Guide Contents

Project Insight: Cnc Auto Tool Changer

Manufacturing Insight: CNC Auto Tool Changer – Accelerating Innovation Through Precision Automation

In today’s fast-paced product development landscape, every second counts. CNC Auto Tool Changers (ATC) are no longer a luxury—they’re a necessity for startups and engineers aiming to iterate quickly without sacrificing precision. At Honyo Prototype, we leverage cutting-edge ATC technology to transform your designs into functional parts with unprecedented speed and accuracy.

Why ATC is Critical for Product Development Speed

Eliminates manual tool changes, reducing machine downtime by up to 70% and enabling continuous operation during multi-step machining processes

Ensures consistent quality across complex geometries—critical for functional prototypes where tolerances of ±0.01mm are non-negotiable

Accelerates design iteration cycles by cutting setup times from hours to minutes, enabling engineers to validate concepts faster and reduce time-to-market

Precision Meets Efficiency: Honyo’s Advanced ATC Capabilities

Industry-leading 3/4/5-axis ATC systems engineered for tight tolerances (±0.01mm) and surface finishes that meet aerospace and medical standards

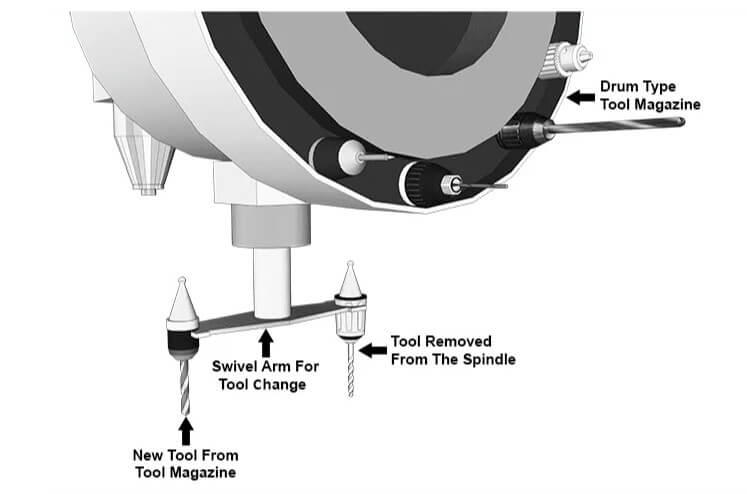

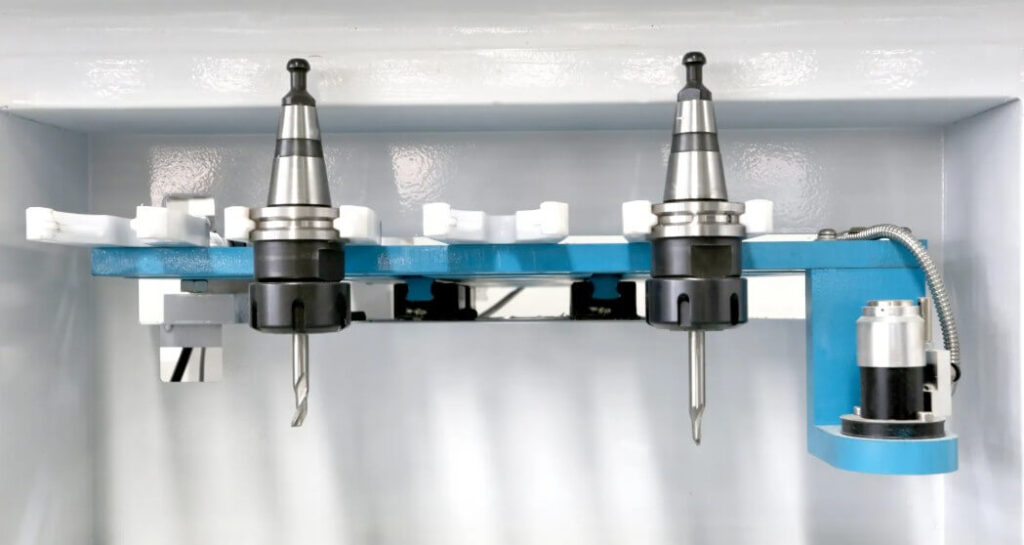

Seamless integration of high-speed spindles and precision tooling—no compromise on accuracy when switching tools mid-process

Optimized for both rapid prototyping and small-batch production, eliminating secondary operations and reducing total lead time by 40%

Your Digital Manufacturing Partner: From Design to Delivery in Record Time

Instant online quotes powered by AI—get real-time pricing and manufacturability feedback within seconds of uploading your CAD file

End-to-end digital workflow with automated progress tracking—prototype to delivery in as little as 24 hours, with transparent communication at every step

Dedicated engineering support to optimize designs for ATC efficiency—maximizing material utilization and minimizing costs without sacrificing quality

At Honyo Prototype, we don’t just machine parts—we engineer solutions that propel your innovation forward. Partner with us to transform your prototypes into market-ready products with unmatched speed and precision.

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

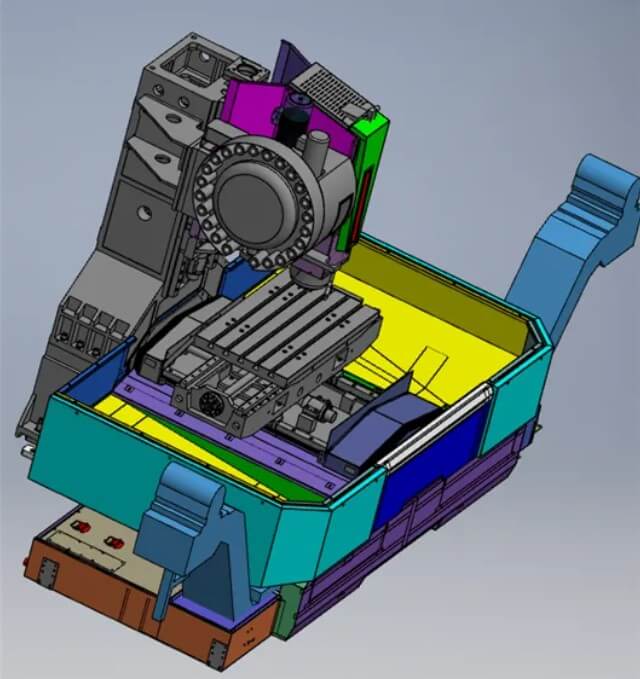

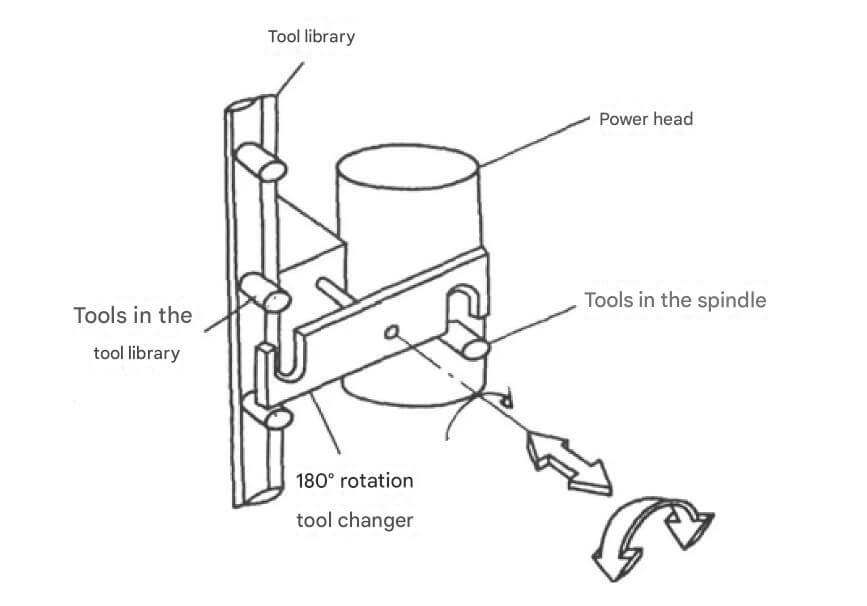

Advanced CNC Auto Tool Changer (ATC) Technology

Multi-Axis Precision: 3/4/5-axis CNC machining with ±0.01mm tolerances for complex geometries and functional prototypes.

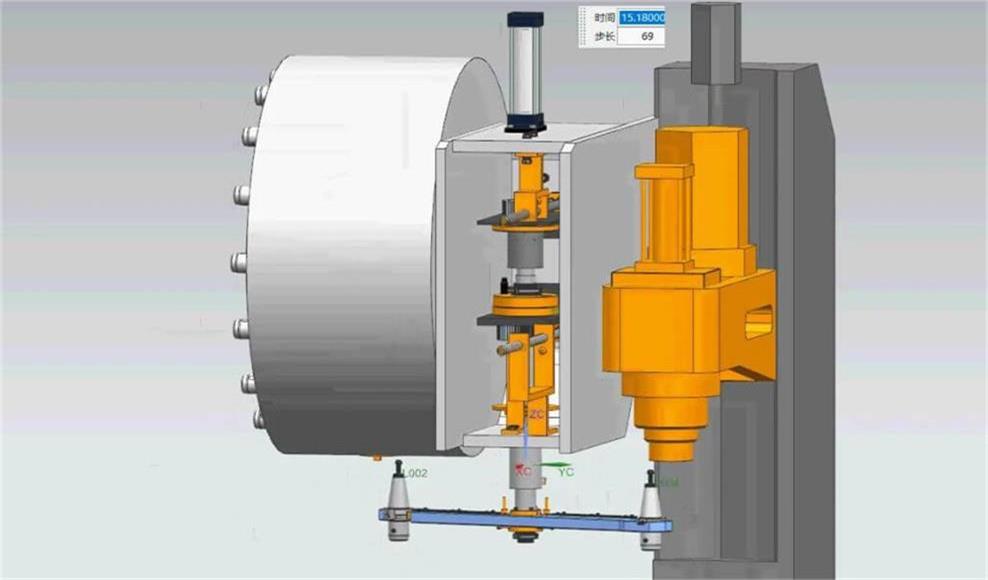

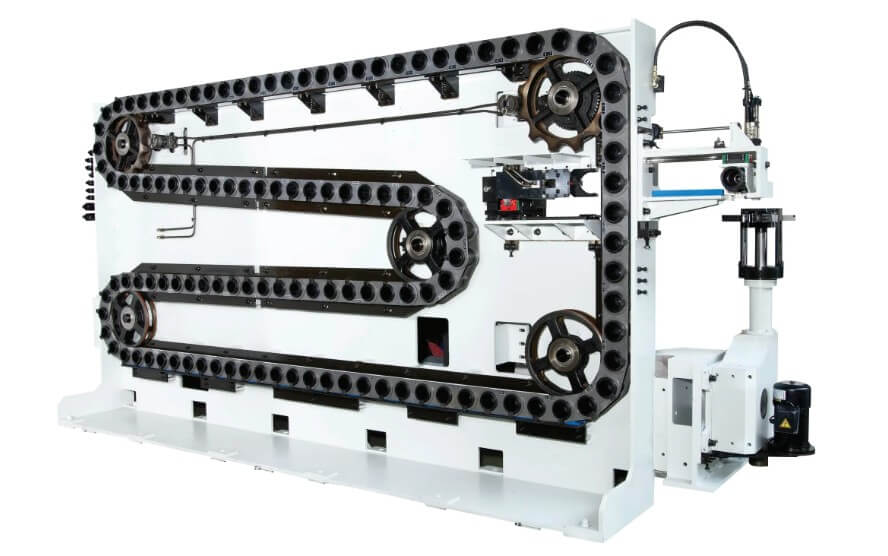

Seamless Automation: Integrated ATC systems enable uninterrupted multi-tool operations, eliminating manual intervention and reducing setup time by up to 50%.

Material Agnostic Excellence: Precision machining across metals, plastics, composites, and exotic alloys for diverse industry applications.

Scalable Production Without Compromise

Prototype to Mass Production: Effortlessly scale from 1 custom part to 10,000+ high-volume runs with consistent quality and precision.

ISO 9001 Certified Quality: Rigorous in-process and final inspections ensure every component meets stringent industry standards.

Lean Manufacturing Optimization: Strategic resource allocation minimizes waste while maximizing throughput for cost-effective solutions.

Digital-First Efficiency Engine

Instant AI-Powered Quotes: Upload CAD files for real-time pricing and lead time estimates—no manual quotes, no delays.

Accelerated Turnaround: Predictive scheduling and automated workflows reduce lead times by up to 40% through optimized production planning.

Transparent Collaboration: Track project progress in real-time via our client portal with proactive engineering support and updates.

Materials & Surface Finishes

Material Options & Finishes for Precision Auto Tool Changer Components

At Honyo Prototype, we engineer CNC-machined auto tool changer (ATC) components with industrial-grade precision—ensuring seamless integration, durability, and performance for your hardware innovation. Our material and finish expertise is built around solving real-world challenges: reducing downtime, extending service life, and optimizing cost without sacrificing accuracy. With tight tolerances of ±0.01mm and AI-driven design support, we turn your concepts into functional reality—faster than ever.

Optimal Materials for Critical ATC Components

Aluminum 6061: Lightweight, corrosion-resistant, and easy to machine. Ideal for structural frames, housings, and non-critical components where weight savings and rapid prototyping are priorities.

Aluminum 7075: Aerospace-grade strength (2x stronger than 6061) with excellent fatigue resistance. Perfect for high-stress parts like tool holders, spindle mounts, and load-bearing interfaces.

Stainless Steel 304/316: 304 for general corrosion resistance (e.g., internal components); 316 for marine/chemical environments. Essential for parts exposed to coolants, cleaning agents, or harsh industrial conditions.

Brass: Superior electrical conductivity and anti-galling properties. Best for electrical contacts, bushings, and threaded components requiring low friction and wear resistance.

PEEK (Polyetheretherketone): High-temp stability (up to 250°C), chemical resistance, and self-lubricating. Ideal for insulating parts, wear pads, and moving components in extreme environments where metal isn’t feasible.

Surface Finishes That Maximize Performance & Durability

Anodizing (Type II/III): Hard anodizing (Type III) adds 50µm of wear-resistant coating for aluminum tool holders—critical for high-cycle ATC mechanisms.

Electroplating (Nickel/Chromium): Enhances hardness and corrosion protection for steel components like guide rails or fasteners.

Precision Polishing (Ra 0.4µm): Ultra-smooth surfaces for mating interfaces to eliminate galling and ensure consistent tool-change accuracy.

Powder Coating: Durable, scratch-resistant finish for external housings—available in custom colors for brand alignment.

Passivation (Stainless Steel): Removes surface contaminants to maximize corrosion resistance for 304/316 parts in wet or corrosive settings.

DLC (Diamond-Like Carbon) Coating: Ultra-low friction and extreme wear resistance for high-wear areas like tool changer fingers or pivot points.

How to Choose the Right Material for Your ATC Design

Wear-Prone Moving Parts: Use 7075 aluminum with hard anodizing or PEEK for low-friction, high-cycle durability.

Corrosive Environments: Opt for 316 stainless steel with passivation or anodized 6061 for coolant exposure.

Electrical Isolation Needs: PEEK or brass with nickel plating for sensor mounts or wiring components.

Prototyping vs. Production: Start with cost-effective 6061 aluminum for rapid iterations; transition to 7075 or stainless steel for end-use parts requiring strength.

Thermal Management: Aluminum for heat dissipation in motor housings; PEEK for high-temp zones near spindles.

Accelerate Your Project with Honyo’s Smart Manufacturing

✅ AI-Powered Instant Quoting: Upload your CAD in seconds—get real-time pricing with zero manual estimates. No more waiting days for quotes.

✅ 5-Axis Precision Machining: Tight tolerances of ±0.01mm ensure flawless fit, function, and reliability for complex ATC mechanisms.

✅ 7-Day Turnaround Guaranteed: Prototype in 3 days, production in 5–7 days. Fast-track your time-to-market without compromising quality.

✅ End-to-End Expertise: Our engineers collaborate with you to optimize every detail—material selection, finish, and tolerances—for peak performance and cost efficiency.

Ready to build? Get Your Instant Quote in under 60 seconds—engineered for precision, designed for speed.

From Quote to Part: Our Process

How It Works: From CAD to Part in Record Time

At Honyo Prototype, we’ve redefined precision manufacturing with a seamless, AI-driven workflow that turns your design into a high-quality part faster than ever. No more guesswork, no hidden delays—just transparent, efficient production from day one.

✅ Step 1: Upload CAD File

Simple & Secure: Drag-and-drop your 3D model (STP, STEP, IGES, SLDPRT, etc.) directly to our cloud platform.

No Format Hassles: Our system automatically validates file integrity and compatibility—no manual checks needed.

Global Access: Work from anywhere, anytime. Your design is encrypted and stored securely in our ISO-certified system.

💡 Step 2: Instant AI-Powered Quote

Real-Time Cost Visibility: Our proprietary algorithm analyzes geometry, materials, tolerances (+/- 0.01mm), and tooling requirements in seconds—not days.

Transparent Pricing: See exact costs upfront, including machining, setup, and shipping. No surprises, no hidden fees.

Optimized for Your Project: AI cross-references your design against Honyo’s 3/4/5-axis capabilities to suggest cost-saving tweaks before you commit.

Example: A complex 5-axis bracket design might show a 15% cost reduction by adjusting wall thickness—automatically flagged in your quote.

🔍 Step 3: Automated DFM Analysis

Proactive Problem-Solving: Our AI scans for manufacturability issues like sharp internal corners, thin walls, or toolpath collisions—before production starts.

Human + Machine Expertise: Every analysis is reviewed by Honyo’s senior engineers to ensure actionable feedback (e.g., “Add draft angles for easier ejection”).

Faster Iterations: Receive a downloadable DFM report with clear recommendations—cut redesign cycles by up to 50%.

⚙️ Step 4: Precision Production & Delivery

Automated Tool Changer (ATC) Efficiency: Our industrial-grade ATC systems (7–20+ tools) slash non-productive time by 90% compared to manual changeovers.

Tight Tolerance Mastery: Every part is machined to ±0.01mm precision—verified by in-process laser measurement systems.

Rapid Turnaround: Functional prototypes delivered in 3–5 days; low-volume production in 7–10 days.

End-to-End Visibility: Track your order in real-time via our customer portal—from cutting to shipping.

Why it matters: For hardware startups, this means moving from prototype to market in weeks, not months. For procurement teams, it’s consistent quality with zero lead-time surprises.

🌟 The Honyo Difference

We don’t just machine parts—we engineer solutions. By merging AI speed with human expertise, we eliminate the “quote-to-production gap” that stalls innovation. Your vision, transformed with precision, transparency, and speed—guaranteed.

Powered by Susan Leo’s vision for accessible, next-generation manufacturing.

Start Your Project with Honyo

Start Your Project with Honyo

Precision Meets Efficiency with ATC CNC Machining

Industrial-grade precision: Achieve ±0.01mm tolerances across 3/4/5-axis CNC machining with automatic tool changer (ATC) for complex geometries and end-use parts—no compromise on quality.

Cost-effective innovation: Skip expensive machine investments. Our service delivers factory-grade precision at a fraction of the cost, ideal for startups scaling from prototypes to production.

Seamless multi-tool workflows: ATC enables unattended operation, reducing manual intervention and accelerating production cycles for intricate designs.

AI-Powered Efficiency from Quote to Delivery

Instant online quotes: Get real-time pricing in seconds via our AI-driven platform—transparent, no hidden fees, and optimized for your design complexity.

Smart optimization: Our algorithms refine toolpaths, material usage, and machining sequences to cut costs and lead times without sacrificing precision.

Rapid turnaround: Prototype in 72 hours or scale to volume production with consistent quality—track progress 24/7 through our digital dashboard.

Partner with Industry Experts

Founder-led excellence: Susan Leo and our Shenzhen engineering team combine 15+ years of precision manufacturing expertise with cutting-edge innovation to solve your toughest challenges.

Contact us today:

📧 info@hy-proto.com

📞 +86 139 2843 8620

Visit our facilities: See precision manufacturing in action at our Shenzhen and Dongguan campuses—book a tour to collaborate on your next breakthrough.

“At Honyo, we don’t just machine parts—we engineer solutions that accelerate your product journey from concept to market.”

— Susan Leo, Founder

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.