidden fees.

Dynamically adjust material, volume, or geometry parameters to see instant pricing updates, empowering data-driven decisions.

Step 3: Collaborative DFM Analysis

Receive expert Design for Manufacturing (DFM) feedback within 24 hours, with actionable insights to optimize design for cost and manufacturability.

Collaborate in real-time through our interactive platform to refine designs and resolve potential issues before production begins.

Step 4: Rapid Production & Delivery

Leverage Honyo’s Shenzhen-based facility to produce high-quality parts using steel/aluminum molds, overmolding, and insert molding—ideal for low-volume bridge production (100–10,000+ units).

Track project progress in real-time via our transparent customer portal, with proactive updates at every stage.

Guaranteed on-time delivery with expedited options for time-sensitive projects, ensuring your product reaches market faster.

Start Your Project with Honyo

Precision Rapid Tooling & Injection Molding Solutions for Hardware Innovators

Why Honyo Prototype?

Bridge Tooling for Low-Volume Production: Seamlessly transition from prototyping to 100–10,000+ parts with cost-effective steel and aluminum molds—perfect for startups scaling without heavy capital investment.

Advanced Capabilities:

High-precision steel and aluminum molds for durability and complex geometries

Overmolding & insert molding for multi-material components with perfect integration

Industry-leading Brown & Sharpe CNC machines ensuring ±0.001″ tolerance consistency

Engineered for Speed:

AI-driven design for manufacturability (DFM) analysis cuts iteration time by 40%

48-hour prototype mold turnaround

Scalable production workflows from 100 to 10,000+ parts

Accelerate Your Time-to-Market

Online Instant Quote: Generate accurate, real-time pricing in seconds—no paperwork, no delays.

AI-Powered Platform: Automate DFM checks, material selection, and process planning for flawless execution.

Fast Turnaround Guarantee: 30% faster lead times than industry average, with end-to-end traceability.

Start Your Project with Honyo

Founder-Led Innovation: Susan Leo and our engineering team bring 15+ years of precision manufacturing expertise to optimize your project from concept to production.

Contact Us Today:

📧 Email: info@hy-proto.com

📞 Phone: +86 139 2843 8620

Visit Our Facilities: Explore our Shenzhen and Dongguan hubs—see our smart manufacturing ecosystem in action.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.